WELCOME MACHINE GUARDING CORPORATE SAFETY TRAINING 29 CFR 1910.211-222

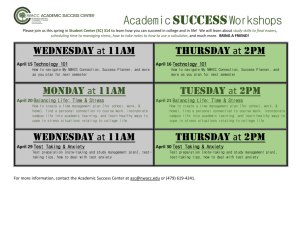

advertisement

MACHINE GUARDING CORPORATE SAFETY TRAINING 29 CFR 1910.211-222 WELCOME NWACC Business & Industry Workforce Development Institute O - ‹#› BASIS FOR THIS COURSE Proper Machine Guarding Results in Accident Reduction Elimination of Workplace Injuries & Illnesses Where Possible Reduction of Workplace Injuries & Illnesses Where Possible Development of Efficient Machine Guarding Techniques OSHA Safety Standards Require: Machines Be Properly Guarded Training Be Conducted Hazards and Precautions Be Explained A “Safety” Program Be Established Job Hazards Be Assessed and Controlled NWACC Business & Industry Workforce Development Institute O - ‹#› REGULATORY STANDARD THE GENERAL DUTY CLAUSE FEDERAL - 29 CFR 1903.1 EMPLOYERS MUST: Furnish a place of employment free of recognized hazards that are causing or are likely to cause death or serious physical harm to employees. Employers must comply with occupational safety and health standards promulgated under the WilliamsSteiger Occupational Safety and Health Act of 1970. OSHA ACT OF 1970 NWACC Business & Industry Workforce Development Institute O - ‹#› INDUSTRY CONSENSUS STANDARDS ANSI - B11.2 Hydraulic presses B11.3 Power Press Brakes B11.10 Metal Sawing Machines B11.11 Gear Cutting Machines B11.12 Roll-Forming and Bending Machines B11.14 Coil Slitting Machines B11.15 Pipe, Tube, and Shape Bending B11.16 Metal Powder Compacting Presses B11.17 Horizontal Hydraulic Extrusion B11.18 Coiled Steel Processing NWACC Business & Industry Workforce Development Institute O - ‹#› INDUSTRY CONSENSUS STANDARDS ANSI - B11.19 Machine Tools, Safeguarding B11.20 Manufacturing Systems/Cells NWACC Business & Industry Workforce Development Institute O - ‹#› PROGRAM REQUIREMENTS ALL EMPLOYERS MUST: Install Machine Safeguards MACHINE GUARDING PROGRAM Review Job Specific Hazards Implement Corrective Actions Conduct Hazard Assessments Conduct Accident Investigations Provide Training to All Required Employees Control Workplace Hazards Using PPE As a Last Resort NWACC Business & Industry Workforce Development Institute O - ‹#› BASICS OF MACHINE GUARDING Where Mechanical Hazards Occur The Point of Operation: Power Transmission Apparatus: Other Moving Parts: NWACC Business & Industry Workforce Development Institute O - ‹#› BASICS OF MACHINE GUARDING Where Mechanical Hazards Occur The Point of Operation: Where work is performed on the material, such as: Cutting Shaping Boring Forming of stock NWACC Business & Industry Workforce Development Institute LATHE O - ‹#› BASICS OF MACHINE GUARDING Where Mechanical Hazards Occur Power Transmission Apparatus: All components of the mechanical system which transmit energy to the part of the machine performing the work. 300 RPM NWACC Business & Industry Workforce Development Institute O - ‹#› BASICS OF MACHINE GUARDING Where Mechanical Hazards Occur Other Moving Parts: Any part of the machine which moves while the machine is working. Rotating parts Feed mechanisms Reciprocating parts Transverse moving parts Auxiliary parts of the machine NWACC Business & Industry Workforce Development Institute O - ‹#› BASICS OF MACHINE GUARDING Hazardous Mechanical Motions and Actions A wide variety of mechanical motions and actions may present hazards to the worker: Rotating members Reciprocating arms Moving belts Meshing gears Cutting teeth Any parts that impact or shear NWACC Business & Industry Workforce Development Institute O - ‹#› BASICS OF MACHINE GUARDING Hazardous Mechanical Motions and Actions Recognition of these hazards is the first step toward protecting workers from the danger they present. NWACC Business & Industry Workforce Development Institute O - ‹#› BASICS OF MACHINE GUARDING Hazardous Mechanical Motions Motions Rotating Reciprocating Transversing NWACC Business & Industry Workforce Development Institute NIP POINT O - ‹#› BASICS OF MACHINE GUARDING Hazardous Mechanical Actions Actions Cutting Punching Shearing Bending NWACC Business & Industry Workforce Development Institute SHEARITE CUTTING BLADES O - ‹#› BASICS OF MACHINE GUARDING Hazardous Mechanical Motions Rotating Motions - Collars - Couplings - Cams - Clutches - Flywheels - Shaft ends - Spindles - Meshing gears - Horizontal shafts - Vertical shafts NWACC Business & Industry Workforce Development Institute O - ‹#› BASICS OF MACHINE GUARDING Hazardous Mechanical Motions Rotating Motions Rotating motions can grip clothing, and through mere skin contact force a limb into a dangerous position. The danger increases when projections such as set screws, bolts, nicks, abrasions, and projecting keys or set screws are exposed on rotating parts. NWACC Business & Industry Workforce Development Institute O - ‹#› BASICS OF MACHINE GUARDING Hazardous Mechanical Motions Reciprocating Motions NIP POINT NIP POINT RECIPROCATING NWACC Business & Industry Workforce Development Institute MOTION O - ‹#› BASICS OF MACHINE GUARDING Hazardous Mechanical Motions Reciprocating Motions RECIPROCATING MOTION CAUGHT “IN-BETWEEN” OR “STRUCK-BY” NWACC Business & Industry Workforce Development Institute O - ‹#› BASICS OF MACHINE GUARDING Hazardous Mechanical Motions Transversing Motions TRAVEL IN-RUNNING NIP POINTS NWACC Business & Industry Workforce Development Institute O - ‹#› BASICS OF MACHINE GUARDING Hazardous Mechanical Motions Rotating Motions NIP POINTS NWACC Business & Industry Workforce Development Institute O - ‹#› BASICS OF MACHINE GUARDING Hazardous Mechanical Actions Cutting Actions - Rotating motions - Reciprocating motions - Transversing motions The danger of cutting action exists at the point of operation where finger, arm and bodily injuries can occur and where flying chips or scrap material can strike the head, particularly in the area of the eyes or face. NWACC Business & Industry Workforce Development Institute O - ‹#› BASICS OF MACHINE GUARDING Hazardous Mechanical Actions Cutting Actions Bandsaws Circular saws Boring machines Drilling machines Turning machines (lathes) Milling machines NWACC Business & Industry Workforce Development Institute O - ‹#› BASICS OF MACHINE GUARDING Hazardous Mechanical Actions Punching Actions 20 TON Power presses Iron workers The principle hazard occurs at the point of operation where stock is inserted, held or withdrawn. NWACC Business & Industry Workforce Development Institute PRESS ACME PRESSES O - ‹#› PRESS BASICS OF MACHINE GUARDING Hazardous Mechanical Actions Shearing/Bending Actions Mechanical shears Hydraulic shears Pneumatic shears The principle hazard occurs at the point of operation where stock is inserted, held or withdrawn. DANGER CUTTING EDGE PRESS PRESS SHEARITE POWER SHEARS SHEAR TERROR NWACC Business & Industry Workforce Development Institute O - ‹#› BASICS OF MACHINE GUARDING Requirements for Safeguards Be securely attached Create no new hazards Withstand operational conditions Allow for safe routine maintenance Allow for safe operator adjustments Withstand environmental conditions Provide protection from falling objects Prevent contact with hazardous conditions Create no interference in the conduct of work O - ‹#› NWACC Business & Industry Workforce Development Institute BASICS OF MACHINE GUARDING Nonmechanical Hazard Considerations: Power sources are potential sources of danger How will guarding affect equipment operation? Ensure proper grounding of systems Replace frayed, exposed , or old wiring Consider effects of - High pressure systems - Extreme temp. conditions - Pulsation, vibration, or leaks - Noise or unwanted sounds - Cutting fluids and coolants HOT SURFACE O - ‹#› NWACC Business & Industry Workforce Development Institute BASICS OF MACHINE GUARDING Operator Training Considerations: Provide instruction and or hands-on training Discuss the purpose of safeguards Cover associated hazards thoroughly Involve guard designers in the training Describe how to properly use safeguards Describe how safeguards provide protection Describe circumstances for safeguard removal Explain what to do if safeguards are damaged Explain what to do if safeguards are missing O - ‹#› NWACC Business & Industry Workforce Development Institute BASICS OF MACHINE GUARDING Operator Training Considerations: Defeating, altering, or removing safeguards can cause injury to co-workers and can leave the person performing such actions liable under the OSHA Act of 1970. NWACC Business & Industry Workforce Development Institute O - ‹#› BASICS OF MACHINE GUARDING Protective Clothing and Equipment Considerations: ENGINEERING CONTROLS Work Station Design Process Modification Tool Selection and Design Mechanical Assist ADMINISTRATIVE CONTROLS Training Programs Pacing FIRST CHOICE SECOND CHOICE Job Rotation/Enlargement Policy and Procedures PERSONNEL PROTECTIVE EQUIPMENT LAST CHOICE Gloves Shields Non-Slip Shoes NWACC Business & Industry Workforce Development Institute Wraps Eye Protection Aprons O - ‹#› BASICS OF MACHINE GUARDING Protective Clothing and Equipment Considerations: Appropriate for the particular hazard(s) Maintained in good condition Properly stored when not in use Kept clean, fully functional, and sanitary NWACC Business & Industry Workforce Development Institute O - ‹#› METHODS OF MACHINE GUARDING Guarding Method Dependant on: Type of material Type of operation Method of handling Size or shape of stock Physical layout of the work area Production requirements or limitations NWACC Business & Industry Workforce Development Institute O - ‹#› METHODS OF MACHINE GUARDING Manufacturers Recommendation: Before beginning the process of guard procurement, design, or installation, the equipment manufacturer should be consulted for advice. NWACC Business & Industry Workforce Development Institute O - ‹#› METHODS OF MACHINE GUARDING Generally: Power transmission apparatus is best protected by fixed guards that enclose the danger areas Point of operation hazard guarding will vary NWACC Business & Industry Workforce Development Institute O - ‹#› METHODS OF MACHINE GUARDING Safeguards Are Grouped Under 5 Classifications: Guards Devices Locations/Distance Feeding and ejection methods Miscellaneous aids NWACC Business & Industry Workforce Development Institute O - ‹#› METHODS OF MACHINE GUARDING GUARDS NWACC Business & Industry Workforce Development Institute O - ‹#› METHODS OF MACHINE GUARDING Guards: Guards are barriers which prevent access to danger areas, there are four general types: Fixed guards Interlocked guards Adjustable guards Self-Adjusting guards NWACC Business & Industry Workforce Development Institute O - ‹#› METHODS OF MACHINE GUARDING Fixed Guards: Fixed guards are a permanent part of the machine and not dependent upon moving parts to perform its intended function. NWACC Business & Industry Workforce Development Institute O - ‹#› METHODS OF MACHINE GUARDING Fixed Guards: ADVANTAGES Can be constructed to suit many different applications In-plant construction is often possible Can provide maximum protection Usually requires minimum maintenance Can be suitable to high production operations Can be suitable to high repetition operations NWACC Business & Industry Workforce Development Institute O - ‹#› METHODS OF MACHINE GUARDING Fixed Guards: LIMITATIONS May interfere with visibility Can be limited to specific operations Machine adjustments and repair often require guard removal, thereby necessitating other means of protection for maintenance personnel NWACC Business & Industry Workforce Development Institute O - ‹#› METHODS OF MACHINE GUARDING Interlocked Guards: Interlocked guards are designed to automatically shut off or disengage the machine if the guard is opened or removed AUTOMATIC VISUAL ALARM NWACC Business & Industry Workforce Development Institute AUTOMATIC AUDIBLE ALARM O - ‹#› METHODS OF MACHINE GUARDING Interlocked Guards: Interlocked guards may use: Electrical power Mechanical power Hydraulic power Pneumatic power OR ANY COMBINATION OF POWER SOURCES NWACC Business & Industry Workforce Development Institute O - ‹#› METHODS OF MACHINE GUARDING Interlocked Guards: Interlocks should not prevent “inching” by remote control if required Replacing guards should restart the machine not automatically IMPORTANT NWACC Business & Industry Workforce Development Institute O - ‹#› METHODS OF MACHINE GUARDING Interlocked Guards: ADVANTAGES Can provide maximum protection Allows access to machine for removing jams without time consuming removal of fixed guards LIMITATIONS Requires careful adjustment and maintenance May be easy to disengage jams NWACC Business & Industry Workforce Development Institute O - ‹#› METHODS OF MACHINE GUARDING Adjustable Guards: Typically adjusted by the operator Accommodate various sizes of stock May require additional operator training Adjustable guards are typically used on: Bandsaws Tablesaws Power presses Routers Similar equipment O - ‹#› NWACC Business & Industry Workforce Development Institute METHODS OF MACHINE GUARDING Adjustable Guards: ADVANTAGES Can be constructed to suit many specific applications Can be adjusted to admit varying sizes of stock LIMITATIONS Hands may enter danger area Protection may not be complete at all times May require frequent maintenance and or adjustment The guard can be defeated by the operator May interfere with visibility NWACC Business & Industry Workforce Development Institute O - ‹#› METHODS OF MACHINE GUARDING Self-Adjusting Guards: Adjusts automatically to the work Accommodate various sizes of stock May require additional operator training Self-Adjusting guards are typically used on: Radial arm saws Tablesaws Circular saws Routers Jointers Similar equipment NWACC Business & Industry Workforce Development Institute O - ‹#› METHODS OF MACHINE GUARDING Self-Adjusting Guards: ADVANTAGES Off-the-shelf guards are often commercially available LIMITATIONS Protection may not be complete at all times May require frequent maintenance and or adjustment May interfere with visibility NWACC Business & Industry Workforce Development Institute O - ‹#› METHODS OF MACHINE GUARDING DEVICES NWACC Business & Industry Workforce Development Institute O - ‹#› METHODS OF MACHINE GUARDING Devices: Devices fall into four general types: Presence-Sensing devices Pullback devices Restraint devices Safety trip controls NWACC Business & Industry Workforce Development Institute O - ‹#› METHODS OF MACHINE GUARDING Devices: Devices may perform one of several function: Stop a machine if a body part is in danger Restrain or withdraw a hand if it is in danger Require activation by the use of both hands Provide a barrier synchronized to the operation NWACC Business & Industry Workforce Development Institute O - ‹#› METHODS OF MACHINE GUARDING Presence-Sensing: Photoelectric Radiofrequency Electromechanical PRESS NWACC Business & Industry Workforce Development Institute ACME PRESSES PRESS O - ‹#› METHODS OF MACHINE GUARDING Presence-Sensing: Before beginning the process of procurement, design, or installation, the equipment manufacturer should be consulted for advice. NWACC Business & Industry Workforce Development Institute O - ‹#› METHODS OF MACHINE GUARDING Presence-Sensing: Photoelectric Radiofrequency Electromechanical 20 TON PRESS NWACC Business & Industry Workforce Development Institute ACME PRESSES PRESS O - ‹#› METHODS OF MACHINE GUARDING Pullback Devices: Attached to Wrists Positioning Critical Adjustment Critical Maintenance Critical Training Critical Must Stop Machine Immediately! NWACC Business & Industry Workforce Development Institute NYLON PULLBACK STRAPS ATTACHED TO WRISTBANDS O - ‹#› METHODS OF MACHINE GUARDING Restraint Devices: Uses Cables or Straps Affixes to Hands May Need Feeding Tools Adjustment Critical Positioning Critical Maintenance Critical Training Critical Must Restrain Body Part From Hazard! NWACC Business & Industry Workforce Development Institute O - ‹#› METHODS OF MACHINE GUARDING Safety Trip Controls: Body Trip Bars Hand/Arm Trip Bars Tripwire Cables Positioning Critical Adjustment Critical Maintenance Critical Training Critical Manual Reset Needed Must Stop Machine Immediately! NWACC Business & Industry Workforce Development Institute O - ‹#› METHODS OF MACHINE GUARDING Two-Hand Control: Needs Constant Pressure Needs Concurrent Pressure Positioning Critical Adjustment Critical Maintenance Critical Training Important Must Stop Machine Immediately! NWACC Business & Industry Workforce Development Institute 20 TON PRESS ACME PRESSES PRESS O - ‹#› METHODS OF MACHINE GUARDING Location/Distance Safeguarding: Position Dangerous Areas of Machines So That They Are Not Assessable During Normal Operations. Examples Include: Position Hazard Areas Against a Wall Locate Hazards Out of Reach of Operators Add Enclosures or Fences to Restrict Access Design Stock Feeding Openings Away From Hazards Position the Operators Control Station Away From Hazards NWACC Business & Industry Workforce Development Institute O - ‹#› METHODS OF MACHINE GUARDING Feeding and Ejection Methods: Automatic Feeds - Fed From Rolls, Indexed by Machine Semiautomatic Feeds - Fed by Chutes, Movable Dies, Dial Feed, Plungers, or Sliding Bolsters Automatic Ejection - Air or Mechanical Ejection Semiautomatic Ejection - Air or Mechanical Ejection Initiated by The Operator Robotics - Perform Work Usually Performed by Operator NWACC Business & Industry Workforce Development Institute O - ‹#› METHODS OF MACHINE GUARDING Feeding and Ejection Methods: Manufacturers Should Be Consulted to Determine: Feeding and Ejection Add-on Options Latest Technology Available Best Available Technology Operator Training Requirements Maintenance Staff Training Requirements Cost Estimates for Upgrades Feasibility Assessment Information NWACC Business & Industry Workforce Development Institute O - ‹#› METHODS OF MACHINE GUARDING Miscellaneous Aids: Examples of Possible Applications: Awareness Barriers - (Not adequate for continuous hazards) Color coding of hazard areas Signage Shields (i.e. splash, eye protective, thermal etc.) Holding and Positioning Tools NWACC Business & Industry Workforce Development Institute O - ‹#› METHODS OF MACHINE GUARDING Guard Construction: Many Machines Come With Safeguards Many Older Machines Now Have Safeguards Available Manufacturers Are Increasingly More Concerned With Liability Companies Not Specialized in Guarding Issues NWACC Business & Industry Workforce Development Institute O - ‹#› METHODS OF MACHINE GUARDING Builder Designed and Installed Guards: Usually Conform to Design and Function of Machine Better Can Be Designed to Strengthen the Machine in Some Way or to Serve Some Additional Functional Purposes NWACC Business & Industry Workforce Development Institute O - ‹#› METHODS OF MACHINE GUARDING User Designed and Installed Guards: Often the Only Practical Solution for Older Equipment Can Be Designed and Built to Fit Unique & Changing Situations Can Be Installed on Individual Dies and Feeding Mechanisms Can Help Promote Safety Consciousness in the Workplace Sometimes Do Not Conform As Well As “Builder Designed” Depending on Talent and Resources May Be Poorly Designed NWACC Business & Industry Workforce Development Institute O - ‹#› METHODS OF MACHINE GUARDING Point-of-Operations Guards : Defined as: “The area on a machine where work is actually performed upon the material being processed.” Complicated by the Number and Complexity of Machines in Use Must Fully Safeguard the Employee Must Allow Production to Continue Hazard Analysis Is Usually Required If Poorly Designed, Built, or Installed Guards May Create a Hazard Rather Than Eliminating One. NWACC Business & Industry Workforce Development Institute O - ‹#› METHODS OF MACHINE GUARDING Mechanical Power Transmission Apparatus Guards: The only openings usually needed are for: Lubrication Adjustment Repair Inspection 300 RPM NWACC Business & Industry Workforce Development Institute O - ‹#› METHODS OF MACHINE GUARDING Guard Material: Under Many Circumstances, Metal Is the Best Material for Guards. Guard Framework Is Usually Made From Structural Shapes, Pipe, Bar, or Rod Stock. Filler Material Generally Is Expanded or Perforated or Solid Sheet Metal or Wire Mesh. It May Be Feasible to Use Plastic or Safety Glass Where Visibility Is Required. Guards Made of Wood Generally Are Not Recommended Because of Their Flammability and Lack of Durability and Strength. However, in Areas Where Corrosive Materials Are Present, Wooden Guards May Be the Better Choice. NWACC Business & Industry Workforce Development Institute O - ‹#› LOCKOUT TAGOUT OVERVIEW 29CFR - 1910 - 147 29CFR - SAFETY AND HEALTH STANDARDS 1910 - GENERAL INDUSTRY 147 - LOCKOUT TAGOUT STANDARD NWACC Business & Industry Workforce Development Institute O - ‹#› LOCKOUT TAGOUT OVERVIEW TITLE - CONTROL OF HAZARDOUS ENERGY SEPTEMBER 1, 1989 - FINAL RULE ISSUED JANUARY 2, 1990 - FINAL RULE TOOK EFFECT NWACC Business & Industry Workforce Development Institute O - ‹#› LOCKOUT TAGOUT OVERVIEW Authorized Employee The Person Who Locks or Tags Out Machines To Perform Servicing or Maintenance. Affected Employee An Employee Whose Job Requires Him or Her To Operate or Use a Machine or Piece of Equipment On Which Servicing or Maintenance Is Being Performed. NWACC Business & Industry Workforce Development Institute O - ‹#› LOCKOUT TAGOUT OVERVIEW DANGER LOCKED OUT DO NOT OPERATE This Lock/Tag may only be removed by NAME: _______________ DEPT : _______________ EXPECTED COMPLETION DATE: ________________ TIME: _________________ NWACC Business & Industry Workforce Development Institute O - ‹#› LOCKOUT TAGOUT OVERVIEW Normal Operations 1. Covered If an Employee Must Remove or Bypass Guards or Devices 2. Covered Where Employees Are Required to Put A Body Part in a Machine Process Area 3. Covered Where Employees Are Required to Put A Body Part in a Machine Having a Danger Zone NWACC Business & Industry Workforce Development Institute O - ‹#› TIPS FOR USING CONTRACTORS REMEMBER, YOU CONTROL YOUR FACILITY OR AREA! REVIEW THEIR PROCEDURES WITH THEM BEFORE STARTING THE JOB! DETERMINE THEIR SAFETY PERFORMANCE RECORD! DETERMINE WHO IS IN CHARGE OF THEIR PEOPLE! DETERMINE HOW THEY WILL AFFECT YOUR EMPLOYEES! NWACC Business & Industry Workforce Development Institute O - ‹#› MACHINE GAURDING NWACC Business & Industry Workforce Development Institute O - ‹#› MACHINERY AND MACHINE GUARDING SAFETY •MECHANICAL POWER PRESSES AND BENCH GRINDERS NWACC Business & Industry Workforce Development Institute O - ‹#› MECHANICAL POWER PRESSES TWO TYPES: FULL REVOLUTION OR PART REVOLUTION (CLUTCH DRIVEN). NO GUARDS OR SWEEPS ALLOWED FOR HANDFEEDING. PRESENCE SENSING DEVICES ALLOWED ON PART REVOLUTION ONLY. PULLBACKS MAY BE USED, BUT REQUIRES INSPECTION FOR EACH SHIFT, OPERATOR OR DIE SETUP. O - ‹#› NWACC Business & Industry Workforce Development Institute POWER PRESSES •GATES ARE RECOMMENDED FOR HANDFEEDING: TYPE A FOR BOTH PART OR FULL REV PRESSES. TYPE B NOT RECOMMENDED FOR FULL REV. • ALL PRESSES REQUIRE POINT OF OPERATION SAFEGUARDING. •FOR NON-HANDFEED OPERATIONS, GUARDS MAY BE USED. •GUARD OPENINGS MUST CONFORM TO 1910.217, TABLE O-10 O - ‹#› NWACC Business & Industry Workforce Development Institute BENCH GRINDERS WORK REST GAP MUST BE WITHIN 1/8 INCH OF WHEEL. TONGUE GUARD GAP MUST BE WITHIN 1/4 INCH OF WHEEL. WHEEL GUARD MUST COVER SPINDLE, END NUT AND FLANGE. INSPECT BLOTTER, WHEEL MOUNTING HOLE, FLANGES, COLLET BEFORE USE. MAKE SURE SPINDLE SPEED DOES NOT EXCEED O - ‹#› NWACC Business & Industry Workforce Development WHEEL RPMInstitute RATING.