Laboratory Safety Training University of Massachusetts - Dartmouth

advertisement

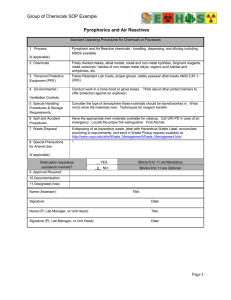

University of Massachusetts Dartmouth Laboratory Safety Training Environmental Safety & Health Public Safety Purpose This presentation provides faculty, staff and students with important information regarding the use of hazardous chemicals in the workplace. If you are receiving this training it means that you work with these chemicals. Discuss any questions regarding the proper handling and disposal of chemicals with your supervisor. Environmental Safety & Health If you have questions regarding this presentation on Laboratory Safety you may contact Amy Pacheco: x6912 or akampersol@umassd.edu Robert Casparius: x8176 or rcasparius@umassd.edu Training Outline Federal Laboratory and HazCom Standards Material Safety Data Sheets (MSDS) Administrative Procedures Chemical Toxicology Engineering Controls Personal Protective Equipment (PPE) Emergency Procedures (Spills) Chemical Storage/Disposal Working Safely With Chemicals Defined under two Occupational Safety and Health Administration (OSHA) regulations Hazard Communication Standard 29 CFR 1910.1200 Promulgated 25 November 1983 Occupational Exposure to Hazardous Chemicals in Laboratories 29 CFR 1910.1450 Promulgated 1 May 1990 Hazard Communication Purpose To ensure that the hazard of all chemicals are evaluated and that the information is transmitted to employees; in this case the faculty, staff and students at the University. Accomplished via: Container labeling Material Safety Data Sheets (MSDS) Employee training Occupational Exposure to Chemicals in the Laboratory Purpose Provide employees with the necessary tools to protect themselves and their co-workers. Accomplished via: Knowledge Administrative Procedures Engineering Controls Personal Protective Equipment (PPE) Staff and Student’s Responsibility Comply with all laboratory safety policies and procedures while working in the laboratory When in doubt about a particular safety policy or procedure ask the Principal Investigator or Laboratory Supervisor Staff and Student’s Responsibilities (continue) Attend training classes Learn the chemical hazard by reading the MSDS Know the signs and symptoms of exposure Know the proper personal protective equipment (PPE) to use Know emergency procedures Principal Investigator’s Responsibility Provide staff and students access to MSDSs for all chemicals used in the laboratory Ensure that all staff and students comply with laboratory safety policies and procedures while working in the laboratory Ensure that all safety equipment is available for use and working properly Responsibility of Environmental Safety & Health Provide Policies and Procedures for the safe use, storage and disposal of hazardous materials Provide MSDS upon request Conduct periodic training Conduct periodic laboratory inspections UMD Safety Policy and Procedures (Future) Laboratory Safety Plan Hazardous Communication Program Hazardous Waste Management Exposure Control Plan Personal Protective Equipment Emergency Procedure Guide Chemical Hygiene Plan A program documenting procedures, personal protective equipment, and work practices that are capable of protecting the employee from the health hazards used in that particular work place. Keep exposure levels below the permissible exposure limit (PEL). Intended to comply with OSHA Standard 29 CFR 1910.1450 Employee Rights Request and obtain information on hazardous chemicals in your workplace. Be informed of hazardous chemicals you come in contact with on your job. Access to written material. MSDS Chemical Hygiene Plan Hazardous Communication Material Safety Data Sheets (MSDS) A document provided by the manufacturer that contains information on the potential hazards and how to work safely with the chemical product. Should be able to provide one to any inspector or person who asks. Common website: www.hazard.com Example: Bleach Material Safety Data Sheets (MSDS) Manufacturer’s Info Name, address and phone number Common names Hazardous Ingredients Hazard Characteristics Routes of entry Physical hazards Health hazards First Aid Measures Fire Fighting Measures Accidental Release Handling and Storage Exposure Control Personal Protective Equipment Acceptable Exposure Levels Chemical Information/Toxicology OSHA Requirement Chemical manufacturers or importers shall ensure that distributors and employers are provided an appropriate material safety data sheet with their initial shipment, and with the first shipment after a material safety data sheet is updated; The employer shall maintain in the workplace copies of the required material safety data sheets for each hazardous chemical, and shall ensure that they are readily accessible during each work shift to employees when they are in their work area(s). (Electronic access, microfiche, and other alternatives to maintaining paper copies of the material safety data sheets are permitted as long as no barriers to immediate employee access in each workplace are created by such options.) Sources of MSDS The company providing the chemical Fisher Scientific Sigma-Aldrich On-Line Sources Fisher Scientific Hazard Sigma-Aldrich NFPA Diamond Blue – Health Red – Flammability Yellow – Reactivity White – Special Hazards NFPA Diamond Health (blue) 0 to 4 where 0 is no hazardous and 4 most hazardous Fire (red) 0 to 4 where 0 is not flammable and 4 extremely flammable Reactivity (yellow) 0 to 4 where 0 is not reactive and 4 is explosive Special Hazards: Water Reactive Radioactive Alkaline Acid Corrosive Oxidizing Labeling Manufacture label Chemical name Appropriate warnings. Name and address of manufacturer. In-house label Chemical name Date Appropriate warnings Your name Labeling and the NFPA Diamond Signs (Entrance to Lab) Signs (Laboratory Refrigerator) Signs on Cabinets Hazards at UMASS-Dartmouth Health Hazards Acute Health Effects Immediate Examples: burns, headache, vomiting, nausea Chronic Health Effects Long Term Examples: Carcinogens: Acrylamide Mutagens: Sodium Azide, Ethidium Bromide Teratogens: Organic mercury compounds Chemical Toxicology Toxicology is the study of how chemicals cause undesirable effects on humans. Signs and Symptoms of Exposure Know the signs and symptoms associated with exposure to the chemicals in your workplace. Be observant for these signs and symptoms. Know what to do if you are exposed. Chemical Toxicology Routes of Entry Inhalation Absorption Ingestion Injection Chemical Toxicology Inhalation The most common route of exposure. Can be in the form of a gas, vapor or dust. Example: Formaldehyde Can be deposited in the airways or absorbed through the lungs and into the blood stream. Blood can then circulate the toxin to the rest of the body. Chemical Toxicology Absorption Skin acts as a barrier between the environment and the organs of the human body. Skin can be attacked directly. Examples: Acids and Bases Skin can be penetrated. Examples: Phenol, Nitrobenzene Chemical Toxicology Ingestion Rarely takes place by deliberate swallowing of toxic substances. Food and drinks can become contaminated by dust, mist and fumes. Dust on hands, face and clothing can get into the mouth by licking one’s lips or wiping one’s face. Chemical Toxicology No eating or drinking in laboratories or storing food in laboratory refrigerators or cold rooms. Chemical Toxicology Injection Occurs through accidental needle sticks, puncture wounds or through broken skin / open wounds. May produce rapid response when injected because the chemical / toxin is introduced directly into the blood stream. Personal Protective Equipment Examples of PPE Lab Coat Aprons Gloves Safety Glasses Face Shields Booties Respirators Minimum PPE Lab Coat Gloves Safety Glasses Personal Protective Equipment Lab Coats and Aprons Personal Protective Equipment Gloves Latex and Nitrile Personal Protective Equipment Safety Goggles and Glasses Respirator Use Requirements for wearing a respirators Have a physical Be fit-tested for the respirator Be trained in the proper use of the respirator Engineering Controls Ventilation Room air exchanges Local ventilation Fume Hoods BioSafety Cabinet Glove Boxes Containments Flammable and Acid Cabinets Secondary Containment Air Exchange Definition: Refers to the rate at which outside replaces indoor air in a building, expressed in either air changes per hour (ACH) cubic feet per minute (cfm). Local Ventilation A local source of ventilation is used over equipment that may give off a gas, fume or dust. Similar to a fan over a stove to remove smoke from cooking food. Fume Hood An enclosed area with a local exhaust used for working with chemicals that have the potential to give off fumes. dust or gases. Fume hoods should be check for operability, sash height and annual certification prior to use. BioSafety Cabinet Used for working with biological agents to protect the researcher from the agent. Filters airborne contaminants before exhausting air. Confirm operability and annual inspection prior to use. Glove Box Chemical Storage Acid Storage Flammable Storage Secondary Containment Gas Cylinders Use local ventilation for hazardous gases Secure tank to wall or bench Ensure there are no kinks in hose Close valve remove regulator and attach a cap to cylinder prior to moving it Secure Gas Cylinder Cryogenics Do not transfer to open container and transport Wear personal protective equipment prior to transferring liquid from Dewar Gloves Face Shield & Safety Glasses PPE for work with LN Eye Protection Full face shield with safety goggles is best Heavy, loose fitting leather or cryogenic gloves Lab coat Long Pants – no cuffs to avoid spill collection Closed toe shoes Do not tuck pants into shoes/boots Electrical Safety Ground Fault Interrupter Used near sources of water, such as bathroom sinks Protects people Circuit breaker is a property protector Extension cords vs power strips Transporting Chemicals Use two hands when carrying chemicals or A chemical carrier Emergency Procedures Spills (chemical or radioactive) Small (less than or equal to 500 ml) Large Personal Contamination Gas Leak (flammable, toxic corrosive, oxygen) Explosion Fire Small Spill Attempt to contain the spill with absorbent or paper towels to keep it from spreading Control access to the affected area Contact professor or Principal Investigator If need be contact EH&S at x8176 Take Steps to clean spill, wearing the appropriate PPE Large Spill Remain calm. Protect yourself and colleagues from harm If the large spill is not deemed dangerous to occupants of the laboratory Contain the spill and control access to the area Contact your professor or Principal Investigator Contact ES&H at x8176 Large Spill If deemed dangerous to the laboratory occupants, exit the lab and confine the spill or fumes by closing the lab door If necessary, pull fire alarm to evacuate the building Call UMASS Public Safety x9191 Spill Cleanup Personal Contamination Remain calm Protect yourself and your colleagues from further harm Wash any chemical or radioactive material off for >15 minutes If necessary use emergency showers/eyewash stations Personal Contamination Seek medical attention if needed If necessary call Public Safety at x9191 Contact your professor or Principal Investigator Contact EH&S at x8176 Emergency Shower Eyewash Station Check Operability Eye wash and showers. Department must check for operability. Need to be down weekly. Gas Leak If a person notices a gas leak and deems it dangerous to laboratory occupants Evacuate the lab and confine by closing the door If need be, pull fire alarm to evacuate the building Report leak to your Department Chair who contact Facilities Gas Leak If found to be limited in extent and reasonably safe, attempt to shut off source of gas leak If the gas leak continues after shutting off valve contact Facilities to repair spigot In the Event of a Fire Know ahead of time where to exit the building in the event of a fire Activate the fire alarm system Exit the building via one of the designated exits Fire Safety and PASS Pull: Pin from handle Aim: Fire extinguisher Squeeze: Handle to release agent Sweep: Fire extinguisher at fire Chemical Storage / Disposal Do not evaporate chemicals in the fume hood Do not mix incompatible chemicals Use the proper waste container Rinse empty bottles and deface label Label all chemical waste Storage of Chemicals Write the date received on new chemical containers coming into the lab Do not store chemicals on the floor Do not store liquid chemicals on shelves where you have to reach above your head for them Return chemicals to the appropriate storage location after use Do not store incompatible chemicals together Chemical Compatibility If there is any doubt regarding the possible reaction, don’t mix chemicals Examples of incompatible chemicals Flammables and acids Chlorates and ammonia salts Nitric acid and acetic acid Sodium metal and water NIOSH website: School Chemistry Laboratory Safety Guide Appendix E – Incompatible chemicals http://www.cdc.gov/niosh/docs/2007-107/appendixE.html Cabinets Storage of Acids Storage of Flammables Refrigerator •Do not store flammables in a standard refrigerator. •Do not store food, beverages or ice for human consumption in refrigerators. •Label refrigerator doors with a warning label about not storing food in it. Minimizing waste generation Order only the amount of chemical required for the experiment. Excessive stocks of hazardous chemicals, radioactive material and infectious agents presents serious storage, safety and disposal problems. Try to find non-hazardous alternatives to conduct your research. Waste Types Hazardous: chemicals Medical: items contaminated with biological agents, toxin, blood or body fluids Universal: florescent lights, computers and monitors Radioactive: P-32, C-14, Uranium Identifying Waste Proper laboratory waste disposal begins at the experimental design stage. When evaluating the experiment to be performed consider the types of waste that will be generated in procedure. If in doubt ask your Principal Investigator or laboratory supervisor Contact EH&S for assistance Satellite Accumulation Area Satellite Accumulation Area Area must be posted Caps must be secure on bottles when not transferring waste to container Containers must be stored within a designated secondary container Must be at or near the point of generation and under the control of the trained person directly responsible for the waste. Container Management Container must be compatible with the waste that is stored in it. Incompatible containers must be segregated. Containers must be in good condition, not ruptured or leaking. Container Labeling All containers must be labeled with a UMASS DARTMOUTH Hazardous waste label. Hazardous waste labels must be clearly visible and legible. Information on the Label All hazardous constituents (no formulas or abbreviations). The chemical’s associated hazards (e.g. “corrosive, ignitable”) The date the container becomes full and ready for pickup. The building/laboratory information found at the bottom of the tag. Documentation Hazardous waste pickup Routine pickups on Tuesdays Call 1-508-999-8242 or 1-978-547-9851 Hazwaste@umassd.edu What is wrong with these pictures What is wrong with these pictures What is wrong with these pictures What is wrong with these pictures Unlabeled Containers What is wrong with these pictures What is wrong with these pictures What could be wrong with these pictures Open Bottles found in lab Chemical Storage Room Environmental Safety & Health Tel. # 8176