Building Services Drain-waste-vent (DWV)

advertisement

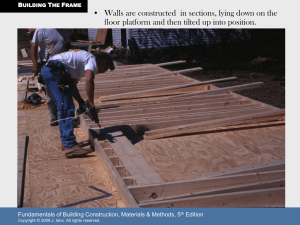

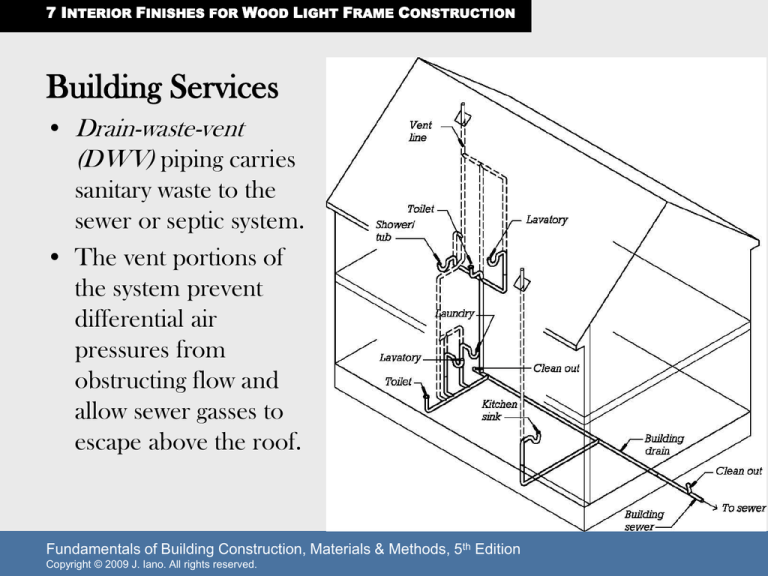

7 INTERIOR FINISHES FOR WOOD LIGHT FRAME CONSTRUCTION Building Services • Drain-waste-vent (DWV) piping carries sanitary waste to the sewer or septic system. • The vent portions of the system prevent differential air pressures from obstructing flow and allow sewer gasses to escape above the roof. Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. BUILDING SERVICES • Drain-waste-vent (DWV) piping: cast iron below and PVC above • The horizontal stub is for connection to a sink or other fixture. Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. BUILDING SERVICES • Water supply piping carries hot and cold domestic (potable) water to fixtures throughout the house. Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. BUILDING SERVICES Bathroom plumbing rough-in: • DWV piping, left • Water supply distribution manifolds for a hot tub, right • Metal nail guards attached to edge of blocking protect DWV piping from future nail or screw damage after wallboard or other finishes are installed and piping is concealed. Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. BUILDING SERVICES • In a forced air heating system, a fan pushes heated air through supply ducts to various spaces throughout the building. • Return air ducts carry return air back to the furnace. • With the addition of an exterior compressor and an evaporator (heat exchanger) within the furnace, cooled air can also be provided. Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. BUILDING SERVICES • Forced-air heating and air conditioning with insulated ductwork • Note how wallboard has been preinstalled behind the furnace and ductwork. Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. BUILDING SERVICES Furnace hookups • natural gas supply piping (left, black) • refrigerant piping between evaporator coil in furnace and exterior air conditioning compressor (middle and right, two copper pipes, one covered with black foam insulation) • evaporator drain pan piping (lower, white) • exhaust vent for furnace and future water heater (upper, metallic) • Furnace supply air is ducted out of the top. Return air is ducted in from below (via a crawlspace). Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. BUILDING SERVICES • Termination of supply duct at ceiling framing, ready to receive finish ceiling and register Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. BUILDING SERVICES • In a radiant heat system, heated water moves through plastic pipes embedded in floors. These heated surfaces then radiate heat into the building spaces. • Ventilation air must be provided by some other system. Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. BUILDING SERVICES • Proprietary floor underlayment panels for installing hydronic heating tubes under the finish floor Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. BUILDING SERVICES • A pair of electrical panels are fed by the main service from below and, in turn, feed branch circuits above. • Black piping to left is natural gas for a backyard grill connection on opposite side of wall. Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. BUILDING SERVICES • The cavities in light frame construction make it relatively easy to route piping and wiring throughout the structure. • Allowable spacing and sizing of web penetrations in I-joists are established by the joist manufacturer. Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. BUILDING SERVICES • Holes drilled in framing members for electrical cable routing are filled with expansive foam to minimize air leakage within this exterior wall assembly. • Such foam may also used to seal penetrations in fireblocking between floors to maintain the necessary resistance to the spread of fire within the framing cavities. • Nail guards protect the wiring from future damage by nails or screws after the walls are finished and the wiring becomes concealed. • (The larger metal plate is for seismic requirements.) Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. BUILDING SERVICES • A plastic fixture box, for power outlets or switches, is nailed to a wall stud. • Outside the box, the cable is secured to the stud by an insulated staple. • Inside the box, individual black and white insulated wires, a bare ground wire, and red wire nuts used to connect wire ends can be seen. • The box is mounted proud of the stud so that its face will be flush with the finish surface of the wall once the wallboard or other finish materials are applied. Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. BUILDING SERVICES • Concrete block fireplace construction • According to the IBC, combustible wood framing cannot come within 2 inches of the sides or front, or 4 inches of the back, of a masonry fireplace. • Note the hollow clay flue to the left serving a separate fireplace (or other appliance) at a lower level. Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. 7 INTERIOR FINISHES FOR WOOD LIGHT FRAME CONSTRUCTION COMPLETING THE BUILDING ENCLOSURE Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. COMPLETING THE BUILDING ENCLOSURE • Glass fiber batt thermal insulation is being installed between framing members. • Unfaced batts, like those shown here, are held in place by friction. • (Manufacturers recommend wearing protective gloves and clothing when handling glass fiber materials to avoid skin irritation.) Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. COMPLETING THE BUILDING ENCLOSURE • A worker on stilts installs paper-faced glass fiber batt insulation into the ceiling/roof framing. Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. COMPLETING THE BUILDING ENCLOSURE • These walls are insulated with unfaced batts. In a heating climate, a separate vapor retarder, such as sheet plastic, will be added before the wallboard is installed. • The insulation batts in the roof are paper-faced. The paper facing acts as the vapor retarder. • The recessed light fixtures must either be rated for direct contact with insulation, or the insulation must be maintained a specified distance from the fixtures to avoid overheating. • Such fixtures, if not carefully installed and sealed, are a potential source of air leakage between the heated interior and the ventilated air space above the insulation. Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. COMPLETING THE BUILDING ENCLOSURE • Where plumbing pipes run in exterior walls, they must be kept to the interior side of the insulation to minimize the risk of freezing. • Note the use of spray foam insulation (left) to fill narrow framing cavities not easily insulated with batts. Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. COMPLETING THE BUILDING ENCLOSURE • Spray foam insulation is used to fill the gap between rough openings and the frames of doors and windows, a space that is otherwise prone to air leakage. • This foam must not be expansive or it could distort the door or window frame. • Note the protruding tapered shim. During installation of the door frame, pairs of such shims are inserted from opposite sides and adjusted to hold the frame in position. Finish nails driven through the frame hold the shims in place. The projecting portions of the shims are sawed or snapped off before the casings are applied. Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. COMPLETING THE BUILDING ENCLOSURE • In comparison to batt insulation, spray foam insulation results in a more air-tight building enclosure with the potential for improved energy savings. • Some foam types also have significantly higher insulating values per inch of thickness than other common insulation materials. Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. COMPLETING THE BUILDING ENCLOSURE • Blown-in insulation types include cotton, glass fibers, and cellulose (shown here). • In comparison to glass fiber batts, blown-in insulation tends to more completely fill framing cavities without gaps or voids, reducing heat loss due to convective air movement within the wall cavity. Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. COMPLETING THE BUILDING ENCLOSURE • In heating climates, a vapor retarder is required on the heated side of the wall. Common materials include: – sheet plastic – paper or aluminum foil insulation facing – paint primers with low vapor permeability. • Some foam insulations also have sufficiently low vapor permeability to act as vapor retarders. Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. 7 INTERIOR FINISHES FOR WOOD LIGHT FRAME CONSTRUCTION WALL AND CEILING FINISH Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. WALL AND CEILING FINISH • Walls and ceilings are most commonly finished with gypsum wallboard (drywall). • Joints between boards are finished level and smooth with reinforcing tape and, usually, three distinct coats of joint compound (spackle). • Depressions in the wallboard made by fasteners are also leveled with joint compound. Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. WALL AND CEILING FINISH • The rough edges that remain where gypsum wallboard is cut to fit around openings for windows, doors, registers, and other items are typically covered with finish trim. Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. WALL AND CEILING FINISH • Gypsum veneer plaster consists of a thin plaster coating over specially formulated gypsum board base. • It creates a harder, more durable surface than conventionally finished gypsum wallboard. • Where skilled plasterers are plentiful, this type of wall and ceiling finish may also be cost-competitive with conventional wallboard. Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. 7 INTERIOR FINISHES FOR WOOD LIGHT FRAME CONSTRUCTION MILLWORK AND FINISH CARPENTRY Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. MILLWORK AND FINISH CARPENTRY • Millwork: Finished carpentry components, such as moldings, doors, cabinets, stairs, etc. manufactured offsite • Right: A finish carpenter uses a powered miter saw to cut wood molding (casings) for trimming out a door frame. Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. MILLWORK AND FINISH CARPENTRY • The head (top) casing is being installed using a pneumaticallypowered finish nail gun. • Note the mitered ends which will join with the jamb (side) casings. Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. MILLWORK AND FINISH CARPENTRY • These moldings were manufactured from short scraps of material, joined end-to-end in the factory, to create longer pieces. • Once the trim pieces are painted, they will appear continuous. Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. MILLWORK AND FINISH CARPENTRY • Installation of the side casings is almost complete. Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. MILLWORK AND FINISH CARPENTRY • A six panel door (the panels are barely visible in this photograph), hung with three hinges • The door has been drilled for the lockset close to its left edge. • Doors may be prehung in the factory or fitted and installed on site. Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. MILLWORK AND FINISH CARPENTRY • The sides and top of a window are trimmed in a manner similar to that for a door. • The bottom of the window opening is trimmed with a sill and apron. Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. MILLWORK AND FINISH CARPENTRY • A site-built custom stair • Stairs can also be prefabricated in a millworking shop. Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. MILLWORK AND FINISH CARPENTRY • Wood strip ceiling Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. MILLWORK AND FINISH CARPENTRY • Painted gypsum wallboard walls and ceilings • Stone flooring (foreground) • Wood baseboards and trim • Wood stairs • Wood flooring (beyond) • Custom wood casework Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. MILLWORK AND FINISH CARPENTRY • Painted wood trim including baseboards, door casings, wall cornice, and cased ceiling beams • Six paneled doors (left) • Glazed French doors (center) • Wood strip flooring Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved. MILLWORK AND FINISH CARPENTRY • Custom wood casework • Wide plank wood flooring • Wood decking ceiling • Exposed heavy timber framing • Gypsum wallboard walls Fundamentals of Building Construction, Materials & Methods, 5th Edition Copyright © 2009 J. Iano. All rights reserved.