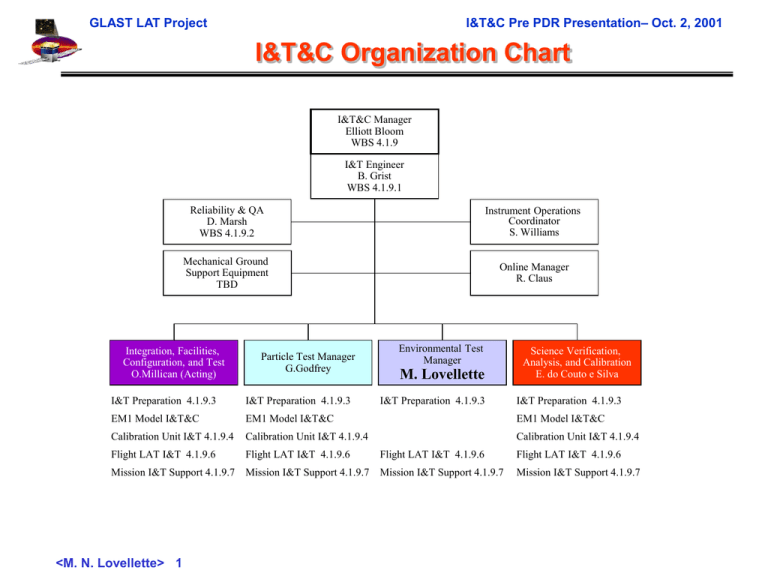

I&T&C Organization Chart – Oct. 2, 2001 GLAST LAT Project

advertisement

GLAST LAT Project I&T&C Pre PDR Presentation– Oct. 2, 2001 I&T&C Organization Chart I&T&C Manager Elliott Bloom WBS 4.1.9 I&T Engineer B. Grist WBS 4.1.9.1 Reliability & QA D. Marsh WBS 4.1.9.2 Instrument Operations Coordinator S. Williams Mechanical Ground Support Equipment TBD Online Manager R. Claus Integration, Facilities, Configuration, and Test O.Millican (Acting) Particle Test Manager G.Godfrey Environmental Test Manager M. Lovellette I&T Preparation 4.1.9.3 I&T Preparation 4.1.9.3 EM1 Model I&T&C EM1 Model I&T&C EM1 Model I&T&C Calibration Unit I&T 4.1.9.4 Calibration Unit I&T 4.1.9.4 Calibration Unit I&T 4.1.9.4 Flight LAT I&T 4.1.9.6 Flight LAT I&T 4.1.9.6 Flight LAT I&T 4.1.9.6 Flight LAT I&T 4.1.9.6 Mission I&T Support 4.1.9.7 Mission I&T Support 4.1.9.7 Mission I&T Support 4.1.9.7 Mission I&T Support 4.1.9.7 <M. N. Lovellette> 1 I&T Preparation 4.1.9.3 Science Verification, Analysis, and Calibration E. do Couto e Silva I&T Preparation 4.1.9.3 GLAST LAT Project I&T&C Pre PDR Presentation– Oct. 2, 2001 Function of Environmental Test • Demonstrate the the LAT meets all environmental requirements – – – – Electromagnetic Compatibility Structure: “modes” & “loads” Thermal limits Workmanship • Exact test requirements/ implementation is TBD • Do not over test <M. N. Lovellette> 2 GLAST LAT Project I&T&C Pre PDR Presentation– Oct. 2, 2001 ENVIRONMENTAL TEST FLOW • Before shipment to NRL there will be combined preship and environmental test readiness review • Functional test required before and after each environmental test • Inspection of instrument will be performed before and after each test RECEIVING INSPECTION EMI/EMC EMI TRR MODAL SURVEY VIBE TRR VIBE/ ACOUSTIC TBAL/TVAC TVAC TRR TRR = Test Readiness Review <M. N. Lovellette> 3 POST TEST INSPECTION PRE SHIP REVIEW GLAST LAT Project I&T&C Pre PDR Presentation– Oct. 2, 2001 EMI/EMC TESTING • Test to: GSFC 433-RQMT-0005 • Demonstrates that adequate margin exists between susceptibility and noise levels • Ensure compatibility of LAT with other SV systems • Ensure compatibility of other SV system with LAT • Principal test areas – – – – – Radiated Emissions Conducted Emission Radiated Susceptibility Conducted Susceptibility Magnetic survey if required • Baseline test facility Naval Center for Space Technology – 2 Anechoic chambers • Typical test duration 3-5 days <M. N. Lovellette> 4 GLAST LAT Project I&T&C Pre PDR Presentation– Oct. 2, 2001 MODAL SURVEY • Verifies dynamic characteristics of structure • Issue: – With the deletion of the qual. grid we expect the requirement for a fixed base modal survey • Not determined at this point if this will be done on the grid with mass simulators or on the integrated LAT – Late in the program if there is a problem • Modes could also be verified with a base driven shake • Fixed base modal survey can be done at NRL – Expected duration one week <M. N. Lovellette> 5 GLAST LAT Project I&T&C Pre PDR Presentation– Oct. 2, 2001 Random vibration/acoustic • Verifies workmanship • Verifies structural integrity • Verifies modes • Can be performed by random vibration testing, acoustic, or vibroacoustic testing • Typical test duration 3 - 5 days <M. N. Lovellette> 6 GLAST LAT Project I&T&C Pre PDR Presentation– Oct. 2, 2001 Thermal Balance Testing • Verifies thermal model • Verifies ability to operate in vacuum and at upper and lower temperature limits • Test should be performed in as close to flight configuration as possible – – – – Thermal blankets Heat pipes Radiators Facility inputs: heaters/ solar simulators/ cold plates • Thermal model is verified for cold case and hot case • Functional tests performed after cold soak and during hot plateau • Possibly performed after integration with SV <M. N. Lovellette> 7 GLAST LAT Project I&T&C Pre PDR Presentation– Oct. 2, 2001 Thermal Cycling • Verification of workmanship • Plan is for four total cycles at integrated LAT level – Thermal balance counts as one • Duration of cycles TBD • Comprehensive performance testing to be performed at each plateau • Functional testing will be performed throughout TVAC except when the instrument must be off for cooling ramps/soaks TBAL Hot Close door & Functional test TBAL Cold ~28 days <M. N. Lovellette> 8 GLAST LAT Project I&T&C Pre PDR Presentation– Oct. 2, 2001 QA / MA Support • GSE verification – Mechanical GSE document verification • Shipping containers • Transportation dolly • Test fixtures • Lifting fixtures • Cooling cart (if required) – Electrical GSE document verification • Computer system • Ground power system • Test harnesses • Breakout boxes • Preship review and verification • Dispensation of open problem/non conformance reports and their impact on further testing <M. N. Lovellette> 9 GLAST LAT Project I&T&C Pre PDR Presentation– Oct. 2, 2001 QA/MA - con’t • Receiving inspection at NRL • Verification of cleanliness, temperature, humidity controls and ESD • Test facilities verification • Review test plans and procedures • Test support and verification of test results • Preparation of work orders, anomaly and anomaly resolution reports • Inspection of hardware prior to and after test • Preparation and management of test logs and status reporting – – – – – Test conductors log Event logbook Anomaly reports Configuration status Mate/demate logs, etc. <M. N. Lovellette> 10 GLAST LAT Project I&T&C Pre PDR Presentation– Oct. 2, 2001 Schedule • FY02: – PDR Test requirements definition – CDR Preliminary test plans & resource identification • FY03 – Finalize test plans – Finalize resource identification / allocation • FY04 – Finalize test procedures – Begin environmental testing • FY05 – Complete environmental testing – Prepare test reports, close all anomalies – Support observatory level environmental testing • FY06 – Support LEO <M. N. Lovellette> 11