Prequalification of In Vitro Diagnostics Programme- Internal Document

advertisement

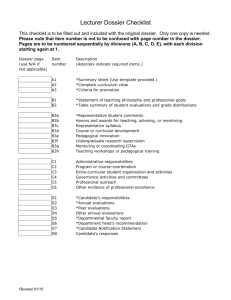

___________________________________ Prequalification Team ─ Diagnostics Prequalification of In Vitro Diagnostics Programme- Internal Document INTERNAL REPORT ON THE PRODUCT DOSSIER SCREENING Purpose of the document The Prequalification of In Vitro Diagnostics Programme utilizes internal procedures to ensure the efficient review and assessment of all applications to the Programme. One such process is the screening for completeness of the manufacturer’s submitted product dossier before it undergoes substantive technical review. The purpose of this document is to identify if a dossier meets a minimum threshold of acceptability and whether to progress towards prequalification assessment. PQDx_009 v3.0 / 15 December 2014 Page 1 of 24 Prequalification of In Vitro Diagnostics Programme- Internal Document INTERNAL REPORT ON THE PRODUCT DOSSIER SCREENING Application Number: PQDx Product Name: Manufacturer Name: Product code(s)/catalogue number(s) and regulatory version: Product kit size(s) (number of tests per kit): Date product dossier received by WHO: Date dossier screened: T/kit DD/MM/YYYY DD/MM/YYYY Name of PQDx screening reviewer: PQDx clearance: Name and signature Date: DD/MM/YYYY PQDx_009 v3.0 / 15 December 2014 Page 2 of 24 Table of Contents Table of Contents ....................................................................................................................... 3 Scope......................................................................................................................................... 6 Legend of Codes Used ................................................................................................................ 6 1. Comparison with the Letter of Agreement .............................................................................. 6 2. Product Dossier Screening Overview ...................................................................................... 6 3. The Product Dossier ............................................................................................................... 7 4. Dossier Format ....................................................................................................................... 7 5. Product Information ............................................................................................................... 7 5.1. Regulatory versions of this product ..............................................................................................7 5.2. Product description including variants (configurations) and accessories .....................................9 5.3. Essential principles (EP) checklist ................................................................................................10 5.4. Risk analysis and control summary .............................................................................................10 6. Design and Manufacturing Information ................................................................................ 10 6.1. Product design .............................................................................................................................10 6.1.1. Design overview ...............................................................................................................10 6.1.2. Formulation and composition ..........................................................................................10 6.1.3. Biological safety ................................................................................................................11 6.1.4. Documentation of design changes ...................................................................................11 6.2. Manufacturing process ................................................................................................................11 6.2.1. Overview of manufacture.................................................................................................11 6.2.2. Sites of manufacture ........................................................................................................12 6.2.3. Key suppliers.....................................................................................................................12 7. Product performance specifications, and associated validation and verification studies ........ 12 7.1. Analytical Studies........................................................................................................................12 7.1.1. Specimen type ..................................................................................................................13 7.1.2. Analytical performance characteristics ............................................................................13 7.1.2.1. Accuracy of measurement ............................................................................................13 PQDx_009 v3.0 / 15 December 2014 Page 3 of 24 7.1.2.1.1. Trueness of measurement .........................................................................................13 7.1.2.1.2. Precision of measurement .........................................................................................13 7.1.2.1.2.1. Repeatability............................................................................................................13 7.1.2.1.2.2. Reproducibility ........................................................................................................14 7.1.2.2. Analytical sensitivity ......................................................................................................14 7.1.2.3. Analytical specificity ......................................................................................................14 7.1.2.4. Traceability of calibrators and control material values ................................................15 7.1.2.5. Measuring range of the assay .......................................................................................15 7.1.2.6. Validation of assay cut-off .............................................................................................15 7.1.2.7. Validation of assay procedure – reading time ..............................................................15 7.2. Stability (excluding specimen stability) .......................................................................................16 7.2.1. Claimed shelf life ..............................................................................................................16 7.2.2. In-use stability ..................................................................................................................16 7.2.3. Shipping stability ..............................................................................................................16 7.3. Robustness Studies ......................................................................................................................17 7.4. Clinical evidence (clinical or diagnostic sensitivity and specificity).............................................17 7.4.1. Clinical evaluation - Manufacturer ...................................................................................18 7.4.2. Clinical evaluation - Independent study/ies .....................................................................18 8. Labelling .............................................................................................................................. 19 8.1. Labels ...........................................................................................................................................19 8.2. Instructions for use ......................................................................................................................19 8.3. Instrument manual ......................................................................................................................19 9. Commercial history .............................................................................................................. 20 9.1. Countries of supply ......................................................................................................................20 9.2. Adverse events and field safety corrective actions .....................................................................20 10. Regulatory history .............................................................................................................. 21 11. Quality management system .............................................................................................. 21 11.1. Quality manual ..........................................................................................................................21 11.2. Quality management system certification ................................................................................22 4. Dossier Format ..................................................................................................................... 23 4.1. Dossier submission format ..........................................................................................................23 PQDx_009 v3.0 / 15 December 2014 Page 4 of 24 4.2. Layout and order .........................................................................................................................23 4.3. Language......................................................................................................................................23 12. Product Dossier Screening Report ....................................................................................... 24 PQDx_009 v3.0 / 15 December 2014 Page 5 of 24 Scope This internal report on the screening of the submitted product dossier has been prepared to provide summary information on the product dossier screening and a recommendation, such that the PQ Team can make a decision on whether to progress the dossier towards a prequalification assessment. Legend of Codes Used The below listed codes should be used in the column on the right side of the checklist in this document. Y N N/A Yes No Not applicable (comments required) 1. Comparison with the Letter of Agreement Question Has the original signed Letter of Agreement been submitted as the cover letter of the dossier? Does the application number on the Product dossier checklist match with the PQ number stated on the Letter of Agreement? Does the product name match with the name provided in the Letter of Agreement? Does the product code(s) match with the code(s) provided in the Letter of Agreement? Does the manufacturer name match with the name provided in the Letter of agreement? 2. Product Dossier Screening Overview PQDx_009 v3.0 / 15 December 2014 Page 6 of 24 Y / N / NA Comments/Explanation Question Was the dossier submitted with the Product dossier checklist?1 For each requirement, were the volumes/pages clearly labelled in the checklist? Y / N / NA Comments/Explanation Question Y / N / NA Has the authorized contact person for the manufacturer signed and dated the manufacturer declaration on the checklist? Is the authorized contact person for the manufacturer that signed the declaration the same person as detailed on the pre-submission form2 and named in the authorization letter from the manufacturer? Comments/Explanation 3. The Product Dossier 4. Dossier Format See page 21 of this document. 5. Product Information 5.1. Regulatory versions of this product Question Was Section 5.1 submitted? Did the manufacturer identify if there are multiple regulatory versions of this product? 1 2 WHO document PQDx_049: Product Dossier Checklist WHO document PQDx_015: Application Form PQDx_009 v3.0 / 15 December 2014 Page 7 of 24 Y / N / NA Comments/Explanation Choose name of type of regulatory approval. RoW: specify country (CE-mark) Directive 98/79/EC: Self-declared CE-mark, Annex III Full quality assurance certificate, Annex IV.3/ Product design examination certificate, Annex IV.4 Type examination certificate, Annex V/ Production quality assurance certificate, Annex VII USFDA: Premarket Approval (PMA) or 510(k) clearance Health Canada: Medical device license and summary report for a Class III IVD or Medical device license and summary report for a Class IV IVD TGA Australia: License for manufacture/ AUST R Number Full quality assurance certificate/ Application audit report/ Production quality assurance certificate JMHLW Japan: License for manufacturer/ Recognized foreign/ manufacturer/ Minister’s approval If the product has multiple regulatory versions, did the manufacturer clearly indicate which regulatory version of the product is submitted for prequalification assessment? Choose name of type of regulatory approval. RoW: specify country (CE-mark) Directive 98/79/EC: Self-declared CE-mark, Annex III Full quality assurance certificate, Annex IV.3/ PQDx_009 v3.0 / 15 December 2014 Page 8 of 24 Product design examination certificate, Annex IV.4 Type examination certificate, Annex V/ Production quality assurance certificate, Annex VII USFDA: Premarket Approval (PMA) or 510(k) clearance Health Canada: Medical device license and summary report for a Class III IVD or Medical device license and summary report for a Class IV IVD TGA Australia: License for manufacture/ AUST R Number Full quality assurance certificate/ Application audit report/ Production quality assurance certificate JMHLW Japan: License for manufacturer/ Recognized foreign/ manufacturer/ Minister’s approval For all of the documents submitted in the product dossier, is the regulatory version to which they relate identified? If there are documents that do not relate to the regulatory version submitted for prequalification, is a justification provided for their inclusion in the product dossier? 5.2. Product description including variants (configurations) and accessories Question Was Section 5.2 submitted? Is the intended use of the diagnostic identified? Y / N / NA PQDx_009 v3.0 / 15 December 2014 Page 9 of 24 Comments/Explanation 5.3. Essential principles (EP) checklist Question Was an EP checklist submitted in the form of a table? Is the product name and product code the same as that for the product submitted for PQ? Y / N / NA Comments/Explanation Y / N / NA Comments/Explanation Y / N / NA Comments/Explanation Y / N / NA Comments/Explanation 5.4. Risk analysis and control summary Question Was Section 5.4 submitted? Has a risk analysis been submitted? Has a summary report of risks identified during the risk analysis process and conclusion/statement been submitted? Is the product name and product code the same as that for the product submitted for PQ? 6. Design and Manufacturing Information 6.1. Product design 6.1.1. Design overview Question Did the manufacturer provide information on the design overview of the product? Did the manufacturer provide a flowchart of the design process, including design inputs and outputs for the product for prequalification? 6.1.2. Formulation and composition Question Did the manufacturer provide for each of the ingredients formulation/composition information (e.g. information such as nucleic acid sequences for primers, ingredient lists for buffers, amino acid sequence details for recombinant proteins) PQDx_009 v3.0 / 15 December 2014 Page 10 of 24 Did the manufacturer identify the sources of the materials from which the IVD components are constructed? 6.1.3. Biological safety Question Is there a list of all biological components included in the product under assessment? Bacterial origin Viral origin Parasitic origin Animal origin (such as plasma, cells, tissues, or their derivatives) Human origin (such as plasma, cells, tissues, or their derivatives) Y / N / NA Comments/Explanation Y / N / NA Comments/Explanation Y / N / NA Comments/Explanation 6.1.4. Documentation of design changes Question Did the manufacturer provide records of design changes for the product submitted for prequalification? If the manufacturer claims no changes, is there a statement that no changes have been made to the product since design lock down? 6.2. Manufacturing process 6.2.1. Overview of manufacture Question Has an overview of the entire manufacturing process been submitted? Has a manufacturing flow chart of the entire manufacturing process been submitted? PQDx_009 v3.0 / 15 December 2014 Page 11 of 24 6.2.2. Sites of manufacture Question Was a list of all critical manufacturing sites that are involved in the manufacture of this product provided? For each site, are the following included: The name of the site The physical address of the site A description of the component manufacture/stage of the manufacturing process carried out at the site A description of the manufacturing site A simple site plan highlighting production areas The number of employees at the site A description of any other manufacturing that occurs at this site Y / N/ NA Comments/Explanation Y / N / NA Comments/Explanation 6.2.3. Key suppliers Question Did the manufacturer provide a list of all key suppliers of ingredients/products/services for the manufacture of this product? 7. Product performance specifications, and associated validation and verification studies 7.1. Analytical Studies Question For each study submitted under section 7.1., are the study description, study identifier, product identifier (for example, lot numbers), IFU version used, identification of both PI and scientist conducting the study, date of study initiation, and the date of completion included? PQDx_009 v3.0 / 15 December 2014 Page 12 of 24 Y / N / NA Comments/Explanation 7.1.1. Specimen type Question Are the different specimen types that can be used with the product identified, including anticoagulants used to collect plasma? Were studies that address duration, temperature, number of allowable freeze/thaw cycles and specimen stability claims done to support: Stability claims Storage claims Is there a summary of the study findings? Is there a study protocol and full report? Y / N / NA Comments/Explanation Y / N / NA Comments/Explanation Y / N / NA Comments/Explanation 7.1.2. Analytical performance characteristics 7.1.2.1. Accuracy of measurement 7.1.2.1.1. Trueness of measurement Question Was Section 7.1.2.1.1. submitted, including a study protocol and study report? 3 Is there a summary of the study findings? Is there a study protocol and full report? 7.1.2.1.2. Precision of measurement 7.1.2.1.2.1. Repeatability Question Was Section 7.1.2.1.2.1. submitted? Is there a summary of the study findings? 3 Trueness measures apply to both quantitative and qualitative assays only when a reference standard or method is available. PQDx_009 v3.0 / 15 December 2014 Page 13 of 24 Is there a study protocol and full report? 7.1.2.1.2.2. Reproducibility Question Was Section 7.1.2.1.2.2. submitted? Is there a summary of the study findings? Is there a study protocol and full report? Y / N / NA Comments/Explanation Y / N / NA Comments/Explanation Y / N / NA Comments/Explanation 7.1.2.2. Analytical sensitivity Question Was Section 7.1.2.2. submitted? Is there a summary of the study findings, including a conclusion? Is there a study protocol and full report? For a quantitative assays, were the following parameters identified and were details provided on how they were derived: Limit of blank (LoB): the number of standard deviations above the mean value of the specimen without analyte (measurand) Limit of detection (LoD): the lowest concentration distinguishable from zero, based on measurements of specimens containing analyte (measurand) Limit of quantitation (LoQ): the lowest concentration at which precision and/or trueness are within specified criteria 7.1.2.3. Analytical specificity Question Was Section 7.1.2.3. submitted? Is there a summary of the study findings? Is there a study protocol and full report? Were interference and cross-reactivity evaluated? PQDx_009 v3.0 / 15 December 2014 Page 14 of 24 7.1.2.4. Traceability of calibrators and control material values Question If the product includes calibrators and/or controls: Was Section 7.1.2.4. submitted? Y / N / NA Comments/Explanation Y / N / NA Comments/Explanation Y / N / NA Comments/Explanation Y / N / NA Comments/Explanation 7.1.2.5. Measuring range of the assay Question Was Section 7.1.2.5. submitted? Is there a summary of the study findings? Is there a study protocol and full report? For a qualitative test: Has a hook effect been documented or is there an explanation for why it is not applicable? 7.1.2.6. Validation of assay cut-off Question Was Section 7.1.2.6. submitted? If not applicable, was a rationale provided? Is there a summary of the study findings? Is there a study protocol and full report? 7.1.2.7. Validation of assay procedure – reading time Question Was Section 7.1.2.7. submitted? Is there a summary of the study findings? Is there a study protocol and full report? PQDx_009 v3.0 / 15 December 2014 Page 15 of 24 7.2. Stability (excluding specimen stability) Question For each study submitted under section 7.2., are a study description, study identifier, product identifier (for example, lot numbers), IFU version used, identification of both PI and scientist conducting the study, date of study initiation and the date of completion included? Y / N / NA Comments/Explanation Y / N / NA Comments/Explanation Y / N / NA Comments/Explanation 7.2.1. Claimed shelf life Question Was Section 7.2.1. submitted? Is there a summary of the study findings? Is there a study protocol and full report? 7.2.2. In-use stability Question Was Section 7.2.2. submitted? Was an in-use stability study done for each assay component? Is there a summary of the study findings? Is there a study protocol and full report? 7.2.3. Shipping stability Question Was Section 7.2.3. submitted for studies on one lot of product? Y / N / NA PQDx_009 v3.0 / 15 December 2014 Page 16 of 24 Comments/Explanation Is there a summary of the study findings? Is there a study protocol and full report? 7.3. Robustness Studies4 Question Y / N / NA Was Section 7.3. submitted? Are a study description, study identifier, product identifier (for example, lot numbers), IFU version used, identification of both PI and scientist conducting the study, date of study initiation and the date of completion included? Were studies done to address operator/human factors? Were studies done to address specimen integrity and handling issues? Were studies done to address reagent integrity issues? Were studies done to address hardware, software and electronics integrity issues? Were studies done to address issues related to the stability of calibration and internal controls? Were studies done to address issues related to environmental factors and their impact on reagents, specimens, and test results? For each of the issues to be addressed below to address robustness, were a full study protocol, method of data analysis and study conclusion provided? Comments/Explanation 7.4. Clinical evidence (clinical or diagnostic sensitivity and specificity) Question Are a study description, study identifier, product identifier (for example, lot numbers), identification of both PI and scientist conducting the study, IFU version 4 Y / N / NA Comments/Explanation If a performance study has been conducted that includes human factors/usability end points, reference to the studies and endpoints should be made (but full results do not need to be repeated). PQDx_009 v3.0 / 15 December 2014 Page 17 of 24 used, date of study initiation and the date of completion included for all the studies submitted in this section? 7.4.1. Clinical evaluation - Manufacturer Question Was Section 7.4.1. submitted? Is there a summary of the study findings? Is there a study protocol and full report? Did the manufacturer provide details of the product lots/batches used for the evaluation, including lot number, date of expiry, and the storage conditions of the product prior to and during the study? Y / N / NA Comments/Explanation Y / N / NA Comments/Explanation 7.4.2. Clinical evaluation - Independent study/ies Question Was Section 7.4.2. submitted? Has the manufacturer provided details of at least one independent performance evaluation for the product under assessment5,6 Is there a summary of the study findings? Is there a study protocol and full report? Did the manufacturer provide details of the product lots/batches used for the evaluation, including lot number, date of expiry, and the storage conditions of the product prior to and during the study? 5 Only information from independent performance evaluations that have been carried out by centres that have the capability of performing scientifically sound evaluation studies for the product in question should be included. 6 Testimonials from hospitals, laboratory staff, product users, patients, or testimonials of any other kind are not considered to be evidence of performance and should not be considered during review. PQDx_009 v3.0 / 15 December 2014 Page 18 of 24 IF APPLICABLE: If the study has been published in peer-reviewed scientific literature, did the manufacturer provide publication details for the study? 8. Labelling 8.1. Labels Question Was Section 8.1. submitted? Have copies of all packaging labels for the assay (outer package labels and component labels) been provided? Y / N / NA Comments/Explanation Y / N / NA Comments/Explanation Y / N / NA Comments/Explanation 8.2. Instructions for use Question Was Section 8.2. submitted? Does the IFU apply to all product codes submitted for PQ (i.e. different packaging sizes with exactly the same components)? Is the IFU the same version submitted with the pre-submission form (i.e. document version number and release date)? 8.3. Instrument manual Question IF APPLICABLE: Was Section 8.3. submitted? Was a copy of the instrument manual and/or associated operator manuals included? If the instrument manual is large, an electronic version (CD or DVD) may be included instead of a hard copy. PQDx_009 v3.0 / 15 December 2014 Page 19 of 24 9. Commercial history 9.1. Countries of supply Question Was Section 9.1. submitted? Has the manufacturer provided a list of all countries in which the product is currently supplied together with the year when supply started? Has the manufacturer provided current evidence of the listed market approvals/incountry registration for sale, such as in-country registration documentation, in original or certified copy/ies?7 Has the manufacturer provided detailed information about the training and support network that is available in each country of supply? Were the product’s global minimum and maximum price of supply for the last financial year provided (in USD)? Y / N / NA Comments/Explanation Y / N / NA Comments/Explanation 9.2. Adverse events and field safety corrective actions Question Was Section 9.2. submitted? Did the manufacturer provide a list of all adverse events within the last five years that did affect, or could have potentially affected, the performance of the assay, safety of the person being tested, safety of users of this test, or safety of any person associated with this product, along with details of the corrective and preventive action taken? Has the manufacturer provided a list of all events within the last five years that required field safety corrective action? IF APPLICABLE: If the manufacturer claims that no adverse events have occurred in the last five years, has a signed attestation (in original copy) declaring so been provided? 7 The evidence must clearly show that the product under assessment falls within the scope of the submitted regulatory approval. PQDx_009 v3.0 / 15 December 2014 Page 20 of 24 10. Regulatory history Question Was Section 10. submitted? Has a list of National Regulatory Authorities which have provided current regulatory approval(s) for the supply of this product in their country/region of authority been provided? Have details of the type of regulatory approval obtained from each National Regulatory Authority been provided? Is it clear that the submitted approvals refer to the product undergoing prequalification? Have current evidence of the listed regulatory approvals, such as certified copies of certificates from the regulatory authority, been provided in original or certified copy?8 IF APPLICABLE: Did the manufacturer provide details regarding any situations in which this product was rejected by a National Regulatory Authority, situations in which an application for regulatory approval was withdrawn, or situations in which regulatory approval has been withdrawn? IF APPLICABLE: If any of the regulatory approvals were for export only, did the manufacturer clearly identify this? Y / N / NA Comments/Explanation Y / N / NA Comments/Explanation 11. Quality management system 11.1. Quality manual Question Was Section 11.1. submitted? Was an organizational chart provided? 8 The evidence must clearly show that the product under assessment falls within the scope of the submitted regulatory approval. PQDx_009 v3.0 / 15 December 2014 Page 21 of 24 Was a complete list provided of all valid quality management system documents, with the document title and document number, relevant to this product? Were documented procedure(s) for the control of design and development changes provided? Were documented procedure(s) relevant to risk management planning and implementation provided? Were documented procedure(s) relevant to the control of non-conforming goods, including, but not limited to, procedures for corrective and preventive actions, recalls, field safety notices, etc., provided? Were documented procedure(s) relevant to the control of the key suppliers noted in Section 6.1.1. Design Overview provided? 11.2. Quality management system certification Question Was Section 11.2. submitted? Does the manufacturer hold a current ISO 13485:2003 certification? Alternatively, does this quality management system meet the requirements of the USFDA Code of Regulation 21 CFR 820? Alternatively, does the quality management system meet the requirements of other similar standards (e.g. those required by other jurisdictions)? If yes, please provide details. Has a certified copy of this certification been provided?9 Does the scope of the certification cover this product? At a minimum has the manufacturer submitted the most recent inspection report issued by the certification body, (if applicable, related to the ISO 13485:2003 certification)? 9 Check for validity. PQDx_009 v3.0 / 15 December 2014 Page 22 of 24 Y / N / NA Comments/Explanation 4. Dossier Format 4.1. Dossier submission format Question Has one printed copy and one identical e-copy of the entire dossier been provided? Is there a statement attesting that the content of the electronic copy is identical to that of the printed copy? Are the volumes provided bound or in a clearly marked ring-binders? Y / N / NA Comments/Explanation Y / N / NA Comments/Explanation Y / N / NA Comments/Explanation 4.2. Layout and order Question Is a paging format of 1 of 2, 2 of 2 and so on, used? Is the dossier clearly divided into sections as per the Product Dossier Checklist (PQDx_049) and are pages of each section numbered logically? Is the information fully cross-referenced to the WHO Prequalification of IVDs requirements using the Product Dossier Checklist, document PQDx_049? Has one printed copy and one identical e-copy of the entire dossier been provided? For the electronic copy of the dossier: Is the electronic copy in PDF format and is it not protected by a password? Is the name of the descriptive of its content and meaningful to the reviewer? Is the PDF file searchable rather than a scan of the source document? Is there a statement attesting that the content of the electronic copy is identical to that of the printed copy? If the manufacturer claims no changes, is there a statement that no changes have been made to the product since design lock down? 4.3. Language Question Have all documents been provided in English? Have translations been provided for foreign-language documents, including PQDx_009 v3.0 / 15 December 2014 Page 23 of 24 certification details of the translator, an official document attesting to the accuracy of the translation, and the original document? 12. Product Dossier Screening Report Screening reviewer recommendation: Y / N / NA Does the dossier contain all the prescribed sections? Comments: Date of screening reviewer report: Screening reviewer name and signature DD/MM/YYYY PQDx_009 v3.0 / 15 December 2014 Page 24 of 24 Comments