EFFECTS OF AMBIENT OXYGEN ON IGNITION OVER A By

advertisement

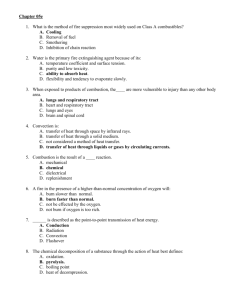

EFFECTS OF AMBIENT OXYGEN ON IGNITION OVER A VERTICALLY THIN SOLID FUEL By TZUNG-HSIEN LIN Associate Professor Department of Mechanical Engineering, Southern Taiwan University of Technology, Yung Kang, Tainan, Taiwan 710 Full-length paper Corresponding Author: Tzung-Hsien Lin Department of Mechanical Engineering Southern Taiwan University of Technology, 1 Nan Tai Road, Yung Kang City, Tainan County, Taiwan 710 Telephone : 886-6-2533131 Ext 3542 FAX : 886-6-2425092 E-mail : thlin@mail.stut.edu.tw ABSTRACT A numerical study on the spontaneous ignition process of a vertically placed solid thin fuel heated by external radiation in normal gravity, quiescent environment was made. The ambient oxygen mass fraction is varied from 35 % down to the non-ignition limit. It was found that in the non-ignition case, the maximum reaction rate and maximum temperature in gas-phase were too weak to onset the combustion reaction. For the ambient oxygen concentration greater than 17 % the ignition and transition to flame spread all are achievable. The low ambient oxygen concentration has larger and stronger ignited flame than the high ambient oxygen concentration at the instant of ignition occurs. The flame grows rate was found faster than the purely opposed and purely concurrent spread flames. Although it has smaller ignited flame, the propagating flame in high ambient oxygen concentration becomes longer and stronger in structure than the low oxygen flame. The results reveal that, the flame grows rate in transition increase with the increasing in ambient oxygen concentration. NOMENCLATURE A s pre-exponential factor for fuel pyrolysis B frequency factor for gas-phase reaction C p average specific heat for gas mixture Cs specific heat for solid fuel D species diffusivity Da Damkohler number E activation energy for gas phase reaction f stoichiometric oxidizer/fuel mass ratio g gravitational acceleration Gr Grashof number k thermal conductivity Le Lewis number m s fuel mass burning rate P pressure Pr Prandtl number q heat of combustion per unit mass of fuel R universal gas constant S surface radiant heat loss parameter T temperature t time u velocity parallel to the fuel surface v velocity normal to fuel surface Vr reference velocity, g f * / * 1/ 3 x distance along fuel surface y distance normal to fuel surface Y mass fraction thermal diffusivity * thermal diffusion length, / Vr emissivity dynamic viscosity density of gas phase Stefan-Boltzmann constant fuel-bed half thickness F gas phase reaction rate Overhead dimensional quantities Superscripts * reference state flux Subscripts F gaseous fuel f adiabatic flame temperature O oxidizer s solid phase sf burnout state w fuel wall ambient conditions max maximum boundary min minimum boundary ex external e Earth INTRODUCTION There are many environmental factors that can affect the spontaneous ignition behavior of a solid material heated by external radiant flux. These factors including the intensity or/and distribution of incident radiant source, magnitude of force or/and natural convective flow velocity, orientation of solid fuel surface, strength of ambient pressure and concentration of ambient oxygen. To understand the effects of these factors are important for fire protection because ignition is an initiation of fire. Literatures investigated the ignition of a solid fuel in normal gravity can be brief review as follows: In the study of Alvares and Martin (1971) and of Ohlemiller and Summerfield (1971), the effects of atmospheres, oxygen concentration, incident flux and inert diluents on ignition delay time were investigated. The results indicated that the ignition delay time decreases monotonically as the total pressure, incident flux and oxygen concentration increase. Kashiwagi (1979a, 1979b, 1981) experimentally studied the radiative ignition mechanism of both horizontally and vertically placed materials. The investigation indicated that the absorption of external radiation by the vaporized fuel in gas phase will raise its temperature above the fuel surface and can cause ignition. Kashiwagi (1982) further indicated that under the same external radiant flux, the ignition delay time was shorter for the horizontal fuel than that of the vertical fuel; the effect of sample orientation on ignition was reported. Mutoh, et al. (1978) and Yoshizawa and Kubota (1982) experimentally observed the radiative ignition of a horizontal sample. The ignition location and ignition delay time were examined under various radiant fluxes. Both experiments shown the ignition occurred at the axis symmetric line in gas phase above the sample surface. On the other hand, many theoretical analyses limited in the one-dimensional model such as Kashiwagi (1974), Kindelan and Williams (1977), Gandhi and Kanury (1988), Amos and Fernandez-Pello (1988), Tzeng et al. (1990), and Park and Tien (1994). Whereas, Kushida et al. (1992) take the advantage of neglect the natural convection effect to simplify the formulation, an two-dimensional axisymmetric, time-dependent model but with potential flow assumption, were used to investigate the ignition in microgravity environment. In the work of Nakabe et al. (1994) and of Mcgrattan et al. (1996), extend that work to investigate the effects of ambient oxygen, external radiant flux distribution, and slow forced flow on ignition delay time and subsequent transition to flame spread. The results indicated that the ignition delay time decreases with the increasing in peak flux of external radiation. A three dimensional model used by Kashiwagi et al. (1996) to study the effects of slow forced wind on ignition and transition to flame spread in microgravity. The results were compared with the experiments obtained in drop tower, and indicated that there are no significant effects of slow wind on ignition delay time. Nakamura et al. (2000) investigated the effects of gravity and ambient oxygen on ignition of a horizontally placed solid fuel. Two ignition types were identified over the whole range of ambient oxygen and gravity level. Lin and Chen (1999), and Lin and Chen (2000) developed time-dependent models to investigate the ignition of thin and thick solid fuel in normal gravity, respectively. The ignition processes were described. Lin (2001) extends the former model to study the buoyant flow effect on ignition delay time and flame spreads behavior in elevated gravity. The model results described the flame blowoff extinction process and indicated that the ignition delay time increases with the buoyant flow brought by the gravity level. In light of the above literature review, it is revealed that the effect of ambient oxygen on the ignition behavior of a vertical sample in normal gravity has not been exploded. When a horizontally placed sample is heated, the pyrolysis fuel vapor eject into the oxygen atmosphere and start to mixed with the ambient oxygen by means of the mass difussion and convection. Since the fuel vapor eject direction is coincide with that of the buoyant flow, the mixture rise as a vertical plume. The ignition point could either at the tip or inside of the plume (Nakamura et al., 2000). Whereas, for a vertically placed sample, the eject fuel vapor is in transverse direction of the buoyant flow. In this situation a hot boundary layer of mixture adjacent to the surface is formed instead of a hot plume. Under this circumstance the ignition behavior is quite different from the former. The main purpose of this study is to investigate numerically the effects of ambient oxygen on the ignition behavior of a vertically oriented thin solid fuel in normal gravity. The gas phase model including the time-dependent, two-dimensional mass, momentum, energy and species conservation equations with second order reaction kinetics describe the combustion of the fuel gases. The solid phase consists of time-dependent mass and energy balance equations with Arrhenius equation describe the solid pyrolysis. The physical problem will be described as follows. MATHEMATICAL MODEL Figure 1 shows a schematic illustration for the ignition of a vertical thin fuel sample heated by an external radiant heat source in normal gravity. At time zero, a Gaussian distribution radiant heat flux with peak value 5 W/cm2 and half width 0.5 cm is applied in the middle of the sample with the center aimed at the original of the coordinate. The thermal degradation of the solid begins as the surface temperature reaches its pyrolysis value through the absorption the external radiant heat. The evolved fuel vapors mix with the ambient oxidizer to form a combustible mixture of boundary layer due to the buoyancy. If the local temperature in the boundary layer is high enough to onset the runaway chemical reaction, ignition occurs. This transient process is analyzed by solving the time dependent conservation equations in the solid and the gas phases simultaneously. The numerical model used in this study is basically the same as previous (Lin and Chen, 1999), but here we have somewhat modified to suit the configuration of ignition in the middle of an infinite vertical sample and also account for the solid surface radiative heat loss. This model solves the system of governing equations in dimensionless form. For the choice of scaling parameters and non-dimensionalized procedures, refer to Lin and Chen (1999). The dimensionless gas phase governing conservation equations are summarized in Table 1. The dimensionless solid phase governing equations can be expressed as follows: Mass Conservation ms s E A s s exp( s ) . t Ts (1) Energy Conservation Ts 2 Ts T s s m L 1 C T 1 s s t x 2 Pr Gr y w qex S 1 Ts4 . (2) The non-dimensional form of external radiant heat flux, q ex , can be expressed as q ex Q ex exp(-x2). (3) where Q ex is the non-dimensional peak value of the external radiant heat flux, x and are the non-dimensional half width, and the shape constant of the Gaussian distribution, respectively. All of these quantities are various in different oxygen concentration due to the variation in thermal length brought by the change of ambient oxygen concentration. The expression of Q ex can be found in the non-dimensional parameters list in Table 2. The governing equations are subjected to the following boundary and initial conditions. I. Boundary conditions in dimensionless form are: Gas phase At x=xmin: u 0, v 0, T 1, YF 0, YO YO . (4) At x=xmax: u v T YF YO 0 , P P . x x x x x (5) At y=0: u 0, T Ts , mw w v w mw mw YFw mw YOw Y F Pr Le Gr y Y O Pr Le Gr y w w . (6) At y=ymax: u 0, v 0, T 1, YF 0, YO YO , P P . y (7) Solid phase At x=xmin: s 1, Ts 1 . (8) At x=xmax: s 1, Ts 1 . (9) II. Initial conditions in dimensionless form are: Gas phase At t0: u 0, v 0, T 1, YF 0, YO YO , P P . (10) Solid phase At t0: s 1, Ts 1 . (11) The strong coupling between pressure and velocity in the full unsteady Navier-Stokes equations are solved using the SIMPLE algorithm (Patankar, 1980). In each time step, iteration of both the gas-phase and solid-phase equations are calculated separately, and the solid phase is coupled with the gas phase through the linkage of the conductive heat feed back from the gas phase to the solid phase; as can been seen in the solid phase energy balance equation, Equation (2). The numerical calculations began when the external radiant heat flux applied on the sample at time zero. The solid phase calculation was carried out first to obtain the pyrolysis mass flux, the fuel wall blowing velocity, and the surface temperature which to be used as the boundary conditions in the gas phase calculation. After the convergence of the solid phase calculation, the gas phase calculations were carried out with the updated interfacial boundary conditions that were the previous values of the pyrolysis mass flux and the surface temperature. When the gas phase calculations were completed, the solid phase variables were also updated then went into the next time step to start with the solid phase calculation. A non-uniform grid of exponential distribution in the gas phase was used with the highest concentration of grid point near the gas-solid interface, where the ignition will possible occurred, to capture the dramatically change in the temperature and flow field. The grid sizes are chosen according to the optimization between the solution resolution and the requirements for computational time and memory space. The selected non-dimensional computational domain is 143.859.7, and the corresponding grid points is 19640. The non-dimensional time step in each computed oxygen concentration case is chosen such that the corresponding physical time step are equal in all cases, that is 0.137 s. RESULTS AND DISCUSSION Table 3 lists the properties for both gas and solid phase used in this study together with the reference they are adopted from. The gas-phase specific heat C p , density * , thermal diffusivity * , thermal conductivity k * , and viscosity * are evaluated at the reference temperature T * , i.e., T * ( Tf T ) / 2 . These gas-phase thermal properties vary with the ambient oxygen concentration, because the varying in the adiabatic flame temperature Tf . Numerical computations were conducted for range of the ambient oxygen percentages from 15 % to 35 % with an increase increment of 2 %. The lower limit was a case that the ignition does not occur, while the upper limit was chosen that the ignition delay time no longer significant change as the oxygen percentage increase. To illustrate the trend of ambient oxygen concentration effects on the ignition behaviors, we demonstrate five different oxygen concentrations computation results, that is, 15 %, 17 %, 21 %, 27 %, and 35 %. Non-ignition case The distributions of gas-phase temperature and gas-phase fuel reaction rate at four different times for 15 % ambient oxygen concentration are shown in figure 2 and figure 3, respectively. As shown in figure 2, the maximum gas-phase temperature region moves upward due to the consumption of the solid fuel and remains at a constant value about 660 K as time increases. Figure 3 shows corresponding reaction rate at four different times. It can be seen that the maximum reaction rates also remains at a constant value of about 0.30910-4 g/cm3/s in all times. In this study we defined, as in the previous studies (Ferkul and T’ien (1994), Nakabe et al. (1994)), the gas phase reaction rate of 10-4 g/cm3/s contour as a visible flame boundary. Thus the maximum temperature and maximum reaction rate are relatively weak, and the vigorous chemical reaction and rapid heat release, which characterize the ignition, do not occur in all times. There is no flame appears, therefore, this is a non-ignition case due to a low oxidizer concentration which can not supply the fuel vapor to react to reach the combustion reaction. Effects of ambient oxygen The premixed mixture distributions at the instant before ignition occur of four different ambient oxygen concentrations are shown in figure 4. It can be seen that, low ambient oxygen percentage has larger amount of pre-ignition premixed mixture than that of high ambient oxygen. This is because of the lower ambient oxygen concentration duration a larger ignition delay time, which needs for the mixture to react to reach the required temperature and reaction rate that can on set the ignition. As a consequence, a larger amount of fuel gas evolved to accumulate to form a larger amount of premixed mixture. Figure 5 shows the effect of ambient oxygen concentration on ignition delay time. The ignition delay time decreases exponentially with a increasing in the ambient oxygen concentration. The same trend has been found in one-dimensional model of nature convective ignition (Park and Tien (1994)), as well as in zero-gravity ignition over a horizontal thin fuel (Nakamura et al. (2000)). The ignition delay time remains almost constant as the ambient oxygen concentrations higher than 35 %. The existence of this minimum ignition delay time is mainly attributed to the time required for the solid to absorb the external radiation to reach the pyrolysis temperature. The distributions of gas-phase fuel reaction rate and flow velocity vector, temperature, and fuel and oxygen mass fraction at the instant of ignition are shown in figure 6-8, respectively. Each figure consists of four plots in different ambient oxygen concentration. At this instant, the rapid increase in reaction rate release a large amount of heat result in a sudden gas expansion and sudden temperature increase in gas phase. According F =110-4 to the visible flame definition mentioned above (reaction rate g/cm3/s), the flame shape at the instant of ignition of various ambient oxygen concentrations are shown in figure 6. As show in figure 6, lower ambient oxygen concentration has longer ignited flame length because of larger amount of premixed mixture has been reacted which accumulated before the ignition occur (see figure 4). For the same reason, the lower ambient oxygen concentration has bigger and stronger ignited temperature distribution because of a larger amount of mixture has been reacted and a larger amount of heat has been released, as can be seen in figure 7. Because of the ignition delay time does not change significant for the ambient oxygen concentration higher than 35 %. The ignite flame temperature and flame size does not change significant for the ambient oxygen concentration higher than 35 %. The distributions of fuel and oxygen mass fraction at the instant of ignition in figure 8 are quite different from those of the pre-ignition in figure 4. In figure 4, before ignition occurs, the fuel gas and the oxidizer are mixed as a mixture whereas in figure 8, at the instant of ignition, we can distinguish the fuel gas side from the oxidizer side. Propagating flame Figure 9 and 10 show the reaction rate and temperature contours of propagating flame in four different ambient oxygen concentrations at time of 2.055 s after the ignition occurs. All flame fronts propagate beyond the width of the external radiation heat source (0.5 cm) at this moment. These indicate that the transition from ignition to flame spread are achievable for all cases. Compare to the concurrent flame (Chen and Hou, 1991) and opposed flame (Duh and Chen, 1991), it is found that the flame structure are longer and stronger. This is because of the flames are initiated at the middle of fuel sample, and then spread not only in opposed but also in concurrent direction with the buoyancy flow which result in a longer pyrolysis length. Moreover, the flame grows faster than those in the purely opposed or concurrent flame when in the transition process because of the larger amount of evolved fuel gas. On the other hand, high oxygen concentration flame has longer and stronger flame structure than that in low oxygen concentration although it has weaker and smaller ignited flame. This can be seen in figure 6 and figure 9, in case of 35 % oxygen, the flame length reaches about 11 cm, and the flame temperature reaches a value of 2600 K within 2.055 s of flame grows times. It also indicates that, the flame grows rate increases with the increasing in ambient oxygen concentration. Flame grows much faster in high oxygen concentration than in low oxygen concentration. CONCLUTIONS Ignition and subsequent transition to flame spread over a vertical solid thin fuel heated by external radiation has been investigated numerically. The external radiant heat flux is Gaussian distribution to model the ignition heat source in laboratory, and applied at the middle of the longitude of the fuel sample at time=0 s. By varying the ambient oxygen concentration as study parameter, a non-ignition case, 15 %, was found. In this case, the ambient oxidizer was too dilute to react the fuel gas to reach the combustion reaction rate, thus the sudden gas expansion and rapid heat release, which characterize the ignition were not occur. For the ambient oxygen concentration greater than 17 % the ignition and transition to flame spread all are achievable. It was shown that, because of the greater ignition delay time, the low ambient oxygen concentration has larger amount of pre-ignition mixture accumulate near the fuel surface before ignition occur, which result in a larger and stronger ignited flame than the high ambient oxygen concentration at the instant of ignition occur. The flame grows rate was found faster than the purely opposed and purely concurrent flames. After 2.055 s grow times, the propagating flame in high ambient oxygen concentration becomes longer and stronger in structure than the low oxygen flame although it has smaller ignited flame. The results reveal that, the flame grows rate in transition increase with the increasing in ambient oxygen concentration. ACKNOWLEDGMENTS The author thanks the National Science Council of Taiwan for financially supporting this research under contract no. NSC 90-2212-E-218-006. REFERENCES Altenkirch, K. A., Eichhorn, R., and Shang, P. C. (1980). Buoyancy Effects on Flame Spreading Down Thermally Thin Fuels, Combustion and Flame, 3771-83. Alvares, N. J., and Martin, S. B. (1971). Mechanisms of Ignition of Thermally Irradiated Cellulose, Thirteenth Symposium (International) on Combustion, The Combustion Institute, Pittsburgh, p. 905. Amos, B., and Fernandez-Pello, A. C. (1988). Model of the Ignition and Flame Development on a Vaporizing Combustible Surface in a Stagnation Point Flow:Ignition by Vapor Fuel Radiation Absorption, Combustion Science and Technology, 62331-343. Chen, C. H. and Hou, W. H. (1991) Diffusion Flame Stabilization and Extinction Under Naturally Convective Flows, Combustion and Flame, 83:309-324. Duh, F. C. and Chen, C. H. (1991) A Theory for Downward Flame Spread over a Thermally-Thin Fuel, Combustion Science and Technology, 77:291-305. Ferkul, P. V. and T’ien, J. S. (1994) A Model of Low-Speed Concurrent Flow Flame Spread over a Thin Fuel, Combustion Science and Technology, 99:345-370. Frey, A. E. and T’ien, J. S. (1979). A theory of flame spread over a solid fuel including finite rate chemical kinetics, Combustion and Flame, 36263-289. Gandhi, P. D., and Kanury, A. M. (1988) Thresholds for Spontaneous Ignition of Organic Solids Exposed to Radiant Heating, Combustion Science and Technology, 57:113-128. Hottel, H. C. and Sarofim, A. F. (1967) Radiative Transfer, New York, McGraw-Hill. Kashiwagi, T. (1974). A Radiative Ignition Model of a Solid Fuel, Combustion Science and Technology, 8:225-236. Kashiwagi, T. (1979a). Experimental Observation of Radiative Ignition Mechanisms, Combustion and Flame, 34231-244. Kashiwagi, T. (1979b). Effects of Attenuation of Radiation on Surface Temperature for Radiative Ignition, Combustion Science and Technology, 20225-234. Kashiwagi, T. (1981). Radiative Ignition Mechanism of Solid Fuels, Fire Safety Journal, 3185-200. Kashiwagi, T. (1982). Effects of Sample Orientation on Radiative Ignition, Combustion and Flame, 44223-245. Kashiwagi, T., McGrattan, K. B., Olson, S. L., Fujita, O., Kikuchi, M., and Ito, K. (1996). Effects of Slow Wind on Localized Radiative Ignition and Transition to Flame Spread in Microgravity, Twenty-Sixth Symposium (International) on Combustion, The Combustion Institute, Pittsburgh, p. 1345. Kindelan, M., and Williams, F. (1977). Gas-Phase Ignition of a Solid with In-Depth Absorption of Radiation, Combustion Science and Technology, 1647-58. Kushida, G., Baum, H. R., Kashiwagi, T., and di Blasi, C. (1992). Heat and Mass Transport From Thermally Degrading Thin Cellulosic Materials in a Microgravity Environment, Journal of Heat Transfer, 114:494-502. Lin, T. H. (2001). Time-Dependent Model of a Buoyant Downward Flame Spread over a Thermally Thin Solid Fuel, Numerical Heat Transfer, Part A, 40: (in press). Lin, T. H., and Chen, C. H. (1999). Numerical Analysis of Ignition and Transition to Downward Flame Spread Over a Thermally-Thin Solid Fuel, International Journal of Transport Phenomena, 1:255-275. Lin, P. H., and Chen, C. H. (2000). Numerical Analysis for Radiative Autoignition and Transition to Flame Spread Over a Vertically Oriented Solid Fuel in a Gravitation Field, Combustion Science and Technology, 151:157-187. McGrattan, K. B., Kashiwagi, T., Baum, H. R., and Olson, S. L. (1996). Effects of Ignition and Wind on the Transition to Flame Spread in a Microgravity Environment, Combustion and Flame, 106:377-391. Mutoh, N., and Hirano, T., and Akita, K. (1978). Experimental Study on Radiative Ignition of Polymethylmethacrylate, Seventeenth Symposium (International) on Combustion, The Combustion Institute, Pittsburgh, p. 1183. Nakabe, K., McGrattan, K. B., Kashiwagi, T., Baum, H. R., Yamashita, H., and Kushida, G. (1994). Ignition and Transition to Flame Spread Over a Thermally Thin Cellulosic Sheet in a Microgravity Environment, Combustion and Flame, 98361-374. Nakamura, Y., Yamashita, H., and Takeno, T. (2000). Effects of Gravity and Ambient Oxygen on a Gas-Phase Ignition Over a Heated Solid Fuel, Combustion and Flame, 120:34-48. National Bureau of Standards (1955). Table of Properties of Air at Atmospheric Pressure, Circular 564, US. Ohlemiller, T. J., and Summerfield, M. (1971). Radiative Ignition of Polymeric Materials in Oxygen / Nitrogen Mixtures, Thirteenth Symposium (International) on Combustion, The Combustion Institute, Pittsburgh, p. 1087. Park, S. H., and Tien, C. L. (1994). Radiation Induced Ignition of Porous Solid Fuels, Combustion Science and Technology, 95:173-192. Patankar, S. V. (1980). Numerical Heat Transfer and Fluid Flow, McGraw Hill, New York. Tzeng, L. S., Atreya, A, and Wichman, I. S. (1990). A One-Dimensional Model of Piloted Ignition, Combustion and Flame, 80:94-107. Yoshizawa, Y., and Kubota, H. (1982). Experimental Study on Gas-Phase Ignition of Cellulose Under Thermal Radiation, Nineteenth Symposium (International) on Combustion, The Combustion Institute, Pittsburgh, p. 787. Table 1 Gas Phase Governing Equations u v S t x y x x y y Equation Continuity 1 x-Momentum u y-Momentum v Energy T Fuel YF Oxidizer YO Gr Gr S 0 p Su x f p Sv y F q Pr Gr F Pr Gr Le F f Pr Gr Le where Su 1 u v 2 v 3 x Gr x y Gr x 3 x Gr y Sv 1 v u 2 u 3 y Gr y x Gr y 3 y Gr x Table 2 Nondimensional Parameters Symbol Parameter group Value As A s * / Vr2 variable C Cp / Cs 0.798 E E / R T 35.196 Es E s / R T Gr g ( f ) 3 / * ks ks / k* 0.781 L L / Cs T -2.005 Le /D 1.000 Pr / 0.705 Q ex * / s T Vr2 Cs Q ex variable q q / Cp T 45.349 S * T3 / k * Vr variable t tVr / variable T * / T 5.235 Cs s Vr / k * Variable * 50.685 *2 Variable Table 3 Gas and solid properties values Symbol Units Value Reference As cm/s 1.001010 Frey and T’ien (1979) B cm3/mols 1.001012 Duh and Chen (1991) Cp J/gK f (T*) Natl. Bur. Stan. (1955) Cs J/gK 1.260 Altenkirch et al. (1980) E J/mol 8.720104 Duh and Chen (1991) Es J/mol 1.255105 Frey and T’ien (1979) f 1.185 Altenkirch et al. (1980) k* W/cmK f( T * ) Natl. Bur. Stan. (1955) ks W/cmK 1.25510-3 Frey and T’ien (1979) L J/g 753.0 Altenkirch et al. (1980) q J/g 1.674104 Altenkirch et al. (1980) R J/molK 8.314 Natl. Bur. Stan. (1955) T K 298 Altenkirch et al. (1980) * cm2/s f( T * ) Natl. Bur. Stan. (1955) 0.92 Hottel, Sarofim (1967) * g/cms f( T * ) Natl. Bur. Stan. (1955) * g/cm3 f( T * ) Natl. Bur. Stan. (1955) s g/cm3 0.750 Altenkirch et al. (1980) cm 9.810-3 Altenkirch et al. (1980)