Week 5 3.1 Introduction:

advertisement

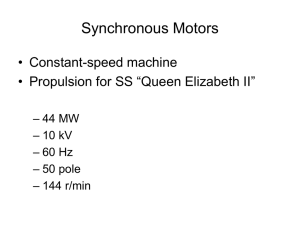

3. Synchronous machine Week 5 3.1 Introduction: Synchronous motors are motors that always run at the same speed regardless of load. Synchronous motors are somewhat more complex than squirrel-cage and wound rotor motors and, hence, are more expensive. There is no slip in a synchronous motor, that is, the rotor always moves at exactly the same speed as the rotating stator field.. The machine consists of three main parts: Stator, which carries the three phase winding, Rotor, with one DC winding or permanent magnets Slip rings or excitation machine (exciter) (in case of electrical excitation). Synchronous motors are used whenever exact speed must be maintained or for power factor correction. Synchronous motors are more expensive than other types for the lower horsepower ratings, but may possibly be more economical for 100 hp and larger ratings. 3.2 Stator construction: The stator of a synchronous generator holds a three-phase winding where the individual phase windings are distributed 120° apart in space and is sometimes called the armature winding. The stator must be made of laminated iron sheets in order to reduce eddy currents. 3.3 Rotor construction: The rotor holds a field winding,which is magnetized by a DC current( the field current). The rotating field winding can be energized through a set of slip rings and brushes (external excitation), or from a diode-bridge mounted on the rotor (self-excited). The rectifier-bridge is fed from a shaft-mounted Metal frame Laminated iron core with slots Insulated copper bars are placed in the slots to form the three-phase winding alternator, which is itself excited by the pilot exciter. In externally fed fields, the source can be a shaftdriven dc generator, a separately excited dc generator, or a solid-state rectifier. Several variations to these arrangements exist. There are two types of rotors: Salient-pole rotor (Fig.2) for low-speed machines (e.g.hydro-generators) Cylindrical rotor (Fig.3) for high-speed machines (e.g. turbo-generators). 1 3. Synchronous machine Week 5 3-Phase Stator Winding Rotor Field Winding Brushes - + Slip Rings Cylindrical Pole Rotor Field current a- Schematic diagram showing a cylindrical rotor of a synchronous machine Steel retaining ring Shaft Shaft Wedges DCcurrent current DC terminals terminals b- cylindrical rotor of a synchronous machine Figure3.1: cylindrical rotor of a synchronous machine 2 3. Synchronous machine Week 5 3-Phase Stator Winding Rotor Field Winding Brushes - + Slip Rings Salient Pole Rotor Field current a- Schematic diagram showing a salient-pole rotor of a synchronous machine Slip rings Pole Fan DC excitation winding b- salient-pole rotor of a synchronous machine Figure3.2: Salient-Pole rotor of a synchronous machine 3.4 Principle of operation of the synchronous generator: When the 3phase rotor is rotated (by an external prime-mover) the rotating magnetic flux(induced by DC current) induces voltages in the stator windings. These voltages are sinusoidal with a magnitude that depends on the field current, and also differ by 120° in time and have a frequency determined by the angular velocity of the rotation. 3.5 Principle of operation of the synchronous motor: The stator is supplied with three phase supply in order to develop a rotating magnetic field. Also the rotor is supplied with DC supply to produce constant magnetic field. As a result of the interaction of these two fields, the rotor will start to move. However, the synchronous motor is not self started. Consequently, it usually equipped with squirrel cage windings that mounted on the pole faces of the synchronous motor rotor. These rotor windings 3 3. Synchronous machine Week 5 are frequently referred to as damper or amortisseur windings. Thus, the synchronous motor starts as an induction motor. When the motor accelerates to near synchronizing speed (about 95% synchronous speed), DC current is introduced into the rotor field windings. This current creates constant polarity poles in the rotor, causing the motor to operate at synchronous speed as the rotor poles "lock" onto the rotating AC stator poles. 3.6 Excitation Methods Two methods are commonly utilized for the application of the direct current (DC) field current to the rotor of a synchronous motor. Brush-type systems apply the output of a separate DC generator (exciter) to the slip rings of the rotor. Brushless excitation systems utilize an integral exciter and rotating rectifier assembly that eliminates the need for need for brushes and slip rings. 3.7 Method of Synchronization There are three basic method of synchronizing two or more machine: . Bright lamp method . Dark lamp method . automatic method 4