High Aspect Ratio and Complex Shaped Blind Micro Holes by Micro EDM 姓名:盧世宗

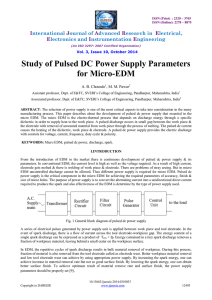

advertisement

High Aspect Ratio and Complex Shaped Blind Micro Holes by Micro EDM 姓名:盧世宗 學號:m97r0101 98.05.19 大綱 • 前言 • 實驗步驟 • 結果與討論 前言 • 在微細放電加工很難做出高深寬比的微小 加工孔因為加工時會有殘存材料的碎片因 為孔徑太小加工液無法帶走加工屑導致放 電異常與電極過度磨損降低加工精度。 • 本論文提出一個新的辦法可以有效的把加 工屑去除提高加工精度。 實驗步驟 Hole exit Hole entrance. 電極消耗比較 較複雜的加工孔 Triangular blind hole Square blind hole. P ntago al blind hole. 結果與討論 In micro EDM, the discharge gap is very small, and the size of the electrode is too small to use internal and/or external flushing to remove debris. In this paper, a new approach using planetary movement of the electrode is proposed to reduce the debris concentration and improve precision. The planetary movement of electrode provides extra space for debris removal. Therefore, the material removal rate increases and the electrode wear reduces. This method has been verified by machining of micro holes with high aspect ratio and blind noncircular micro holes. 參考文獻 Z . Y . Yu, k . P . Rajurkar ,H . Shen , High Aspect Ratio and Complex Shaped Blind Micro Holes by Micro EDM 謝謝聆聽~