下載/瀏覽

advertisement

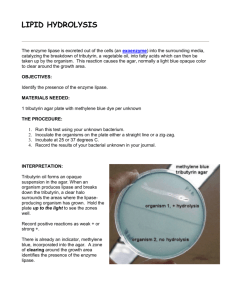

第一組 : 黃潔儀 葉冠諝 黃建國 指導教授 : 褚俊傑老師 日期 : 2014.04.24 Introduction Lipase are an important group of biotechnologically relevant enzymes and use in many ways: 1. The processing of fats and oils, detergents 2. Degreasing formulations(脫脂配方) 3. Food processing 4. The synthesis of fine chemicals and pharmaceuticals, paper manufacture 5. Production of cosmetics and pharmaceuticals 6. Accelerating the degradation of fatty waste and polyurethane(聚氨酯) Production of lipase was available from many sources: The most suitable sources for lipase production are microbes including 1. bacteria 2. fungi 3. yeast Lipase production is dependent upon a number of factors including 1. carbon 2. nitrogen sources, 3. pH, 4. temperature, 5. aeration 6. inoculums size MATERIALS AND METHODS Material and method of determination of Lipases (triacylglycerol hydrolase) 6.Partial Purification of Lipase 1.Collection of Samples 5.Optimization 4.Fermentation 3.Lipolytic Activity 2.Isolation and Identification of Bacteria 7.Enzyme Characterization 7.1>Determination of Optima and Stability of Temperature and pH 7.2>Application Study Collection of Samples 1. Samples such as soil, coconut, milk were subjected to serial dilution. 2. Serially diluted samples were plated to nutrient agar plates 3. kept for incubation at 37°C for 24-48 hours and the plates were observed for growth. Isolation and Identification of Bacteria Isolated bacterial cultures were examined for various morphological and biochemical characteristics Tested by: 1. 2. 3. 4. 5. 6. 7. 8. 9. Gram staining motility Indole test MR test VP test Citrate test Gelatin test Urease test Catalase test Lipolytic Activity All the isolated cultures were inoculated into tributyrin agar (三丁酸甘油酯瓊脂平板)plates and kept for incubation at 37°C for 24 hours and observed for zone formation A clear zone around the colonies indicates the production of lipase. Fermentation 1. Fermentation was carried out in shake flask using a complex medium 2. The flask containing 40mL fermentation medium were inoculated by 18 h old vegetative inoculums. 3. The inoculums development and the fermentations were carried out at 30°C for 7 days at 100 rpm Optimization 1. Lipase production was optimized at different pH (7 - 10), b. different temperature (30 - 60°C) c. incubation period (1-5 days) d. constant shaking at 120 rpm. a. 2. Bacteria were cultured in nutrient broth with 1% olive oil. 3. lipase activity will be measured every 12 h to determine the maximum lipase producing period. Partial Purification of Lipase 1.in order to precipitate fatty acids: the culture supernatant was treated with 0.4M CaCl2 followed by centrifugation at 4°C and 12,857 g for 30 min. 2.allowing protein precipitation: The supernatant was collected in a glass beaker and to it chilled acetone was added slowly, with continuous stirring, up to 70% (v/v) concentration and kept at 20°C for 4 h Partial Purification of Lipase 3.Harvested the precipitates: centrifugation at 4°C and 12,857g for 30 min. 4.Allowing the solubilization of proteins: The pellet thus obtained was resuspended in 34 mL of 20 mM Tris-HCl buffer (pH 8.0) Supernatant was then subjected to ultrafiltration and dialyzed overnight against same buffer at 4°C. Determination of Optima and Stability of Temperature and pH Optimum temperature for activity of the lipase was determined by carrying out at selected temperatures from 30 to 70°C. The optimum pH was determined by monitoring lipase activity at pH values between 6- 10. Application Study 1. 5g of meat was weighed 2. it was autoclaved at 121°C for 15 lbs for 30 minutes. 3. The enzyme filtrate was added to meat 4. incubated at 37°C for 72 hours for the observation of the lipolytic activity on the meat. RESULT AND DISCUSSION Result and discussion of determination of Lipases (triacylglycerol hydrolase) 6. Optimization Studies 1. Samples Collected 5. Total Protein Estimation by Lowry’s Method 4. Enzyme Assay 7.Partial Purification of Lipase Enzyme: 3. Fermentation 8.Characterization Study: 2. Microbiological Examination 9.Application Study Samples Collected 47 isolates were obtained which was then inoculated to tributyrin media and observed for zone formation. Among the 47 isolates 3 isolates (KMCC CB301, 302, 303) were found to produce maximum zone formation of 15, 20 and 35 mm, respectively Pseudomonas sp (KMCCCB301) Bacillus sp (KMCCCB302) Lactobacillus sp (KMCCCB303) Microbiological Examination Bacillus sp (KMCCCB302) Pseudomonas sp (KMCCCB301), Lactobacillus sp (KMCCCB303). Microbiological Examination 1.Indole test: determine the ability of the organism to convert tryptophan into the indole. All the tested organisms give negative response. It mean it cannot convert tryptophan into the indole Also, it mean the used bacteria do not produce other material to affect the production of lipase. Microbiological Examination 2.The methyl red test is used to identify enteric bacteria (腸道細菌)based on their pattern of glucose metabolism. All enteric initially produce pyruvic acid from glucose metabolism. Some enteric subsequently use the mixed acid pathway to metabolize pyruvic acid to other acids. These bacteria are called methyl-red positive Other enteric subsequently use the butylene glycol pathway to metabolize pyruvic acid to neutral end-products. These bacteria are called methyl-red-negative. All the tested organisms give negative response. Also, it mean the used bacteria do not produce other material to affect the production of lipase. Microbiological Examination 3.Voges–Proskauer test used to detect acetoin in a bacterial broth culture. A cherry red color indicates a positive result, while a yellow-brown color indicates a negative result. +VE -VE KMCC CB301 and KMCC CB302 give positive response KMCC CB303 organisms give negative response. It mean KMCC CB301 and KMCC CB302 can detect Acetoin and KMCC CB303 cannot Microbiological Examination 4.The citrate test detects the ability of an organism to use citrate as the sole source of carbon and energy. Production of sodium bicarbonate (NaHCO3) as well as ammonia (NH3) from the use of sodium citrate and ammonium salts results in alkaline pH. This results in a change of the medium’s color from green to blue. KMCC CB301 and KMCC CB302 give positive response KMCC CB303 organisms give negative response Microbiological Examination 5.Gelatin hydrolysis test is used to detect the ability of an organism to produce gelatinase Positive: Partial or total liquefaction of the inoculated tube even after exposure to cold temperature of ice bath or refrigerator (4oC) Negative: Complete solidification of the inoculated tube even after exposure to cold temperature of ice bath or refrigerator (4oC) All the tested organisms give positive response. It mean they can produce gelatinase Microbiological Examination 6.Urease test is used to detect the ability of an organism to produce urease. Urease is an enzyme that breaks the carbon-nitrogen bond of amides to form carbon dioxide, ammonia, and water. Positive result purple/pink colour Negative result colour of medium remains unchanged KMCC CB301 give positive response KMCC CB302 and KMCC CB303 organisms give negative response Microbiological Examination 7.The presence of catalase in the test isolate is detected using hydrogen peroxide. Positive result: bubbling indicates the presence of catalase Negative result: No bubbling KMCC CB301 and KMCC CB302 give positive response KMCC CB303organisms give negative response Fermentation After fermentation, the turbidity was detected by using spectrophotometer: Lactobacillus sp showed absorbance of 1.34 Bacillus sp showed absorbance of 1.15 Pseudomonas sp showed absorbance of 1.20 Lactobacillus showed highest turbidity Enzyme Assay Pseudomonas sp showed the lipase activity was 10U/mL Bacillus sp showed the lipase activity was 18U/mL Lactobacillus sp showed the lipase activity was 35U/mL The highest the lipase activity was Lactobacillus sp Total Protein Estimation by Lowry’s Method The Lowry protein assay is for determining the total level of protein in a solution. The total protein concentration is exhibited by a color change of the sample solution in proportion to protein concentration, which can then be measured using colorimetric techniques. Total Protein Estimation by Lowry’s Method: the total protein content : Lactobacillus sp = 1.8mg/ml Bacillus sp = 1.63mg/ml Pseudomonas sp =1.2mg/ml Lactobacillus sp showed highest total protein content Optimization Studies Lipase production increased with increase in temperature from 30 to 40°C. Maximum production of lipase was 39 U/ml was obtained at 40°C Lipase production begin to decline at 50°C. Optimization Studies lipase production increased with increase in pH from 6 to 9 constantly. Maximum lipase production of 39.6 U/ml was observed at pH 9. Lipase production declined at pH 10 Partial Purification of Lipase Enzyme The purification of lipase resulted in 2 fold purification with 75% recovery by ammonium sulfate precipitation. The purification of crude enzyme through dialysis gave purification fold of 36.5 with 66.6% recovery of lipase from Lactobacillus sp. Characterization Study The maximum stability of the enzyme was observed in the temperature range of 30 to 40°C for Lactobacillus sp. The lipolytic activity declined at 50 °C Characterization Study The pH stability curve showed that the lipase was stable in the range of pH 8 -9. Application Study After the incubation period, the beginning of degradation of meat was observed along with a very strong smell. This may be because of the lipid present in the meat get degraded by lipase enzyme conclusion conclusion When compared with production of lipolytic enzymes between Bacillus sp and Lactobacillus sp and Pseudomonas sp by fermentation It was concluded that Lactobacillus sp could be used as a new potent microbial source of lipase. It is because The maximum lipase activity of Lactobacillus sp reached was 32 U/ml with a purification fold of 36.5 and a yield of 66.6 %. Thanks for your attention !