Wendy's ... Biggie size it EF 152 Lee Allan TJ Burrell

Wendy's ... Biggie size it

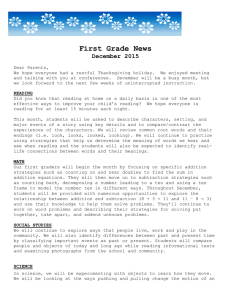

EF 152

Lee Allan

TJ Burrell

Catherine Click

Chris Earwood

Design

Generator

Plexiglass, copper wire, magnets, metal rod

Windmill

Balsa wood, cut by us with scroll saw

Electrical

• Magnets rotate perpendicular to the coils of the copper wire

• Magnets rotation excited electrons to allow them to travel along coils

• Electrons travel to LED to complete a full circuit lighting up the LED

Mechanical

• Blades of the fan are not flat and perfectly straight to allow them to spin in the wind easily

• When the fan rotates the metal rod connected to it rotates

• Metal rod then allows magnets to rotate within copper wires to create circuit

Efficiency

Pmax = 0.5 * ρ * A * v 3

Pmax = maximum available power from wind = .49403 Watts

ρ = air density = 1.225 kg/m^3 v = wind speed = 1.7 m/s

A = area of rotor sweep = πr^2

R = radius = 9in = 0.2286 m

V = 2.24volts

I = 56.3mAmperes = 0.0563A

Pgen = power from generator=V * I = 0.126112 Watts

Efficiency = Pgen / Pmax = 0.126112W / (0.5 * 1.225kg/m^3

* π(0.2286m)^2 * (1.7 m/s)^3) = 0.25527 = 25.5%

Design Problems

• First problem was copper coils wrapped parallel to the way the magnets were spinning

• Magnets did not have enough strength to produce much of a charge in our original design

• Magnet orientation was inhibiting magnetic field formation

• Creating a windmill that will rotate enough to spin the magnets to produce the charge we needed

Conclusion

• Orientation of magnets affects the electric current through the coil

• Sometimes better to start over from scratch then try to fix another project

• Efficiency was increased by simplifying the design which reduced sources of friction