An Aggregate Planning Example Month

advertisement

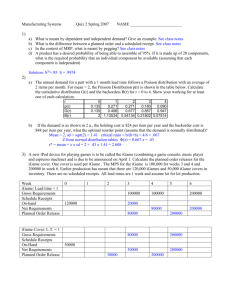

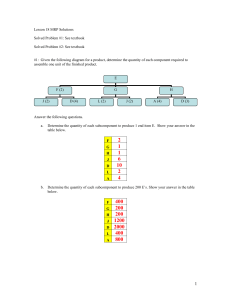

An Aggregate Planning Example The Stampede Popcorn Company has forecasted demand for the next six months as follows: Month Expected Demand (cases) Production Days Sep 210 22 Oct 180 21 Nov 220 22 Dec 350 18 Jan 500 19 Feb 400 21 The company also knows that it has the following costs: Inventory Carrying: Labour-hours to produce a case: Average pay rate: Overtime pay rate: $4 per case per month 1.2 hours per case $8 per hour ($64 per day) $10 per hour The company wants to analyse three different aggregate plans. Plan 1: maintain a constant workforce throughout the six month period, with no layoffs and no overtime. Average Requirement = Total Expected Demand Number of Production Days = Assuming beginning inventory = 0 and planned ending inventory = 0, what will happen each month? Month Production Demand Inventory Ending Inventory Forecast Change Sep Oct Nov Dec Jan Feb = Labour hours required per day = 1.2 hours per case x Workforce required = Costs Inventory = Labour = Total = Plan 2: Maintain workforce at a constant level to meet the lowest demand month, and meet all demand above this level by subcontracting. The subcontracting cost to produce a case is $20. Lowest demand month is: Daily Demand = Monthly Demand / Production Days = Total Labour Hours = Workforce required = In house production = Subcontract units = Costs Labour = Subcontracting = Total = Plan 3: The workforce size will be varied by hiring and firing, and the production rate will equal demand. The cost of increasing the production rate (ie training and hiring) is $15 per extra unit produced. The cost of decreasing the production rate (ie layoff) is $10 per unit not produced. Month Forecast Sep Production Cost Hiring Cost Layoff Cost Total Cost Oct Nov Dec Jan Feb An MRP Example The components for the Awesome speaker kit are shown in the diagram below: Question 1: How many of each component are required to produce a new order of 50 Awesome Speaker kits? Part A: Part B: 2 x number of As = Part C: 3 x number of As = Part D: 2 x number of Bs + 2 x number of Fs = Part E: 2 x number of Bs + 2 x number of Cs = Part F: 2 x number of Cs = Part G: 1 x number of Fs = Question 2: Given the lead times shown in the table, contract a gross material requirements plan and draw up a production schedule that will satisfy the demand for 50 Awesome speaker kits by week 8. Component: Lead Time (weeks): A 1 1 B 2 2 C 1 D 1 E 2 3 4 5 F 3 6 A. Required Order Release B. Required Order Release C. Required Order Release E. Required Order Release F. Required Order Release D. Required Order Release G. Required Order Release G 2 7 9 Lead Time 1 week 2 weeks 1 week 2 weeks 3 weeks 1 week 2 weeks Question 3: The company has the on-hand inventory shown in the table below. Construct a net requirements plan. Component: On Hand: A 10 B 15 C 20 D 10 E 10 F 5 G 0 Lot Size Lead Time On Hand Item ID A B C E F D G 1 Gross Requirements Projected On Hand Net Requirements Planned Order Receipts Planned Order Releases Gross Requirements Projected On Hand Net Requirements Planned Order Receipts Planned Order Releases Gross Requirements Projected On Hand Net Requirements Planned Order Receipts Planned Order Releases Gross Requirements Projected On Hand Net Requirements Planned Order Receipts Planned Order Releases Gross Requirements Projected On Hand Net Requirements Planned Order Receipts Planned Order Releases Gross Requirements Projected On Hand Net Requirements Planned Order Receipts Planned Order Releases Gross Requirements Projected On Hand Net Requirements Planned Order Receipts Planned Order Releases 2 3 4 5 6 7 8