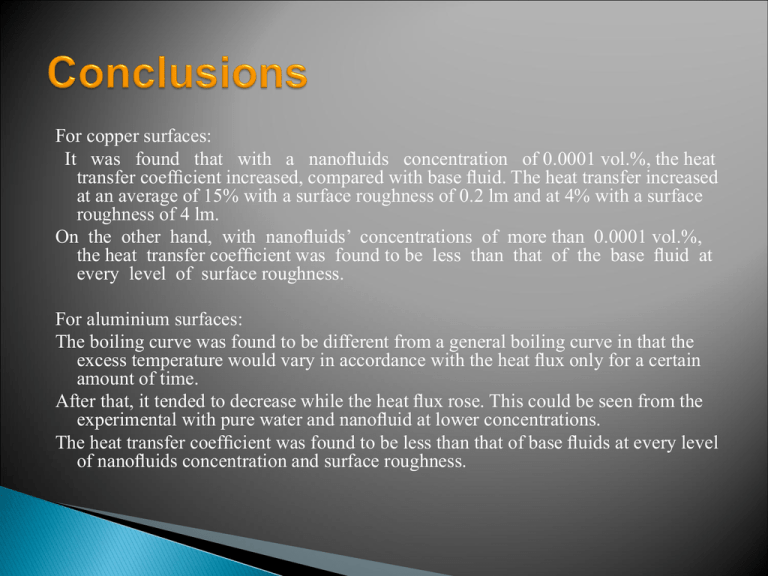

For copper surfaces:

advertisement

For copper surfaces: It was found that with a nanofluids concentration of 0.0001 vol.%, the heat transfer coefficient increased, compared with base fluid. The heat transfer increased at an average of 15% with a surface roughness of 0.2 lm and at 4% with a surface roughness of 4 lm. On the other hand, with nanofluids’ concentrations of more than 0.0001 vol.%, the heat transfer coefficient was found to be less than that of the base fluid at every level of surface roughness. For aluminium surfaces: The boiling curve was found to be different from a general boiling curve in that the excess temperature would vary in accordance with the heat flux only for a certain amount of time. After that, it tended to decrease while the heat flux rose. This could be seen from the experimental with pure water and nanofluid at lower concentrations. The heat transfer coefficient was found to be less than that of base fluids at every level of nanofluids concentration and surface roughness. When comparing copper with aluminium surfaces using nanofluids and base fluid as experimental substances, it was found that aluminium surfaces yielded higher heat transfer coefficients than copper surfaces. This difference was apparent at high heat flux levels. When comparing surface roughness of 0.2 lm with 4 lm using nanofluids and base fluid as experimental substances, it was found that the surface roughness of 4 lm yielded a higher heat transfer coefficient than the surface roughness of 0.2 lm. This difference could also be seen at high heat flux levels. Thank you for your attention