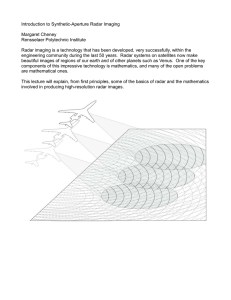

The Design of Radar Corner Reflectors for the Australian Geophysical Observing System

advertisement