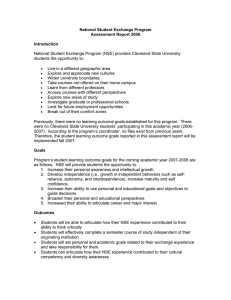

QUALITY COUNTS FNSE NSE Minna BranchTechnical 1

advertisement

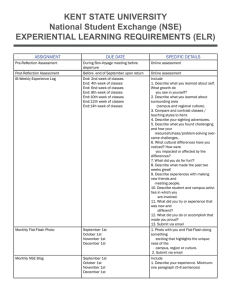

QUALITY COUNTS ENGR. DR. Y. A. ADEDIRAN, FNSE NSE Minna BranchTechnical Lecture, 16/2/2008 1 WHAT IS QUALITY? • All the features and characteristics of a product or service that contribute to the satisfaction of a customer’s needs or, Conformance of a product or service to specifications NSE Minna BranchTechnical Lecture, 16/2/2008 2 Customer’s Needs: • • • • • • Price Safety Availability Maintainability Reliability Usability NSE Minna BranchTechnical Lecture, 16/2/2008 3 QUALITY CONTROL Use of techniques and activities to achieve, sustain, and improve the quality of a product Activities involved: • Specifications • Design • Production or installation • Inspection • Review of usage Responsibilities of functional areas NSE Minna BranchTechnical Lecture, 16/2/2008 4 QUALITY ASSURANCE (QA) All the actions necessary to provide adequacy or effectiveness with a view to having timely corrective measures and feedback initiated when necessary. - Policy, planning, and administration Design assurance and design change control Production Quality control User contact and field performance Employee selection, training and motivation NSE Minna BranchTechnical Lecture, 16/2/2008 5 RESONSIBILITY FOR QUALITY • • • • • • • Marketing Design or Production engineering Manufacturing (process) engineering Manufacturing Inspection and Test Packaging and shipping Product (or after-sales) service Quality is designed into the product! NSE Minna BranchTechnical Lecture, 16/2/2008 6 ECONOMICS OF QUALITY Quality costs cut departmental lines. • Identifiable costs: inspection, instrumentation, quality personnel salaries • Others: cost of scrap and rework, customer dissatisfaction, loss of reputation Generally, overall cost is reduced as quality improves. NSE Minna BranchTechnical Lecture, 16/2/2008 7 Direct Quality Costs: • • • • Prevention costs Appraisal costs Internal failure costs External failure cost NSE Minna BranchTechnical Lecture, 16/2/2008 8 Direct Quality Costs (contd): • • • • • Prevention cost Quality engineering Design development Quality planning Quality training Utilities NSE Minna BranchTechnical Lecture, 16/2/2008 9 Direct Quality Costs (contd): • • • • • Appraisal costs Inspection and test of materials Inspection and test of product Product-quality audit Materials and services consumed Equipment calibration and maintenance NSE Minna BranchTechnical Lecture, 16/2/2008 10 Direct Quality Costs (contd): Internal Failure costs • • • • • • Scrap Rework Failure analysis Re-inspection Fault of supplier Downgrading NSE Minna BranchTechnical Lecture, 16/2/2008 11 Direct Quality Costs (contd): External Failure • • • • • • Complaints Rejected and returned Repair Warranty charges Errors Liability NSE Minna BranchTechnical Lecture, 16/2/2008 12 Direct Quality Costs (contd): Cost Total cost Prevention & Appraisal Cmin Failure costs Quality Level Qoptimal NSE Minna BranchTechnical Lecture, 16/2/2008 13 Indirect Quality Costs • Customer-incurred cost • Customer dissatisfaction cost • Loss-of –reputation cost NSE Minna BranchTechnical Lecture, 16/2/2008 14 Total Quality Cost Cost Total costs Cmin Direct costs Indirect costs Quality Level Qoptimal NSE Minna BranchTechnical Lecture, 16/2/2008 15 Quality Management Problems in Nigeria Low quality of Nigeria-mad products could be traced to: • lack of quality control depts in industries • None or unqualified staff in QC depts • High level of illiteracy • Lack of awareness on how, where and when to seek redress • Inadequate consumer protection NSE Minna BranchTechnical Lecture, 16/2/2008 16 Quality Management Problems in Nigeria (contd) • People (employers and consumers) thinking that quality is not their responsibility • People thinking of short gains rather than long-term profitability • Low efficiency of regulatory bodies • ……. NSE Minna BranchTechnical Lecture, 16/2/2008 17 Recommended solutions against low quality product/service • • • • Recognizing the need for quality Building quality awareness into in everyone Adequate consumer protection Adequate and straightforward legal procedure for aggrieved consumers • Adoption of management policy on quality • Motivation of employees NSE Minna BranchTechnical Lecture, 16/2/2008 18 Recommended solutions (contd) • Clear definition (in writing) of the standard/specifications of quality • Provision of adequate inspection coverage using appropriate methods and tools • Keeping adequate inspection records • Adequate training of quality personnel • Having continuous evaluation and feedback mechanisms NSE Minna BranchTechnical Lecture, 16/2/2008 19 THANKS FOR THE ATTENTION NSE Minna BranchTechnical Lecture, 16/2/2008 20