WELCOME JOB HAZARD ANALYSIS CORPORATE SAFETY TRAINING 29 CFR 1910.132 - 138

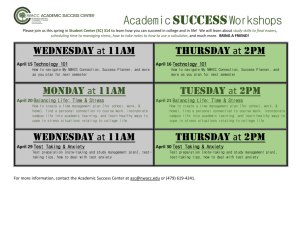

advertisement

JOB HAZARD ANALYSIS CORPORATE SAFETY TRAINING 29 CFR 1910.132 - 138 WELCOME NWACC Business & Industry Workforce Development Institute I - ‹#› BASIS FOR THIS COURSE DAILY EXPOSURE TO JOB HAZARDS BY THOUSANDS OF WORKERS DAILY EXPOSURE TO NUMEROUS ERGONOMIC STRESSORS DAILY EXPOSURE TO NUMEROUS PHYSICAL HAZARDS EFFICIENCY CAN BE GREATLY IMPROVED OSHA SAFETY STANDARDS REQUIRE: Establishment of a “safety” program Training be conducted Job Hazards be assessed Hazards and precautions be explained NWACC Business & Industry Workforce Development Institute I - ‹#› APPLICABLE REGULATIONS 29CFR - SAFETY AND HEALTH STANDARDS 1910 - GENERAL INDUSTRY DANGER EYE PROTECTION REQUIRED BEYOND THIS POINT 132 - GENERAL REQUIREMENTS 133 - EYE AND FACE PROTECTION 134 - RESPIRATORY PROGRDTION 135 - HEAD PROTECTION 136 - FOOT PROTECTION 137 - ELECTRICAL PROTECTION 138 - HAND PROTECTION NWACC Business & Industry Workforce Development Institute I - ‹#› GENERAL PROGRAM REQUIREMENTS ALL EMPLOYERS MUST: REVIEW JOB SPECIFIC HAZARDS CONDUCT HAZARD ASSESSMENTS JOB HAZARD ANALYSIS PROGRAM INSTITUTE SAFE WORK PRACTICES ENSURE PPE IS NOT DAMAGED OR DEFECTIVE CERTIFY THAT ASSESSMENTS HAVE BEEN DONE PROVIDE TRAINING TO ALL REQUIRED EMPLOYEES INSTALL ENGINEERING CONTROLS WHERE POSSIBLE INSTITUTE ADMINISTRATIVE CONTROLS WHERE POSSIBLE ASSESS AND ISSUE PPE TO CONTROL HAZARDS AS A LAST RESORT I - ‹#› NWACC Business & Industry Workforce Development Institute TRAINING REQUIREMENTS THE EMPLOYER MUST PROVIDE TRAINING: THE USE OF EQUIPMENT. WHEN PPE IS NECESSARY. JOB HAZARD SAFETY WHAT PPE IS NECESSARY. THE LIMITATIONS OF THE PPE. PROVIDE RETRAINING AS REQUIRED. CARE AND MAINTENANCE OF EQUIPMENT. TRAIN ALL EMPLOYEES PRIOR TO JOB ASSIGNMENT. NWACC Business & Industry Workforce Development Institute I - ‹#› RETRAINING REQUIREMENTS REQUIRED WHEN THERE IS A: CLOSE-CALL EVENT PROGRAM RELATED INJURY JOB HAZARD SAFETY CHANGE IN JOB ASSIGNMENT NEW HAZARD OR EQUIPMENT NEW HAZARD CONTROL METHODS FAILURE IN THE SAFETY PROCEDURES REASON TO DOUBT EMPLOYEE PROFICIENCY NWACC Business & Industry Workforce Development Institute I - ‹#› JOB HAZARD ANALYSIS IS IMPORTANT A JHA WILL HELP: Improve quality. SAFETY Improve absenteeism. STATISTICS Maintain a healthier work force. Reduce injury and illness rates. Acceptance of high-turnover jobs. Workers feel good about their work. Reduce workers’ compensation costs. Elevate OSHA compliance to a higher level of awareness. I - ‹#› NWACC Business & Industry Workforce Development Institute INDUSTRIAL HYGIENE CONTROLS ENGINEERING CONTROLS Work Station Design Process Modification Tool Selection and Design Mechanical Assist ADMINISTRATIVE CONTROLS Training Programs Pacing FIRST CHOICE SECOND CHOICE Job Rotation/Enlargement Policy and Procedures PERSONNEL PROTECTIVE EQUIPMENT LAST CHOICE Gloves Shields Non-Slip Shoes NWACC Business & Industry Workforce Development Institute Wraps Eye Protection Aprons I - ‹#› WORKSITE ANALYSIS WORKSITE ANALYSIS IS DIVIDED INTO FOUR MAIN PARTS: 1. Gathering information from available sources. 2. Conducting baseline screening surveys to determine which jobs need a closer analysis. 3. Performing job hazard analyses of those work stations with identified risk factors. 4. After implementing control measures, conducting periodic surveys and follow-up to evaluate changes. NWACC Business & Industry Workforce Development Institute I - ‹#› JOB RISK FACTORS PERSONAL RISK FACTORS AFFECTING THE JOB 1. Age 2. Gender 3. Attitude 4. Training 5. Strength 6. Work method 7. Loose clothing 9. Anthropometry 10. Loose or long hair 11. Hearing deficiencies NWACC Business & Industry Workforce Development Institute I - ‹#› JOB RISK FACTORS Continued JOB RISK FACTORS Static work posture a) Standing b) Sitting Work platforms or stairs Torso flexion (bending) a) Mild (up to 45 degrees) b) Severe (greater than 45 degrees) Work heights (too high or too low) Floor surfaces (wet, smooth, vibration) NWACC Business & Industry Workforce Development Institute I - ‹#› JOB RISK FACTORS Continued JOB RISK FACTORS Noise/vibration a) Frequency very important b) Can amplify through the body Environment a) Hot (sweat, reduced grip, fatigue) b) Cold (gloves reduce grip by as much as 30%) Lighting a) posture problems (because of inability to see) NWACC Business & Industry Workforce Development Institute I - ‹#› JOB RISK FACTORS Continued JOB RISK FACTORS Trip hazards Confined spaces Electrical hazards Inadequate ventilation Lockout tagout requirements Machine guarding requirements Motorized vehicles (forklifts, etc.) Oxygen defencicy or enrichment Hazards associated with “Hotwork” Inappropriate personal protective equipment I - ‹#› NWACC Business & Industry Workforce Development Institute JOB RISK FACTORS Continued JOB RISK FACTORS Fall hazards Mechanical hazards Engulfment hazards Respiratory hazards Flammable gases or vapors Airborne cumbustible dusts NWACC Business & Industry Workforce Development Institute I - ‹#› JOB RISK FACTORS Continued WHAT OTHER RISK FACTORS CAN YOU THINK OF THAT ARE ASSOCIATED WITH YOUR WORKPLACE? NWACC Business & Industry Workforce Development Institute I - ‹#› JOB AND TASK ANALYSIS Continued CONDUCTING THE JHA IDENTIFY THE JOB TO STUDY COLLECT THE DATA EVALUATE THE DATA FORMULATE CONTROL MEASURES NWACC Business & Industry Workforce Development Institute I - ‹#› JOB AND TASK ANALYSIS Continued COLLECTING THE DATA JHA ASSESSMENT FORMS DIRECT OBSERVATION VIDEO TAPE ACTION PHOTOGRAPHS DOCUMENTARY ACCOUNTS ACCIDENT STATISTICS NWACC Business & Industry Workforce Development Institute I - ‹#› JOB AND TASK ANALYSIS Continued EVALUATING THE DATA TASK DESCRIPTION SUB-TASK DESCRIPTION ELEMENT DESCRIPTION RISK FACTOR/HAZARD IDENTIFICATION NWACC Business & Industry Workforce Development Institute I - ‹#› JOB AND TASK ANALYSIS Continued FORMULATING CONTROL MEASURES ELIMINATE OR REDUCE EXPOSURE ENGINEERING CONTROL MEASURES ADMINISTRATIVE CONTROL MEASURES APPLICATION OF SAFE WORK PRINCIPLES PERSONAL PROTECTIVE EQUIPMENT NWACC Business & Industry Workforce Development Institute I - ‹#› JOB AND TASK ANALYSIS Continued JOB HAZARD ANALYSIS FORM STEP - Action Being Performed HAZARD - Description of potential Injury CAUSE - Probable cause of potential injury PREVENTION - Prevention control measure NWACC Business & Industry Workforce Development Institute I - ‹#› JOB AND TASK ANALYSIS Continued JOB HAZARD ANALYSIS JOB TITLE LEFT HAND RIGHT HAND FREQUENCY NOTES POSTURE FORCE NWACC DURATION Business & Industry Workforce Development Institute - Action Being Performed - How is it Used - How is it Used - Usually times per minute - Supporting information - Acceptable to extreme - High, Medium, Low - Quantifiable amount - Length of Stressor I - ‹#› JOB AND TASK ANALYSIS Continued STEPS IN CONDUCTING JOB HAZARD ANALYSIS STEP 1 - DETERMINE GENERAL CONDITIONS OF JOB STEP 2 - BREAK DOWN THE JOB STEP 3 - IDENTIFY THE HAZARDS STEP 4 - EVALUATE THE HAZARDS STEP 5 - RECOMMEND PROTECTIVE MEASURES STEP 6 - REVISE THE JHA AS NECESSARY NWACC Business & Industry Workforce Development Institute I - ‹#› JOB AND TASK ANALYSIS Continued STEP 1 - DETERMINING GENERAL CONDITIONS OF JOB SET THE EMPLOYEE TO BE OBSERVED AT EASE. POINT OUT THAT YOU ARE STUDYING THE JOB NOT PERFORMANCE! INVOLVE THE EMPLOYEE IN THE ANALYSIS. SPEAK WITH CO-WORKERS. DETERMINE THE EFFECT OF THE JOB ON CO-WORKERS. REVIEW ANTICIPATED RISK FACTORS REVIEW GENERAL CONDITIONS FOR PERFORMING JOB. NWACC Business & Industry Workforce Development Institute I - ‹#› JOB AND TASK ANALYSIS Continued STEP 2 - BREAKING DOWN THE JOB LIST EACH STEP IN ORDER OF OCCURRENCE. RECORD EACH STEP OF JOB ACTION. GO OVER THE STEPS WITH THE EMPLOYEE. FINALIZE THE STEPS INVOLVED. NWACC Business & Industry Workforce Development Institute I - ‹#› JOB AND TASK ANALYSIS Continued STEP 3 - IDENTIFYING THE HAZARDS EXAMINE EACH STEP TO DETERMINE EXISTING HAZARDS. ASK THESE KINDS OF (WHO & WHAT) QUESTIONS: CAN CLOTHING OR JEWELRY GET CAUGHT? WHAT FIXED OBJECTS COULD CAUSE PUNCTURES? WHAT COULD THE WORKER GET CAUGHT “BETWEEN”? WHAT CAN THE WORKER GET CAUGHT IN, REACHING OVER, UNDER, AROUND OR THROUGH ETC.? IS THE WORKER OFF-BALANCE AT ANY TIME? NWACC Business & Industry Workforce Development Institute I - ‹#› JOB AND TASK ANALYSIS Continued STEP 3 - IDENTIFYING THE HAZARDS (Continued) ASK THESE KINDS OF (WHO & WHAT) QUESTIONS: IS THE WORKER POSITIONED DANGEROUSLY? WHAT REPETITIVE MOTION INJURIES ARE LIKELY? WHAT MOVING PARTS COULD STRIKE THE WORKER? CAN THE WORKER FALL FROM ONE LEVEL TO ANOTHER? CAN THE WORKER BE INJURED FROM CARRYING HEAVY OBJECTS? WHAT ENVIRONMENTAL HAZARDS EXIST? NWACC Business & Industry Workforce Development Institute I - ‹#› JOB AND TASK ANALYSIS Continued STEP 4 - EVALUATING THE HAZARDS ASK THESE KINDS OF (WHY & HOW) QUESTIONS: WHY ISN’T PPE SERVICEABLE? WHY IS PPE IMPROPERLY WORN? WHY DOESN’T PPE FIT PROPERLY? HOW CAN LOCKOUT PROCEDURES BE IMPROVED? WHAT CAUSES THE WORKER TO CONTACT SHARPS? WHY HAS PROPER TRAINING NOT BEEN CONDUCTED? HOW CAN THE FLOW OF WORK BE ORGANIZED BETTER? NWACC Business & Industry Workforce Development Institute I - ‹#› JOB AND TASK ANALYSIS Continued STEP 5 - RECOMMENDING PROTECTIVE MEASURES DETERMINE IF THE JOB COULD BE PERFORMED IN ANOTHER WAY TO REDUCE THE HAZARDS. LIST EACH SAFER JOB STEP OR PROTECTIVE MEASURE. BE SPECIFIC! IF JOB HAZARDS ARE STILL PRESENT: REDUCE NECESSITY. REDUCE FREQUENCY. CONSIDER JOB ROTATION. CONSIDER JOB ENLARGEMENT. NWACC Business & Industry Workforce Development Institute I - ‹#› JOB AND TASK ANALYSIS Continued STEPS IN CONDUCTING JOB HAZARD ANALYSIS STEP 6 - REVISING THE JHA JHA’S MUST BE REVIEWED & REVISED PERIODICALLY. REPEAT JHA’S CAN CATCH HAZARDS ON THE SECOND LOOK. IF AN INJURY OR CLOSE-CALL OCCURS REDO THE JHA. RETRAINING SHOULD FOLLOW EACH JHA. NWACC Business & Industry Workforce Development Institute I - ‹#› OSHA'S PERCEPTION OF A SUCCESSFUL PROGRAM 1. DETAILED WRITTEN HAZARD ASSESSMENTS 2. DETAILED WRITTEN SAFETY PROCEDURES 3. EXTENSIVE EMPLOYEE TRAINING PROGRAMS 4. PERIODIC REINFORCEMENT OF TRAINING 5. SUFFICIENT DISCIPLINE REGARDING IMPLEMENTATION 6. FOLLOW-UP NWACC Business & Industry Workforce Development Institute I - ‹#›