INTRODUCTION TO AUTOCAD 1 WEEK (13)

advertisement

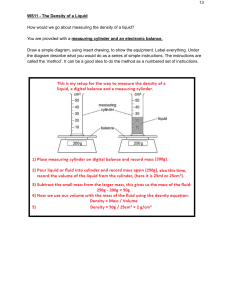

INTRODUCTION TO AUTOCAD 1 TECHNICAL DRAWING MEC 112 week 1 WEEK (13) 13.0: SURFACE DEVELOPMENT 13.1: Introduction Many articles such as cans , pipes , elbows , boxes , ducts , hoppers , etc. , are manufactured from sheet metals. Generally a template of their original flat shape is firstly produced; this forms an orthogonal drawing . Also the template includes allowances for bending and seam , bearing , in mind the thickness of material used . Surface development methods: There are basic methods of pattern development . - the parallel line method the radial line method . the triangulation method . choosing a method depends totally on the shape of the product to be produced and can be seen through examples . 1) Right cylinder To develop a pattern for a right cylinder , it is important to understand that, practically , a cylinder is regarded as a multi-sided prism with circle base. To develop a pattern means to unroll the sheet as shown in Fig.(25) To develop a pattern , the following steps are to be followed : 1- Draw front and top views of the cylinder . 2- Divide the top view (circle ) into 12 equal parts ( graphically using the appropriate set square or analytically by dividing the circumference D over 12 π, i.e. , π D /12) and number them from 1 to 12 . 3- Project the point 1-12 from top view vertically upwards across the front view . 4- Project two lines parallel to the base of the front view from the top side and bottom side of cylinder towards the right hand side of board . 5- Measure one of the divided parts and step off this length 12-times along the development base line . 6- Complete the development as shown in fig.106 INTRODUCTION TO AUTOCAD 1 TECHNICAL DRAWING MEC 112 week 1 13.2: TASK (6)