Optimal Commutation of a BLDC Motor by Utilizing the Symmetric Terminal Voltage

advertisement

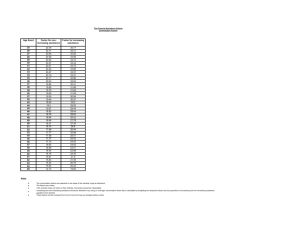

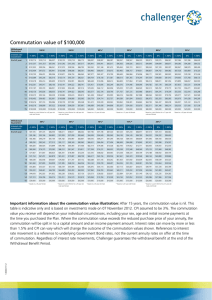

IEEE TRANSACTIONS ON MAGNETICS, VOL. 42, NO. 10, OCTOBER 2006 Optimal Commutation of a BLDC Motor by Utilizing the Symmetric Terminal Voltage G. H. Jang and M. G. Kim Precision Rotating Electromechanical Machine Laboratory (PREM), Department of Precision Mechanical Engineering,Hanyang University, Seoul 133-791, Korea 1 Professor : Ying-Shieh, Kung Student ID : Yi-Chun,Chen SN : M9920206 Date : 2011.03.23 Outline Abstract I. INTRODUCTION II. DETECTION OF COMMUTATION POSITION OF A BLDC MOTOR III. SYSTEM IMPLEMENTATIONS AND EXPERIMENTAL VERIFICATION IV. CONCLUSION 2 Abstract This paper presents a method to determine the improved commutation position of a brushless DC (BLDC) motor in such a way as to generate the symmetric terminal voltages of the nonenergized phase at the beginning and end of the commutation period. If the BLDC motor is energized at the exact commutation position, the terminal voltage of the nonenergized phase at the beginning of commutation is equal to the terminal voltage at the end of commutation, and the waveform of the terminal voltage should be symmetric. This paper also develops a DSP-based sensorless BLDC motor controller to implement the proposed method and to verify its effectiveness experimentally. This research shows that the proposed method improves the performance of 3 a BLDC motor by increasing torque and efficiency. I. INTRODUCTION(1/2) A BRUSHLESS DC (BLDC) motor is used in various applications of electromechanical systems because of its high efficiency and good controllability over a wide range of speed. The position information of a rotor is identified by using the sensors or the sensorless algorithms in order to energize the correct phase of windings at the exact commutation position. 4 I. INTRODUCTION(2/2) Some researchers have proposed several methods to detect the exact rotor position for optimal commutation. Chen and Liaw have proposed an intelligent commutation tuning method by minimizing winding current [3]. Song and Choy presented a new rotor position estimation method based on neutral voltage compensation [4]. Their methods have disadvantages to monitor both current and terminal voltage, and the latter did not present the experimental verification. 5 II. DETECTION OF COMMUTATION POSITION OF A BLDC MOTOR(1/6) When a BLDC motor is running, back-emf is induced in each phase and the position information of a rotor can be identified by monitoring the zerocrossing of the back-emf voltage where the voltage of neutral point is equal to the terminal voltage of nonenergized phase. However, it may not be easy to identify the zero-crossing position because high frequency components due to pulse width modulation (PWM) switching are involved in the terminal voltage. This method generally uses the low-pass filter to remove high-frequency components of the terminal voltage due to PWM switching. 6 II. DETECTION OF COMMUTATION POSITION OF A BLDC MOTOR(2/6) However, it results in the detection error of rotor position, i.e., the phase delay between the exact and the detected position information of a rotor, which is mainly affected by rotor speed, PWM frequency, and characteristics of the low-pass filter. Fig. 1 shows the back-emf waveform and the terminal voltage due to the change of commutation position. EB , EE, VB, and VE are the back-emf and the terminal voltage of nonenergized. Theoretically, the exact commutation should start at the shift angle of 30 electrical degrees after the rotor passes the exact zero-crossing position. 7 II. DETECTION OF COMMUTATION POSITION OF A BLDC MOTOR(3/6) If the BLDC motor is energized at the exact commutation position, EB and VB should be equal to EE and VE due to the trapezoidal shape of the back-emf voltage. The waveform of the terminal voltage should be symmetric as well. On the other hand, if there is a phase delay due to the low-pass filter, the actual commutation will start at the shift angle of 30 electrical degrees after the rotor passes the detected zero-crossing position. They result in the asymmetric waveform of the terminal voltage of the nonenergized phase, which is dominantly affected by the commutation position. 8 9 II. DETECTION OF COMMUTATION POSITION OF A BLDC MOTOR(4/6) Fig. 2 shows the asymmetric waveform of the filtered terminal voltage when a BLDC motor is energized at the incorrect commutation position. VBF and VEF are the filtered terminal voltages of the nonenergized phase at the beginning and end of the commutation period, respectively. Measured values of VBF and VEF are not symmetric not only because the low-pass filter distorts the actual shape of the terminal voltage when it changes abruptly, but also because there exists the freewheeling current in the switching of the commutation circuit. 10 II. DETECTION OF COMMUTATION POSITION OF A BLDC MOTOR(5/6) The slope of the filtered terminal voltage of the nonenergized phase is linear near the zero-crossing position so that and VBF,VEF without taking the effect of the low-pass filter and the freewheeling current into account, can be estimated with the following equations: where T, Z, and A are the shift angle, magnitude, and slope of the filtered terminal voltage at the zero-crossing position, respectively. 11 12 II. DETECTION OF COMMUTATION POSITION OF A BLDC MOTOR(6/6) Fig. 3 shows the algorithm of the proposed method. First, T, Z, and A are measured and calculated before and after the commutation period, respectively, and they are averaged during N electrical rotations in order to minimize the measurement error. Then, VBF and VEF are calculated by (1). If VBF is smaller than VEF, commutation has begun earlier than the exact commutation position. Then the shift angle increases in such a way as to increase VBF and decrease VEF so that the commutation position moves back. In the opposite case, the shift angle decreases so that the commutation position moves forward. This procedure repeats until VBF is equal to VEF and the terminal voltage is symmetric in the improved commutation of a BLDC motor. 13 14 III. SYSTEM IMPLEMENTATIONS AND EXPERIMENTAL VERIFICATION(1/5) Fig. 4 shows a DSP-based sensorless BLDC motor controller to implement the proposed method and to verify its effectiveness [5]. The position information of a rotor is detected by monitoring the back-emf voltage, and a DSP controls the switching of the inverter circuit and the speed of the motor with the proportional - integral (PI) control. A PWM signal is digitally generated by using timers. A low-pass filter is used in order to remove high-frequency components of the terminal voltage due to PWM switching. Speed, back-emf, and terminal voltage are directly monitored in the computer through communication circuits and the user interface program. 15 16 III. SYSTEM IMPLEMENTATIONS AND EXPERIMENTAL VERIFICATION(2/5) The proposed method is verified for a BLDC motor used in a computer hard disk drive. It has 8 poles and 12 slots, threephases, Y-winding, and the rated operating speed of 7200 r/min with a 3.5-in disk by a bipolar drive. It is driven by the supplied voltage of 12 V. Fig. 5 shows the measured filtered terminal and neutral voltages at the speed of 7200 r/min. The DSP determines the zero-crossing position by comparing the voltage of the neutral point with the terminal voltage of the nonenergized phase. The voltage at the zero-crossing position, ZB, is also measured by the DSP. The slope of the terminal voltage, , is calculated by measuring the terminal voltages four times every PWM period (12.8 s) from the zero crossing position. 17 18 III. SYSTEM IMPLEMENTATIONS AND EXPERIMENTAL VERIFICATION(3/5) The shift angle, TB, is determined by using the timer of the DSP. Then the DSP estimates the filtered terminal voltage of the nonenergized phase at the beginning of the commutation period, VBF, by using (1). The procedure is repeated to estimate the terminal voltage of the nonenergized phase at the end of the commutation period, VEF, and the improved commutation is determined by using the algorithm in Fig. 3. For the improved commutation of the given motor, the shift angles from the detected zero-crossing position (which is adjusted in the developed controller automatically) are 22 electrical degrees at 7200 r/min and 19 electrical degrees at 9200 r/min. 19 III. SYSTEM IMPLEMENTATIONS AND EXPERIMENTAL VERIFICATION(4/5) Fig. 6 shows the variation of terminal voltage and phase current by using the conventional method and the proposed method at 7200 r/min, respectively. The terminal voltages of the nonenergized phase at the beginning and end of the commutation period are determined to be 11.67 V and 7.94 V in the conventional method, and 10.68 V and 10.32 V in the proposed method, respectively. This shows that the terminal voltage of the proposed method is much more symmetric than that of the conventional method. The current ripples (peakto-peak value of phase current) of the proposed method and the conventional method are 0.23 A and 0.33 A, respectively, and the former is smaller than the latter by 30.3%. 20 21 III. SYSTEM IMPLEMENTATIONS AND EXPERIMENTAL VERIFICATION(5/5) The reduction of current ripple may contribute to the decrease of the ripple of torque and speed, and consequently vibration and noise. Fig. 7 shows the variation of input power due to the shift angle. Because the speed of the rotor is controlled constantly under the constant load, the output power is assumed to be constant regardless of shift angle. By applying the proposed method, the input power is reduced from 2.68 W to 2.59 W (3.4%) at 7200 r/min and from 4.38 W to 4.17 W (4.8%) at 9200 r/min. This shows that the proposed method increases the output torque by 22 selecting the improved commutation position so that it results in the reduction of input power and the increase of efficiency consequently. 23 IV. CONCLUSION This paper has presented a method to detect the improved commutation position of a BLDC motor by utilizing the symmetric terminal voltages of the nonenergized phase at the beginning and end of the commutation period. It also develops a DSP-based sensorless BLDC motor controller to implement the proposed method and to verify its effectiveness experimentally. The proposed method can be effectively applied to improve the performance of a BLDC motor. 24 Thanks for your attention! 25