Effect of gallium incorporation on the spray pyrolysis Journal of Crystal Growth

advertisement

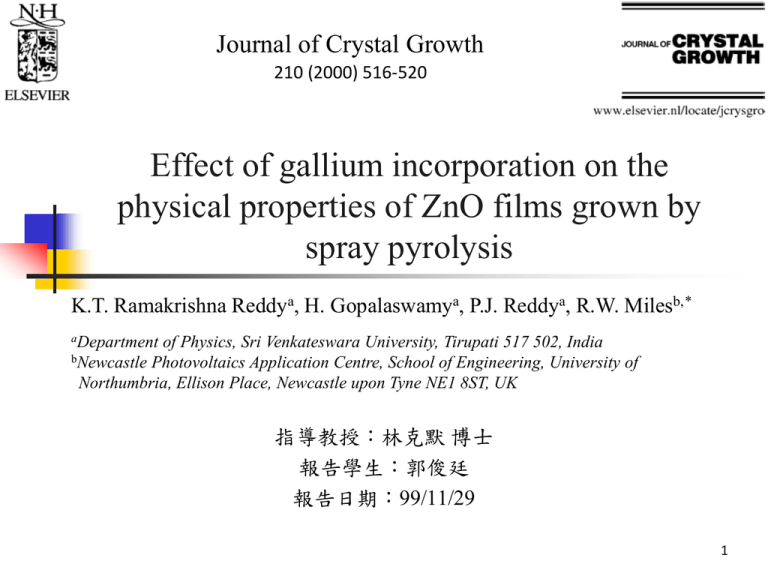

Journal of Crystal Growth 210 (2000) 516-520 Effect of gallium incorporation on the physical properties of ZnO films grown by spray pyrolysis K.T. Ramakrishna Reddya, H. Gopalaswamya, P.J. Reddya, R.W. Milesb,* aDepartment of Physics, Sri Venkateswara University, Tirupati 517 502, India bNewcastle Photovoltaics Application Centre, School of Engineering, University of Northumbria, Ellison Place, Newcastle upon Tyne NE1 8ST, UK 指導教授:林克默 博士 報告學生:郭俊廷 報告日期:99/11/29 1 Outline Introduction Experimental procedure Results and discussion Conclusions 2 Introduction Although gallium doped zinc oxide films grown by sputtering have shown very low resistivities of 10-3~10-4 Ωcm, the technique is neither economically viable nor suitable for coating large area substrates. In this study, we have chosen spray pyrolysis for the deposition of ZnO:Ga films in view of its simplicity and economics. In the present paper, we report on the influence of gallium doping concentration on the physical properties of ZnO : Ga films prepared by spray pyrolysis. 3 Experimental procedure The spraying liquid consisted of zinc acetate dissolved in isopropyl alcohol and deionised water with a solution concentration of 0.1 M. The solution was sprayed at the rate of 6 ml min-1 onto Corning 7059 glass substrates kept at a substrate temperature, (TS), of 350 ℃. Purified compressed air with a flow rate of 8 l min-1 was used as the carrier gas. The nozzle to substrate distance was about 25 cm. For doping the films with gallium, gallium trichloride solution was added to the starting solution and the doping concentration was varied from 0.0 to 8.0 at.%. 4 The structural studies were carried out using X-ray diffraction and scanning electron microscopy. The grain size of the films was calculated using the Scherrer formula [21] and the extent of preferred orientation of the films was evaluated using the texture coefficient of the films[22]. The electrical properties of the films at room temperature were measured using the van der Pauw method. The optical transmission of the films was recorded using a Hichachi, U3400 UV-VIS-NIR, double beam spectrophotometer in the wavelength range 300~2500 nm. 5 Results and discussion It can be seen from the XRD spectra and the scanning electron micrographs that all the deposited films are polycrystalline and from the XRD spectra that the films have the wurtzite crystal structure with a (002) preferred orientation. The other weak orientations observed were (100), (101), (102) and (110). Fig. 1. XRD spectra of sprayed ZnO:Ga thin films formed at Ts=350 ℃. 6 Fig. 2. Scanning electron micrographs of ZnO:Ga films grown at Ts=350℃. 7 The decrease of texture coefficient at higher doping levels has also been observed by Goyal et al.[24] in indium-doped zinc oxide films grown by spray pyrolysis. They have attributed this behaviour to the interstitial inclusion of dopant atoms resulting in the poor structure of the films and therefore the texture coefficient decreases. Fig. 3. Variation of texture coefficient and grain size with gallium content in ZnO films. 8 It varied from 3.6×10-1 to 1.0×10-3 Ωcm and the films formed with 5.0 at% of gallium had a resistivity of 1.5×10-3 Ωcm. The decrease in the resistivity of the films by gallium doping can be explained by considering the atomic radius and electronegativities of zinc and gallium. Fig. 4. Change of electrical resistivity and transmittance with gallium content in ZnO films. 9 In addition, the electronegativity of gallium (1.13) is close to that of zinc (0.99) when compared to other dopants so that the localization effect of conduction electrons by gallium becomes very small. The mobility of the charge carriers followed the same behaviour of the texture coefficient with a maximum value of 17 cm2 V-1 s-1 at a gallium concentration of 5.0 at%. As the doping level is increased, more dopant atoms occupy the zinc lattice sites which results in more charge carriers. However, after a certain level of doping, the Ga atoms can not occupy zinc lattice sites and they have a tendency to occupy interstitial sites where they form neutral defects and become ineffective as dopant impurities. 10 Conclusions 隨著不同濃度Ga的摻雜,GZO薄膜在物理特性上有明顯的改變。 透過XRD的結構分析得知,GZO薄膜為多晶纖鋅礦結構,在 (002)方面有優選取向。 在摻雜5 at.%的GZO薄膜,有最低的電阻率1.5×10-3 Ωcm,其穿 透率也大於85%,已達可應用在太陽能電池之透明電極上。 在這研究中,摻雜鎵得到了高載子密度濃度,在電阻率方面也 比摻雜鋁和銦來得低。 11 Thanks for your attention 12