WELCOME AN INTRODUCTORY COURSE OCCUPATIONAL ERGONOMICS

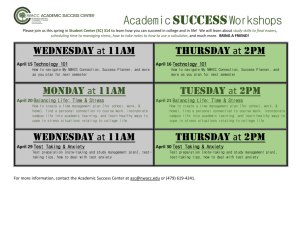

advertisement

OCCUPATIONAL ERGONOMICS AN INTRODUCTORY COURSE WELCOME NWACC Business & Industry Workforce Development Institute ER - ‹#› BASIS FOR THIS COURSE THOUSANDS OF WORKERS CAN BENEFIT FROM ERGONOMICS DAILY EXPOSURE TO NUMEROUS ERGONOMIC STRESSORS DAILY EXPOSURE TO NUMEROUS PHYSICAL HAZARDS EFFICIENCY CAN BE GREATLY IMPROVED OSHA SAFETY STANDARDS REQUIRE: Establishment of a “safety” program Training be conducted Ergonomic stressors be assessed Hazards and precautions be explained NWACC Business & Industry Workforce Development Institute ER - ‹#› ERGONOMICS DEFINED VARIOUS AUTHORS DEFINE ERGONOMICS AS: The study of man’s relationship with his or her workplace. Fitting the task to the person rather than forcing him/her to adapt to the work environment. Designing the workplace to prevent occupational injury and illness. NWACC Business & Industry Workforce Development Institute ER - ‹#› ERGONOMICS DEFINED (Continued) VARIOUS AUTHORS DEFINE ERGONOMICS AS: Discovering the capabilities and limitations of the human body. The art and science that addresses workers’ job performance and well-being in relation to their job tasks, tools, equipment and environment. The study of the relationship between people and machines or between employees and their environment. NWACC Business & Industry Workforce Development Institute ER - ‹#› ERGONOMICS DEFINED (Continued) VARIOUS AUTHORS DEFINE ERGONOMICS AS: The study of the interaction between the worker and the process at the workplace. WHAT OTHER DEFINITIONS HAVE YOU HEARD? NWACC Business & Industry Workforce Development Institute ER - ‹#› ERGONOMICS IS IMPORTANT ERGONOMICS PLAYS A ROLE IN APPROXIMATELY 50% OF ALL WORKPLACE INJURIES. ERGONOMICS WILL HELP: Improve quality. Improve absenteeism. SAFETY Maintain a healthier work force. STATISTICS Reduce injury and illness rates. Acceptance of high-turnover jobs. Workers feel good about their work. Reduce workers’ compensation costs. Elevate OSHA compliance to a higher level of awareness. NWACC Business & Industry Workforce Development Institute ER - ‹#› ERGONOMICS A MULTI-DISCIPLINARY APPROACH THINK ABOUT THE NUMBER OF WAYS ERGONOMICS IMPACTS OUR DAILY LIFE! NWACC Business & Industry Workforce Development Institute ER - ‹#› TYPICAL APPLICATIONS APPLICATIONS WORK STATION DESIGN TOOL SELECTION AND DESIGN OFFICE SAFETY IMPROVEMENT VIDEO DISPLAY TERMINALS (VDT’S) SAFETY BACK INJURY REDUCTION AND PREVENTION MANUAL MATERIAL HANDLING IMPROVEMENT CUMULATIVE TRAUMA DISORDER (CTD) REDUCTION NWACC Business & Industry Workforce Development Institute ER - ‹#› KEY PROGRAM ELEMENTS (Continued) MEDICAL MANAGEMENT Follow-up Recordkeeping Symptom surveys Health surveillance Classify job demands Disability management Establish treatment protocols Periodic reviews with physicians Early symptoms reporting mechanism Health care providers must be part of the program NWACC Business & Industry Workforce Development Institute ER - ‹#› KEY PROGRAM ELEMENTS (Continued) ERGONOMICS WORKING GROUP WRITTEN PROGRAM EMPLOYEE INVOLVEMENT TOP MANAGEMENT COMMITMENT REGULAR PROGRAM ACTIVITY, REVIEW AND EVALUATION NWACC Business & Industry Workforce Development Institute ER - ‹#› KEY PROGRAM ELEMENTS (Continued) HAZARD PREVENTION AND CONTROL PPE REDUCTION ENGINEERING CONTROLS ADMINISTRATIVE CONTROLS OPTIMIZATION OF WORK PRACTICES DANGER EYE PROTECTION REQUIRED BEYOND THIS POINT NWACC Business & Industry Workforce Development Institute ER - ‹#› INDUSTRIAL HYGIENE AND ERGONOMIC CONTROLS ENGINEERING CONTROLS Work Station Design Process Modification Tool Selection and Design Mechanical Assist ADMINISTRATIVE CONTROLS Training Programs Pacing FIRST CHOICE SECOND CHOICE Job Rotation/Enlargement Policy and Procedures PERSONNEL PROTECTIVE EQUIPMENT LAST CHOICE Gloves Shields Non-Slip Shoes NWACC Business & Industry Workforce Development Institute Wraps Eye Protection Aprons ER - ‹#› INDUSTRIAL HYGIENE AND ERGONOMIC CONTROLS OCCUPATIONAL RISK FACTORS: Occupational risk factors are defined as any attribute of a job or task that we know increases the probability of injury or illness. INAPPROPRIATE 1. Force - Including- Internal or External 2. Posture - Such as - Extreme Twisting or Bending 3. Repetition - Including- Muscle Group Overexertion 4. Insufficient Rest - Including- Muscle Group Overexertion NWACC Business & Industry Workforce Development Institute ER - ‹#› WORKSITE ANALYSIS WORKSITE ANALYSIS IS DIVIDED INTO FOUR MAIN PARTS: 1. Gathering information from available sources. 2. Conducting baseline screening surveys to determine which jobs need a closer analysis. 3. Performing ergonomic job hazard analyses of those work stations with identified risk factors. 4. After implementing control measures, conducting periodic surveys and follow-up to evaluate changes. NWACC Business & Industry Workforce Development Institute ER - ‹#› WORKSITE ANALYSIS Continued SYMPTOM SURVEY 1. NOTE AREAS OF PAIN OR DISCOMFORT! 2. WHAT DO YOU FEEL IS THE SOURCE? 3. WHAT ENVIRONMENTAL CHANGES WOULD HELP? 4. WHAT OTHER FEEDBACK CAN BE GATHERED? NWACC Business & Industry Workforce Development Institute FRONT BACK ER - ‹#› INCIDENCE RATES INCIDENCE RATES: incidence rates for upper extremity disorders and/or back injuries should be calculated by counting the incidences of CTDs and reporting the incidences per 100 full time workers per year per facility. INCIDENCE RATE (NUMBER OF NEW CASES (200,000 WORK HRS*) PER FACILITY NUMBER OF HOURS WORKED/FACILITY/YR * 200,000 = APPROXIMATE ANNUAL WORK HOURS FOR 100 WORKERS. * THE SAME METHOD SHOULD BE APPLIED TO DEPARTMENTS, PRODUCTION LINES, OR JOB TYPES WITHIN EACH FACILITY. NWACC Business & Industry Workforce Development Institute ER - ‹#› INCIDENCE RATES (Continued) SAMPLE INCIDENCE RATE CALCULATION: (NUMBER OF NEW CASES (200,000 WORK HRS*) PER FACILITY NUMBER OF HOURS WORKED/FACILITY/YR IF YOU EXPERIENCED 2 CARPAL TUNNEL CASES LAST YEAR, IN A POPULATION OF 100 EMPLOYEES. WHAT IS THE INCIDENCE RATE? 2 X 200,000 IR = IR = 100 X (50 X 40 hrs) 400,000 200,000 IR = 2 CASES OF CARPAL TUNNEL PER 100 PERSON-YEARS OF EXPOSURE * 200,000 = APPROXIMATE ANNUAL WORK HOURS FOR 100 WORKERS. * THE SAME METHOD SHOULD BE APPLIED TO DEPARTMENTS, PRODUCTION LINES, OR JOB TYPES WITHIN EACH FACILITY. NWACC Business & Industry Workforce Development Institute ER - ‹#› ANTHROPOMETRY DEFINED ANTHROPOMETRY: The technology of measuring and quantifying various human physical traits such as size, weight, proportion, mobility and strength. NWACC Business & Industry Workforce Development Institute ER - ‹#› ANTHROPOMETRY DEFINED ENGINEERING ANTHROPOMETRY: The application of anthropometric data to equipment, workplace and job design to enhance the efficiency, safety and comfort of the operator. NWACC Business & Industry Workforce Development Institute ER - ‹#› ANTHROPOMETRIC DIMENSIONS Inches Abbreviated Table of Anthropometric Dimensions Physical Dimension 1. Stature 2. Eye ht. 3. Hip ht. 4. Elbow ht. MEN 5th 64.0 59.6 33.1 39.6 NWACC Business & Industry Workforce Development Institute 50th 62.5 64.2 36.2 42.9 WOMEN 95th 73.0 68.7 39.4 46.5 5th 59.3 55.3 29.1 36.6 50th 63.4 59.3 31.9 39.6 95th 67.3 63.4 42.7 42.7 ER - ‹#› ERGONOMIC RISK FACTORS PERSONAL RISK FACTORS 1. 2. 3. 4. 5. 6. 7. Age Gender Attitude Training Strength Work method Anthropometry NWACC Business & Industry Workforce Development Institute ER - ‹#› ERGONOMIC RISK FACTORS Continued JOB RISK FACTORS 1. Weight of load 2. Location/size of load 3. Frequency of the Task 4. Duration and pace of cycle 5. Stability of load 6. Coupling of load 7. Travel distances of worker 8. Reach distances of worker 9. Symmetry between worker and the object held NWACC Business & Industry Workforce Development Institute ER - ‹#› ERGONOMIC RISK FACTORS Continued JOB RISK FACTORS 10. Static work posture a) Standing b) Sitting 11. Work platforms or stairs 12. Torso flexion (bending) a) Mild (up to 45 degrees) b) Severe (greater than 45 degrees) 13. Work heights (too high or too low) 14. Floor surfaces (wet, smooth, vibration) NWACC Business & Industry Workforce Development Institute ER - ‹#› ERGONOMIC RISK FACTORS Continued JOB RISK FACTORS 15. Environment a) Hot (sweat, reduced grip, fatigue) b) Cold (gloves reduce grip by as much as 30%) 16. Lighting a) posture problems (because of inability to see) 17. Noise/vibration a) Frequency very important b) Can amplify through the body NWACC Business & Industry Workforce Development Institute ER - ‹#› ERGONOMIC RISK FACTORS Continued WHAT ARE THE PRIMARY RISK FACTORS ASSOCIATED WITH YOUR JOB? NWACC Business & Industry Workforce Development Institute ER - ‹#› JOB AND TASK ANALYSIS UNIT LOADS: DEFINED AS: The unit to be moved or handled at any one time. THE CONTAINER, CARRIER, OR SUPPORT USED TO MOVE MATERIALS MUST BE INCLUDED AS PART OF THE UNIT LOAD. NWACC Business & Industry Workforce Development Institute ER - ‹#› JOB AND TASK ANALYSIS Continued FACTORS AFFECTING UNIT LOADS THE MATERIAL TO BE UTILIZED THE QUANTITY OF MATERIAL TO BE HANDLED THE SUSCEPTIBILITY OF THE MATERIAL TO DAMAGE THE NUMBER OF TIMES THE UNIT LOAD IS HANDLED THE RECEIVING, STORING, SHIPPING, AND HANDLING METHODS THE ENVIRONMENTAL CONDITIONS TO WHICH THE LOAD IS EXPOSED NWACC Business & Industry Workforce Development Institute ER - ‹#› JOB AND TASK ANALYSIS Continued DESIGNING THE UNIT LOAD OPTIMIZE THE WEIGHT OF THE LOAD REDUCE THE SIZE OF THE LOAD INSURE STABILITY OF THE LOAD OPTIMIZE LOAD COUPLING - HAND TO LOAD - FOOT TO FLOOR NWACC Business & Industry Workforce Development Institute ER - ‹#› JOB AND TASK ANALYSIS Continued DEFINITION OF TERMS: Fundamental Movements or acts “ELEMENT” - Search - Select - Grasp - Reach - Move - Hold - Position NWACC Business & Industry Workforce Development Institute - Inspect - Assemble - Disassemble - Delay (unavoidable) - Delay (avoidable) - Plan - Rest (overcome fatigue) ER - ‹#› JOB AND TASK ANALYSIS Continued DEFINITION OF TERMS: The time required to complete one sequence of tasks sub- tasks, or elements. “CYCLE” Example: 1. 2. 3. 4. Assemble new box Put bottles in box from conveyor Stack boxes on pallet Go to step 1 NWACC Business & Industry Workforce Development Institute ER - ‹#› JOB AND TASK ANALYSIS Continued TASK ANALYSIS IDENTIFY THE JOB TO STUDY COLLECT THE DATA EVALUATE THE DATA FORMULATE CONTROL MEASURES NWACC Business & Industry Workforce Development Institute ER - ‹#› JOB AND TASK ANALYSIS Continued IDENTIFYING THE JOB TO STUDY ACCIDENT INVESTIGATIONS ACCIDENT STATISTICS COMPLAINTS & OPERATOR FEEDBACK PRODUCTION BOTTLENECKS, HIGH ERRORS HIGH EMPLOYEE TURNOVER JOBS NWACC Business & Industry Workforce Development Institute ER - ‹#› JOB AND TASK ANALYSIS Continued COLLECTING THE DATA DIRECT OBSERVATION VIDEO TAPE ACTION PHOTOGRAPHS DOCUMENTARY ACCOUNTS ACCIDENT STATISTICS NWACC Business & Industry Workforce Development Institute ER - ‹#› JOB AND TASK ANALYSIS Continued EVALUATING THE DATA TASK DESCRIPTION SUB-TASK DESCRIPTION ELEMENT DESCRIPTION RISK FACTOR/HAZARD IDENTIFICATION NWACC Business & Industry Workforce Development Institute ER - ‹#› JOB AND TASK ANALYSIS Continued FORMULATING CONTROL MEASURES APPLICATION OF ERGONOMIC PRINCIPLES CORRECTIVE ACTION FOR NON-COMPLIANCE ELIMINATE OR REDUCE EXPOSURE NWACC Business & Industry Workforce Development Institute ER - ‹#› JOB AND TASK ANALYSIS Continued TASK ANALYSIS FORM TASK DESCRIPTION LEFT HAND RIGHT HAND FREQUENCY NOTES POSTURE FORCE DURATION NWACC Business & Industry Workforce Development Institute - Action Being Performed - Usage - Usage - Usually per minute - Supporting information - Acceptable to extreme - High, Medium, Low - Length of Stressor ER - ‹#›