Inventory Management & Aggregate Planning Assignment Solutions

advertisement

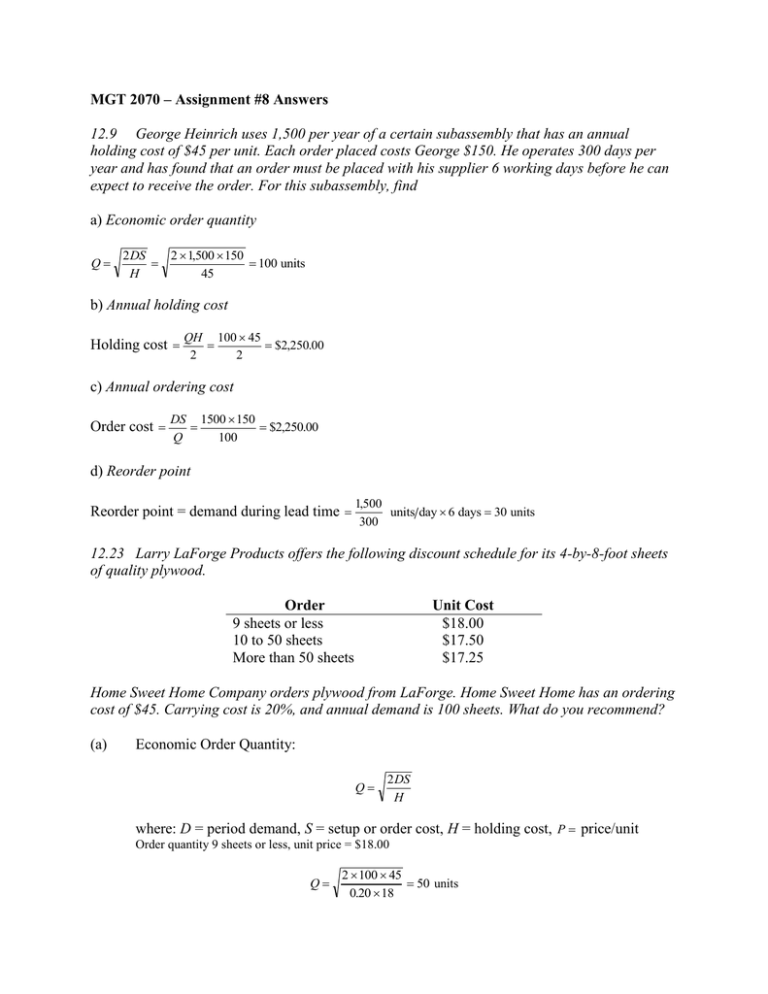

MGT 2070 – Assignment #8 Answers 12.9 George Heinrich uses 1,500 per year of a certain subassembly that has an annual holding cost of $45 per unit. Each order placed costs George $150. He operates 300 days per year and has found that an order must be placed with his supplier 6 working days before he can expect to receive the order. For this subassembly, find a) Economic order quantity Q 2 DS 2 1,500 150 100 units H 45 b) Annual holding cost Holding cost QH 100 45 $2,250.00 2 2 c) Annual ordering cost Order cost DS 1500 150 $2,250.00 Q 100 d) Reorder point Reorder point = demand during lead time 1,500 units day 6 days 30 units 300 12.23 Larry LaForge Products offers the following discount schedule for its 4-by-8-foot sheets of quality plywood. Order 9 sheets or less 10 to 50 sheets More than 50 sheets Unit Cost $18.00 $17.50 $17.25 Home Sweet Home Company orders plywood from LaForge. Home Sweet Home has an ordering cost of $45. Carrying cost is 20%, and annual demand is 100 sheets. What do you recommend? (a) Economic Order Quantity: Q 2 DS H where: D = period demand, S = setup or order cost, H = holding cost, P price/unit Order quantity 9 sheets or less, unit price = $18.00 Q 2 100 45 50 units 0.20 18 Total cost order cost holding cost purchase cost DS QH 100 45 50 0.20 18 PD 18 100 Q 2 50 2 90 90 1,800 $1,980 see note at end of problem re. actual price (b) Order quantity 10 to 50 sheets: unit price = $17.50 Q 2 100 45 50.7 units or 51 units 0.20 17.50 Total cost order cost holding cost purchase cost DS QH 100 45 51 0.20 17.50 PD 17.50 100 Q 2 51 2 88.23 89.25 1750.00 1927.48 (c) Order quantity more than 50 sheets: unit price = $17.25 Q 2 100 45 511 . units or 51 units 0.20 17.25 Total cost order cost holding cost purchase cost DS QH 100 45 51 0.20 17.25 PD 17.25 100 Q 2 51 2 88.24 87.98 1,725.00 $1,90122 . Therefore, order 51 units. Note: Order and carrying costs are not equal due to rounding of the EOQ to a whole number. 13.3 The president of Daves Enterprises, Carla Daves, projects the firm’s aggregate demand requirements over the next eight months as follows: Jan Feb Mar Apr 1,400 1,600 1,800 1,800 May June July Aug 2,200 2,200 1,800 1,400 Her operations manager is considering a new plan, which begins in January with 200 units on hand and ends with zero inventory. Stockout costs of lost sales is $100 per unit. Inventory holding cost is $20 per unit per month. Ignore any idle-time costs. The plan is called plan A. Plan A. Vary the workforce level to execute a “chase” strategy by producing the quantity demanded in the prior month. The December demand and rate of production are both 1,600 units per month. The cost of hiring additional workers is $5,000 per 100 units. The cost of laying off workers is $7,500 per 100 units. Evaluate this plan. Month Dec Jan Feb Mar Apr May Jun Jul Aug Demand 1400 1600 1800 1800 2200 2200 1800 1400 Production 1600 1200 1600 1800 1800 2200 2200 1800 1400 Hire Fire Cost 400 $30,000 $20,000 $10,000 $0 $20,000 $0 $30,000 $30,000 $140,000 400 200 400 400 400 Total cost for the plan is $140,000. Note that we do not attempt to include the costs of production – we assume that production costs are the same between all three plans and can therefore be cancelled out in any comparison. Also note that in January, we must incur the firing cost to move from a production level of 1600 to one of 1200. 13.4 Using the information in problem 13.3, develop plan B. Produce at a constant rate of 1,400 units per month, which will meet minimum demands. Then use subcontracting, with additional units at a premium price of $75 per unit. Evaluate this plan by computing the costs for January through August. Month Dec Jan Feb Mar Apr May Jun Jul Aug Demand Production 1400 1600 1800 1800 2200 2200 1800 1400 1400 1400 1400 1400 1400 1400 1400 1400 Ending Inv. 200 200 0 0 0 0 0 0 0 Subcontract Cost 400 400 800 800 400 $4,000 $0 $30,000 $30,000 $60,000 $60,000 $30,000 $0 $214,000 Total cost for the plan is $214,000. Note that the cost for January is to carry over the 200 extra units in inventory for a month. In February, the inventory is used up. 13.5 Daves is now considering plan C. Beginning inventory, stockout costs, and holding costs are provided in Problem 13.3. a) Plan C. Keep a stable workforce by maintaining a constant production rate equal to the average requirements and allow varying inventory levels. The average requirement is found by summing the total demand from January through August, and dividing the result by 8 months to find 1,775 units per month. Month Dec Jan Feb Mar Apr May Jun Jul Aug Demand Production 1400 1600 1800 1800 2200 2200 1800 1400 1775 1775 1775 1775 1775 1775 1775 1775 Ending Inv. 200 575 750 725 700 275 0 0 375 Stockout 150 25 Cost $11,500 $15,000 $14,500 $14,000 $5,500 $15,000 $2,500 $7,500 $85,500 Total cost for the plan is $85,500. We would recommend plan C over plan A or B. b) Plot the demand with a graph that also shows average requirements. Conduct your analysis for January through August. 2,200 2,100 2,000 1,900 1,800 1,775 1,700 1,600 1,500 1,400 0 Jan Feb Mar Apr May Jun Jul Aug