AGE 322 AGRICULTURAL MECHANISATION

advertisement

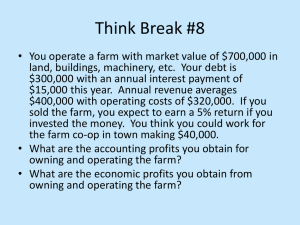

AGE 322 AGRICULTURAL MECHANISATION 2 Units Course Lecturer: Engr. Dada P.O.O. Department of Agricultural Engineering Office Location: Civil Engineering Building. Office No:3 FUNAAB Email: dadafemo@yahoo.com, dadapo@unaab.edu.ng What is Agricultural Mechanisation Study of the manufacture, utilisation, distribution, repair and maintenance of all machines involving farming operations from land clearing to processing. Use of farm machinery Aims of Mechanisation To increase productivity To remove farm drudgery To improve on product quality To reduce cost of labour To increase income Provision of employment opportunities Improve livelihood of farmers Levels of mechanisation Human – – – – – Power rating(0.1 HP), most primitive Highly inefficient High energy consumption Low cultivated area Animal – Power rating(1-5 HP) – Better than manual/human – Larger capacity for animal drawn tools – Prone to Tsetse fly infestation – Competition for meat/milk by humans Mechanical – Power rating(10-200HP) – More coverage of land – Highly efficient – High productivity – Expensive – Needs skilled labour Other sources of Power Solar – From the sun (continous, 3.41X106 Joules/m2 – Useful for: space heating, water heating and crop drying Wind – Used with wind vanes Nuclear – – – – Clean source Easily controlled High power generation Application through electric power Biogas/Bioenergy – Renewable source of energy The tractor Tractors can be classified in terms of their capacity (power rating) and type (wheel, crawler etc). Wheel type can be of two types namely Two-wheeled and four-wheeled. Others include: earth moving types and industrial types. Power rating ranges from 1.3 to 150 HP Selection of farm tractors To select appropriate size of farm tractors, the following must be considered. Farm area to be cultivated Type of crops to grow Soil structure Financial capability Size of implement to be driven Tractor as a Prime mover Drives all other farm machinery PTO for energy generation Provision of Draft power for tillage tools through 3-hitch system Used for trailing and transportation of farm produce Hydraulic output for equipment lifting Internal Combustion Engines Burns fuel internally Mixture of fuel and air Power generated by the explosion of burnt mixture of fuel and air Common types Include: – Gasoline/Otto cycle – Diesel Engine Engine parts Stationary parts – – – – – Engine block Cylinders Cylinder head Crankcase Sump – – – – Crankshaft Main bearings Flywheel Camshaft – – – – Piston Connecting rods Valves Valve seats Rotating parts Reciprocating parts Engine Accessories – Electrical system – Cooling system Agricultural Machinery management Policies are necessary for successful implementation of Agricultural mechanization strategy. Policies are established by Government to achieve objectives. strategies defines the way in which policies are implemented. Some key policies are: Subsidies Credits Taxes and Duties Private, Corporate or Government Ownership Input and output prices Public investment. Cost Analysis The maintenance of an accurate record of costs is an indispensable part of the machinery manager’s job. Such records assist decision making processes that are the core of good machinery management. Ultimate goal of a machinery manager is to maximize enterprise profits, get a higher output from his machines at minimum cost. Time of replacement of a machine is one of the most important decision making activity of the machinery manager. Cost analysis (Contd) Machinery costs are divided into two categories: Fixed cost (Independent of use) eg. Machinery investment, taxes, housing, insurance etc. Variable cost (associated with use) eg. Fuel, daily service, power, labour, lubrication etc. Depreciation: The amount by which the value of a machine decreases with the passage of time whether used or not. The value declines due to the following: Part worn out with use Expense of operating machine increases with time New or more efficient machine is available Change in use of the enterprice. Cost analysis (Contd) Methods of calculating Depreciation 1. Straight-line method 2. Declining balance method 3. Sum of the year digits method Service life of a machine (Physical Life): Needed to estimate depreciation. It terminates instantly due to irreplaceable part or irreparable part. Economic Life of a machine: The length of time from purchase to that point where it is more economical to replace with a second machine than to continue with the first. Accounting life of a machine: Predicted life of a machine in hours of use based on the surveyed use of existing machines and on design life used by the manufacturer. Cost Analysis (Contd) Renting and Leasing Repair costs Interest, tax, Insurance and Shelter Approximate Annual Cost: Estimation for future cost of use for farm machines is important to machinery managers. Good estimates help in costs of production, size selection and replacement decisions can be made. The actual costs are determined at the end of each year from cost records Approximate Annual cost Approximate annual cost are determined by summing expected FC and VC. The total cost per year of a machine can be expressed as: AC = FC%/100 X P + CA/SWE X [R&M +L + O+F+T] Where: AC is Annual cost N/yr FC is Fixed Cost percentage (decimal) P is Initial Purchase price (N) A is annual area use (Acres) S is Forward speed (km/hr) W is Effective width of action of machine (m) E is field efficiency (decimal) R&M is repair and maintenance cost (N) C is a constant 10 or 8.25 L is labour cost (N/yr) O is Oil cost (N/yr) F is fuel cost (N/yr) T is Cost of tractor use by the machine (N/yr) Equipment Selection An efficient method of matching equipment to the true needs of agriculture will benefit both the manufacturer and the farmer. The selection of an equipment is a complex problem at farm level. To select field machinery, the following factors must be taken into consideration. Implement performance Timeliness Power availability Labour Ability to anticipate and recognize significant trends in the technology Machinery selection In field machinery selection, the most pertinent variable is size or capacity of the machine. The basis for selecting the proper capacity field machine is to find the minimum cost by using the equation: AC = FC%/100 X P + 8.25/SWE X [R&M +L + O+F+T] (Where the symbols have their usual meaning) If all the variables are expressed in terms of per metre of machine wheel basis with the exception of T, then AC = f(w) Graph relating annual cost and machine width. Power Selection Cost of power is significant in many operations. Some implements are self propelled but most are powered by tractors. Tractor capacity is designated by horsepower. The annual cost for a farm power unit can be expected to consist of AC = FC%/100 X P + hours used X [R&M +L + O+ KAYV] Where K = timeliness factor Y = Potential crop yield (t/ha) A = Area (acres) V = Value of crop (N) Used Equipment Equipment selection also involves some decision about the economic of purchasing used machinery. When the price of a used equipment drops below its actual worth, there is an economic opportunity for the employment of a used machine. In the decision to purchase a used equipment, the machinery manager should recognize and distinguish between Price and Value. The following can also guide decision on purchase of used equipment. 1. Evaluate wear 2. Recognize the adequacy of prior maintenance 3. Evaluate and judge deterioration due to age 4. Be knowledgeable in performance of various models 5. Be skilled. Machinery management Involves thorough knowledge of: Mechanical principles and limitations of the machine. Efficient operations in the field Appropriate machine maintenance Timely repair and replacement Selection of a machine system Economic analysis of actual or proposed activities. Machinery management (contd) Discussions on the under listed Field Operations Field Patterns Calibration Loss determination Field Adjustments Repair and maintenance Preventive maintenance References Farm machinery management by Introduction to farm machinery by Kepner