SAFE CHEMICAL HANDLING ‹#› H - 1

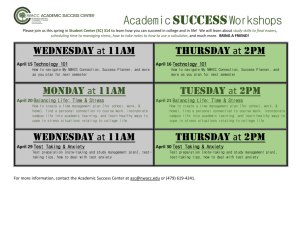

advertisement

SAFE CHEMICAL HANDLING HAZARDOUS MATERIALS 1 3 0 NWACC Business & Industry Workforce Development Institute H - ‹#› SAFE CHEMICAL HANDLING OSHA TRAINING OSHA 29 CFR 1910 WELCOME NWACC Business & Industry Workforce Development Institute H - ‹#› BASIS FOR THIS COURSE THE BOTTOM LINE TRAINING YOU TO BE KNOWLEDGEABLE OF HOW TO LOWER YOUR LIFETIME WORKPLACE EXPOSURE AND DOSAGE TO THE CHEMICALS AND TOXIC MATERIALS YOU ARE POTENTIALLY EXPOSED TO IN YOUR DAILY WORKING LIFE! NWACC Business & Industry Workforce Development Institute H - ‹#› REGULATORY STANDARD FLAMMABLE AND COMBUSTIBLE LIQUIDS 29CFR - 1910 - 106 29CFR - SAFETY AND HEALTH STANDARDS 1910 - GENERAL INDUSTRY FLAMMABLE LIQUID FLAMMABLE LIQUID ETHYLMETHYL NASTY ETHYLMETHYL NASTY NWACC Business & Industry Workforce Development Institute 106 - FLAMMABLE AND COMBUSTIBLE LIQUIDS H - ‹#› REGULATORY STANDARD HAZARD COMMUNICATION 29CFR - 1910 - 1200 29CFR - SAFETY AND HEALTH STANDARDS 1910 - GENERAL INDUSTRY 1200 - HAZCOM STANDARD NWACC Business & Industry Workforce Development Institute H - ‹#› PERSONAL PROTECTIVE EQUIPMENT PERSONAL PROTECTIVE EQUIPMENT REQUIREMENTS: Follow Local Job Procedures. Review the Relative Material Safety Data Sheet. If You Have Questions Consult Your Supervisor. NWACC Business & Industry Workforce Development Institute H - ‹#› GENERAL CONCEPTS OF TOXICOLOGY EVERYTHING IS TOXIC; IT ALL DEPENDS ON THE DOSE HOW WELL THE BODY ACCEPTS A SUBSTANCE DEPENDS ON: THE TYPE OF SUBSTANCE THE AMOUNT (DOSE) ABSORBED THE PERIOD OF TIME OVER WHICH IT IS ABSORBED THE SUSCEPTIBILITY/SENSITIVITY OF THE PERSON EXPOSED NWACC Business & Industry Workforce Development Institute H - ‹#› GENERAL CONCEPTS OF TOXICOLOGY DEGREE OF HARM TO BODY DEPENDENT ON: CONDITIONS OF USE PHYSICAL PROPERTIES OF THE CHEMICAL ROUTES OF EXPOSURE DURATION OF THE EXPOSURE CONCENTRATION OF THE CONTAMINANT IN AIR INDIVIDUAL SUSCEPTIBILITY OF THE EXPOSED PERSON TOXICITY OF THE CHEMICAL NWACC Business & Industry Workforce Development Institute H - ‹#› STATES OF MATTER SOLID LIQUID GAS CHANGE OF STATE CAN OCCUR DUE TO: HEAT COLD ATMOSPHERIC PRESSURE INTERACTION WITH OTHER CHEMICALS NWACC Business & Industry Workforce Development Institute H - ‹#› STATES OF MATTER AIRBORNE CONTAMINANTS: FUME VAPOR DUST GAS MIST SMOKE NWACC Business & Industry Workforce Development Institute H - ‹#› TYPES OF PROCESSES OPEN CLOSED NWACC Business & Industry Workforce Development Institute H - ‹#› TYPES OF PROCESSES OPEN PLATING DEGREASING PARTS PAINTING NWACC Business & Industry Workforce Development Institute CLOSED REFINING DISTILLING GAS PRODUCTION H - ‹#› HANDLING GASES HAZARDS: PRESSURE TOXICITY EXPLOSION CORROSIVITY FIRE NWACC Business & Industry Workforce Development Institute REACTIVITY H - ‹#› HANDLING GASES GASES - PRE-OPERATION SAFETY 1. Inspect cylinder for damage before use. 2. Ensure “in use” label is present. 3. Ensure all labels and warnings are readable. 4. Place upright on stable dry surface. 5. Ensure cylinder is restrained above mid-point. 6. Keep heat, flame, and electricity away from cylinder. 7. Operate in accordance with local safety procedures. NWACC Business & Industry Workforce Development Institute H - ‹#› HANDLING GASES GASES - POST-OPERATION SAFETY 1. Ensure “empty” or like label present. 2. Remove from operation following procedures. 3. Ensure valve closed completely and cap cylinder. 4. Never roll, transport cylinders using handtruck. 5. Never underestimate hazards associated with compressed gases. NWACC Business & Industry Workforce Development Institute H - ‹#› STORING GASES GASES - STORAGE REQUIREMENTS Store only in designated areas. Store and use on a first-in, first-out basis. Never store without proper labeling. Identify all empty cylinders. Store like gases with like gases. Separate empty cylinders from full ones. Store within proper temperature ranges. NWACC Business & Industry Workforce Development Institute H - ‹#› STORING GASES GASES - STORAGE REQUIREMENTS Store outside when possible. Protect from weather and direct sunlight. Ensure storage areas meets guidelines. Never store where temperature can rise to 130f. Place caps on stored cylinders. Store valve end up in a secure area. Inspect and properly tag defective cylinders. NWACC Business & Industry Workforce Development Institute H - ‹#› STORING GASES THE BOTTOM LINE Follow all safety guidelines. Review current storage requirements. Know - compressed gas association rules. Know - NFPA rules. Know - OSHA rules. Know - the local policy. Never underestimate compressed gases! NWACC Business & Industry Workforce Development Institute H - ‹#› HANDLING IGNITABLE LIQUIDS TYPES AND DEFINITIONS: Flashpoint - minimum ignition temp. for ignitable vapor Flammable - flashpoint below 100 deg. (F.) Combustible - flashpoint at or above 100 deg. (F.) Pyrophoric - can ignite spontaneously Flammable range - vapor/air ratio that will burn Volatility - tendency to change to vapor state NWACC Business & Industry Workforce Development Institute H - ‹#› HANDLING IGNITABLE LIQUIDS CHECK FOR COMPATIBILITY! SOLVENT NWACC Business & Industry Workforce Development Institute OXIDIZER H - ‹#› STORING IGNITABLE LIQUIDS STORING FLAMMABLE AND COMBUSTIBLE LIQUIDS: LEVELS OF STORAGE: HAZARDOUS MATERIALS STORAGE FACILITY IN-PLANT STORAGE CABINETS TOTES, DRUMS/BARRELS PORTABLE CONTAINERS NWACC Business & Industry Workforce Development Institute FLAMMABLE LIQUIDS H - ‹#› STORING IGNITABLE LIQUIDS HAZARDOUS MATERIALS STORAGE FACILITY Dedicated fire suppression system Make-up air Exhaust ventilation Explosion-proof lighting and heating Floor drains 2-Hour fire rating on structure Proper signage and safety procedures NWACC Business & Industry Workforce Development Institute FLAMMABLE LIQUIDS H - ‹#› STORING IGNITABLE LIQUIDS TOTES, DRUMS AND BARRELS Should be moved to storage ASAP Make best use of just-in-time system Bonding wires must be used FLAMMABLE Local fire codes must be considered LIQUIDS Bonding - container to container Grounding - container to structural ground No ignition sources within 25 feet NWACC Business & Industry Workforce Development Institute H - ‹#› STORING IGNITABLE LIQUIDS PORTABLE CONTAINERS Bond from drum to container during transfer Store in safety cabinets when not in use Check for leak-tightness Check for serviceable vent mechanism Do not remove flame arrester screens Do not overfill (high temps will cause overflow) Follow warnings and safety procedures NWACC Business & Industry Workforce Development Institute FLAMMABLE LIQUIDS H - ‹#› STORING IGNITABLE LIQUIDS GENERAL SAFETY PRECAUTIONS Remove electrical equipment Use spark resistant tools Use safe techniques to move containers Use proper dispensing faucets Follow warnings and use labels Properly dispose of empty containers Follow proper inspection procedures NWACC Business & Industry Workforce Development Institute FLAMMABLE LIQUIDS H - ‹#› HANDLING CORROSIVE LIQUIDS ACIDS BASES OXIDIZERS AFFECT OTHER MATERIALS BY CONTACT: Acids and bases affect material by contact Acids and bases affect each other Oxidizers increase hazard during fires NWACC Business & Industry Workforce Development Institute H - ‹#› HANDLING CORROSIVE LIQUIDS DOT DEFINITION OXIDIZER A material such as a chlorate, permanganate, or inorganic peroxide that will give off oxygen readily to stimulate the combustion of organic material. OXIDIZER NWACC Business & Industry Workforce Development Institute H - ‹#› HANDLING CORROSIVE LIQUIDS OXIDIZERS Provide oxygen for combustion React violently with flammables and combustibles Must be kept separate from all other classes of materials OXIDIZER NWACC Business & Industry Workforce Development Institute H - ‹#› HANDLING CORROSIVE LIQUIDS DOT DEFINITION CORROSIVE A liquid or solid that causes visible Destruction or irreversible damage To skin tissue at the point of contact, Or that has a severe corrosion rate on steel. CORROSIVE MATERIALS NWACC Business & Industry Workforce Development Institute H - ‹#› HANDLING CORROSIVE LIQUIDS OSHA DEFINITION CORROSIVE ACID A chemical that causes visible destruction of, or irreversible alterations in living tissue by chemical action at the site of contact. NWACC Business & Industry Workforce Development Institute H - ‹#› HANDLING CORROSIVE LIQUIDS ACIDS AND BASES - pH. THE pH OF A LIQUID IS THE NUMERICAL MEASURE OF ITS RELATIVE ACIDITY OR ALKALINITY. THE RANGE IS FROM 0 - 14 WITH A NEUTRAL LEVEL EXPRESSED AS A pH OF 7.0. ABOVE 7.0 THE LIQUID IS MORE ALKALINE OR BASIC. BELOW 7.0 THE LIQUID IS MORE ACIDIC. NWACC Business & Industry Workforce Development Institute H - ‹#› HANDLING CORROSIVE LIQUIDS ACID ACIDS AND BASES BASE COMMON ACIDS (pH 0-6) COMMON BASES (pH 8-14) HYDROCHLORIC ACID HYDROFLUORIC ACID NITRIC ACID PHOSPHORIC ACID CHROMIC ACID NWACC Business & Industry Workforce Development Institute SODIUM HYDROXIDE (LYE) SODIUM HYPOCHLORITE (BLEACH) AQUEOUS AMMONIA POTASSIUM HYDROXIDE (POTASH) AMMONIUM HYDROXIDE H - ‹#› HANDLING CORROSIVE LIQUIDS CHECK FOR COMPATIBILITY! LOW pH ACID NWACC Business & Industry Workforce Development Institute BASE HIGH pH H - ‹#› STORING CORROSIVE LIQUIDS STORAGE Inspect before placing in storage Separate acids from bases Separate acids & bases from other materials Use drip pans under containers Use personal protective equipment (PPE) Use correct dilutions sequences Use approved storage containers CORROSIVE MATERIALS NWACC Business & Industry Workforce Development Institute H - ‹#› HANDLING HIGHLY TOXIC LIQUIDS HANDLING Can react with themselves or other materials Water and air reactives are greatest concern Know the adverse health effects Restrict access to these materials Carefully review storage requirements Ensure sufficient training levels achieved Use adequate personal protective equipment Use approved storage containers HIGHLY TOXIC MATERIALS NWACC Business & Industry Workforce Development Institute H - ‹#› HANDLING HIGHLY TOXIC LIQUIDS CHECK FOR COMPATIBILITY! BLEACH NWACC Business & Industry Workforce Development Institute AMMONIA H - ‹#› STORING HIGHLY TOXIC LIQUIDS STORAGE Inspect before placing in storage Separate from incompatibles Use personal protective equipment (PPE) Use approved storage containers HIGHLY TOXIC MATERIALS NWACC Business & Industry Workforce Development Institute H - ‹#› HANDLING REACTIVE LIQUIDS HANDLING Know the adverse health effects Know the reactive nature of the material Separate from incompatibles Restrict access to these materials Carefully review storage requirements Ensure sufficient training levels achieved Use adequate personal protective equipment Use approved storage containers NWACC Business & Industry Workforce Development Institute REACTIVE MATERIALS H - ‹#› HANDLING REACTIVE LIQUIDS CHECK FOR COMPATIBILITY! MAGNESIUM NWACC Business & Industry Workforce Development Institute WATER H - ‹#› STORING REACTIVE LIQUIDS STORAGE Inspect before placing in storage Separate from incompatibles Use personal protective equipment (PPE) Use approved storage containers REACTIVE MATERIALS NWACC Business & Industry Workforce Development Institute H - ‹#› HANDLING SOLID MATERIALS HANDLING - PORTABLE CONTAINERS DRUMS/BARRELS TOTES BAGS HANDLING - BULK STORAGE TANKS HOPPERS SILOS NWACC Business & Industry Workforce Development Institute HIGHLY TOXIC MATERIALS H - ‹#› HANDLING SOLID MATERIALS TRANSFER Manual method Mechanical method Follow safety procedures Avoid suspending particles Use dust control techniques RESPIRATORY HAZARD HAZARDS Dust primary hazard NWACC Business & Industry Workforce Development Institute H - ‹#› HANDLING SOLID MATERIALS PARTICLE SIZE 0.25 1.00 5.00 TIME TO FALL 1 FOOT 590.0 54.0 2.5 * MINUTES MINUTES MINUTES = MICRON * = SHAPE IS A FACTOR NWACC Business & Industry Workforce Development Institute RESPIRATORY HAZARD H - ‹#› STORING SOLID MATERIALS STORAGE Inspect container before placing in storage Separate from incompatibles Use mechanical devices to lift heavy bags Use personal protective equipment (PPE) Protect from contamination in storage Use exhaust ventilation Empty bags have residual product inside Use approved storage containers NWACC Business & Industry Workforce Development Institute H - ‹#› EMPTY CONTAINER MANAGEMENT HANDLING AND DISPOSAL Inspect container for product residuals Do not use empty containers as trash cans Check with environmental management Triple rinse reusable containers Remember - residual product is hazardous too Follow local procedures Check with supervisor if policy is unclear NWACC Business & Industry Workforce Development Institute H - ‹#›