Lily Pollen Tube Cell Wall Growth Sylvester McKenna, Larry Winship,

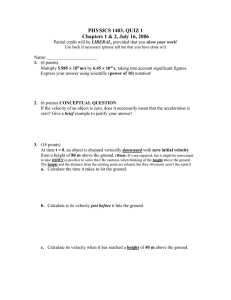

advertisement

Lily Pollen Tube Cell Wall Growth

Sylvester McKenna,

Larry Winship,

Research in the lab of Peter Hepler

Math by Joe Kunkel

Pollen tube auto-peak-identification.

1. Growing tubes have 200+ image frames with

600+ pixel length. Automation is a priority.

2. The tube tip profile does not always own the

maximum density on the profile.

3. The profiles do not always have two distinct

peaks associated with the outer and inner edge.

How does one deal with shoulder peaks.

4. The outer base density differs from the inner

base density.

Pollen tube axial profile tip ID:

True tip profile.

• In some tubes the maximum fringe is not the tip profile!

• Auto-identification of tip profiles must deal with all cases.

Spurious peak.

True tip profile.

R scripting:

•

Wall_1_Prep.R

–

•

Wall_2_dGauss.R

–

•

Initial peak identification allows 2 peaks to

be given a peak pixel location.

Peak refinement allows fractional pixel

identification by fitting two Gausian curves

to the DIC profile of the pollen tube tip wall.

Shoulders on primary peaks can be

identified as a Gaussian component.

Wall_3_Anal.R

–

Wall-thickness and Tip Velocity crosscorrelation analysis.

R script 1: Wall_1_Prep.R menu …

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

back | <

fwd | >

98% dx | 102% dx | +

tog-5 | 5

+2nd | 2

-2nd | 1

no_force | 0

goto | g

browse | b

cntr | c

sort | s

wid | w

nar | n

abort | *

sets previous 10 profiles as current.

set next 10 profiles as current.

decrease the Y-axis focus span.

increase the Y-axis focus span.

shift span of profiles by 5.

add or re-add a second peak.

remove a second peak.

remove force on choosing a peak.

go to any frame in the series.

allows examining current variables.

allows choice of a new focus for a frame.

does a sort of the peak orders for current.

widen the X-axis pixel span.

narrow the X-axis pixel span.

close down the program.

R script 1: Wall_1_Prep.R I/O

•

Input

–

–

–

–

–

Requests the name of a ‘.log’ file.

Asks if the log file is new.

If not new, asks for a numeric suffix of prior output.

Asks if an output in memory should be used/recovered.

Asks for a numeric suffix to add to an output file.

• A menu allows character driven choice of changes to identifying

pollen tube tip profile parameters:

– Identify a proximal profile peak pixel.

– Review auto-chosen peaks and allow changes.

• Produces an output file identified by a numeric suffix:

–

–

–

–

–

–

Cols 2-3: peak-1 and peak-2 X-axis location in um.

Cols 9,11: peak-1 and peak-2 integer pixel location.

Cols 10,12: peak-1 and peak-2 standard deviation (1 by default)

Col 7: 0, 1, 2 auto peaks or 3, a forced set of peaks.

Col 8: 0, 1 indicates whether current means and SD are set.

Col 4,5,6: F, D , Diff parameters for mixing Gaussian distributions.

R-script 2: Wall_2_dGauss.R

• Helps fit a pair of

Gaussian distributions

to the pollen tube DIC

profile.

• Menu allows changes

to mean and SD of

leading and trailing

Gaussian distributions.

• Ends with using

means to estimate tip

velocity and wall

thickness.

R script 2: Wall_2_dGauss.R I/O

•

Input

–

–

–

–

Requests the name of a ‘.log’ file.

Asks for a numeric suffix of prior output.

Asks if an output in memory should be used/recovered.

Asks for a numeric suffix to add to an output file.

• A menu allows character driven choice of changes to set pollen tube

tip profile parameters:

– Identify profile peaks that need mean, SD, F and D adjustment.

– Allows inheritance of SD, F and D parameters from previous profile.

– Sets Col 8 to 1 when adjustments have been made.

Contour

prior to

fitting

• Produces an output file identified by a numeric suffix:

–

–

–

–

–

–

Cols 2-3: peak-1 and peak-2 X-axis location in um.

Cols 9,11: peak-1 and peak-2 integer pixel location.

Cols 10,12: peak-1 and peak-2 standard deviation (1 by default)

Col 7: 0, 1, 2 auto peaks or 3, a forced set of peaks.

Col 8: 0, 1 indicates whether current means and SD are set.

Col 4,5,6: F, D , Diff parameters for mixing Gaussian distributions.

• Each contour must be adjusted individually, thus a need for

efficiency.

Contour

after

fitting

Protocol for fitting contours to a tip profile:

• The means, u1 and u2, are preliminarily set

as the center of the pixel identified as the

peak of a DIC fringe. The SDs are

preliminarily set to 1 for convenience.

• Means, u1 and u2, and SDs are changeable

in adjustable sub-pixel increments.

• The joint contour is auto adjusted to

coincide with the peak of the contour data

with parameter F for visual display.

• The relative contribution of peak 1 and 2 to

the joint contour is adjustable in increments

by parameter D to visually conform to data.

• u1, SD1, u2, SD2, F and D are stored in an

output matrix which can reproduce the

predicted outline.

• SDs, F and D are inheritable as an aid.

• Wall Thickness is computed as u2-u1. Tip

Velocity is computed from the positions of

u1 in adjacent frames.

Contour

prior to

fitting

Contour

after

fitting

Sample output of Wall_dGauss.R:

Wall_3_Anal.R: Wall thickness and Tip Velocity

Sample output of Wall_Anal.R:

• Original data fit with lowess(f=0.02)

• Corrected by subtracting median with lowess(f=0.2)

Wall_3_Anal.R: Wall thickness and Tip Velocity

…for data set 061506f …

Sample output of Wall_Anal.R:

A.

B.

• A. Auto-correlation of tip-velocity.

• B. Cross-correlation of Tip-Velocity with Wall Thickness.

• Shows that Tip Velocity follows Wall-Thickness peak but predicts the

Wall-Thickness trough better. Is that significant and meaningful?

• Are these conclusions generalizeable to other data sets?

Wall_3_Anal.R: Wall thickness and Tip Velocity

…offset correlations for data set 061506f …

A.

Sample output of Wall_Anal.R:

B.

• A. Correlation of Tip-velocity preceding Wall thickness by 3-7 frame units.

• B. Correlation of Tip-Velocity after Wall Thickness by 3-7 frame units.

• Shows that Tip Velocity predicts Wall-Thickness, r2 = 0.44, but predicts the WallThinness a bit better, r2= 0.59. Is that significant and meaningful?

• Are these conclusions generalizeable to other data sets?

Andy.R: Wall thickness and Tip Velocity

…ANOVA of set 061506f …

Sample output of Andy.R:

•

•

•

•

Individually Velocity is correlated with Wall Thickness (-7 and +6) by (r = 0.66, -0.77).

Using both provides a better joint correlation of r = 0.80.

Wall-Thickness predicts Tip Velocity, r2= 0.64 which is better than the individual

explanations (r2 = 0.44, 0.59). This is significant and meaningful!

Are these conclusions generalizeable to other data sets?

Andy.R: Wall thickness and Tip Velocity

…ANOVA of set 061506f …

Output of Andy.R:

•

•

•

•

Individually Velocity is correlated with Wall Thickness (-7 and +6) by (r = 0.66, -0.77) or

(r2 = 0.44, 0.59).

Using both provides a better joint correlation of r = 0.80 or 64% of variability.

The effects are not visually or dramatically but are statistically significant.

Are these conclusions generalizeable to other data sets? (now have two sets consistent.)

How Andy.R and was initially used

• Wall_3_Anal.R provided an output

matrix: 061506fs.log2.out.csv of

Velocity plus offset Wall Thickness

data. The original Nframes of data

needed to be trimmed by 7 lines at

beginning and end to allow for

offsets of the wall data in both

directions.

• This data with a column of 1’s

representing the mean was submitted

to Andy.R and the equation V = u +

Wth(-7) + Wth(+6) was evaluated.

• The contribution of the two WallThickness offsets to predicting V

were tested by subtraction and found

to be both highly significant.

• The parameters of the

equation were used to

predict V and the result

was found to explain

64% of the variability of

V.

• Eventually 6-tubes data

would be analyzed

together.

GAM analysis 1

•

•

•

•

Formula: Velocity ~ s(Wp3) + s(Wp4) + s(Wp5) + s(Wp6) + s(Wp7) + s(Wm3) + s(Wm4) + s(Wm5) + s(Wm6) +

s(Wm7)

Parametric coefficients:

Estimate Std. Error t value Pr(>|t|)

(Intercept) 0.001956 0.002167 0.903 0.368

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Approximate significance of smooth terms:

edf Est.

rank

F

s(Wp3)

1.000

1

6.027

s(Wp4)

2.327

5

3.053

s(Wp5)

1.064

3

1.597

s(Wp6)

1.000

1

4.210

s(Wp7)

1.672

4

1.926

s(Wm3)

2.038

5

1.422

s(Wm4)

3.597

8

2.752

s(Wm5)

1.000

1

1.257

s(Wm6)

1.000

1

0.023

s(Wm7)

5.487

9

2.133

--Signif. codes: 0 ‘***’ 0.001 ‘**’ 0.01 ‘*’ 0.05 ‘.’ 0.1 ‘ ’ 1

•

•

•

R-sq.(adj) = 0.75 Deviance explained = 77.4%

GCV score = 0.0011155 Scale est. = 0.001005 n = 214

Conclusion: Focus on the significant offsets (-7, -4, 3, 4, 6)!

p-value

0.01498 * <- {1 df thus it does not need smooth)

0.01123 * <0.19140

0.04155 * <- {1 df thus it does not need smooth)

0.10772

0.21795

0.00672 **<0.26368

0.88051

0.02855 * <-

GAM analysis 2

•

•

•

•

Formula: Velocity ~ s(Wp3) + s(Wp4) + s(Wp6) + s(Wm4) + s(Wm7)

Parametric coefficients:

Estimate Std. Error t value Pr(>|t|)

(Intercept) 0.001956 0.002197 0.891 0.374

•

•

•

•

•

•

•

•

•

Approximate significance of smooth terms:

edf

Est.rank F

p-value

s(Wp3)

1.000

1

6.943

0.00908 ** {1 df thus it does not need smooth)

s(Wp4)

2.531

6

3.245

0.00458 **

s(Wp6)

1.052

3

8.940

1.39e-05 *** { ~1 df thus it does not need smooth?)

s(Wm4)

4.010

9

5.753

4.23e-07 ***

s(Wm7)

4.921

9

2.508

0.00968 **

--Signif. codes: 0 ‘***’ 0.001 ‘**’ 0.01 ‘*’ 0.05 ‘.’ 0.1 ‘ ’ 1

•

•

R-sq.(adj) = 0.743 Deviance explained = 75.9%

GCV score = 0.0011079 Scale est. = 0.0010327 n = 214

GAM analysis 3

•

•

•

•

Formula: Velocity ~ s(Wp6) + s(Wm7)

Parametric coefficients:

Estimate Std. Error t value Pr(>|t|)

(Intercept) 0.001956 0.002581 0.758 0.449

•

•

•

•

•

•

Approximate significance of smooth terms:

edf

Est.rank F

p-value

s(Wp6)

2.080

5

25.57

< 2e-16 ***

s(Wm7)

1.001

2

16.68

1.89e-07 ***

--Signif. codes: 0 ‘***’ 0.001 ‘**’ 0.01 ‘*’ 0.05 ‘.’ 0.1 ‘ ’ 1

•

•

R-sq.(adj) = 0.645 Deviance explained = 65%

GCV score = 0.0014538 Scale est. = 0.001426 n = 214

•

The model : Velocity ~ s(Wp6) + s(Wm7) + s(Wp6,Wm7) yielded no evidence of

an interaction between the leading peak of Wall-Thickness and trailing trough.

GLM and GAM correlations

Data set 061506f:

•R

•

•

•

•

•

Vo

Ve

pG

pG2

pG3

• R2

•

•

•

•

•

Vo

Ve

pG

pG2

pG3

Vo

Ve

pG

pG2

pG3

1.000

0.844

0.880

0.871

0.806

0.844

1.000

0.975

0.972

0.944

0.880

0.975

1.000

0.993

0.930

0.871

0.972

0.993

1.000

0.934

0.806

0.944

0.930

0.934

1.000

Vo

Ve

pG

pG2

pG3

1.000

0.713

0.774

0.759

0.650

0.713

1.000

0.951

0.945

0.891

0.774

0.951

1.000

0.987

0.865

0.759

0.945

0.987

1.000

0.873

0.650

0.891

0.865

0.873

1.000

all offsets

(-7, -4 , 3, 4, 6)

Wall thickness and Tip Velocity

… / / GLM on set 061506f … then GAM /

Output of GAM /\ vs GLM /\ /\ :

•

•

•

•

Individually Velocity is correlated with Wall Thickness, (-7 and +6) by (r = 0.66, -0.77).

Using both provides a better joint correlation of r = 0.80 (r2=0.64) above in red.

Knowledge of Wall Thickness explains substantial amounts of the variation of Tip Velocity.

The general additive model (GAM) achieves an r =0.88 (r2=0.77) using 10 Wall

Thickness offsets. An r =0.87 (r2=0.76) using 5 Wall Thickness offsets (-7, -4 , 3, 4, 6).

Replicates of Corr 1, 2:

Replicates of Corr 3, 4:

Replicates of Corr 5, 6:

Analysis of 6 tube data via GLM

1.

Velocity and Wall-thickness offset data from

6 tubes were combined into one data +

design matrix.

Analysis of dispersion script andy.R was

used to fit Velocity to Wall-Offset and

pollen-tube specific effects:

Vmi = u + WTpj + WTmk + tubem

2.

3.

•

•

•

•

•

4.

5.

i = image frame 1…Nm

j = Wall thicknesses offset plus direction

k = Wall thicknesses offset mins direction

m = Pollen tube #, 1…6.

Nm = Number of image frames in tube m.

Since these items are all correlated, they

must be analyzed by subtraction from a joint

reduction of Velocity Sums of Squares.

Wall thickness as measured physically and

by PI fluorescence can each be measured in

what sense they can predict Tip Velocity.

Tube data sample sizes:

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

>

t(Xdes[N1,12:16])%*%Xdes[N1,12:16]

Tube1 Tube2 Tube3 Tube4 Tube5

Tube1

210

0

0

0

0

Tube2

0

0

0

0

0

Tube3

0

0

0

0

0

Tube4

0

0

0

0

0

Tube5

0

0

0

0

0

>

t(Xdes[N2,12:16])%*%Xdes[N2,12:16]

Tube1 Tube2 Tube3 Tube4 Tube5

Tube1

0

0

0

0

0

Tube2

0

187

0

0

0

Tube3

0

0

0

0

0

Tube4

0

0

0

0

0

Tube5

0

0

0

0

0

>

t(Xdes[N3,12:16])%*%Xdes[N3,12:16]

Tube1 Tube2 Tube3 Tube4 Tube5

Tube1

0

0

0

0

0

Tube2

0

0

0

0

0

Tube3

0

0

210

0

0

Tube4

0

0

0

0

0

Tube5

0

0

0

0

0

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

>

t(Xdes[N4,12:16])%*%Xdes[N4,12:16]

Tube1 Tube2 Tube3 Tube4 Tube5

Tube1

0

0

0

0

0

Tube2

0

0

0

0

0

Tube3

0

0

0

0

0

Tube4

0

0

0

210

0

Tube5

0

0

0

0

0

>

t(Xdes[N5,12:16])%*%Xdes[N5,12:16]

Tube1 Tube2 Tube3 Tube4 Tube5

Tube1

0

0

0

0

0

Tube2

0

0

0

0

0

Tube3

0

0

0

0

0

Tube4

0

0

0

0

0

Tube5

0

0

0

0

210

>

t(Xdes[N6,12:16])%*%Xdes[N6,12:16]

Tube1 Tube2 Tube3 Tube4 Tube5

Tube1

210

210

210

210

210

Tube2

210

210

210

210

210

Tube3

210

210

210

210

210

Tube4

210

210

210

210

210

Tube5

210

210

210

210

210

N1= 210, N2= 187, N3= 210, N4= 210, N5= 210, N6= 210

Design Matrix X: Independent Vars

ß

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

[1,]

[2,]

[3,]

[4,]

[5,]

[6,]

[7,]

[8,]

[9,]

[10,]

[11,]

[12,]

[13,]

[14,]

[15,]

[16,]

[17,]

[18,]

[19,]

[20,]

Mean WTp3 WTp4 WTp5 WTp6 WTp7 WTm3 WTm4 WTm5 WTm6 WTm7 Tube1 Tube2 Tube3 Tube4 Tube5

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

-68

-41

-10

18

50

29

78

113

172

130

71

102

84

102

146

99

58

42

15

-10

-41

-10

18

50

29

78

113

172

130

71

102

84

102

146

99

58

42

15

-10

-12

-10

18

50

29

78

113

172

130

71

102

84

102

146

99

58

42

15

-10

-12

-31

18

50

29

78

113

172

130

71

102

84

102

146

99

58

42

15

-10

-12

-31

-62

50

29

78

113

172

130

71

102

84

102

146

99

58

42

15

-10

-12

-31

-62

-5

-44

-14

-53

-67

-76

-74

-68

-41

-10

18

50

29

78

113

172

130

71

102

84

102

Velocity = X ß + error

-34

-44

-14

-53

-67

-76

-74

-68

-41

-10

18

50

29

78

113

172

130

71

102

84

31

-34

-44

-14

-53

-67

-76

-74

-68

-41

-10

18

50

29

78

113

172

130

71

102

-11

31

-34

-44

-14

-53

-67

-76

-74

-68

-41

-10

18

50

29

78

113

172

130

71

43

-11

31

-34

-44

-14

-53

-67

-76

-74

-68

-41

-10

18

50

29

78

113

172

130

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

E[Velocity] = X ß

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

R-prompt plotting of 6 Velocity curves

> par(mar=c(0.1, 0.1, 0.1, 0.1) + 0.1) # reduces margins

> layout(matrix(c(1:6), 6, 1, ))

# creates multi-plot layout

> plot(Velocity[N1], typ='p')

# plot tube 1 data

> lines(EVel[N1], typ='l', lwd=3) # add expected tube 1 line

> plot(Velocity[N2], typ='p')

#…

> lines(EVel[N2], typ='l', lwd=3)

> plot(Velocity[N3], typ='p')

> lines(EVel[N3], typ='l', lwd=3)

> plot(Velocity[N4], typ='p')

> lines(EVel[N4], typ='l', lwd=3)

> plot(Velocity[N5], typ='p')

> lines(EVel[N5], typ='l', lwd=3)

> plot(Velocity[N6], typ='p')

> lines(EVel[N6], typ='l', lwd=3)

E[Velocity] = X ß, R = 0.749, R2 = 0.561

Tip velocity is fit by a common function of prior and succeeding wall-thicknesses.

061406q

061506c

061506e

061506f

061506l

061506m

Analysis of 6 tube data via GAM

1.

Velocity and Wall-thickness offset data from

6 tubes were combined into one data +

design matrix.

require(mgcv):

Vmi ~ s(WTpj) + s(WTmk) + tubem

2.

3.

•

•

•

•

•

4.

5.

6.

7.

i = image frame 1…Nm

j = Wall thicknesses offset in plus direction

k = Wall thicknesses offset in minus direction

m = Pollen tube #, 1…6.

Nm = Number of image frames in tube m.

Since these items are all correlated, they

must be analyzed by subtraction from a joint

reduction of Velocity Sums of Squares.

Wall thickness as measured physically and

by PI fluorescence can each be measured in

what sense they can predict Tip Velocity.

There is no significance to different pollen

tubes in predicting tip velocity in either

GLM or GAM analysis!! Ergo, it is a very

uniform process!!!

Rscript to compare GAM to GLM fit:

source("Velo-WTglm+WTgam.R")

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Formula: Velocity ~ s(WTp3) + s(WTp4) + s(WTp5) +

s(WTp6) + s(WTp7) + s(WTm3) + s(WTm4) + s(WTm5) +

s(WTm6) + s(WTm7) + Tube1 + Tube2 + Tube3 + Tube4 +

Tube5

Parametric coefficients:

Estimate Std. Error t value Pr(>|t|)

(Intercept) 0.001402 0.001489 0.942 0.346

Tube1

-0.003875 0.003468 -1.118 0.264

Tube2

0.003306 0.003983 0.830 0.407

Tube3

0.002695 0.003435 0.785 0.433

Tube4

-0.003875 0.003468 -1.118 0.264

Tube5

0.001558 0.003357 0.464 0.643

Approximate significance of smooth terms:

edf Est.rank F p-value

s(WTp3) 5.040

9 5.775 6.93e-08 ***

s(WTp4) 5.164

9 4.150 2.77e-05 ***

s(WTp5) 1.000

1 6.281 0.01234 *

s(WTp6) 4.348

9 2.049 0.03131 *

s(WTp7) 7.188

9 2.533 0.00704 **

s(WTm3) 6.520

9 4.826 2.37e-06 ***

s(WTm4) 1.000

1 1.780 0.18238

s(WTm5) 5.287

9 2.620 0.00533 **

s(WTm6) 8.557

9 4.061 3.80e-05 ***

s(WTm7) 5.922

9 3.009 0.00148 **

--Signif. codes: 0 ‘***’ 0.001 ‘**’ 0.01 ‘*’ 0.05 ‘.’ 0.1 ‘ ’ 1

•

•

R-sq.(adj) = 0.601 Deviance explained = 61.8% R = 0.786

GCV score = 0.002865 Scale est. = 0.0027353 n = 1237

E[Velocity] = GAM(X), R = 0.786, R2 = 0. 618

Tip velocity is fit by GAM(wall-thicknesses+tube#) and compared to GLM.

061406q

061506c

061506e

061506f

061506l

061506m

Notes on R-scripts

Fixes of Wall R-scripts 0.9:

1.

2.

3.

4.

Added memory of a recent log file.

Added output of a CSV file of Velocity and

offset Wall thicknesses used to analyze the

prediction of Velocity using andy.R and

GAM.

Problem with sort routine when reloading

an output file. Needed to be loaded

as.matrix() rather than as a data frame.