Reducing mechanical activation-induced amorphisation of salbutamol sulphate by co-processing with selected

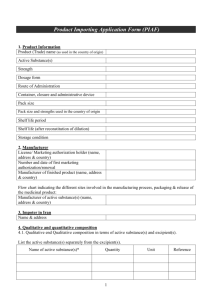

advertisement

1 Reducing mechanical activation-induced amorphisation of salbutamol sulphate by co-processing with selected carboxylic acids 2 3 4 5 6 7 8 9 10 11 12 13 14 Vincent Curtin, Youness Amharar, Kieran H. Gallagher, Sarah Corcoran, Lidia Tajber, Owen I. Corrigan and Anne Marie Healy* 15 (Grant No. 07/SRC/B1158 and Grant No. 12/IP/1408). 16 17 Abstract 18 The unintentional generation of amorphous character in crystalline active 19 pharmaceutical ingredients (APIs) is an adverse consequence of mechanical 20 activation during dosage form manufacture. In this study, we assess and compare 21 the ability of low glass transition temperature (Tg) dicarboxylic acids to mitigate 22 amorphisation of a model API, salbutamol sulphate (SS), on both co-milling and co- 23 mixing. 24 SS processed alone, as well as co-milled and co-mixed composites of the API with 25 glutaric acid (GA), adipic acid (AA) and pimelic acid (PA) were characterised by 26 powder X-ray diffraction (pXRD), differential scanning calorimetry (DSC) and dynamic 27 vapour sorption (DVS). 28 Milling and dry mixing of SS both resulted in pXRD amorphous materials. No 29 amorphous content of SS was detected by DVS on co-milling with 50 % w/w GA, School of Pharmacy and Pharmaceutical Sciences, University of Dublin, Trinity College, Dublin 2, Ireland. Author Information: *University of Dublin, Trinity College, School of Pharmacy and Pharmaceutical Sciences, Panoz Institute, Dublin 2, Ireland. E-mail: healyam@tcd.ie. Tel: +353 (0) 1 896 1444. Acknowledgement: This work was supported by the Science Foundation Ireland 1 30 while amorphisation was more than halved, relative to the API milled alone, on co- 31 milling with 50 % w/w AA and PA, respectively. Co-mixing with each excipient also 32 resulted in a decrease in API amorphicity, although the extent of reduction was 33 considerably less compared to the co-milling experiments. 34 The solubility (Solexcipient) of each excipient in amorphous SS was determined by 35 thermal methods. No further reduction in API amorphisation was achieved on co- 36 mixing with 50% w/w excipient, compared to concentrations corresponding to the 37 solubility of each excipient in the amorphous API (SolGA = 36%, SolAA=21%, 38 SolPA=22%). PXRD confirmed gradual dissolution over time of GA in amorphous SS 39 on co-mixing. In contrast to co-mixing, co-milling SS at excipient weight fractions 40 above their respective solubilities in the amorphous drug resulted in further 41 reductions in API amorphisation. This is thought to be due to the generation of a 42 molecular dispersion of amorphous API, supersaturated with excipient, thereby 43 leading to a more pronounced composite Tg lowering effect. 44 The results indicate that co-processing with low Tg excipients is an effective strategy 45 at minimising amorphisation of an API on mechanical activation. 46 Keywords Mechanical activation, amorphous, glass transition temperature, 47 salbutamol sulphate, crystalline. 48 49 50 51 52 53 54 55 2 56 57 1. Introduction 58 It is well recognised that subjecting drugs to routine pharmaceutical unit operations 59 can result in changes to the solid state properties of the material (Morris et al., 2001; 60 Lin et al., 2010). This can result in the transformation of a highly ordered crystalline 61 material to a disordered, high energy amorphous state (Feng et al., 2008; Patterson 62 et al., 2007). An amorphous system, despite its advantages of enhanced solubility 63 and dissolution rate, will be thermodynamically metastable relative to its crystalline 64 form and can revert back to the lower energy state with time. This can have serious 65 implications in terms of manufacturability, processability and stability (Hancock and 66 Zografi, 1997; Yu, 2001). 67 68 Mechanical activation is a term used to describe the increase in free energy of a solid 69 on mechanical processing, and is generally assumed to arise from operations such as 70 milling, grinding, compaction and compression, which results in breakage or fracture 71 of a solid (Hüttenrauch et al., 1985). However it was shown by Mosharraf and 72 Nystrom in 1999, that ‘gentler’ operations such as dry mixing can activate solids. The 73 authors noted a considerable change in the solid state structure of griseofulvin on 74 mixing, which also resulted in an increase in solubility. More recently, Hockerfelt et 75 al in 2009 reported that griseofulvin could be completely amorphised by dry 76 blending without particle breakage. 77 78 Milling, when compared to dry mixing, is a considerably more energetic process and 79 is known to amorphise several APIs (Gusseme et al., 2008; Willart et al., 2012; Willart 3 80 et al., 2001). Balani et al (2010) noted that amorphisation of milled salbutamol 81 sulphate could be reduced by co-milling the API with crystalline excipients, such as α 82 lactose monohydrate, adipic acid and magnesium stearate. They suggested that the 83 effects observed were associated with the presence of excipient acting as seed 84 crystals, coupled with a temperature increase from the milling operation. 85 demonstrated that co-milling sulfadimidine with a series of low glass transition 86 temperature (Tg) excipients was an effective strategy to minimise amorphisation of 87 the drug (Curtin et al., 2013). It was highlighted that excipients which showed good 88 solubility in the API exerted a Tg lowering effect, resulting in composite Tg values 89 lower than that of the API alone, which could mitigate amorphisation of the API. In 90 contrast, a crystalline excipient (malic acid) which displayed very poor solubility in 91 the API was found to promote amorphisation of the drug. We 92 93 In this work we evaluate and compare, for the first time, the influence of two 94 mechanical operations on a model API co-processed with low Tg excipients. The 95 objective of the study was to compare the effect of two different modes of 96 mechanical activation (milling and dry mixing) on salbutamol sulphate (SS) and to see 97 if co-processing with low Tg excipients could prevent or minimise amorphisation of 98 the API. SS was chosen because of its high glass transition temperature (120 °C) and 99 its known propensity to amorphise when milled (Balani et al., 2010; Griesdale et al., 100 2011; Brodka-Pfeiffer et al., 2003). The excipients chosen were glutaric acid, adipic 101 acid and pimelic acid based on their structural similarity and their low glass transition 102 temperatures according to the Tg=Tmx0.7 rule (Fukuoka et al., 1989; Kerc and Srcic, 103 1995). Their respective solubilites in amorphous SS were determined by thermal 4 104 methods. Freeze drying was used to produce amorphous API: excipient systems 105 which enabled composite Tg values to be determined. The milled and dry mixed API, 106 as well as the API:excipient co-processed systems were characterised with respect to 107 their X-ray diffraction, thermal and vapour sorption properties. 108 109 2. Materials and Methods 110 2.1. Materials. Salbutamol sulphate (SS) raw material (molar weight (Mw) = 576.70 111 g.mol-1) was purchased from Camida Ltd. (Clonmel, Ireland). Adipic acid (AA) (Mw = 112 146.14 g.mol-1), glutaric acid (GA) (Mw = 132.11 g.mol-1), and pimelic acid (PA) (Mw = 113 160.17 g.mol-1) were purchased from Sigma-Aldrich, Ireland. 114 diameter 5mm were purchased from Sigma-Aldrich, Ireland. Ethanol (99.5 %, v/v) 115 was purchased from Corcoran Chemicals, Ireland. Water, ultra-pure, was prepared 116 from a Millipore Elix advantage water purification system. Acetonitrile, HPLC grade, 117 was purchased from Fisher Scientific (Ireland). Triethylamine was purchased from 118 Sigma Aldrich, Ireland. Glass beads of 119 120 2.2. Methods. 121 2.2.1. Milling. Ball milling of SS and excipients was performed with a PM 100 high 122 energy planetary mill (Retsch, Germany) at room temperature. 2.5 g of material was 123 placed in stainless steel milling jars of 50 cm3 volume with three stainless steel balls 124 of diameter 20 mm, corresponding to a ball to powder mass ratio of 40:1. The speed 125 of the solar disk was set at 400 rpm. Every 20 minutes of milling was followed by a 126 pause period of 10 minutes to avoid overheating (Curtin et al., 2013). Total milling 5 127 time was kept constant at 3 hours (h) corresponding to an effective milling time of 2 128 h. SS was co-milled with GA at different weight percentages of excipient (XGA = 5, 20, 129 35, 50 %). SS was also co-milled with 21 % and 50 % w/w AA, and 22 % and 50 % 130 w/w PA. API:excipient co-processed systems are named in accordance to the % 131 weight fraction of each component. For instance SS95:GA5 refers to a system 132 composition of 95% w/w SS and 5% w/w GA. 133 performed at least in duplicate. All milling experiments were 134 135 2.2.2. Dry mixing 136 Dry mixing experiments were performed using a Turbula mixer operating at 64 rpm 137 (360 ml tubes, W.A. Bachofen, Switzerland) based on the method used previously by 138 Hockerfelt et al., 2009. The API and API:excipient fractions were mixed with glass 139 beads in the weight proportion 1:99 of powder to beads. A total powder content of 140 0.78 g was used for the dry mixing experiments. Experiments were performed at 141 different times, ranging from 2 h to 24 h. SS was dry mixed with each excipient at a 142 concentration corresponding to its solubility in the amorphous drug. The 24 h mixes 143 were also performed at 50 % w/w excipient. All mixing experiments were performed 144 at least in duplicate. 145 146 2.2.3. Freeze drying 147 API:excipient mixtures of various weight fractions ranging from 95:5 to 50:50 were 148 dissolved in deionised water and stirred for 24 hours at room temperature to yield 149 aqueous solutions with a concentration of 5% w/w total solid. The solutions were 150 then sonicated for 10 minutes and filtered through a 0.45 micron syringe filter to 6 151 ensure the absence of any residual crystals. The resulting aliquots (5 ml) were then 152 poured into 50 ml plastic tubes, which were immersed in liquid nitrogen for 15 min 153 and then loaded into a VirTis wide mouth filter seal glass flasks and attached to one 154 of the manifold ports of a benchtop VirTis 6K freeze-dryer model EL (SP Scientific, 155 USA). A Vacuum of 29-31 mtorr was obtained by the use of an Edwards 5 RV5 rotary 156 vane dual stage mechanical vacuum pump (Edwards, England). After 48 hours of 157 freeze drying the tubes were removed and capped. This was performed in duplicate 158 for all mixtures. 159 160 2.2.4. Spray drying 161 PA was spray dried as a solution in ethanol/water 7:3 v/v using a Buchi-290 Mini 162 Spray Dryer, as previously described (Curtin et al., 2013). The inlet temperature was 163 maintained at 78 °C, outlet temperature was between 42 – 49 °C and a feed 164 concentration of 0.4 % w/v was used. Spray drying was performed in the open mode 165 configuration using compressed air as the drying medium with a pump rate of 30 % 166 (8 ml/min), aspirator setting of 100 % and air flow of 40 mm (473 L/h). 167 168 2.2.5. Powder X-ray diffraction. 169 Powder X-ray diffraction (pXRD) measurements were performed on samples placed 170 on a low background silicon sample holder using a Rigaku Miniflex II desktop X-ray 171 diffractometer (Rigaku, Tokyo, Japan), as previously described (Curtin et al., 2013). 172 The pXRD patterns were recorded from 5 ° to 40 ° on the 2 theta scale at a step of 173 0.05 ° s-1. The X-ray tube composed of Cu anode (λCUKα = 1.54 Å), was operated 7 174 under a voltage of 30 kV and current of 15 mA. PXRD patterns were recorded at 175 least in duplicate. 176 For quantification of crystalline content by pXRD, the amorphous standard was 177 prepared by milling the API for 2 hours and the crystalline reference standard was 178 obtained by placing SS as received in the DVS at 90% RH until no mass loss events 179 were observed in the kinetic profile. The method employed was based on the 180 method reported by Clas et al. (1995). Zinc oxide was used as an internal standard to 181 determine if there were variations in peak position and intensity. 182 Different weight fractions of crystalline SS (Xc) (Xc = 0.1, 0.25, 0.5, 0.75, 0.9) were 183 prepared by mixing the relevant quantities of crystalline and amorphous reference 184 samples (total mixed sample weight 100 mg) with 10 mg Zinc oxide using an agate 185 mortar and pestle. 186 independent set of reference standards for each weight fraction. Each set of 187 reference standards was analysed by pXRD three times, giving a total of six results 188 for each weight fraction. 189 The pXRD peak used for the quantification of crystalline SS in each sample was at 190 approximately 15.3° 2 theta and was selected due to the lack of interference across 191 all diffraction patterns. Rigaku Peak Integral software was used in the determination 192 of peak intensity for each sample using the Sonnefelt-Visser background edit 193 procedure. 194 195 196 8 This procedure was repeated once to produce a second 197 2.2.6. Thermal analysis. 198 Differential scanning calorimetry (DSC) experiments were conducted using a Mettler 199 Toledo 821e with a refrigerated cooling system (LabPlant RP-100), as previously 200 described (Curtin et al., 2013). Nitrogen was used as the purge gas. Sealed 40 μl 201 aluminium pans with three vent holes were used throughout the study, and sample 202 weights varied between 5 and 13 mg. The system was calibrated for temperature 203 and cell constant using indium and zinc. 204 implemented in all DSC measurements. Analysis was carried out and monitored by 205 Mettler Toledo STARe software (version 6.10) with a Windows NT operating system. A heating rate of 10 °C min-1 was 206 207 2.2.7. Solubility determination by thermal analysis. 208 The solubilities of GA, AA and PA in amorphous milled SS were estimated by thermal 209 analysis, as previously described by Curtin et al., 2013, and will be referred to as 210 Solexcipient hereafter (e.g. SolGA refers to solubility of GA). 211 API:crystalline excipient mixtures containing between 50% and 90% w/w of 212 crystalline excipient were manually mixed using a pestle and a mortar. The resulting 213 powders were then heated on a heating plate at 160 °C under nitrogen atmosphere 214 in order to prevent chemical degradation, subsequently quenched to 25 °C and kept 215 at this temperature for 2 days. At this stage a mixture of crystalline excipient and 216 amorphous API saturated with excipient was obtained, which was confirmed by 217 pXRD. The melting enthalpy of the resulting crystalline phase was then determined 218 by DSC at 20 °C min-1 from 25 °C to 180 °C for SS:AA and 130 °C for SS:GA and SS:PA, 219 respectively, and the average of two values plotted as a function of excipient mass 220 fraction. 9 Firstly, amorphous 221 2.2.8. Thermogravimetric Analysis (TGA) 222 Thermogravimetric analysis (TGA) experiments were conducted on a Mettler Toledo 223 TG 50 apparatus using a method previously described (Bianco et al., 2012). Weighed 224 samples (5–10 mg) were analysed in open aluminium pans placed on a Mettler MT5 225 balance. Samples were heated from 25 to 220 °C at a scanning rate of 10 °C/min 226 under nitrogen purge. Mass loss of the samples recorded were analysed by the 227 Mettler Toledo STARe software. Experiments were performed in duplicate. 228 229 2.2.9. Dynamic vapour sorption (DVS). 230 Sorption isotherms and kinetic profiles of the unprocessed, milled, mixed and co- 231 processed systems were obtained using DVS (Advantage, Surface Measurement 232 Systems, Alperton, UK). The temperature was 25.0 ± 0.1 °C and water was used as 233 the probe vapour. Co-milled samples were dried at 0 % RH and then subjected to 234 step changes of 10 % RH up to either 70 % or 90 % RH, and the reverse for 235 desorption. Second/third sorption cycle isotherms were also determined. Co-mixed 236 samples for each API:excipient system were initially exposed to step changes of 10 % 237 RH up to 90 % RH. Further samples were then simply exposed to humidities below 238 and above the threshold crystallisation RH, the humidity at which crystallisation and 239 mass loss first occurred on the initial DVS run. Final RH value was system specific 240 and was determined on the basis of when crystallisation was complete for milled, 241 mixed and co-processed SS. Absence of a mass loss in the second sorption cycles 242 indicated full crystallisation. The crystalline nature of the systems was confirmed by 243 pXRD. As previously described, the sample mass was allowed to reach equilibrium 244 defined as dm/dt ≤ 0.002 mg/min over 10 min, before the RH was changed (Curtin et 10 245 al., 2013). 246 calculations were performed using eq 1., as described previously by Balani et al. 247 2010. 248 Sample weights were between 7 – 15 mg. % amorphous content = 100 x Amorphous content (1) 249 where Δm is the difference in the mass uptake (%) of the API between the first and 250 second sorption cycles at a system specific RH, ms is the sample mass in the DVS, md 251 is the mass of the API in the overall sample mass, and Δm100 is the difference in 252 mass uptake (%) between the first and second sorption cycles of the amorphous 253 milled standard at a system specific RH. 254 least in duplicate. All DVS experiments were performed at 255 256 2.2.10. Melt quench 257 PA was melt quenched by melting the material in an aluminium pan in the DSC by 258 heating from 25 to 120 °C at 10 °C min-1 and rapidly immersing the molten material 259 in liquid nitrogen. The sample was subsequently reheated on a DSC from 25 to 120 260 °C at 10 °C min-1. 261 262 2.2.11. HPLC analysis 263 The HPLC method was adopted from that of Malkki et al., 1990. The analytical 264 column used was a LiChrosorb RP-18 (250 mm length, diameter 4 mm, particle size 265 10 µm S/N 009897). The column was attached to a Waters 1525 Binary Pump with 266 an in built degasser, a Waters 717 plus autosampler and a Waters 2487 Dual λ 267 Absorbance Detector. Samples were analysed using Breeze software Version 3.30. 11 268 The mobile phase consisted of 0.02M phosphate buffer containing 750 µl 269 triethylamine per 1 litre and acetonitrile (95/5 v/v). Phosphate buffer was adjusted 270 to pH=3.0 after adding triethylamine. Separation was carried out isocratically at 271 ambient temperature (about 22°C) and a flow rate of 1.5ml/min, with UV detection 272 at 265 nm. The measured retention time for SS was approximately 4.9 min (n=2). 273 274 275 276 277 278 279 280 281 282 283 284 285 286 287 288 289 290 291 12 292 3. Results 293 3.1 294 The solubilites of GA, AA and PA in the amorphous API at 25°C were determined by 295 thermal analysis, as described in section 2.2.7. A linear relationship was observed 296 between the composition and the enthalpy of fusion of the excipient for all three 297 systems and the Solexcipient was estimated as the zero enthalpy interception point by 298 extrapolation (Figure 1). The melting enthalpies of the pure excipients were omitted 299 from the plot. 300 ‘amorphous API and crystalline excipient’ where the endothermic peak represents a 301 dissolution, to a system of ‘pure excipient‘ where the endothermic peak is an actual 302 melting event. 303 SolGA, SolAA and SolPA were 36 %, 21 % and 22 % respectively. It should be noted that 304 the method of preparation of the mixtures of crystalline excipient and amorphous 305 API saturated with excipient did not lead to drug degradation, as indicated by HPLC. Solubility determination of GA, AA and PA in amorphous SS. This is because it is not appropriate to compare a system of 306 307 3.2 308 of unprocessed, milled and dry mixed SS. 309 SS raw material displayed Bragg peaks characteristic of a crystalline material. The 310 API was identified as pure form 1 with characteristic diffraction peaks of this solid 311 state form apparent at 10.7o, 11.9o and 12.6o 2 theta (Palacio et al., 2006). SS, in 312 contrast, was amorphous when processed by either milling for 2 hours or dry mixing 313 for 8 hours (Figure 2). 314 The corresponding DSC thermograms are displayed in Figure 3. SS revealed a single 315 endothermic event with a temperature onset of 185 °C. Milled SS revealed a broad 13 Powder X- Ray diffraction, thermal behaviour and vapour sorption analysis 316 endothermic event between 30 – 100 °C believed to be due to release of loosely 317 bound moisture (mass loss of 2 % was noted by TGA analysis up to 100 °C). The glass 318 transition temperature of milled and dry mixed SS occurred at 120 °C. An exotherm 319 just prior to the melting event for the milled material could be due to crystallisation 320 of the amorphous drug. However the event corresponds to the temperature onset 321 of significant mass loss by TGA analysis (data not shown) and may also be due to 322 thermal degradation of the API. 323 The sorption kinetic profiles of the respective systems are shown in Figure 4. SS took 324 up around 0.3% mass at 50% RH followed by a series of sharp mass losses at higher 325 RH. The vapour uptakes for the second and third sorption cycles were comparable 326 with no mass loss events evident. The average % mass uptake at a specific RH from 327 the second and third cycles was then taken as the reference value for crystalline SS. 328 The initial mass losses are attributed to crystallisation events, associated with the API 329 raw material containing a small, but quantifiable amount of amorphous content. 330 Milled and dry mixed SS displayed very similar sorption properties. Both processed 331 samples lost nearly 4% mass during the initial drying step. This was preceded by a 332 mass uptake of nearly 9% at 60% RH in both cases, followed by a very sharp, steep 333 mass loss due to an amorphous to crystalline transformation of the drug. Further 334 mass losses at 70%, 80% and 90% RH indicated that crystallisation was not fully 335 complete after the initial mass loss at 60% RH. Second sorption cycles for both 336 milled and mixed API were almost superimposable and no mass loss here indicated 337 that samples had fully crystallised. The quantification results are independent of the 338 crystallisation kinetics, provided the method allows the sample to reach equilibrium 339 at each partial pressure and the sample has crystallised (Mackin et al., 2002). For all 14 340 mono and binary systems analysed, crystallisation was complete before the start of 341 the second sorption cycle. 342 determined by comparing the difference in % mass uptake between the first and 343 second sorption cycles. Comparing the % mass uptake at 50 % RH for crystalline and 344 amorphous milled SS, with that of the drug as received revealed an amorphous 345 content of 4% ± 1% for SS raw material (Table 1). Amorphous content quantification by DVS was 346 347 3.3 348 The pXRD patterns of the SS:GA co-milled composites are displayed in Figure 5. Co- 349 milling with just 5% w/w GA, a concentration well below SolGA of 36 %, resulted in an 350 amorphous halo similar to that for the API milled alone. Processing at excipient 351 concentrations close to, at, and above the SolGA revealed Bragg peaks specific to the 352 API and indicated that the degree of amorphisation of SS was reduced. 353 The DSC thermograms for the co-milled systems are displayed in Figure 6. An 354 exotherm at around 125 °C was observed for the SS95:GA5 co-milled system which 355 was attributed to crystallisation of the amorphous API. 356 exothermic peak was present in the thermogram of the API milled alone, suggesting 357 that co-milling the drug with just 5 % w/w GA generated a less thermally stable 358 system that that of API milled on its own. No crystallisation exotherms were noted 359 for the co-milled systems at higher weight fractions of excipient, as expected from 360 the pXRD data. 361 polymorphic conversion in the excipient followed by its melting (McNamara et al., 362 2006). The binary system displayed a eutectic-like behaviour very similar to that 363 reported for sulfadimidine co-milled with GA (Curtin et al, 2013). The melting 15 SS co-milled with GA No corresponding The thermal events between 75 – 100 °C correspond to a 364 endotherm is at approx 90° C for all co-milled systems and is at a lower temperature 365 when compared to the melting of either the excipient (99 °C) or drug (185 °C). The 366 melting of excess API at higher temperature is distorted by the simultaneous thermal 367 degradation of the drug. 368 Isotherm plots of SS milled as well as SS:GA co-milled composites are displayed in 369 Figure 7. The SS95:GA5 system crystallised at a lower RH compared to the API milled 370 alone, indicative of a less physically stable system. The mass uptake at 40 % RH was 371 used in the quantification calculations and from Figure 7 it can be seen that uptakes 372 were lower for the co-milled systems compared to the API milled alone. 373 PXRD was used as complementary quantification technique. The calibration curve of 374 peak intensity versus crystalline SS weight fraction (Xc) is displayed in Figure 8 and 375 quantification results are listed in Table 1. The limit of detection was determined by 376 the IUPAC method, as reported by Long and Winefordner (1983), and corresponded 377 to a crystalline weight fraction of 0.1. The limit of quantification was calculated, also 378 by the IUPAC method, to be 0.18. 379 380 Table 1. Summary of amorphous content of SS raw material, SS milled and SS:GA co- 381 milled systems as quantified by DVS and pXRD. System % Amorphous content (±S.D.) DVS pXRD SS 4 (1) 0 SS milled 100 100 SS95:GA5 88 (3) 100 SS80:GA20 13 (6) 0 16 SS65:GA35 8 (4) 0 SS50:GA50 0 0 382 383 3.4 384 SS was co-milled at compositions corresponding to SolAA and SolPA (21 % and 22 % 385 w/w), and above (50 % w/w). The pXRD patterns of the co-milled systems are 386 displayed in Figure 9 and the API amorphous content values, as quantified by DVS 387 using eq. 1, and pXRD, are displayed in Table 2. The presence of Bragg peaks in the 388 co-milled systems, corresponding to the crystalline API, indicated that co-milling with 389 these excipients was effective at reducing the degree of amorphisation of the milled 390 drug (Fig. 9). Interestingly, co-milling at weight fractions of excipient above Solexcipient 391 produced a further reduction in API amorphicity, as indicated by both pXRD and DVS 392 (Table 2). SS co-milled with AA and PA 393 394 Table 2. Summary of amorphous content of SS:AA and SS:PA co-milled systems as 395 quantified by DVS and pXRD. % Amorphous content (± S.D.) System DVS pXRD SS79 : AA21 63 (2) 75 (7) SS50 : AA50 46 (5) 62 (12) SS78 : PA22 64 (2) 60 (15) SS50 : PA50 42 (4) 48 (10) 396 397 398 3.5 17 SS co-mixed with the dicarboxylic acids. 399 SS was co-mixed separately with the three dicarboxylic acids, at compositions 400 corresponding to Solexcipient and for varying times. The amorphous content of the co- 401 mixed composites were quantified by DVS. The kinetic profiles for all the three 402 systems, after dry mixing for 24 h, are displayed in Figure 10 below. 403 404 The mass loss at 70% RH for the SS:GA dry mixed composite indicated that co-mixing 405 did not completely eliminate amorphisation of the API. 406 subsequent mass losses on crystallisation were higher for the SS:AA and SS:PA 407 systems indicating that co-mixing with these excipients was less effective than co- 408 milling at mitigating API amorphisation. Mass uptakes and 409 410 A plot of amorphous content versus dry mixing time is shown in Figure 11. SS dry 411 mixed for 4 h was 93% amorphised, and was completely amorphous after 8 h, as 412 mentioned earlier. Co-mixing experiments were performed for as long as 24 h until a 413 plateau was observed whereby no further changes in API amorphisation with mixing 414 time were noted. After 24 h, co-mixing SS with PA had a negligible effect on 415 amorphisation of the API, co-mixing with AA lowered the amorphous content by 8 % 416 ± 2 %, whereas the co-mixed API composite with GA had an amorphous content 417 reduction of more than 75 %, relative to the API dry mixed alone. 418 419 4. Discussion 420 Milling and dry mixing are two mechanical operations which, although differing 421 considerably in terms of energy input, were capable of completely amorphising SS. 18 422 The dry mixing process took considerably longer than milling (8h v 2h), most 423 probably due to the milder conditions to which the API particles are exposed. 424 The excipients chosen for this study were three dicarboxylic acids which are 425 crystalline in nature. GA and AA were resistant to amorphisation when exposed to 426 milling, spray drying or melt quench (Curtin et al., 2013). In previous work, the Tg 427 values of GA and AA were calculated by the Tg = Tm x 0.7 rule to be -14 °C and 25 °C 428 respectively (Curtin et al., 2013). Moreover these two excipients were proven to be 429 very effective at mitigating amorphisation of sulfadimidine on co-milling (Curtin et 430 al., 2013). 431 When comparing the two sets of quantification results by DVS and pXRD in Table 1, it 432 should be acknowledged that, with pXRD it is difficult to detect amorphous content 433 below 10 %, whereas in the case of DVS, the detection limit is often lower than 1 % 434 (Lehto et al., 2006). For instance, quantification results based on pXRD indicated 435 that API amorphisation was eliminated on co-milling with just 20% w/w GA, in 436 contrast to DVS which detected an amorphous content of 13%. 437 We noted a relationship between the solubility of excipient in the API, the calculated 438 solubility parameter and the degree of amorphisation reduction on co-milling. PA is 439 another dicarboxylic acid, differing only in alkyl chain length from that of GA and AA 440 and has a calculated Tg of -8 °C. PA could not be amorphised when milled, spray 441 dried or melt quenched (data not shown). All three excipients were found to have 442 good solubility in amorphous SS, with AA and PA having similar values of 21 and 22 443 %, respectively, with GA being more soluble, at 36 %. 444 19 445 SS cannot be melted without degradation, therefore freeze drying was used to 446 produce amorphous composites for each API:excipient system. Figure 12 displays a 447 plot of experimental Tg of freeze dried samples and % crystallinity of co-milled 448 systems as a function of GA weight fraction. With XGA < SolGA the composite systems 449 were amorphous. With XGA > SolGA crystallinity associated with the excipient was 450 observed. It should be noted that the melting enthalpy measured for the SS:GA 451 composite, at XGA=50, was in good agreement with the value predicted from the plot 452 presented in Figure 1. In accordance to what was reported in the study with 453 sulfadimidine (Curtin et al., 2013), the crystallinity of the SS:GA co-milled systems 454 approached near maximum and then levelled off at excipient weight fractions very 455 close to SolGA. The freeze dried amorphous composites, at SolGA, had a Tg minimum 456 value of 5 °C. Amorphous composites at a composition corresponding to SolGA would 457 be saturated with excipient and therefore exhibit the lowest possible composite Tg. 458 Increasing the amount of excipient should have no further effect on the Tg and this is 459 why the Tg curve flattens when XGA > SolGA. 460 461 As previously reported, the identification of a single Tg value intermediate to that of 462 the API and excipient was taken as an indicator of a mixed, single phase system (Qian 463 et al., 2010). In contrast, a phase separated amorphous system will display two 464 distinct Tg values. Saunders et al. (2004) noted that a Tg could be detected for a 465 binary system containing as low as 1 % amorphous lactose by using very high 466 scanning rates. As GA, AA and PA are not amenable to amorphisation on their own, 467 in this particular case phase separation of API and excipient in the amorphous state 468 is unlikely. The miscibility of the SS:GA, SS:AA, and SS:PA systems were confirmed by 20 469 the presence of a single Tg value in the freeze dried amorphous samples. At 470 Solexcipient, the SS:AA system had a Tg minimum value of 34 °C and the SS:PA system 471 had a Tg minimum value of 31 °C, respectively, indicating that only GA was capable 472 of producing a composite with an intermediate Tg below that of room temperature 473 (5°C) (Table 3). GA had the lowest calculated Tg value, it was the most soluble of the 474 excipients in the API, it produced the lowest composite Tg on freeze drying, and it 475 proved to be the most effective excipient at mitigating amorphisation on both co- 476 milling and co-mixing. 477 478 It was anticipated that maximal amorphisation reduction of SS on co-milling would 479 be achieved at excipient weight fractions corresponding to SolAA (21%) and SolPA 480 (22%). However this was not the case and, as indicated in Table 2 and 3, a further 481 amorphous content reduction of more than 15 % was observed by DVS, in both 482 cases, on co-milling with 50 % w/w AA and PA. The purpose of using pXRD as a 483 quantification technique in this study was to support the results of the analysis by 484 DVS and demonstrate that the reduction in API amorphicity on co-milling at excipient 485 weight fractions beyond Solexcipient could indeed be observed from an orthogonal 486 method. Results from both DVS and pXRD illustrated that such a reduction in API 487 amorphous content was observed (Table 2). Balani et al. 2010, previously co-milled 488 SS with AA at different weight fractions of excipient and our quantification results by 489 DVS are in agreement with the quantification results reported in that study. 490 Moreover the authors noted an excipient concentration dependent effect on the 491 amorphous content of the API on co-milling. A possible explanation is that the co- 492 milling operation leads to amorphous SS, supersaturated with excipient, which 21 493 conceptually could lead to a greater composite Tg reduction and promote further 494 crystallisation from the amorphous state. 495 amorphous dispersion by co-milling was also extensively reported by Mahieu et al., 496 2013; Caron et al., 2007; Willart et al., 2008. The production of a supersaturated 497 498 Table 3. Summary of experimental solubilites, Tg minimum values of freeze dried 499 amorphous systems, and amorphous content values, as quantified by DVS, for co- 500 milled and co-mixed API:excipient systems. Xexcipient refers to the weight fraction of 501 excipient. % Amorphous content by DVS (± S.D) Tg System Solexcipient (%) minimum (°C) Co-milling (3 h) Co-mixing (24 h) Xexcipient = Xexcipient = Xexcipient = Xexcipient = Solexcipient 50 % w/w Solexcipient 50 % w/w SS:GA 36 5 8 (4) 0 22 (9) 21 (4) SS:AA 21 34 63 (2) 46 (5) 92 (2) 87 (4) SS:PA 22 31 64 (2) 42 (4) 100 99 (1) 502 503 The reduction of API amorphisation by co-mixing was less pronounced than by co- 504 milling. On co-mixing for 24h at compositions corresponding to Solexcipient, the API 505 was still almost 100 % amorphous with PA, while AA and GA lowered API amorphous 506 content by 8 % and 78 %, respectively (Table 3). In order to assess whether a 507 supersaturation effect occurred on co-mixing, as was observed for co-milling, 508 experiments were performed at excipient weight fractions of 50 %w/w. However no 509 difference in API amorphous content on co-mixing at the two different 22 510 concentrations of each excipient was noted (Table 3). Dry mixing is a much milder 511 mechanical operation than milling and with less energy input the likelihood of 512 obtaining a supersaturated state is less. 513 514 Amorphous SS, prepared by dry mixing, was then mixed with 35% w/w crystalline GA 515 and samples were periodically removed over time and evaluated by pXRD. It was 516 noted that Bragg peaks of excipient became less intense initially due to dissolution of 517 the excipient in the amorphous API (Figure 13). 518 peak intensity was noted when the excipient was dry mixed alone (data not shown). 519 After 3 h the system had recrystallised (Figure 13d). This supports the hypothesis 520 that, upon mechanical activation, initial amorphisation of the API is preceded by 521 dissolution of the excipient, which is solubility dependent, and acts to lower the 522 composite Tg and promote crystallisation of the drug. 523 524 525 526 527 528 529 530 531 532 533 23 No comparable reduction in Bragg 534 535 5. Conclusion 536 Both milling and dry mixing SS resulted in a crystalline to amorphous solid state 537 change in the API. We have shown in this work that amorphisation of SS could be 538 effectively eliminated on co-milling with 50% w/w GA, while it could be more than 539 halved on co-milling with 50% w/w AA and PA. Dry mixing of SS with these low Tg 540 excipients also resulted in a less disordered API, although the extent of reduction 541 was less pronounced relative to the corresponding co-milled data. GA was the most 542 effective excipient at mitigating API amorphisation on both mechanical co-processing 543 techniques. It displayed the highest solubility of the excipients in the amorphous 544 drug, and it exerted the most pronounced Tg lowering effect in the amorphous 545 composites. The reduction in API amorphisation on co-mixing achieved at excipient 546 concentrations corresponding to their solubility in the amorphous drug was the 547 same compared to systems with 50% w/w excipient. In contrast, co-milling at the 548 higher concentration of excipient produced a further reduction in API amorphisation. 549 This is thought to be due to a supersaturation effect arising from the more energetic 550 milling process, enabling more excipient to further lower the composite Tg, and 551 promote crystallisation. We have shown that initial amorphisation of the API is 552 preceded by dissolution of the excipient which induces a Tg lowering effect on the 553 resultant composite and induces crystallisation of the drug. 554 low glass transition temperature dicarboxylic acids via two different modes of 555 mechanical activation proved effective at mitigating amorphisation of the API. 556 557 24 Co-processing SS with 558 559 560 561 562 563 564 565 566 567 568 569 570 571 572 573 574 575 576 577 578 579 580 581 582 583 584 585 586 587 588 589 590 591 592 593 594 595 596 597 598 599 600 601 602 6. References Balani, P. N.; Ng, W. K.; Tan, R. B. H.; Chan, S. Y. Influence of excipients in comilling on mitigating milling-induced amorphisation or structural disorder of crystalline pharmaceutical actives. J. Pharm. Sci. 2010, 99 (5), 2462−2474. Bianco, S.; Caron, V.; Tajber, L.; Corrigan, O. I.; Nolan, L.; Hu, Y.; Healy, A. M. Modification of the Solid-State Nature of Sulfathiazole and Sulfathiazole Sodium by Spray Drying. AAPS PharmSciTech. 2012, 13 (2), 647-660. Brodka-Pfeiffer, K.; Langguth, P.; Hausler, H.; Graβ, P. Influence of mechanical activation on the physical stability of salbutamol sulphate. Eur. J. Pharm. Biopharm. 2003, 56 (1), 392−400. Caron, V.; Willart, J. F.; Danede, F.; Descamps, M. The implication of the glass transition in the formation of trehalose/ mannitol molecular alloys by .ball milling. Solid State Commun. 2007, 144 (7−8), 288−292. Clas, S. D.; Faizer, R.; O’Connor, R. E.; Vadas, E. B. Quantification of crystallinity in blends of lyophilized and crystalline MK-0591 using X-ray powder diffraction. Int. J. Pharm. 1995, 121, 73-79. Curtin, V.; Amharar, Y.; Hu, Y.; Erxleben, A.; McArdle, P.; Caron, V.; Tajber, L.; Corrigan, O. I.; Healy, A. M. Investigation of the Capacity of Low Glass Transition Temperature Excipients to Minimize Amorphization of Sulfadimidine on Comilling. Mol. Pharmaceutics 2013, 10, 386−396. Feng, T.; Rodolfo, P.; Carvajal, M. T. Process induced disorder in crystalline materials: Differentiating defective crystals from the amorphous form of griseofulvin. J. Pharm. Sci. 2008, 97 (8), 3207–3221. Fukuoka, E.; Makita, M.; Yamamura, S. Glass state of pharmaceuticals III. Thermal properties and stability of glassy pharmaceuticals and their binary glass systems. Chem. Pharm. Bull. 1989, 37, 1047−1050. Griesdale, L. C.; Jamieson, M. J.; Belton, P. S.; Barker, S. A.; Craig, D. Q. M. Characterization and quantification of amorphous material in milled and spray-dried salbutamol sulfate: A comparison of thermal, spectroscopic, and water vapor sorption approaches. J. Pharm. Sci. 2011, 100 (8), 3114-3129. Gusseme, A. D.; Neves, C.; Willart, J. F.; Rameau, A.; Descamps, M. Ordering and disordering of molecular solids upon mechanical milling: the case of fanaserine. J. Pharm. Sci. 2008, 97 (11), 5000−5012. 25 603 604 605 606 607 608 609 610 611 612 613 614 615 616 617 618 619 620 621 622 623 624 625 626 627 628 629 630 631 632 633 634 635 636 637 638 639 640 641 642 643 644 645 646 647 648 649 Hancock, B. C.; Zografi, G. Characteristics and significance of the amorphous state in pharmaceutical systems. J. Pharm. Sci. 1997, 86 (1), 1−12. Hockerfelt, M. H.; Nystrom, C.; Alderborn, G. Dry mixing transformed microparticles of a drug from a highly crystalline to a highly amorphous state. Pharm. Dev. Technol. 2009, 14 (3), 233–239. Hüttenrauch, R.; Fricke, S.; Zielke, P. Mechanical activation of pharmaceutical systems. Pharm Res. 1985, 2 (6), 302–306. Kerc, J.; Srcic, S. Thermal analysis of glassy pharmaceuticals. Thermochim. Acta 1995, 248, 81−95. Lehto, V. P.; Tenho, M.; Heikkilä, K. V.; Harjunen, P.; Päällysaho, M.; Välisaari, J.; Niemelä, P.; Järvinen, K. The comparison of seven different methods to quantify the amorphous content of spray dried lactose. Powder Technol. 1006, 167, 85-93. Lin, S. Y.; Hsu, C. H.; Ke, W. T. Solid-state transformation of different gabapentin polymorphs upon milling and co-milling. Int. J. Pharm. 2010, 396 (1–2), 83–90. Long, G. L.; Winefordner, J. D. Limit of detection: A closer look at the IUPAC definition. Anal. Chem. 1983, 55 (7), 713-724. Mackin, L.; Zanon, R.; Park, J. M.; Foster, K.; Opalenik, H.; Demonte, M. Quantification of low levels (<10%) of amorphous content in micronized active batches using dynamic vapour sorption and isothermal microcalorimetry. Int. J. Pharm. 2002, 231 (2), 227−236. Mahieu, A.; Willart, J. F.; Dudognon, E.; Danede, F.; Descamps, M. A New Protocol To Determine the Solubility of Drugs into Polymer Matrixes. Mol. Pharmaceutics 2013, 10, 560−566. Malkki, L.; Tammilehto, S. Decomposition of salbutamol in aqueous solutions. I. The effect of pH, temperature and drug concentration. Int. J. Pharm. 1990, 63 (1), 17-22. McNamara, D. P.; Childs, S. L.; Giordano, J.; Iarriccio, A.; Cassidy, J.; Shet, M. S.; Mannion, R.; O’Donnell, E.; Park, A. Use of a glutaric acid cocrystal to improve oral bioavailability of a low solubility API. Pharm. Res. 2006, 23 (8), 1888−1897. Morris, K. R.; Griesser, U. J.; Eckhardt, C. J.; Stowell, J. G. Theoretical approaches to physical transformations of active pharmaceutical ingredients during manufacturing processes. Adv Drug Deliv Rev. 2001;48 (1), 91–114. 26 650 651 652 653 654 655 656 657 658 659 660 661 662 663 664 665 666 667 668 669 670 671 672 673 674 675 676 677 678 679 680 681 682 683 684 685 686 687 688 689 690 691 692 Mosharraf M, Nyström C. The effect of dry mixing on the apparent solubility of hydrophobic, sparingly soluble drugs. Eur. J. Pharm. Sci. 1999, 9 (2), 145–156. Palacio, M. A.; Cuffini, S.; Badini, R. ; Karlsson, A. ; Palacios, S. M. Solid-state characterization of two polymorphic forms of R-albuterol sulfate. J. Pharm. Biomed. Anal. 2007, 43 (4), 1531-1534. Patterson, J. E.; James, M. B.; Forster, A.H.; Lancaster, R. W.; Butler, J. M.; Rades, T. Preparation of glass solutions of three poorly water soluble drugs by spray drying, melt extrusion and ball milling. Int. J. Pharm. 2007, 336 (1), 22-34. Qian, F.; Huang, J.; Hussain, M. A. F. Drug–polymer solubility an miscibility: stability consideration and practical challenges in amorphous solid dispersion development. J. Pharm. Sci. 99 (2010) 2941–2947. Saunders, M.; Podluii, K.; Shergill, S.; Buckton, G.; Royall, P. The potential of high speed DSC (Hyper-DSC) for the detection and quantification of small amounts of amorphous content in predominantly crystalline samples. Int. J. Pharm. 2004, 274, 35-40. Shah, B.; Kakumanu, K.; Bansal, A, K. Analytical techniques for quantification of amorphous/crystalline phases in pharmaceutical solids. J. Pharm. Sci. 2006, 95 (8), 1641-1665. Willart, J. F.; Gusseme, A. D.; Hemon, S.; Odou, G.; Danede, F.; Descamps, M. Direct crystal to glass transformation of trehalose induced by ball milling. Solid State Commun. 2001, 119 (8-9), 501-505. Willart, J. F.; Descamps, M. Solid state amorphisation of pharmaceuticals. Mol. Pharmaceutics 2008, 5 (6), 905−920. Willart, J. F.; Carpentier, L.; Danede, F.; Descamps, M. Solid state vitrification of crystalline griseofulvin by mechanical milling. J. Pharm. Sci. 2012, 101 (4), 1570−1577. Yu, L. Amorphous pharmaceutical solids: preparation, characterization and stabilisation. Adv. Drug Delivery Rev. 2001, 48 (1), 27−42. 693 694 27