Strategic Engineering Change Propagation Analysis in Complex Systems

advertisement

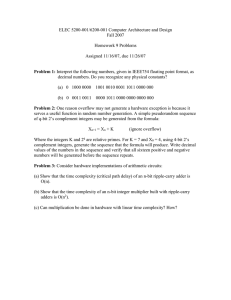

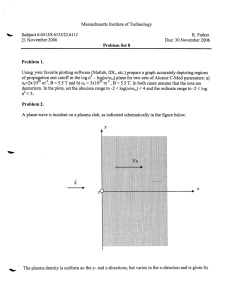

Version 2 Strategic Engineering Designing Systems for an Uncertain Future Change Propagation Analysis in Complex Systems October 7, 2008 Olivier L. de Weck, Ph.D. deweck@mit.edu Associate Professor of Aeronautics and Astronautics and Engineering Systems © Olivier de Weck, Oct 2008 Page 1 Strategic Engineering – “the big picture” technology http://strategic.mit.edu markets regulations flexibility real options commonality platforms System Architecture concept Design for Changeability Temporal Dimension Integrated Modeling and Simulation performance, cost, risk changes Design for Commonality Spatial Dimension standardization Multidisciplinary Design Optimization uncertainty variety “optimal” design more than one variant of the at t=to+Dt requirements change x* at t=to system is needed: x1*, x2, … xn and x* is no longer optimal © Olivier de Weck, Oct 2008 Page 2 F/A-18 Center Barrel Section Y453 Y470.5 Y488 Wing Attachment 74A324001 © Olivier de Weck, August 2008 Page 3 F/A-18 Complex System Change F/A-18 System Level Drawing Fuselage Stiffened Original Change Flight Control Software Changed Manufacturing Processes Changed Center of Gravity Shifted Gross Takeoff Weight Increased © Olivier de Weck, August 2008 Page 4 Change Propagation Analysis in Complex Systems Problem Addressed Understanding change propagation patterns in large technical projects involving hardware, software and human operators Scientific Contribution Developed procedure for data-mining of a large change request database (9 years, 41,500 changes) and analyzing change patterns (“motifs”) as well as classification of system components with a Change Propagation Index (CPI) Outcome, Impact Applied to a large USAF Radar System project at Raytheon. Identified areas that are likely candidates for flexibility infusion Giffin M., de Weck O., Bounova G., Keller R., Eckert C., Clarkson J., “Change Propagation Analysis in Complex Technical Systems”, DETC2007-34652, ASME 2007 Design Engineering Technical Conferences, DETC2007-34871, Las Vegas, NV, September 4-7, 2007 In Press: ASME Journal of Mechanical Design Sponsor: Raytheon Integrated Defense Systems © Olivier de Weck, Oct 2008 Page 5 System Description Complex Sensor System 46 Areas (“Subsystems”) Complex sensor system, complex hardware, software, human operators Derivative of earlier system 9 Year development Hardware Software Program Documentation System Map (graph) Interconnections between areas © Olivier de Weck, Oct 2008 Page 6 Data Set Typical Change Request Change Request Database technical, managerial, procedural track parent, child, siblings by areas with unique ID number chronologically numbered IDs Data Mining Procedure Export from DBMS to text file Written into MySQL database with Perl scripts Equivalent to a MS Word document with 120,000 pages Sorting, Filtering, Anonymizing Write simplified change request format (see right side) ID Number 12345 Date Created Date Last Updated 06-MAR-Y5 10-JAN-Y6 Area Affected 19 Change Magnitude 3 Parent ID 8648 Children ID(s) 15678, 16789 Sibling ID(s) 9728 Submitter eng231 Assignees eng008 eng231 eng018 Associated Individuals Admin_001 Engineer_271 Stage Originated, Defect Reason [blank], [blank] Severity [blank] Completed? 1 © Olivier de Weck, August 2008 Page 7 Change Networks Apply Graph Theory to extract networks of connected changes parent-child changes sibling changes Most changes are only loosely connected 2-10 related changes Some large networks emerged Question: do these networks emerge from a single initial change? (rank) (connected changes) 1 2579 2 424 3 170 4 87 5 64 © Olivier de Weck, August 2008 Page 8 Change Propagation Network Network plot of largest change network in the dataset, with 2579 associated change requests. © Olivier de Weck, August 2008 Page 9 Mapping Changes to affected subsystem areas 30143 27585 28187 28213 28122 28007 28166 30344 28153 27027 28695 23942 28567 28788 28790 28878 23945 28528 27656 30465 28531 23024 28009 28186 26331 23729 28067 23922 32289 29826 29353 26333 30148 28428 23992 2716924980 29538 30614 29547 28846 29399 27627 28821 29711 27023 30771 28529 30126 23821 29226 29731 30548 30466 30501 31471 23925 24781 29227 23831 28696 25481 8000 22850 31973 24927 25476 29744 System Network Map 28162 30503 25053 24659 25515 28601 31972 27952 32645 31966 24926 25463 12156 22946 31235 27592 31967 13320 26117 Change Propagation Network © Olivier de Weck, August 2008 Page 10 Change Propagation Index (CPI) change propagation probability Classify each area Absorber, Carrier, Multiplier instigating area pij cij ( parent ) cij ( sibling ) Ctot ( j ) total completed changes in Area j DDSM Change Propagation Frequency Area 1 2 3 4 5 6 1 0.4843 0.0011 0.0136 0.0057 0.0125 0.0023 2 0.0061 0.0000 0.0000 0.0030 0.0000 0.0000 3 0.0173 0.0000 0.1053 0.0050 0.0012 0.0000 4 0.0224 0.0000 0.0112 0.0449 0.0000 0.0000 5 0.0137 0.0000 0.0000 0.0000 0.1262 0.0000 6 0.0417 0.0000 0.0000 0.0000 0.0000 0.0833 A change in Area 1 caused changes in Area 6 with a frequency of 4.17%. Cout (i ) receiving area Cin (i ) N pij Ctot ( j ) j 1 N p ji Ctot (i ) j 1 CPI (i ) Cout (i ) Cin (i ) Cout (i ) Cin (i ) -1 <= CPI <= +1 © Olivier de Weck, August 2008 Page 11 System Area Classification CPI Spectrum Areas found to be strong multipliers 16: hardware performance evaluation 25: hardware functional evaluation 5: core data processing logic 32: system evaluation tools 19: common software services 3: graphical user interface (GUI) Areas found to be perfect reflectors 27, 41: look like perfect absorbers but actually zero changes implemented despite numerous changes proposed = perfect reflectors © Olivier de Weck, August 2008 Page 12 Change Request Generation Discovered new change pattern: “inverted ripple” Change Requests Written per Month 1500 system integration and test 1200 bug fixes 900 subsystem design 93 89 81 69 65 61 57 53 49 45 41 37 33 29 25 21 17 13 9 5 0 77 300 73 component design 85 major milestones or management changes 600 1 Number Written [Eckert, Clarkson 2004] Month © Olivier de Weck, August 2008 Page 13 Insights Inverse relationship between change magnitude and frequency of occurrence Many change requests are never implemented Large changes are infrequent, small ones are ubiquitous Some are rejected, others are ignored (~ 50%) Changes may form complex networks over time. Most are small (<10 changes), a few large ones exist (beware of these !) Change networks form through coalescence and not necessarily through multistep causal change propagation Changes can propagate between areas that are not direct neighbors in the system DSM (not shown here, but we found this is so) Subsystems can be classified as: Multipliers CPI > ~0.3 Carriers -0.1<CPI<1.0 Absorbers CPI<-0.3 Reflectors of Change CRI>CAI Acceptors of Change CAI>CRI Analysis of change database revealed that Real world change processes more complex than expected Industry data tends to be “noisy” Potential for deriving change impact and likelihood for future projects © Olivier de Weck, August 2008 Page 14 Future Work Change Prediction: Data Processing: Analyze effects of staffing on changes and components Patterns based on which personnel/organization work on the changes? Contractual: Standardize methods for recording and processing data, tracing large change networks in greater depth- attempt to reconstruct logic Staffing and Organization: How good are our predictions regarding actual versus planned effort? How can change propagation patterns observed on past projects be leveraged for future design decisions (e.g. modularity, flexibility) Can change propagation be used to write better prime and sub-contracts? Statistical: Are there critical numbers for change propagation? Limits on the number of propagation steps? . CMI-Sponsored Workshop on Engineering Change MIT Endicott House, October 30-31, 2008 ~ 12 firms from various industries (aerospace, auto, printing, construction) © Olivier de Weck, August 2008 Page 15 Cambridge-MIT-Institute (CMI) Engineering Change Twin Workshops Trinity Hall College, UK University of Cambridge April 7-8, 2008 MIT Endicott House, USA October 29-31, 2008 Reasons for Change Problems discovered during production and operations in the field such as retrofits, recalls ….(melioration) Customization of product variants for different customers and market segments (globalization) Infusion of new technologies during product refreshes or major “block” upgrades (innovation) Cost reduction Initiatives, response to new features introduced by other firms (competition) New government regulations (e.g. fuel economy standards, no lead in electronics …(compliance) Others ….? Workshop Goals Obtain multi-faceted industry perspective on state-of-the art in engineering change practice Present academic perspective and recent research advances to industry Establish a research agenda for the next 5 years Put in place basis for Special Issue of RED* Stimulate interest in follow-up collaboration Establish user community for advanced engineering change methods and tools * Research in Engineering Design (RED) Journal Invited Companies US UK Rolls Royce (A/C Engines)* Perkins (Diesel)* Volvo (Trucks, Engines)* BAE Systems (Defense)* Bosch (Auto Supplier)* BMW (Cars)* BP (Oil & Gas)* MAN Roland (Printing Systems) Arup (Construction) *attended April 2008 Xerox (Printing Systems) Ford, GM (Cars and Trucks) Agusta Westland (Helicopters) Boeing (Aircraft) General Mills (Food) Fluor (Construction) Mack (Highway Trucks) Gerber (Textile Machines) NASA (Spacecraft) Raytheon (Defense Systems) Ventana Systems (S/W) Aberdeen Group United Technologies Corp. Strategic Engineering Strategic Engineering is the process of designing systems and products in a way that deliberately accounts for customization and future uncertainties such that their lifecycle value is maximized. © Olivier de Weck, August 2008 Page 20