OPTIMUM DESIGN OF AN EXPANDED CUMULATIVE EXERGY CONSUMPTION ABSTRACT

advertisement

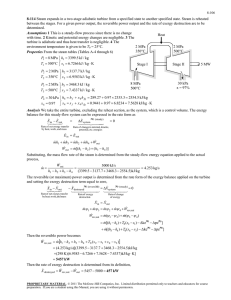

Paper published by: Nigerian Journal of Construction Technology and Management, Vol. 7, No.1, 2006, pp. 146-156 OPTIMUM DESIGN OF AN EXPANDED CUMULATIVE EXERGY CONSUMPTION IN A STRAWBALE-WALLED BUILDING A A Adedeji Department of Civil Engineering, University of Ilorin, Ilorin, Nigeria ABSTRACT An optimization approach is presented in this paper to minimize the effects of environmental impacts, in terms of expanded cumulative energy consumption during a building service life, resulting to negative effects on the occupants due to waste emission. The optimal solution was obtained using the strong-searched and structured genetic algorithms. A numerical example of a multistorey building, which was assumed to be built with cement plastered strawbale panels and was compared with the conventional sandcrete block wall for its life-cycle, is presented as a case study. From this study, the cumulative exergy consumption obtained for strawbale walled building is 25% of sandcrete walled building. The results have further shown that strawbale building has high service cost (LCC) at the initial state of its life cycle, but low energy resource consumption (LCEI). Strawbale building at 30o orientation has the same values for LCC and LCEI, while LCC is higher than LCEI in case of sandcrete walled building for 0o and 30o orientation. Keywords: strawbale, wall, environmental impact, genetic algorithms INTRODUCTION It has been established by the international panel of Climate Change (IPCC, 2001) that beside natural climatic impact, man-made gas emissions are the major root of the climate problem. The enhanced gas and other artificial emissions affect weather patterns, especially in an enclosure and the entire hydrological cycle. Beside the climate changes, there are also some other environmental challenges such as acidification (acid rain), stratospheric ozone depletion, urban air pollution, loss of biological diversity and so on. Both climates change and other environmental problems result to a large extent from emissions arising from human activities, in particular, the burning of fossil fuel (IPCC, 2001). Buildings are energy gluttons and have a large impact on the global climate change and other energy–related environmental issues. It is reported by the U.S. Department of Energy that buildings account for 36% of total primary energy consumption and 67% of electricity consumption (DOE 2002), even in developing countries like Nigeria. More than 35% of energy consumption in our buildings (residential and manufacturing (Oviemuwo 2001, Jekayinfa, 2006)}, especially in Nigeria, is as a result of environmental control (use of mechanical ventilators, such as fan, air conditioners etc) for ventilation because of excessive heat in dry season. As a direct result, buildings account for nearly 35% of CO 2 emissions, 48% of SO2 and 20% of NO2 (DOE, 2002). In response to the buildings’ major impact on the environment, it is importance to explore ways for a better building design that considers environmental performance. Appropriate choice and design of materials that would respond to environmental ecological system is the first and the best approach to this problem. Many studies have been done in order to optimize building design for energy efficiency. These studies used the operating energy consumption or life-cycle cost as the performance criterion to establish optimization model (Adedeji 2002, Miller 1992, Weller 2001, Coley and Schukat 2002). Because the optimal solutions due to energy consumption is usually different, the cost is treated as a constraint on energy–efficient measures. Despite the above efforts, Weimim et al (2003) explained that two major limitations undermine this application in practical building design. These are: (a) Inappropriate environmental performance criterion: This may be due to (i) the unavailability or inconsistency of data for environmental impact of building material and component, (ii) few lifecycle environmental impacts simulation programs are available, (iii) both designers and clients have little interests in reducing embodied environmental impacts because they are not directly Paper published by: Nigerian Journal of Construction Technology and Management, Vol. 7, No.1, 2006, pp. 146-156 related to building costs. These make it necessary to incorporate the holistic impact categories covering the choice of the material that will transfer the climatic condition into the internal microclimate for the use of the tenants. (b) Improper Variable Determination: The inappropriateness of variables can be seen as a variable may not be properly defined. It is not difficult to observe that many parameters such as window types can only take discrete values. For example, the window type is represented by its thermal resistance value (Miller, 1992). Secondly, some variables in the model are not directly design-oriented, but are sort of auxiliary used data as design options. Sometime this gap cannot be easily handled because they are not initially incorporated in to the design. In recognition of the above limitations of former studies, a new optimization model is proposed in this paper as proposed and used by Weimim et al (2003). Since this model relies on exergy and its related concepts which according to Moran and Sciubba (1994) is the maximum theoretical work that can be extracted from a combined system, consisting of a system under consideration. An environment as a system may pass from a given state to an equilibrium state of the environment. In other words the system passes to the dead state at which the combined system (a given state and an equilibrium state) possesses energy but no exergy. These are introduced in the second section. Then the optimization model and the algorithm employed to solve the formulated problem are described. Finally, a case study is presented. EXERGETIC LIFE-CYCLE ASSESSMENT Life-cycle Assessment (LCA) is an analytical tool that can help in understanding and evaluating the resource consumption and waste emissions associated with products, packaging, processes and activities across all stages of their life cycle from materials acquisition to final disposition). The life cycle of buildings is shown in Figure 1 ((ISO, 1997) where the dashed line denotes the scope considered in this optimization study. In Figure1, building material properties are incorporated with its production, since production affects the properties which in turn affect the construction of the structural elements in its life service. Transportation serves for the movement of materials during construction. Natural resource extraction Building material property and production Transportation Element construction in-situ Operation and service Maintenance Demolition Transportation Figure 1 Life circle process of a building ((ISO,1997) As indicated by Barnthouse et al. (1998) global, long-lived impact categories usually have characteristics that can be dealt with by LCA with acceptable theoretical accuracy, but aggregated LCA indication for local and transient impact categories have little practical meanings. Therefore, impact categories considered in this optimization study are the waste emissions that have long-lasting impacts on the internal microclimate namely, sun radiation, moisture and acid rain and its associated chemicals that are penetrating the building envelop material (wall and roof). It is difficult, however, to characterize natural resource depletion and to integrate various impact categories with different units and magnitudes in the context of LCA as reviewed by Finnveden (1994). Though, normalization may not completely address this difficulty because different normalization coefficients may lead to conflicting conclusions when weighting integration alone is used as a technique compare alternatives in conjunction with the exergy process. Unlike energy, exergy is always destroyed because of the irreversible nature of the process. Exergy is an extensive property whose value is fixed by the state of the system once the environmental impact Paper published by: Nigerian Journal of Construction Technology and Management, Vol. 7, No.1, 2006, pp. 146-156 has been specified. Therefore, the evaluation of exergy depends on both the state of a system under consideration and the conditions of the reference environment. Most applications of exergy analysis in the published literatures concentrate on thermal system design (Moran 1982, Adedeji 2002) chemical and metallurgical process analysis (Szargut et al.1988). The exergy can also be incorporated into LCA to address the issues of the natural resource depletion characterization and valuation Cumulative exergy consumption (CExC) was proposed by Szargut et al (1988) of all natural resources consumed in all the exergy of a production process. Unlike cumulative energy consumption, exergy takes into account the non-energetic raw materials obtained from the environment in which the building is built. Therefore, cumulative exergy consumption can be used to measure natural resource depletion. Exergy is not only a measure of resource consumption; it is also a measure of waste emissions. Because, exergy can be used to evaluate the degree of equilibrium between a substance and meaningful relationship can be established between the environment impact potentials and the energy of waste emissions (Ayres et al. 1998). Abatement or lessen energy is employed in this study to evaluate the required energy to remove or isolate the emissions from the building environment. Although the value of abatement energy for a given waste emissions is technology-dependent, it is possible to determine an average abatement for each emission. One of the randomly generated solutions used by Caldas and Norford (2003) in the first generation has performed almost as well as the best Pareto solution in terms of energy, but its construction costs were about 33% higher. Pareto optimization, in genetic algorithm, as the process of the optimizer, is towards the pareto front rather than towards an absolute minimum or maximum. This demonstrates the usefulness of applying the Pareto–front the first to the hundredth generation of only 6% on average (from 24.7 MWh to 23 MWh), but the reduction construction costs was about 41% (from $8434 to $4965) including materials. Costs in the Pareto-front studies may be an effective measure for achieving similar energy performance at lower first costs. Costs for the different materials were obtained by averaging prices provided by several retailers in Nigeria. Thus, by extending the cumulative exergy consumption to include abatement exergy (the beating down of exergy), all the resource inputs and waste outputs can be unified together. This expanded cumulative exergy consumption can consider both resource inputs and waste emissions to the environment. It is particularly suitable for the life cycle optimization with respect to environmental performance. The main advantages of the cumulative exergy consumption are that: Resource depletion and waste emissions can combine together, and therefore, the life cycle environmental impacts can be condensed into one single objective function. Exegetics resources and non-energetic materials can combine together to characterize the resource depletion. Only one criterion is employed to avoid weights or other qualitative judgment in the evaluation of environmental impacts. A demanding task in applying energetic life-cycle assessment is to collect consistent and reliable data for analysis. Because there is available database that can directly provide cumulative energy consumption and environmental impacts covering typical building materials and constructions, a life cycle assessment tool specially developed for buildings, is employed here to extract the natural resource consumption and waste emissions. These data can be used to derive cumulative exergy consumption and abatement exergy. Strawbale masonry (straw bale plastered with cement or other types of suitable mortars) has been selected because of its prominent advantages over conventional wall materials (sandcrete, earth, concrete) in the following aspects. It can offer values of environmental impacts (high insulation material against heat and cold respectively) for each life-cycle stage of a building (Adedeji, 2002). These values are essential to drive cumulative exergy consumption and other building envelopes. The availability of straw (stalks from maize, sorghum, rice, elephant grass etc) they have been considered a wasteful material and may be used rarely for animal feeds. This particular advantage makes it convenient to locate corresponding cost found in data and can be compared with other common materials (sandcrete, earth etc). Paper published by: Nigerian Journal of Construction Technology and Management, Vol. 7, No.1, 2006, pp. 146-156 OPTIMIZATION MODEL AND ALGORITHM Optimization Model Variables in this work represent those parameters that define a building design and were passed to a building simulation program. For example, window-type is a variable in the system. Several window types can be set as alternatives to other window types to the designer’s requirement. Some variables such as window type can only be of discrete type while some variables (e.g., orientation) can be either continuous or discrete. a Side 3 Side 4 Side 2 b North (building) Orientation 30 True North Figure 2 Definition of orientation and aspect ratio. In this research, the types of buildings considered are limited to a rectangular shape with known total floor area. Figure 2 illustrates the definition of some variables, as proposed by Weimin et al (2003) are: Building Orientation (Orientation) Aspect Ratio (aspect Ratio) defined as a/b, where a and b are shown in Figure 2. Window Type (WinType). Window area ratio for each building façade (WinRatio) Wall Type (WallType) in terms of materials Each layer of wall (WallLayer). The total number and the arrangement of layers are dependent on wall type. Roof Type (RoofType). Because it is essential to explore the relationship between economical performance and environmental performance, Life cycle Cost and Life-Cycle Environmental impact (LCEI) are coupled together using weighted secularization method. Assuming (x) is the variable vector, the integrated objective function F(x) can be expressed as: F(x) = w1 LCEI (x) + w2 LCC (x) (1) Paper published by: Nigerian Journal of Construction Technology and Management, Vol. 7, No.1, 2006, pp. 146-156 where w1 and w2 are predefined weights for life-cycle environmental impact and life-cycle cost respectively. LCEI is the life-cycle environmental impact using energy as an indicator criterion, LCC.= life-cycle cost for service. If the weights were reversed and set to (w1 = 1 and w2 = 0) then all the emphasis is placed on minimizing the variance of the objective function without regard to the mean. There are an infinite number of possible weights that are each Pareto optimal, in which its solution is not possible to improve one of the objectives without worsening the others. The weighted sum approach does not generate all the Pareto solutions for some problem, but since this work is focusing on the extreme points of the Pareto front, adoption of this method is adequate (Parkinson et al, 1998). The general expression (for construction and operational or services) to calculate LCEI is: LCEI (x) = EE (x) + OE (x) (2) where EE = Embodied energy, that is the expanded cumulative energy consumption due to building construction and is assumed 0 initially, because most of the sources data before the commencement of the construction are not certain and that the building is assumed not yet in service, and only OE which is the operating energy is considered as the expended cumulative energy consumption due to building operation and service. EE (x) and OE (x) were employed in the analysis when the building is assumed in service. The general expression to calculate LCC is: LCC (x) = IC(x) + OC (x) (3) where, IC = Construction cost due to waste emission, was not as well considered initially in the analysis because the analytical building was assumed not to be in service, but are used during the service life, OC = Operating and service cost, including both demand and energy consumption costs. In this work however, the building load calculations is coupled with the optimization model to estimate the annual peak energy consumption and demand (CExC) due to ventilation in the room as the results of heat produced (QH) by human, lighting (QL), electric motor engine (QE), radiation by heater or wall materials(QR) and ventilators (fan or air conditioner) (QV). Structured Genetics Algorithm The selection of an optimization algorithm depends on the peculiarities of a problem domain. The previous formulated problem in section 3.1, equations (1) to (3) has the following characteristics: If the following variables and corresponding number of alternatives (the number in parenthesis) are considered: orientation (2), aspect Ratio (1), WinType (3), WallType (3), RoofType (1), WinRatio (1), each WallLayer (1), then there are about 2xE6 or 2.5xE10 possible solutions to explore. Both continuous and discrete variables may exist in the same optimization problem. The shape of criteria space is unknown. The genetic algorithm works in the following manners: The first step is to represent a legal solution to the problem to be solved by using a string of genes (a gene is a unit in chromosome controlling heredity), that can take on some value from a specified finite range. This string of genes that represents a solution is the chromosome. Then an initial population of legal chromosomes is constructed at random. And at each generation, the fitness of each chromosome in the population is measured. The fitter chromosomes are then selected to produce offspring for the next generation, which inherit the best characteristics of both the parents – the survivor of the fittest by Darwin’s theory of evolution. After many generations of selection, for the fitter chromosomes, the result is expected to be a population that is substantially fitter than the original. Genetic algorithms consist of: Chromosomal Representation, initial population, fitness evolution, selection, crossover and mutation. Genetic Algorithms (GAs) are good at exploring large search space because of its implicit parallel computation mechanism. The binary string representation can deal with both continuous and discrete variable. Compared with conventional numerical methods, genetic algorithms are able to locate global optimum without trapping into local extreme point. All these advantages determine that GA is an appropriate candidate to solve the above formulated problem. Structured GA lies in its redundant genetic materials and a genetic activation mechanism. Paper published by: Nigerian Journal of Construction Technology and Management, Vol. 7, No.1, 2006, pp. 146-156 CASE STUDY Problem Formulation The 14th (last) floor of a multi-story (Shell House) office building located in Lagos Island, Nigeria, is a building in which the environmental and physical data has been measured and used in this work. The results of measurement and data (size of the rooms, area of opening sizes and types, wall materials and finishes, electrical lighting, fans and air-conditioning power outputs) used were parts of the work carried out by Ojediran (2004). The floor plan has a total area of 238.336m2 with 50-year life expectancy. The following assumptions (materials, and other physical properties) were made and used in the analysis: Only the energy, consumed in the hot season of March, April and May, has been used in the analysis. Rooftop units of aluminum are assumed to be used. Two wall types are considered; cement plastered straw bale and sandcrete block (used for the construction of the specimen building) walls. Other properties are shown in Table 1. Because the sizes of the relatively expensive windows were small, even in the best energyperformance cases, the size values are not used in the analysis. Only one roof type has been considered with asbestos cement hanging ceiling, shielding the heat away from the room. So, the energy factor, through the roof at this stage, is negligible and it was not used in the analysis. Table 1 Average properties of materials Properties Size, L x B x H (mm) Density (kg/m3 U-value (W/m2K) R-value (m K/W) Reliability of wall Strawbale wall 1066 x 406.4 x 584 9300 0.13 (of 420mm thick) 13.21(of 420mm thick) 0.89 Sandcrete wall 445 x 215 x 215 1500 1.73 (of 250mm thick) 0.58 (of 250mm thick) 0.77 Note: U –value = thermal conductivity, R-value = thermal resistivity Energy factors produced and consumed during the three months as the annual peak energy consumption and demand (CExC) in section 3.1 are shown in Table 2 and were obtained using equations (a1) to (a5) in Appendix A.). Energy factor Table 2. Energy consumed per hour Energy consumed (MJ) Strawbale wall Sandcrete wall South East East South East East QH QL QE QR QV Total 0.076 0.076 0.362 0.362 0.476 0.476 0.133 0.133 0.162 0.162 0.567 0.567 0.059 0.067 0.222 0.222 1.417 1.417 6.909 6.909 2.190 2.190 8.193 8.193 Note: (QH) by human, lighting (QL), electric motor engine (QE), radiation by heater or conduction from sun’s heat through wall materials(QR) and ventilators (fan or air conditioner) (QV). For definitions of the energy factors, see Appendix A. Cumulative energy consumption per hour is 2.190 MJ for the building walls built with strawbale and 8.193 MJ for the building with sandcrete. The general inflation rate, discount rate, and energy Paper published by: Nigerian Journal of Construction Technology and Management, Vol. 7, No.1, 2006, pp. 146-156 escalation rate of 30% is not included in the computation as that varies and the addition could be made as required. In October 2005, the electricity rate was N5.187/h (kW) of billing demand of the electricity consumption. Single glazing is the window panel-type used for this building. There are two wall types: masonry sandcrete block wall built as infill into the reinforced concrete frame. In this analysis, the first wall type is composed of cement plastered strawbale as shown in Figure 3a. The second wall type is composed of sandcrete blocks, and finished with cement plasters as shown in Fig.3b. The south-wall absorptivity was always at high values, either 0.6 or 0.8 while the north-wall absorptivity had more random values, because solar gains were not significant in that direction. Hence, its absorptivity values were not used in the analysis. Plaster – Strawbale – Plaster Plaster – Sandcrete - Render Direction of Environmental conditions Microclimatic Region tplaster tstraw t tplaster tplaster tsandcrete tplaster t Figure 3 Sections of the walls Another set of simulation was done with the building rotated by 30o so that it would face South-East. Energy-consumption levels were always higher for this orientation than for South-North, as expected. However, costs remained lower, Considered Genetic algorithms operations are: - Global search algorithms: GA Local search algorithm: gradient method Population size: 20 Crossover rate 0.1 Mutation; 0.1 Reproduction rate: 2 offsprings Generations: 3 of 0.15 Tournament selection and elitist strategy are used in this GA implementation. RESULTS AND DISCUSSION Four weighting sets are used in this study. The two extreme cases (case 1 and case 3) are actually single performance criterion optimization with the life cycle environmental impact and life-cycle cost as the objective function respectively. The minimum function value was obtained from the two extreme weighting cases 2 and 4. The programme for each weighting set are used to normalize the life-cycle environmental impact and life-cycle cost in weighting sets are used to normalize the life-circle environmental impact and life –cycle cost in weighting case 2 and 4. The optimal values of variables obtained from the best run of each weighting set are presented in Table 3 and in Figures 4 and 5. It can be seen from this table and the figures that: Paper published by: Nigerian Journal of Construction Technology and Management, Vol. 7, No.1, 2006, pp. 146-156 (1) The optimal aspect ratio is about 0.33 when the optimization criterion is the life-cycle environmental impact, for the strawbale-walled building and 0.80 for the life-cycle cost for sandcrete-walled building. (2) When environmental performance is the only criterion, the plastered strawbale walled building is economically viable than the building of sandcrete walls. However, sandcrete block wall is recommended when the life-cycle cost is considered in the overall criterion. (3) The minimum allowed window area is preferred for both environmental and economical performance. (4) Threshold is 0.48 in the sandcrete walled building and 076 in strawbale house when considering the cost of material and service as a design criterion. (5) At the weight value of 1, the energy consumption of the two wall materials is the same. It was observed that the energy consumption of strawbale house increases with time, but decreases in the building of sandcrete walls. Table 3 Optimal values of variables from the weighting sets Variables & performance Orientation Aspect ration WinRatio WallType 1 (Strawbale) WallType 2 (Sandcrete) LCEI (MJ) LCC (N) w1=0.7, w2=0.3 1 w1=0.3, w2=0.7 2 w1=1, w2=0 3 W1=0, w2=1 4 30 0.1 0.54 1 0 0.9 0.54 1 0 0.8 0.54 1 0 0.33 0.54 1 1 1 1 1 SB 77066.97 7398234 SC 108537.18 32447643.75 SB 4778.74 36240238.1 SC 130927.95 13984805. SB 27532.36 10568806.71 SC 150617.35 15070. SB 100612.68 46315075.72 SC 85005.53 90302.50 60 2 Sandcrete wall R = 0.4617 6 50 40 30 Strawbale wall, R2 = 0.7824 20 10 0 -10 0 0.3 0.7 1 WEIGHTS (w 1 and w 2) Figure 4 Priority cases (w1, w2) due to life cycle for cost criteria on microclimate condition ENERGY CONSUMPTION ON LIFE-CYCLE (L CEi) MJ 80 70 x10 (N) COST DUE TO MATERIAL AND SERVICES (LCC) Note: LCEI = Life-cycle by environmental impact due to energy resource consumption, LCC =cost due to service. SB = strawbale wall, SC = sandcrete block wall. Note: 1N = $0.0074 (Nov., 2004). 40 35 30 25 20 15 10 5 0 Sandcrete w all, y = -11.237Ln(x) + 37.18 Straw bale w all, y = 12.926Ln(x) + 4.8086 0 0.3 0.7 WEIGHTS (w 1, w 2) Figure 5. Priority cases(w1, w2) due to life-cycle for energy consumption on microclimate The building performance corresponding to each optimal solution is also shown at the bottom of Table 3. The evolution of the best solution ever found for life-cycle environmental impact and lifecycle cost in Figures 4. The process evolves rapidly during the first 30 generations and then slowly at later generations. This demonstrates that genetic algorithms can perform better in locating the optimal region than in local search. It can be observed that the optimization is effective to improve building performance. In Figure 4 and 5, it is shown that cost of materials and the service is low in a sandcrete walled building during its life cycle. The strawbale building consumes less energy during its early service at the weighted value of 1. it is shown in Figure 6 that strawbale walled building resists environmental impact than the sandcrete-walled house at the generation of 0.6 and 0.1 respectively. 1 Paper published by: Nigerian Journal of Construction Technology and Management, Vol. 7, No.1, 2006, pp. 146-156 1.2 Sandcrete wall FITTNESS 1 Strawbale wall 0.8 0.6 0.4 0.2 0 10 20 30 40 50 60 GENERATION Figure 6 Life-cycle environmental impact convergence. CONCLUSION Exergy is a useful concept to be employed in life-cycle environmental optimization problems. It can overcome the difficultly brought by integrating impacts with varied magnitudes and units. With expanded cumulative energy consumption, the optimization problem can be simplified by incorporating all impact categories into one objective function. The results have shown that threshold is 0.48 in the sandcrete walled building and 076 in strawbale house when considering the cost of material and service as a design criterion. At the weight value of 1, the energy consumption of the two wall materials is the same. It was observed that the energy consumption of strawbale house increases with time, but decreases in the building of sandcrete walls. Because the economical performance and environmental performance cannot take optimal values at the same time, a multi-criteria optimization model is highly useful for decision-making in an environmental – friendly building design. A disadvantage of the weighted scarlarization technique is that only one optimal value is obtained for each weighting set. Different weighting sets need to be tested to explore different optimal solution. Nevertheless, the application of the weighted values gives the quick view of the conditions to take into consideration in design. REFERENCES 1. Adedeji, A. A.. (2002), Thermal effects on the bearing capacity of earth wall in optimal design, Association for the Advancement of Modelling and Simulation Techniques in Enterprises (AMSE), France, Modelling B-2002, 71(3), 17 – 28. 2. Ayres, R.U., Ayres, L.W., and Martinas, K. (1998), Energy, waste accounting, and life-cycle analysis, Energy, Vol.23, No5,pp.351-363. 3. Barnthouse, L., Noesen, S. Norris, G., Owens, J., (1998), .Life cycle impact assessment: The state – of- the art, 2nd edition, Setac press, Pensacola, FL. 4. Caldas, L. G. and Norford, L. K. (2003), Genetic algorithms for optimization of building envelopes and design and control of HVAC system, Journal of Solar Energy Environment, Vol. 125, pp.343 350 5. Coley, D.A. and Schukal, S. (2002). Low-energy design: Combining computer-based optimization and human judgment, Building and Environment, Vol.37, pp.1241-1247. 6. DOE.2002 BTS Core data book. U.S. Department of energy. 7. Finnveden, G. (1994). Methods for describing and characterizing resource depletion in the context of life-cycle assessment, Technical Report, Swedish Environmental Research Institute, Stockholm, Sweden. 8. IPCC, Intergovernmental Panel on Climate Change, 2001. Climate change 2001: synthesis report, Cambridge University Press. Paper published by: Nigerian Journal of Construction Technology and Management, Vol. 7, No.1, 2006, pp. 146-156 9. ISO. 1997. ISO 14040: 1997 Environmental management - Life cycle assessment – Principles and framework, International Organization for Standardization. 10. Jekayinfa, S. O.(2006). Energy consumption pattern of selected of mechanical farms in SouthWestern Nigeria, The CIGRE Journal. Vol III. 11. Miller, B.E. 1992. Optimization of building design variables, MS, Department of Mechanical Engineering, Colorado State University, Fort Collins, Co. 12. Moran, M. J. and Sciubba, G. (1994). Exergy analysis principles and practice, Journal of Engineering for Gas Turbines and Power, Vol. 116, pp 285-290. 13. Ojediran, A., (2004), Ventilation assessment in a strawbale walled building, B.Eng. Project submitted to the Departmrnt of Civil Engineering, University of Ilorin, Ilorin, pp 1-71. 14. Oviemuwo, A. O, (2001), The changing structure of Nigeria economy, http//www.ela.doe.gov/emeu/merc/merc94/ei/ei_html 15. Parkinson, A., Soreson, C., Pourhassan, N. (1998), A general approach for robust optimal design, Transaction of the ASME, Journal of Mechanical Design, Vol. 115, pp. 74 – 80. 16. Szargut, J. Morris, D.R., and Steward, F.R. 1988. Energy analysis of thermal, chemical and metallurgical process, Hemisphere Publishing, New York. 17. Weimin, W., Hugues, R., Radu, G. Z.(2003), Optimizing building design with respect to life-cycle environmental impacts, 8th International Conference, Eindhoven, Netherlands, pp 1355-1361. APPENDIX A QH = Ψ(He, Hc,, Hr,, Hs) (a1) where He is Heat loss due to evaporation, Hc is the heat loss/gained by convention, Hr is the heat gained by radiation and Hs is the restored in the body. QL = Ψ(P, c1, c2), (a2) where P is the total energy loss due to radiation, c1 = coefficient of light which depends on the production of heat and c2 = coefficient of electric light (average of 13.0) QE = Ψ(c3, c4, n, m) (a3) where c3, c4 are coefficients for moving electric motor (average of 0.7), residual coefficient (1.0), n = power of motor(maximum of 3000 Watts and m is the motor efficiency ranging from 0.5 kW to 40 kW for efficiency of 70% to 92% respectively. QR = Ψ(Ao, Aos, Lo, Co, S), (a4) where Ao is the effective window area of incoming air, Aos is the area of window exposed to sun’s radiation Lo is total intensity of the sun heating the window, Co is the corrective coefficient ( 1 for a city like Lagos, and1.5 for a rural area) and S is shadow coefficient (ranging from 0.13 to 0.56 of a 45o opened but dark window to translucent semi-dark open 450 illumination) for window glass panel. QV = Ψ (V, Pv, nfa) (a5) where V is the air flow rate given off by ventilator, Pv is the total pressure of ventilation nfa is the ventilation offect on the ventilator (= 0.5)