Efficient Constructive procedures for the ... blocking flow shop scheduling problem Ramon Companys, Imma Ribas

advertisement

Efficient Constructive procedures for the distributed

blocking flow shop scheduling problem

(presented at the 6th IESM Conference, October 2015, Seville, Spain) © I 4e2 2015

Ramon Companys, Imma Ribas

Departament d’Organització d’Empreses. Universitat Politècnica de Catalunya, BarcelonaTech

Barcelona, Spain

Email: ramon.companys@upc.edu, imma.ribas@upc.edu

Abstract— the distributed blocking flow shop scheduling

problem (DBFSP) allows modeling of the scheduling process in

companies with more than one factory, with productive systems

configured as flow shop lines where the blocking constraint has

to be considered. To the best of our knowledge, this variant of the

distributed permutation flow shop scheduling problem has not

been studied. In this paper, we propose some constructive

heuristics that will solve the DBFSP and thus minimize the

maximum completion time among the factories. The proposed

procedures use two approaches that are totally different from

those proposed for the distributed permutation flow shop

scheduling problem (DPFSP). By taking the DPFSP procedures

that we adapted to DBFSP and comparing them to the new

approaches that were specifically designed for DBPFSP, we find

that the latter perform considerably better.

Keywords—distributed blocking flow shop; blocking flow shop;

distributed permutation flow shop; constructive heuristics;

I.

INTRODUCTION

Distributed manufacturing is a common situation for large

enterprises that compete in a globalized market. Because of

current globalization trends, production has shifted from single

factory production to a multi-factory production network [1].

In this environment, the scheduling problems deal with the

allocation of jobs to factories and the scheduling of jobs in each

plant. Since the flow shop configuration is the most common

processing layout, the flow shop scheduling problem has been

studied greatly since the seminal paper of Johnson [2].

However, its extension to a multi-plant environment was first

presented by Naderi and Ruiz [3], who referred to it as the

Distributed Permutation Flow Shop Scheduling Problem

(DPFSP). According to [3], the DPFSP is defined as follows. A

set N of n jobs must be processed by a set G of F identical

factories. Each factory has the same set M of m machines. The

processing times of all the tasks of a given job do not change

from factory to factory. The objective is to minimize the

maximum makespan among factories.

After the publication of [3], several authors proposed

various heuristics to solve this problem ([4]–[13]), but the

blocking constraint has been considered in none of them. The

blocking flow shop scheduling problem allows many

productive systems to be modeled when there are no buffers

between consecutive machines. In general, it is useful for those

systems that have a production line without a drag system that

forces a job to be transferred between two consecutive stations

at pre-established times. Some industrial examples can be

found in the iron and steel industry [14]; in the treatment of

industrial waste and the manufacture of metallic parts [15]; or

in a robotic cell, where a job may block a machine while

waiting for the robot to pick it up and move it to the next stage

[16]. The blocking constraint tends to increase the completion

time of jobs, because the processed job cannot leave the

machine if the next machine is busy. Therefore, the heuristics

designed to schedule jobs in this environment have to consider

this fact in order to minimize the idle time of machines due to

possible blockage. Therefore, the distributed blocking flow

shop scheduling problem (DBFSSP) deals with the allocation

and scheduling of jobs in a multi-factory production network

with the blocking constraint present in the manufacturing

system. It is interesting to study this problem in order to design

specific procedures, since the adaptation of those designed for

the DPFSP probably perform worse than procedures which

consider its characteristics.

In this paper we propose new constructive procedures built

from two different approaches to solve the DBPFSP. The

computational evaluation shows good performance of these

simple procedures, which can be used either to obtain a fast

solution to the problem or as the initial solution procedure in

more sophisticated metaheuristics.

II.

CONSTRUCTIVE HEURISTICS

As stated before, the DPFSP needs to deal with two related

decisions: the allocation of jobs to factories and the sequence

of jobs assigned to each plant. In this paper, we have compared

33 constructive heuristics. 30 of them are formed by combining

ten sequencing methods with three allocation rules (two of

these rules came from the DPFSP literature and the third is a

new approach presented in this paper). The remaining three

heuristics take a different perspective in addressing the

problem considered here.

A. Proposed methods

To the best of our knowledge, no paper dealing with the

distributed blocking permutation flow shop has been published,

but some ideas can be taken from the DPFSP. In particular, the

constructive heuristics proposed in [3] consist of sequencing

jobs according to an ordering rule before being assigned to a

facility in accordance with an allocation rule. In this paper, we

propose a new method for allocating the jobs after sequencing,

as well as three new procedures that use a different approach to

solve the problem.

The new allocation method consists of dividing the job

sequences into F (number of factories) fractions by assigning a

similar load (ΣPi/F) to each plant. Finally, the sequence of jobs

assigned to each plant is improved by an insertion procedure

similar to that used in the second step of NEH [17].

This allocation method has been combined with the

following ten sequencing rules. Some of them are used in the

PFSP and some others were specially designed for the blocking

PFSP: Shortest Processing Time (SPT), Largest Processing

Time (LPT), Johnson rule [2], Palmer’s heuristic [18], CDS

[19], NEH [17], Trapeziums (TR) [20], PF [21], PW [22] and

HPF2[23]. The three last procedures were developed for the

blocking flow shop problem. The resulting heuristics are

named as the sequencing rule plus the number 3, following the

notation used in [3]. Therefore, these heuristics are named

SPT3, LPT3, Johnson3, Palmer3, CDS3, NEH3, TR3, PF3,

PW3 and HPF23.

In the TR rule, two indexes are calculated for each job (S1i

and S2i), according to (3) and (4) respectively. Next, jobs are

scheduled by applying the Johnson algorithm considering S1i

as the processing time of job i in the first machine and S2i as

the processing time of i in the second machine.

m

S1i (m j 1) p j ,i

(3)

j 1

S 2i

m

( j 1) p j ,i

(4)

j 1

It is worth noting that ordering jobs in increasing order of

S3i=S1i-S2i obtains the sequence given by Palmer’s heuristic.

The HPF2 procedure is divided into two steps. The first

step selects a job to be the first job in the sequence, which

minimize the bicriteria index (R(i)). This index considers the

contribution of the job to the completion time (minimum sum

of its processing times, Pi) and the front delay generated. The

selected job is the one whose R(i) value is smaller.

m

R (i )

2 ( m j ) p j ,i

j 1

m 1

m

(1 ) p j ,i

(5)

j 1

The second step builds the remaining sequence to minimize

the timeout of machines and the total flowtime, which is

carried out with index ind1(i,k), where i denotes the job and k

the position, calculated according to (6). Notice that the

timeout can be due to idle time, blocking time or the sum of

both. Therefore, the sequencing rule according to index

ind1(i,k) is adequate when the blocking constraint is

considered.

ind 1 ( i ,k ) μ

m

( c j , k 1( i) c j , k () p j ,i )) (1 μ) ( C i C [ k -1] )

(6)

j 1

Instead of sequencing the jobs first and then the allocation

of jobs to the plants, the new approach considers the jobs and

factories together. Following this philosophy, we have

implemented three methods, which are named RC1_1, RC1_m

and RC2.

In RC1_1 and RC1_m, the first job is selected for each

plant according to index R(i), equation (5). Next, a factory is

first selected in order to proceed with the other jobs. In RC1_1,

the factory selected is the one which has the first machine

available earlier, whereas the factory selected in RC1_m is the

one which has the last machine available sooner. After the

plant is selected, a job is chosen according to index ind2(f,i),

calculated as in (7), where f is one of the factories and f is the

sequence of jobs already sequenced in plant f. Observe that

ind2 differs from ind1 in the second term. In ind2, this term

contemplates the workload of each job, whereas ind1 considers

the contribution of each job to the total flow time.

m

ind 2 (i, k ) ( (c j , k 1 ( f i ) c j , k ( f ) p j ,i )) (1 ).Pi

(7)

j 1

In RC2 the first job assigned to each plant is also selected

with index R(i), but each remaining job and plant are selected

at the same time in order to minimize index ind3(f,i,kf),

calculated as in (8).

m

ind 3( f , i, k f ) ( (c j ,k f 1 ( f i) c j ,k f ( f ) p j ,i )) (1 ).(cm,k f 1 ( f i) c0 ) , (8)

j 1

where c0 is the current minimum makespan of any plant.

Observe that the second term measures the difference between

the partial makespan (completion time obtained with the jobs

already sequenced in this plant) and the minimum partial

makespan obtained in any of the plants. By trying to minimize

this term, the workload of the plants tends to be similar.

The last step in the three presented algorithms improves the

sequence of each plant by using an insertion procedure, similar

to the one used in NEH.

Notice that HPF2, RC1_1, RC1_m and RC2 heuristics have

two parameters (λ and µ) that must be determined adequately.

Their calibration is addressed in the next section.

III.

EXPERIMENTAL EVALUATION

In this section we calibrate and evaluate the presented

procedures against other constructive procedures proposed in

the literature for the DPFSP. These procedures consist of

combining the two allocation methods proposed in [3] with six

sequencing rules: (Shortest Processing Time (SPT), Largest

Processing Time (LPT), Johnson rule [2], Palmer’s heuristic

[18], CDS [19] and NEH [17]). The two allocation methods

are:

(1) Assign job j to the factory with the lowest current Cmax,

not including job j.

(2) Assign job j to the factory which completes it at the

earliest time.

These heuristics are identified by the name of the

sequencing rule plus 1 or 2, depending on the allocation rule

used. We have added the sequencing rules TR, PF, PW and

HPF2 to these groups of heuristicsº.

0.70

6.87

6.77

6.98

6.78

6.91

7.06

7.24

0.75

6.99

6.80

7.03

6.94

7.03

7.21

7.31

As stated before, HPF2, RC1_1, RC1_m and RC2 have two

parameters that must be calibrated. Next, we explain how this

is carried out.

A. Calibration of heuristics

Parameters λ and µ of each heuristic were selected by

measuring the performance of the algorithm, which itself was

done by combining several λ and µ values. The values of λ and

µ ranged from 0 to 1 in increments of 0.05. Therefore, we

tested 21 values for each parameter.

For this test, we used 600 randomly generated instances.

100 instances were grouped into 20 sets of size n x m, 5

instances per set, where n= {25, 50, 100, 200, 400} and m = {5,

10, 15, 20}. All these 100 instances were considered with a

different number of factories. We had F={2,3,4,5,6,7}, which

gave us 600 instances in total.

The performance was measured by the Relative Percentage

Deviation (RPD) from the best solution (minimum makespan),

which was obtained during the experiment using all

combinations of values. Therefore, RPD is calculated as in (9):

RPD

C max k Best k

100 ,

Best k

(9)

TABLE II.

F

TABLE I.

ARPD FOR HPF23 FOR EACH

COMBINATION OF AND FOR HPF23

Values of parameters

0.60

0.65

0.70

0.75

0.80

0.85

0.90

0.45

7.01

6.91

7.17

6.77

6.89

7.21

7.27

0.50

7.02

6.84

7.02

6.72

6.92

7.25

7.31

0.55

6.95

6.86

7.05

6.73

6.87

7.20

7.26

0.60

6.91

6.84

7.01

6.71

6.86

7.14

7.24

0.65

6.97

6.89

7.02

6.78

6.82

7.07

7.23

Value of Parameters

Min

ARPD

2

4.99

0.60

0.70

3

6.06

0.50

0.70

4

6.71

0.60

0.75

5

7.52

0.45

0.80

6

8.09

0.70

0.95

7

8.10

0.15

0.70

Hence, we had 6 matrices for each procedure. Next, in

order to select a unique value that is independent of the number

of plants (F), we calculated the ARPD for each combination of

λ and µ values in the previous 6 matrices. The selected values

of λ and µ came from those that lead to the minimum ARPD.

Table III shows the selected values of λ and µ for each

procedure.

where Cmax,k is the makespan obtained in instance k and Bestk is

the minimum Cmax obtained in this instance by any

combination of values.

For each procedure and number of factories, we built a matrix

with the average RPD (ARPD) value that was obtained

through each combination of λ and µ. As an example, table I

shows a piece of the table built for the calibration of HPF23

when F=4 plants. Notice that the minimum APRD is obtained

when λ=0.6 and = 0.75. A similar table was built for all

numbers of plants. Table II shows the λ and µ values that lead

to the minimum ARPD for each plant.

AND VALUES FOR EACH

NUMBER OF PLANTS

TABLE III.

Procedures

λ AND µ VALUES FOR EACH

PROCEDURE

Values of parameters

RC1_1

1

0.95

RC1_m

0.85

1

RC2

0.75

0.05

HPF2

0.55

0.70

B. Computational evaluation

We compared the 33 implemented constructive procedures

in order to analyze their behavior and to recommend one of

them, if possible, for solving the distributed blocking flow shop

problem.

Among the compared heuristics, 12 of them were presented

in [3] (SPT1, LPT1, Johnson1, Palmer1, CDS1, NEH1, SPT2,

LPT2, Johnson2, Palmer2, CDS2, NEH2). We added to them

TR1, PF1, PW1, HPF21, TR2, PF2, PW2 and HPF22. The

remaining 13 procedures are those presented in this paper:

SPT3, LPT3, Johnson3, Palmer3, CDS3, NEH3, TR3, PF3,

PW3, HPF23, RC_1, RC_m and RC2.

The algorithms were coded in the same language (QB64)

and tested on the same computer, a 3 GHz Intel Core 2 Duo

E8400 CPU with 2 GB of RAM.

The heuristic performance was measured by the Relative

Percentage Deviation (RPD), using the best solution (minimum

makespan) chosen from among the solutions that were obtained

by all of the implemented procedures.

JOHN2

10.75

8.45

6.79

5.80

5.16

4.67

6.94

PAL2

14.15 11.79

9.73

8.62

7.75

7.35

9.90

CDS2

9.05

7.73

6.63

5.65

5.15

4.99

6.53

In order to do a comprehensive analysis of the results, we

separated the heuristics into groups. Three groups use the same

allocation methods, and one group uses RC1_1, RC1_m and

RC2. We first compared the procedures in each group, and then

we selected from each group the two best algorithms in terms

of minimum overall ARPD, in order to compare them with the

two best heuristics from the other groups.

NEH2

7.96

8.37

8.35

7.88

7.87

7.54

8.00

TR2

8.82

6.29

4.91

3.70

2.77

2.43

4.82

PF2

16.29 18.11 19.11 18.80 18.96 18.68

18.33

PW2

15.90 17.87 18.78 18.67 18.65 18.37

18.04

HYB2

16.68 18.67 18.85 18.89 18.85 18.69

18.44

Table IV shows the ARPD calculated for each procedure

and the number of factories. As can be seen, the best

performing heuristic of this group is the one that uses the TR

sequencing rule with an overall ARPD of 7.45 (number in

bold). Notice that NEH1 is better for F=2, but TR1 shows the

best performance for the remaining number of plants. The

second best performing method is CDS1, with an overall

ARPD of 9.35.

TABLE IV.

ARPD VALUES PER HEURISTIC

AND NUMBER OF FACTORIES IN GROUP 1

Heuristics

Number of factories

2

3

4

5

6

7 All

SPT1

18.78 19.35 19.33 19.53 20.20 19.78 19.49

LPT1

18.35 18.49 18.33 17.93 18.08 17.79 18.16

JOHN1

11.95 10.31

PAL1

15.35 13.68 12.57 12.55 11.93 11.21 12.88

CDS1

10.09

NEH1

9.58

9.45

9.15

8.82

8.95

8.47

9.22

8.34

9.24

7.31

6.65

6.35

5.97

9.37

TR1

10.07

PF1

16.65 19.23 19.75 20.68 21.54 21.86 19.95

PW1

16.21 19.33 20.43 21.05 21.88 22.50 20.23

HYB1

16.79 19.19 20.34 20.84 21.60 22.12 20.15

7.45

The results of the heuristics belonging to the second group

are very similar to those from the first group. Table V shows

the ARPD of each heuristic, grouped by number of factories F.

Observe that the best performing procedure is TR2, except for

the case of two factories where NEH2 performs better. The

second best heuristic in this group is also CDS2. Notice that the

allocation rule 2 leads to better performance than allocation

rule 1, just as it does in DPFSP.

TABLE V.

ARPD VALUES PER HEURISTIC

AND NUMBER OF FACTORIES IN GROUP 2

Heuristics

Number of factories

2

3

4

5

6

TABLE VI.

ARPD VALUES PER HEURISTIC

AND NUMBER OF FACTORIES IN GROUP 3

Heuristics

9.56

8.82 10.04 10.63 11.00 11.33 11.61 10.57

8.38

In the third group, Table VI shows the ARPD for each

heuristic and number of factories. Here, the best heuristics

ranking has changed. Remember that in this case the sequence

of jobs is divided into F parts, and each of these parts is

assigned to one factory. This situation is totally different from

that which used the two allocation methods in the previous two

groups. This explains the good performance of the three

sequencing rules proposed for the blocking flow shop problem,

as compared to the others proposed for the DPFSP. These

methods sequence the jobs in order to minimize the idle time of

machines, and this order is maintained in the segment assigned

to each factory.

7 Average

SPT2

17.86 17.51 17.30 16.94 17.17 17.00

17.30

LPT2

17.03 15.83 14.96 14.15 13.78 12.85

14.77

Number of factories

2

3

4

5

6

7 All

SPT3

3.97

5.27

5.27

5.75

6.92

7.00

5.70

LPT3

4.28

4.91

5.46

5.53

6.53

6.33

5.51

JOHN3

5.52

7.10

8.41

8.57

9.02

9.86

8.08

PAL3

6.19

7.43

8.32

8.51

8.98

9.11

8.09

CDS3

5.83

7.22

8.23

8.50

9.05

9.01

7.97

NEH3

3.35

4.28

4.87

5.50

5.61

6.24

4.97

TRAP3

6.41

7.81

8.79

9.46 10.09 10.08

8.77

PF3

2.05

2.22

2.98

3.17

4.05

4.05

3.09

PW3

3.11

3.59

4.16

4.96

5.33

5.67

4.47

HYB3

1.72

2.13

2.71

3.19

4.13

4.37

3.04

It is worth noting that the overall ARPD obtained with

these methods is smaller than that obtained by the best

procedures using allocation rule 2.

Observe that, in this group, PF3 and HPF23 have similar

performance. The overall ARPD is 3.09 and 3.04, respectively.

Notice that HPF23 is slightly better for 2, 3 and 4 plants;

whereas PF3 is slightly better when the number of plants

increases.

Finally, the ARPD of the last group of heuristics is shown

in Table VII. As can be seen, heuristics RC1_1 and RC1_m

perform better than RC2. In particular, RC1_m is the one with

smaller ARPD. This means that, during the allocation process

of jobs, it is better to select the factory which has the last

machine available sooner.

TABLE VII.

ARPD VALUES PER HEURISTIC

AND NUMBER OF FACTORIES IN GROUP 4

Heuristics

Number of factories

2

3

4

5

6

7 All

RC1_1

2.24

3.73

4.46

5.21

5.76

6.58

4.66

RC1_m

2.27

2.89

3.66

4.49

5.78

6.05

4.19

RC2

4.17

4.81

5.34

5.35

7.14

7.58

5.73

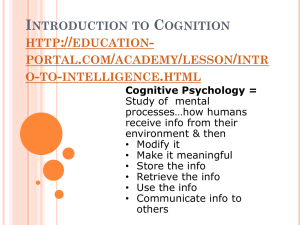

for the heuristic factor (Figure 1), which is the most significant.

As can be seen, there are no statistically significant differences

between PF3 and HPF23, because their confidence intervals

overlap; nor are there significant differences between RC1_m

and RC1_1.

Fig. 1.Interval Plot of compared heuristics at 95% confidence

Interval Plot of Heuristics

95% CI for the Mean

10

9

8

7

ARPD

Next, in order to compare the best heuristics of each group,

we summarize in Table VIII the ARPD values of the two best

methods from each group. From these results, one can see that

HPF23 is the heuristic which performs better if 2, 3, and 4

factories are considered, whereas PF3 is better with 5 factories.

When the number of factories increases (to 6 and 7 factories),

TR2 is the best one.

6

5

4

TABLE VIII.

ARPD VALUES OF THE BEST

HEURISTICS OF EACH GROUP

3

2

Heuristics

RC1 _1

Number of factories

2

3

4

5

6

7

All

TR1

10.1

8.38

7.31

6.65

6.35

5.97

7.45

CDS1

10.1

9.58

9.15

8.95

9.22

9.24

9.37

TR2

8.82

6.29

4.91

3.7

2.77

2.43

4.82

CDS2

9.05

7.73

6.63

5.65

5.15

4.99

6.53

PF3

2.05

2.22

2.98

3.17

4.05

4.05

3.09

HPF23

1.72

2.13

2.71

3.19

4.13

4.37

3.04

RC1_1

2.24

3.73

4.46

5.21

5.76

6.58

4.66

RC1_m

2.27

2.89

3.66

4.49

5.78

6.05

4.19

RC1 _m

PF3

HPF23

CDS2

TR2

CDS1

TR1

A more detailed analysis has been carried out by pairwise

comparison between heuristics using the ARPD as the response

variable. Figure 2 shows the obtained results. The means that

do not share a letter are significantly different.

Fig.2 Tukey Pairwise Comparison

Grouping Information Using the Tukey Method and 95% Confidence

In order to see if the differences observed in the previous

table are significant, we carried out a multifactorial ANOVA

on the results of these heuristics and all instances. The

hypotheses of ANOVA were checked and satisfied. The

response variable is the RPD, and the factors are the algorithm,

n, m and F. Table IX shows the ANOVA results, where it can

be seen that all factors are significant (p-value=0.00).

TABLE IX.

MULTIFACTORIAL ANOVA

TABLE FOR HEURISTICS, n, m AND F

Source

Analysis of Variance

DF Adj SS

Heuristics

7

n

4

1036

m

2

F

5

Adj MS

24898 3556.87

F-Value P-Value

241.44

0.000

258.88

17.57

0.000

2789 1394.31

94.65

0.000

3.34

0.000

246

49.24

To analyze the differences between heuristics, we built the

corresponding mean plot with the confidence interval at 95%

Heuristics

CDS1

TR1

CDS2

TR2

RC1_1

RC1_m

PF3

HPF23

N

720

720

720

720

720

720

720

720

Mean Grouping

9,77715 A

7,85901 B

6,93755

C

5,22055

D

5,06572

D E

4,59480

E

3,48889

F

3,44187

F

As can be observed in Figure 2, PF3 and HPF23 have the

same performance, as well as RC1_1 and RC1_m. Both

groups can be distinguished easily in Figure 1, but we can also

see from this test that TR2 and RC1_m have similar

performance.

A second analysis that is necessary for evaluating heuristic

efficiency is the CPU time required for reaching the solution.

Table X shows the average CPU time in milliseconds for each

procedure and number of factories. The algorithms that

consume the least are those that use allocation methods 1 and

2. Next is the RC1 group. Finally, the algorithms that consume

the most are those that use allocation method 3. Remember

that, in this method, the segment of the original sequence is

first assigned to each plant, and then the insertion procedures

are applied to improve the sequence. This helps to obtain a

high quality solution, but the required CPU time increases

considerably.

Hence, from the overall ARPD point of view, HPF23 or

PF3 are the best heuristics for solving the DBFSP. However,

RC1_m and TR2 cannot be discarded as initial metaheuristic

solution procedures, because they obtain quite good solutions

with less CPU time.

TABLE X.

AVERAGE CPU TIME, IN

MILLISECONDS, FOR EACH HEURISTIC AND

NUMBER OF FACTORIES

Heuristics

Number of factories

2

3

4

5

6

7

All

TR1

2.6

2.6

2.5

3

3

3

2.7

CDS1

7.2

7.2

7.2

7.2

7.2

7.2

7.2

TR2

3

3

2.9

2.9

2.9

2.9

2.9

CDS2

7.2

7.2

7.2

7.2

7.2

7.2

7.2

PF3

226

103

59.6

39.3

28.3

22.4

79.6

HPF23

238

114

70.1

49.8

38.9

32.5

90.5

RC1_1

10.2

10.1

10.5

44.8

34.2

27.1

22.8

RC1_m

10.1

10.1

10.2

44.9

34.2

27.4

22.8

IV.

Another direction for future research is to develop efficient

metaheuristics to solve this problem. Such a method would

make use of these constructive procedures to obtain the initial

solution, since the use of good initial solution procedures

normally lead to improved metaheuristic performance.

ACKNOWLEDGMENT

Ramon Companys and Imma Ribas are partially supported by

the Spanish Ministry of Science and Innovation, under the

project RESULT - Realistic Extended Scheduling Using Light

Techniques, with reference DPI2012-36243-C02-01.

REFERENCES

[1]

J. Behnamian and S. M. T. Fatemi Ghomi, “A survey of multifactory scheduling,” J. Intell. Manuf., no. October 2012, pp. 1–19,

2014.

[2]

S. M. Johnson, “Optimal two-and three-stage production schedules

with set up times included,” Nav. Res. Logist. Q., vol. 1, pp. 61–68,

1954.

[3]

B. Naderi and R. Ruiz, “The distributed permutation flowshop

scheduling problem,” Comput. Oper. Res., vol. 37, no. 4, pp. 754–

768, Apr. 2010.

[4]

J. Gao and R. Chen, “A hybrid genetic algorithm for the distributed

permutation flowshop scheduling problem,” Mar. 2012.

[5]

J. Gao, R. Chen, and Y. Liu, “A Knowledge-based Genetic

Algorithm for Permutation Flowshop Scheduling Problems with

Multiple Factories,” Int. J. Adv. Comput. Technol., vol. 4, no. 7, pp.

121–129, 2012.

[6]

S.-W. Lin, K.-C. Ying, and C.-Y. Huang, “Minimising makespan in

distributed permutation flowshops using a modified iterated greedy

algorithm,” Int. J. Prod. Res., vol. 51, no. 16, pp. 5029–5038, Aug.

2013.

[7]

H. Liu and L. Gao, “A discrete electromagnetism-like mechanism

algorithm for solving distributed permutation flowshop scheduling

problem,” Proc. - 2010 Int. Conf. Manuf. Autom. ICMA 2010, pp.

156–163, 2010.

[8]

V. Fernandez-Viagas and J. M. Framinan, “A bounded-search

iterated greedy algorithm for the distributed permutation flowshop

scheduling problem,” Int. J. Prod. Res., vol. 53, no. 4, pp. 1111–

1123, Aug. 2014.

[9]

B. Naderi and R. Ruiz, “A scatter search algorithm for the

distributed permutation flowshop scheduling problem,” Eur. J.

Oper. Res., vol. 239, no. 2, pp. 323–334, Dec. 2014.

[10]

S. Wang, L. Wang, M. Liu, and Y. Xu, “An effective estimation of

distribution algorithm for solving the distributed permutation flowshop scheduling problem,” Int. J. Prod. Econ., vol. 145, no. 1, pp.

387–396, Sep. 2013.

[11]

Y. Xu, L. Wang, S. Wang, and M. Liu, “An effective hybrid

immune algorithm for solving the distributed permutation flow-shop

scheduling problem,” Eng. Optim., vol. 46, no. 9, pp. 1269–1283,

Oct. 2013.

[12]

J. Gao, R. Chen, and W. Deng, “An efficient tabu search algorithm

for the distributed permutation flowshop scheduling problem,” Int.

J. Prod. Res., vol. 51, no. 3, pp. 641–651, Feb. 2013.

CONCLUSIONS

This paper proposes constructive heuristics for the

Distributed Blocking Flow Shop Scheduling Problem. To the

best of our knowledge, no other paper deals with the same

problem. One typical complication for this problem is that the

blocking constraint tends to increase the completion time of

jobs if the job being processed cannot leave the machine,

which results from the next machine being unavailable.

Therefore, it is interesting to analyze not only the performance

of the adapted heuristics proposed by the DPFSP, but also to

design heuristics that are specific to this problem and that allow

us to address it adequately.

The proposed methods use an approach that is totally

different from those proposed for the DPFSP. After taking the

DPFSP procedures that we adapted to DBFSP and comparing

them to the approaches that were specifically designed for

DBPFSP, we find that HPF23 and PF3 (which consider the

specificity of the DBFSP) performed much better. However,

the time required is considerably greater than for the other

methods. Alternatively, the approach that simultaneously

considers jobs and plants provides good equilibrium between

quality of solutions and the required CPU time. However, we

have observed that when the number of factories increases, the

presented methods lose efficiency, which is contrary to what

happens when the jobs are first ordered and then allocated to

the plant which can complete them at the earliest time

(allocation method 2). Therefore, more research is needed to

analyze how the heuristics behave in these cases, in order to

find variants that overcome this problem and increase their

performance even more.

[13]

J. Gao, R. Chen, W. Deng, and Y. Liu, “Solving multi-factory

flowshop problems with a novel variable neighbourhood descent

algorithm,” J. Comput. Inf. Syst., vol. 8, no. 5, pp. 2025–2032, 2012.

[14]

H. Gong, L. Tang, and C. W. Duin, “A two-stage flow shop

scheduling problem on a batching machine and a discrete machine

with blocking and shared setup times,” Disrupt. Manag., vol. 37, no.

5, pp. 960–969, 2010.

[15]

S. Martinez, S. Dauzère-Pérès, C. Guéret, Y. Mati, and N. Sauer,

“Complexity of flowshop scheduling problems with a new blocking

constraint,” Eur. J. Oper. Res., vol. 169, no. 3, pp. 855–864, 2006.

[16]

S. P. Sethi, C. Sriskandarajah, G. Sorger, J. Blazewicz, and W.

Kubiak, “Sequencing of parts and robot moves in a robotic cell,”

Int. J. Flex. Manuf. Syst., vol. 4, pp. 331–358, 1992.

[17]

M. Nawaz, E. E. Enscore Jr, and I. Ham, “A heuristic algorithm for

the m-machine, n-job flow-shop sequencing problem,” Omega, vol.

11, no. 1, pp. 91–95, 1983.

[18]

D. S. Palmer, “Sequencing jobs through a multi-stage process in the

minimum total time- a quick method of obtaining a near optimum,”

Oper. Res. Q., vol. 16, pp. 101–107, 1965.

[19]

H. G. Campbell, R. A. Dudek, and M. L. Smith, “Heuristic

algorithms for N-job, M-machine sequencing problem,” Manage.

Sci., vol. 16, pp. 630–637, 1970.

[20]

R. Companys, “Métodos heurísticos en la resolución del problema

del taller mecánic,” Estud. Empres., vol. 5, no. 2, pp. 7–18, 1966.

[21]

S. T. McCormick, M. L. Pinedo, S. Shenker, and B. Wolf,

“Sequencing in an Assembly Line with Blocking to Minimize Cycle

Time,” Oper. Res., vol. 37, pp. 925–936, 1989.

[22]

Q.-K. Pan and L. Wang, “Effective heuristics for the blocking

flowshop scheduling problem with makespan minimization,”

Omega, vol. 40, no. 2, pp. 218–229, 2012.

[23]

I. Ribas and R. Companys, “Efficient heuristic algorithms for the

blocking flow shop scheduling problem with total flow time

minimization,” Comput. Ind. Eng., vol. 87, pp. 30–39, Sep. 2015.