University of Alaska Fairbanks Environmental Health, Safety, & Risk Management November 2009

advertisement

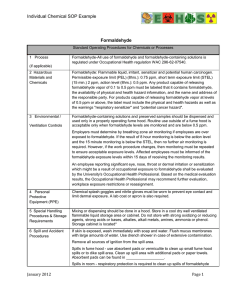

University of Alaska Fairbanks Environmental Health, Safety, & Risk Management November 2009 Introduction to OSHA Standard for Formaldehyde ◦ ◦ Requirements of regulation Permissible exposure limits (PELs) Routes of exposure and health effects Protective measures Handling and storage of formaldehyde Spills and accidents Medical surveillance Waste management 2 OSHA regulates occupational exposures to formaldehyde Scope of 29 CFR 1910.1048 ◦ This standard applies to all occupational exposures to formaldehyde, including exposure to: formaldehyde gas formaldehyde solutions (formalin) materials that release formaldehyde 3 ◦ ◦ ◦ ◦ ◦ Requirements: Must have an MSDS available in the lab Written training materials must be available to employees Must establish “regulated areas” where airborne concentrations of formaldehyde exceed the OSHA permissible exposure limits (PEL) and/or short-term exposure limits (STEL) Medical surveillance must be provided to employees who may be exposed to formaldehyde at concentrations exceeding the PEL or STEL Exposure monitoring will be conducted if formaldehyde concentrations in the workplace exceed the action level 4 OSHA requires that regulated areas be established where airborne formaldehyde concentrations exceed the OSHA PEL and/or STEL values OSHA PEL (averaged over 8 h) 0.75 ppm OSHA STEL (maximum of 15 min/day) 2 ppm OSHA Action level (averaged over 8 h) 0.5 ppm ACGIH STEL (maximum of 15 min/day) 0.3 ppm C Note, this is a ceiling value that must never be exceeded • A written plan must be developed and implemented whenever an employee is exposed above the PEL 5 Regulated areas shall have danger signs posted at entrances and access ways • Only authorized personnel shall enter regulated areas 6 10-37% solutions of formaldehyde stabilized with methanol are typically used at UAF ◦ Formaldehyde gas in solution is called “formalin” ◦ Even though the solutions are stabilized, formaldehyde (and various adducts) are released from the solution Formalin (formaldehyde) is a suspected carcinogen 7 Introduction to OSHA Standard for Formaldehyde ◦ ◦ Requirements of regulation Permissible exposure limits (PELs) Routes of exposure and health effects Protective measures Handling and storage of formaldehyde Spills and accidents Medical surveillance Waste management 8 Exposure routes ◦ Inhalation Sore throat, coughing, shortness of breath Sensitization of respiratory tract 25-30 ppm: pulmonary edema and pneumonitis ◦ Ingestion Severe abdominal pain, violent vomiting, headache, diarrhea, unconsciousness and death Methanol used to stabilize the formaldehyde solution poses additional toxic hazards 9 Exposure routes (cont.) ◦ Skin contact Irritation and/or burns; cracking, scaling, white discoloration Can be absorbed through skin ◦ Eye contact Irritation from vapors, pain, blurred vision May cause irreversible damage if splashed in eyes 10 Long-term effects ◦ Sensitizer: May cause contact dermatitis, other allergic reactions ◦ Vision impairment and liver enlargement from methanol ◦ Carcinogen May cause cancer ◦ Mutagen May cause mutations in DNA 11 Know how to report exposures and illnesses/injuries that are related to the job ◦ Tell your supervisor, complete Accident/Incident Report Remember: symptoms develop over time, so adverse effects may not be immediately noticeable The perception of formaldehyde by odor and eye irritation becomes less sensitive with time as one adapts to formaldehyde ◦ This can lead to overexposure if a worker is relying on formaldehyde's warning properties to alert him or her to the potential for exposure 12 Introduction to OSHA Standard for Formaldehyde ◦ ◦ Requirements of regulation Permissible exposure limits (PELs) Routes of exposure and health effects Protective measures Handling and storage of formaldehyde Spills and accidents Medical surveillance Waste management 13 Primary methods of exposure control ◦ Engineering controls: Always use formalin in a chemical fume hood Check that it is properly functioning ◦ Work practices: Use the smallest amount of formalin necessary Buy in suitable quantities Use safer alternatives whenever possible 14 For working with 37% formalin or 10% formalin: ◦ Protective clothing (lab coats, aprons, suits): Tychem® CPF2, SL, CPF3, F, CPF 4, BR, LV, Responder, TK, or Reflector all have breakthrough times >480 min ◦ Gloves (required when using >1% formalin): Nitrile (>360 min) is the best choice Neoprene (105 min), or PVC (100 min) are ok Rubber or Neoprene/rubber are ok for short use (1015 min) PVA gloves are not recommended 15 For working with formalin at any concentration greater than 1%, splash-proof goggles are required Formaldehyde contact with the eye can range from transient discomfort to severe, permanent corneal clouding and loss of vision 16 Storage of PPE ◦ Store away from sources of formaldehyde Formaldehyde vapors can permeate the lab coat or glove material, reducing its barrier-properties Inspect all PPE prior to use ◦ Check for holes, cracks, degradation Change gloves frequently ◦ Just because the breakthrough time is >360 min doesn’t mean you should use one pair of gloves for 6 hours. Do not reuse disposable gloves 17 Respirators are required ◦ during periods necessary to implement engineering and work practice controls ◦ in operations where engineering controls and work practices are not feasible ◦ in operations where engineering controls and work practices do not prevent exposure below the PEL ◦ in emergencies (spill response) If you use formalin in a fume hood, you should not need to wear a respirator 18 Respirator use follows the requirements given in 29 CFR 1910.134: ◦ Employees must wear respirators if they are required to do so ◦ If required to wear a respirator, employees must have a medical exam (once) and be fit tested (annually) If you feel you need a respirator, contact the UAF Industrial Hygienist at 474-6771 19 Full body protection is required for areas with concentrations above 100 ppm Storage areas for ventilating formaldehyde-contaminated clothing and equipment have signs that read: 20 Introduction to OSHA Standard for Formaldehyde ◦ ◦ Requirements of regulation Permissible exposure limits (PELs) Routes of exposure and health effects Protective measures Handling and storage of formaldehyde Spills and accidents Medical surveillance Waste management 21 37% formalin: ◦ Storage code is RED (flammable) It is also a health hazard, but flammable rating takes precedence ◦ Store in secondary containment 10% formalin: ◦ Storage code is BLUE (health hazard) At this concentration, it is no longer flammable) ◦ Store in secondary containment 22 All containers of formalin must be labeled with the following: ◦ The word “Formalin” and the concentration ◦ Name and address of the responsible party ◦ The words “Potential cancer hazard” and “Respiratory sensitizer” This includes: ◦ Stock solutions (37% or 10%) ◦ Working solutions ◦ Specimens preserved in formalin Labels are available from EHS&RM (474-6771) 23 Introduction to OSHA Standard for Formaldehyde ◦ ◦ Requirements of regulation Permissible exposure limits (PELs) Routes of exposure and health effects Protective measures Handling and storage of formaldehyde Spills and accidents Medical surveillance Waste management 24 Operations involving formaldehyde must have a program in place to detect leaks and spills ◦ Check containers and drums regularly for leaks Place leaking containers in well-ventilated areas ◦ Repair or contain leaks quickly Comply with EPA rules regarding clean-up ◦ Contact EHS&RM Division of Hazardous Materials for immediate assistance with cleanup: 474-5617 25 Employees must leave spill areas unless they have specific duties Never clean up a spill if you are not trained and do not feel comfortable doing so ◦ Call EHS&RM at 474-5617 or 474-5413 for assistance Formalin spill kits are available from EHS&RM ◦ These kits contain: Formaldehyde neutralizer mats Spilfyter® formaldehyde solidifier Aqualockit® water solidifier ◦ Kits are useful for clean up of small spills and to minimize off-gassing of formaldehyde after a large spill 26 Response for small spills (<400 mL) outside of fume hood: ◦ Wearing Nitrile gloves, immediately contain the spill and stop any leaks if present ◦ Use formaldehyde neutralizer (Spilfyter®) on the spill or mop up the formalin solution with towels or formalin neutralizer mats ◦ Place all contaminated towels and gloves in a plastic bag and complete a Non-radioactive Hazardous Materials Transfer Request form and sticker o Call EHS&RM at 474-5617 to report the spill and to have wastes picked up 27 Response for large spills (400 mL or more): ◦ Contain the spill if possible Use neutralizer mats and/or Spilfyter® formalin polymerizer to contain the spill ◦ Leave the lab and alert others to the problem. ◦ Call EHS&RM at the numbers above to report the spill Call 911 if there is an immediate threat to life, health, and/or property 28 Inhalation: Remove victim to fresh air. If not breathing, give artificial respiration. Call a physician Ingestion: If swallowed and the victim is conscious, dilute, inactivate, or absorb the ingested formaldehyde by giving milk, activated charcoal, or water. Keep affected person warm and at rest. Get medical attention immediately. If vomiting occurs, keep head lower than hips. 29 Skin Contact: Immediately flush skin with plenty of water for at least 15 minutes while removing contaminated clothing and shoes. Wash clothing and thoroughly clean shoes before reuse. Get medical attention immediately. Eye Contact: Immediately flush eyes with plenty of water for at least 15 minutes, lifting lower and upper eyelids occasionally. Get medical attention immediately. Know the locations of showers and eyewash facilities 30 Introduction to OSHA Standard for Formaldehyde ◦ ◦ Requirements of regulation Permissible exposure limits (PELs) Routes of exposure and health effects Protective measures Handling and storage of formaldehyde Spills and accidents Medical surveillance Waste management 31 Medical surveillance is required ◦ prior to assignments to areas where exposure may be above STEL ◦ at least annually where exposure may be at or above the STEL ◦ whenever an employee shows signs/symptoms of toxic levels of exposure Exposure levels are determined without regard to respirator use Medical surveillance includes: ◦ administration of medical disease questionnaire ◦ determination if a medical examination is necessary ◦ examinations for employees who are at increased risk for exposure to formaldehyde Medical examinations include: ◦ a physical exam ◦ laboratory examinations ◦ any other necessary tests ◦ counseling of employees Written physician opinions include: ◦ physician’s opinion about employee’s medical condition ◦ recommended limitations ◦ statement of medical conditions Employees get copies of the written opinions within 15 working days • Records are retained for the duration of employment plus 30 years Introduction to OSHA Standard for Formaldehyde ◦ ◦ Requirements of regulation Permissible exposure limits (PELs) Routes of exposure and health effects Protective measures Handling and storage of formaldehyde Spills and accidents Medical surveillance Waste management 36 Place formaldehyde-contaminated waste in sealed, intact containers, clearly labeled with: ◦ “Formaldehyde Waste” ◦ “Danger: Toxic, Potential Cancer Hazard” ◦ the concentration of the solution in the container Keep the container sealed at all times when not adding wastes to it Comply with EPA rules regarding waste disposal ◦ Complete a “Non-radioactive Hazardous Materials Transfer” form and sticker ◦ Contact EHS&RM Hazmat Division for pickup and/or assistance at 474-5617 37 Quiz is located at: www.uaf.edu/safety Complete quiz, click the “send quiz to EHS&RM” button. ◦ Training ◦ UAF Safety Training PowerPoints NOTE: There is no need to contact EHS&RM to let us know you have finished the quiz. fysafety@uaf.edu is checked throughout the day, and your score will be electronically filed for future reference. 38