Biomedical and Bioengineering Design EDUCATION MODULE Part 1: Why Prevention through Design? Bioengineering

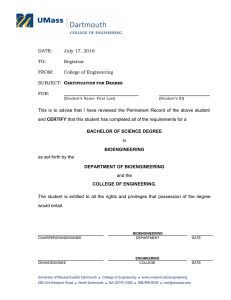

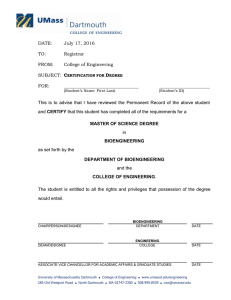

advertisement

[Photo courtesy of Thinkstock] Biomedical and Bioengineering Design Part 1: Why Prevention through Design? EDUCATION MODULE Developed by Denny C. Davis, PhD, PE Howard P. Davis, PhD Washington State University Bioengineering Guide for Instructors Topic Introduction to occupational safety issues, accident data, and “Prevention through Design” (PtD) concept Slide numbers Approx. minutes 5-14 30 Methods for addressing occupational hazards, hierarchy of controls, addressing safety in design 15-19 10 Mechanical risks, needlestick case study (with video) 20-21 15 Hazardous materials case study (with video) 23-24 15 Surgical fires case study (with video) 25 10 Quiz and scoring rubric 26 10 Summary 27 2 Bioengineering Learning Objectives • Explain the Prevention through Design (PtD) concept. • List reasons why project owners may choose to incorporate PtD in their projects. • Recognize differing types of bioengineering workplace hazards. • See Prevention through Design (PtD) as a critical element of a sound business strategy. Bioengineering Overview • Occupational safety and the “Prevention through Design” (PtD) concept • Approaches and considerations when using PtD • Case studies of different types of accidents, related to PtD • Summary and quiz [Photo courtesy of Thinkstock] Bioengineering Introduction to Prevention through Design EDUCATION MODULE Structural Bioengineering Steel Worker Safety and Health • ACTIVITY: In pairs, prepare a list of things you would want presented in workplace safety training. – Types of hazards to expect – Causes of hazards (things to avoid) – Procedures to prevent accidents – – – Protective clothing Protective apparatus Operating procedures [Photo courtesy of Clip Art] – Responses when accidents occur – – – – First aid Where to find help How to minimize injury Reporting • Discuss findings: How important is this safety training to: – – – – Students and technicians in labs? Equipment/instrument fabricators Patients in hospitals or clinics? Engineers in design and development? [Photo courtesy of Clip Art] Bioengineering Worker Safety and Health • ACTIVITY: In pairs, prepare a list of things that can be done (methods) to reduce the number and severity of workplace accidents. – – – – – Post warnings Train in safe operations Wear safety clothing Add safety appliances to equipment Redesign to remove hazard [Photo courtesy of Clip Art] • Discuss findings – What does each method accomplish? – Which method is most effective? Why? Bioengineering Worker Safety and Health • Occupational Safety and Health Administration (OSHA) [http://osha.gov/] – – – – – Part of the Department of Labor Ensures safe and healthful workplaces Sets and enforces standards Provides training, outreach, education, and assistance Note: State regulations possibly more stringent • National Institute for Occupational Safety and Health (NIOSH) [http://www.cdc.gov/niosh/] – Part of the Department of Health and Human Services, Centers for Disease Control and Prevention – Conducts research and makes recommendations for the prevention of work-related injury and illness Bioengineering OSHA Regulations (Standards - 29 CFR*) relevant to biomedical workplaces • • • • • • • • • 1910.1904 Recordkeeping requirements 1910.1030 Bloodborne pathogens 1910.1096 Ionizing radiation 1910.1200 Chemical hazard communication standard 1910.36 Means of egress 1910.900 Ergonomics program 1910 Subpart S Electrical safety standard 1910 Subpart D Walking working standard 1910 Subpart L Fire safety standard * Code of Federal Regulations. See CFR in references. Bioengineering Example: OSHA Regulations (Standards - 29 CFR) 29 CFR 1910.1030 Bloodborne pathogens • 1910.1030(d)(2) Engineering and Work Practice Controls – 1910.1030(d)(2)(i) Engineering and work practice controls shall be used to eliminate or minimize employee exposure. Where occupational exposure remains after institution of these controls, personal protective equipment shall also be used. – 1910.1030(d)(2)(ii) Engineering controls shall be examined and maintained or replaced on a regular schedule to ensure their effectiveness. • 1910.1030(d)(3) Personal Protective Equipment – 1910.1030(d)(3)(i) Provision. When there is occupational exposure, the employer shall provide, at no cost to the employee, appropriate personal protective equipment such as, but not limited to, gloves, gowns, laboratory coats, . . . . Bioengineering Fatality Assessment and Control Evaluation NIOSH FACE Program www.cdc.gov/niosh/face/ Bioengineering Work-related Death from Injury Rate of Fatal Injuries by Sector (2010) Educational and health services Financial activities Information Retail trade Government Rate of work-related deaths from injuries, selected occupations, 2010 Manufacturing Leisure and hospitality Professional and business services Utilities Other services (exc. Public administration) Wholesale trade Construction Transportation and warehousing Mining Agriculture, forestry, fishing and hunting 0 5 10 15 20 25 30 Fatal Injuries per 100 FTE (200,000 hrs) Source: Bureau of Labor Statistics (BLS) 2010a Bioengineering Work-related Death from Injury 1,600 1,400 Deaths per Year 1,200 1,000 Highway incidents 800 Homicides 600 Falls Struck by object 400 Source: Bureau of Labor Statistics (BLS) 1992-2010 200 0 1990 1995 2000 2005 2010 2015 Year Bioengineering Non-fatal Accidents and Illnesses -- Healthcare Social assistance total Nursing care facilities Nursing and residential care facilities total Hospitals total Job Impacted Reported Cases Ambulance services Physicians, outpatient, ambulance total Health care and social assistance total Source: Bureau of Labor Statistics (2010b) 0.0 2.0 4.0 6.0 8.0 10.0 12.0 Number of Occurrences (per 100 FTE) Bioengineering Approaches to Address a Risk ACTIVITY: In pairs, identify a list of criteria that should be used in selecting the best approach to reducing risk. • • • • • Likelihood of preventing a failure or cause for injury Likelihood of reducing or eliminating injury Cost Potential for enhancing comfort of workers Potential for reducing stress of supervisors Discussion • The best approach does all of the above. Bioengineering Judge Alternatives for Reducing Risk of Injury ------------------------- Criteria --------------------------Possible Method Prevent Failure Reduce Injury Reduce Cost Worker Stress Supv Stress Total Put Safeguards in Place +1 +1 -1 -1 0 0 Find a Substitute +1 +1 -1 +1 +1 +3 Personal Protective Equipment -1 +1 -1 +1 -1 Redesign to Remove Hazard +1 +1 +1 +1 +1 +5 Train Workers to Avoid Dangers 0 0 -1 -1 0 -2 -1 Ratings: -1 = bad, 0 = neutral, +1 = good Bioengineering Hierarchy of Controls per ANSI/AIHA Z10-2005 best ELIMINATION best Design it out SUBSTITUTION Use something else ENGINEERING CONTROLS Isolation and guarding ADMINISTRATIVE CONTROLS Training and work scheduling PERSONAL PROTECTIVE EQUIPMENT Control effectiveness Required clothing (Last resort) Business value Slide Adapted from ANSI/AIHA Z10-2005 Bioengineering Occupational safety and health in design process Stage Activities Problem definition Identify specific needs for safety in the solution. Quantify allowable risks Concept selection Identify concepts with potential for safety; evaluate concepts using risk analysis techniques Preliminary design Eliminate hazards, if possible; substitute less hazardous agents/processes; establish risk minimization targets for remaining hazards; assess risk; and develop risk control alternatives Detailed design Select safety controls; conduct process hazard reviews Procurement Develop specifications for procurements; develop “checks and tests” for safety acceptance testing on procured items Prototype fabrication Control fabrication site safety and fabricator safety Preliminary deployment Conduct “checks and tests”; pre-start up safety reviews; develop SOPs; risk/exposure assessment; and management of residual risks Start up and use Education, management of change, modification of SOPs Graphic: Courtesy of Denny Davis Bioengineering Safety Payoff During Design High Conceptual design Detailed design Ability to influence safety Procurement Fabrication Start-up Low Project timeline [Adapted from Szymberski 1997] Bioengineering Examining safety case studies Bioengineering examples of safety risks • For each case, identify the following: 1. Potential accident 2. Potential impacts 3. Candidate actions to alleviate risks Bioengineering Bioengineering safety – mechanical risk • One of the most ubiquitous mechanical risks to workers in biomedical environments is a needle stick injury. • Among health care workers in the United States it is estimated that 600-800 thousand needle stick injuries occur each year 1. • Needle stick injuries can lead to contraction of serious blood borne pathogens. • Needle stick injuries are under-reported. 1. Trim CJ, Elliott TSJ (2003) Bioengineering Bioengineering safety – mechanical risk • View the video 1of a needle stick case study • After viewing the video, brain storm ways PtD concepts could be applied to the problem. • Compare the results of the brainstorming session to the standards found here2:How to Prevent Needlestick and Sharps Injuries Video courtesy of the Centers for Disease Control Bioengineering Bioengineering safety – hazardous materials • Many bioengineering environments involve laboratory settings. There are many hazards that can occur in these settings due to hazardous materials. These can be of biological, chemical, explosive nature or due to their physical size such as nanomaterials. • View the video1 highlighting accidents that have occurred in laboratory settings. Source: U.S. Chemical Safety and Hazard Investigation Board Bioengineering Bioengineering safety – hazardous materials • How could you design a handling process that would eliminate the risk of fire due to pyrophoric materials coming in contact with the air? • What other safeguards should have been in place? • Hazardous materials come in a variety of types including chemical, biological and now nanoparticle materials. There are standards for handling each type. Bioengineering Bioengineering safety – Surgical Fires • View this video from the FDA - Preventing Surgical Fires • Surgical fires are a good example of cascading events where multiple factors coincide to create an accident. • In Bioengineering, the multidisciplinary environment requires being alert to interacting events (originating from different individuals) leading to an unsafe condition Bioengineering QUIZ: What Have You Learned? 1. Define “Prevention through Design” in the context of increasing safety in a workplace environment. 2. List four general ways in which safety can be improved, and order these according to the “hierarchy of controls” for achieving safety. 3. Give three reasons why safety makes good business sense. 4. Explain how embracing “Prevention through Design” might affect what engineers do during the problem definition stage of design. 5. Who is NIOSH and how might NIOSH assist in an engineer’s work? Bioengineering Summary • Accidents don’t just happen. Many elements can impact the risk for an incident. • The most effective way to prevent unsafe conditions is to anticipate them and design them out. • As a bioengineering professional, this is an important responsibility that is part of your job. Bioengineering References Cited in Lesson • CFR. Code of Federal Regulations. Washington, DC: U.S. Government Printing Office, Office of the Federal Register. • BLS [2010a]. Census of Fatal Occupational Injuries Summary, 2010. Fatal occupational injuries by industry and selected event or exposure. Revised CFOI data from 2010. Washington, DC: U.S. Department of Labor, Bureau of Labor Statistics, Safety and Health Statistics Program. [www.bls.gov/iif/oshwc/cfoi/cftb0250.pdf]. • BLS [2002-2010]. Census of Fatal Occupational Injuries Charts, 1992-2010 (revised data). Four most frequent work-related fatal injury events, 1992–2010. Washington, DC: U.S. Department of Labor, Bureau of Labor Statistics, Safety and Health Statistics Program. [www.bls.gov/iif/oshwc/cfoi/cfch0009.pdf]. Bioengineering References Cited in Lesson (continued) • BLS [2010b]. Industry Injury and Illness Data - 2010. Nonfatal (OSHA recordable) injuries and illnesses. Industry incidence rates and counts. Washington, DC: U.S. Department of Labor, Bureau of Labor Statistics, Safety and Health Statistics Program. [www.bls.gov/iif/oshwc/osh/os/ostb2813.txt]. • AIHA [2005]. Occupational health and safety management systems. American Industrial Hygiene Association, Fairfax, VA. ANSI/AIHA Z10-2005. • Szymberski R [1997]. Construction project planning. TAPPI J 80(11):69–74. • Trim CJ, Elliott TSJ [2003]. A review of sharps injuries and preventative strategies. J Hosp Infect 53:237–242. Bioengineering References Cited in Lesson (continued) • CDC [2012] Stop Sticks : Video - NIOSH [Internet]. Available from: http://www.cdc.gov/niosh/stopsticks/video.html • CDC [2012]. NIOSH Publications and Products - Home Healthcare Workers: How to Prevent Needlestick and Sharps Injuries (2012-123) [Internet]. Available from: http://www.cdc.gov/niosh/docs/2012-123/ • Yang L, Mullan B. [2011]. Reducing needle stick injuries in healthcare occupations: an integrative review of the literature. ISRN nursing 2011. • CSB [date unknown]. Video Room Detail, U.S. Chemical Safety and Hazard Investigation Board [Internet]. [cited 2012 Jul 3] Available from: http://www.csb.gov/videoroom/detail.aspx?VID=61. Bioengineering Additional References for Lesson #1 • CDC [2012]. Nanotechnology - NIOSH Workplace Safety and Health Topic [Internet]. [date unknown];[cited 2012 Jul 3] Available from: http://www.cdc.gov/niosh/topics/nanotech/ • CDC [2012]. NIOSH Publications and Products - General Safe Practices for Working with Engineered Nanomaterials in Research Laboratories (2012147) [Internet]. [date unknown];[cited 2012 Jul 3] Available from: http://www.cdc.gov/niosh/docs/2012-147/ • Song Y, Du X, Li X. [2009]. Exposure to nanoparticles is related to pleural effusion, pulmonary fibrosis and granuloma. Eur. Respir. J. European Respiratory Journal; 34(3):559–567. • Rushton E, Jiang J, Leonard S, Eberly S, Castranova V, Biswas P, Elder A, Han X, Gelein R, Finkelstein J, Oberdorster G. [2010]. Concept of Assessing Nanoparticle Hazards Considering Nanoparticle Dosemetric and Chemical/Biological Response Metrics. Journal of Toxicology and Environmental Health, Part A; 73:5–6. Bioengineering Additional References for Lesson #1 (cont’d) • O’Brien N, Cummins E. [2010]. Ranking initial environmental and human health risk resulting from environmentally relevant nanomaterials. Journal of Environmental Science and Health, Part A; 45(8):992–1007. • Pacurari M, Castranova V, Vallyathan V. [2010]. Single- and Multi-Wall Carbon Nanotubes Versus Asbestos: Are the Carbon Nanotubes a New Health Risk to Humans? Journal of Toxicology and Environmental Health, Part A; 73:5–6. • Phillips JI, Green FY, Davies JC, Murray J. [2010]. Pulmonary and systemic toxicity following exposure to nickel nanoparticles. American journal of industrial medicine; 53(8):763–7. • Video Room Detail - U.S. Chemical Safety and Hazard Investigation Board [Internet]. [date unknown]; [cited 2012 Jul 3] Available from: http://www.csb.gov/videoroom/detail.aspx?VID=61. Bioengineering Additional References for Lesson #1 (cont’d) • CDC. NIOSH Pocket Guide to Chemical Hazards (NPG) [Internet]. [date unknown];[cited 2012 Jul 3] Available from: http://www.cdc.gov/niosh/npg/default.html. • CDC. Workplace Safety and Health Topics - Chemicals - NIOSH [Internet]. [date unknown]; [cited 2012 Jul 3] Available from: http://www.cdc.gov/niosh/topics/chemical.html. • CDC. Biosafety in Microbiological and Biomedical Laboratories (BMBL) 5th Edition [Internet]. [date unknown];[cited 2012 Jul 3] Available from: http://www.cdc.gov/biosafety/publications/bmbl5/index.htm. • Mecklem RL, Neumann CM. [2003]. Defining and managing biohazardous waste in U.S. research-oriented universities: a survey of environmental health and safety professionals. J Environ Health; 66(1):17–22.[cited 2012 Jun 29]. Bioengineering Additional References for Lesson #1 (cont’d) • CDC. NIOSH [2009]. Publications and Products - Recommendations for the Selection and Use of Respirators and Protective Clothing for Protection Against Biological Agents (2009-132) [Internet]; [cited 2012 Jul 3] Available from: http://www.cdc.gov/niosh/docs/2009-132/. • CDC. Occupational Exposure to Antineoplastic Agents: Introduction NIOSH Workplace Safety and Health Topic [Internet]. [date unknown]; [cited 2012 Jul 3] Available from: http://www.cdc.gov/niosh/topics/antineoplastic/. • Dreesen DW. [1980]. Identifying biohazards in university research. Am J Public Health 1980 Oct; 70(10):1108–1110.[cited 2012 Jun 29]. • Cocchiarella L, Deitchman SD, Young DC. [2000]. Report of the Council on Scientific Affairs. Biohazardous waste management: What the physician needs to know. American Medical Association. Arch Fam Med 2000 Jan; 9(1):26–29.[cited 2012 Jun 29]. Bioengineering