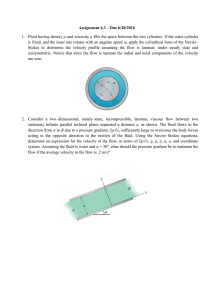

Mathematical Modeling of Convective Heat Transfer:

advertisement

Mathematical Modeling of Convective Heat Transfer:

Single Phase through Subcooled Boiling Flows

by

Matthew P. Wilcox

A Thesis Submitted to the Graduate

Faculty of Rensselaer Polytechnic Institute

in Partial Fulfillment of the

Requirements for the degree of

MASTER OF SCIENCE

Major Subject: MECHANICAL ENGINEERING

Approved:

_________________________________________

Ernesto Gutierrez-Miravete, Thesis Adviser

Rensselaer Polytechnic Institute

Hartford, Connecticut

April 2013

i

© Copyright 2013

By

Matthew P. Wilcox

All Rights Reserved

ii

TABLE OF CONTENTS

TABLE OF CONTENTS ................................................................................................. iii

LIST OF TABLES ............................................................................................................. v

LIST OF FIGURES ......................................................................................................... vii

ABSTRACT ..................................................................................................................... ix

1. INTRODUCTION ....................................................................................................... 1

1.1

RESEARCH ....................................................................................................... 2

1.2

CONTENT ......................................................................................................... 3

2. HEAT TRANSFER AND FLUID FLOW: THEORY ................................................ 5

2.1

GOVERNING EQUATIONS ............................................................................ 5

2.2

NUMERICAL METHODS................................................................................ 6

2.3

NATURAL CONVECTION .............................................................................. 8

2.4

LAMINAR FLOW ............................................................................................. 9

2.5

TURBULENT FLOW ...................................................................................... 10

2.5.1

2.6

2.7

CALCULATING TURBULENCE PARAMETERS .......................... 13

TWO-PHASE FLOW ...................................................................................... 15

2.6.1

MODELING TWO-PHASE FLOWS .................................................. 17

2.6.2

POPULATION BALANCE MODEL.................................................. 18

BOILING HEAT TRANSFER ........................................................................ 19

3. HEAT TRANSFER AND FLUID FLOW: MODELING ......................................... 21

3.1

NATURAL CONVECTION ............................................................................ 21

3.1.1

HORIZONTAL CYLINDER ............................................................... 21

3.1.2

VERTICAL PLATE ............................................................................ 28

3.2

LAMINAR FLOW ........................................................................................... 34

3.3

TURBULENT FLOW ...................................................................................... 38

3.3.1

TURBULENT FLOW WITHOUT HEAT TRANSFER ..................... 38

3.3.2

TURBULENT FLOW WITH HEAT TRANSFER ............................. 43

iii

3.4

3.5

TWO-PHASE FLOW ...................................................................................... 46

3.4.1

GAS MIXING TANK .......................................................................... 46

3.4.2

BUBBLE COLUMN ............................................................................ 51

3.4.3

BUBBLE COLUMN WITH POPULATION BALANCE MODEL ... 56

BOILING FLOWS ........................................................................................... 60

3.5.1

POOL BOILING .................................................................................. 60

3.5.2

SUBCOOLED Flow BOILING ........................................................... 66

4. DISUSSION AND CONCLUSIONS ........................................................................ 81

REFERENCES ................................................................................................................ 83

iv

LIST OF TABLES

Table 2.5.1-1: Turbulent Flow Input ............................................................................... 14

Table 2.5.1-2: Turbulence Parameter Calculation ........................................................... 14

Table 3.1.1-1: Horizontal Cylinder Model Input ............................................................. 22

Table 3.1.1-2: Horizontal Cylinder Model Water Density .............................................. 22

Table 3.1.1-3: Mesh Validation for Horizontal Cylinder Model ..................................... 27

Table 3.1.2-1: Vertical Plate Model Input ....................................................................... 29

Table 3.1.2-2: Vertical Plate Model Water Density ........................................................ 29

Table 3.1.2-3: Mesh Validation for Vertical Plate Model ............................................... 33

Table 3.2-1: Laminar Flow Model Input ......................................................................... 35

Table 3.2-2: Laminar Flow Model Water Density .......................................................... 35

Table 3.2-3: Mesh Validation for Laminar Flow Model ................................................. 37

Table 3.3.1-1: Turbulent Flow Without Heat Transfer Model Input ............................... 39

Table 3.3.2-1: Turbulent Flow With Heat Transfer Model Input .................................... 44

Table 3.3.2-2: Turbulent Flow Model Water Density ..................................................... 44

Table 3.3.2-3: Mesh Validation for Turbulence With Heat Transfer Model ................... 46

Table 3.4.1-1: Gas Mixing Tank Model Input ................................................................. 48

Table 3.4.1-2: Mesh Validation for Gas Mixing Tank Model ......................................... 50

Table 3.4.2-1: Bubble Column Model Input ................................................................... 52

Table 3.4.2-2: Mesh Validation for Bubble Column Model ........................................... 56

Table 3.4.3-1: Population Balance Model Input .............................................................. 57

Table 3.4.3-2: Bubble Size Distribution – Surface Tension of 0.072 N/m ..................... 59

Table 3.4.3-3: Bubble Size Distribution – Surface Tension of 0.0072 N/m ................... 60

Table 3.5.1-1: Pool Boiling Model Input......................................................................... 61

Table 3.5.1-2: Pool Boiling Model Water Density .......................................................... 62

Table 3.5.1-3: Mesh Validation for Pool Boiling Model................................................. 65

Table 3.5.2-1: Subcooled Flow Boiling Model Input ...................................................... 69

Table 3.5.2-2: Subcooled Flow Boiling Model Water Properties ................................... 70

Table 3.5.2-3: Boiling Model Study Case Input .............................................................. 71

Table 3.5.2-4: Boiling Model Study Case Results .......................................................... 74

Table 3.5.2-5: Initial Conditions Study Case Input ......................................................... 75

v

Table 3.5.2-6: Initial Condition Study Case Results ....................................................... 75

Table 3.5.2-7: Axial Location Liquid Volume Fraction .................................................. 76

Table 3.5.2-8: Absolute Impact on Liquid Volume Fraction .......................................... 78

Table 3.5.2-9: Relative Impact on Liquid Volume Fraction ........................................... 79

Table 3.5.2-10: Mesh Validation for Subcooled Boiling Model ..................................... 80

vi

LIST OF FIGURES

Figure 2.5-1: Transition from Laminar to Turbulent Flow.............................................. 11

Figure 2.6-1: Flow Regimes ............................................................................................ 15

Figure 2.6-2: Baker Flow Pattern .................................................................................... 16

Figure 2.7-1: Boiling Heat Transfer Regimes ................................................................. 19

Figure 3.1.1-1: Heated Cylinder Schematic .................................................................... 21

Figure 3.1.1-2: Temperature (K) ..................................................................................... 23

Figure 3.1.1-3: Density (kg/m3) ....................................................................................... 23

Figure 3.1.1-4: Velocity Vectors (m/s) ............................................................................ 24

Figure 3.1.1-5: Interference Fringes Around a Heated Horizontal Cylinder (K) ............ 25

Figure 3.1.1-6: Temperature at θ = 30° Vs. Radial Distance .......................................... 26

Figure 3.1.1-7: Temperature at θ = 90° Vs. Radial Distance .......................................... 26

Figure 3.1.1-8: Temperature at θ = 180° Vs. Radial Distance ........................................ 27

Figure 3.1.2-1: Vertical Plate Schematic ......................................................................... 28

Figure 3.1.2-2: Temperature (K) ..................................................................................... 30

Figure 3.1.2-3: Velocity Vectors (m/s) ............................................................................ 30

Figure 3.1.2-4: Interference Fringes Around a Heated Vertical Plate (K) ...................... 31

Figure 3.1.2-5: Dimensionless Temperature as a Function of Prandtl Number .............. 32

Figure 3.1.2-6: Dimensionless Temperature as a Function of Prandtl Number .............. 33

Figure 3.2-1: Laminar Flow Schematic ........................................................................... 34

Figure 3.2-2: Velocity Profile .......................................................................................... 34

Figure 3.2-3: Radial Velocity (m/s) ................................................................................. 36

Figure 3.2-4: Temperature (K) ........................................................................................ 36

Figure 3.2-5: Wall Shear Stress ....................................................................................... 37

Figure 3.3.1-1: Turbulent Flow Without Heat Transfer Schematic................................. 38

Figure 3.3.1-2: Velocity Magnitude ................................................................................ 38

Figure 3.3.1-3: Wall Shear Stress .................................................................................... 40

Figure 3.3.1-4: Radial Velocity (m/s) ............................................................................. 40

Figure 3.3.1-5: dAxial-Velocity/dx ................................................................................. 40

Figure 3.3.1-6: Flow Results for Mass Flow Rate of 0.5 kg/s ......................................... 41

Figure 3.3.1-7: Flow Results for Larger Mass Flow Rate of 1.5 kg/s ............................. 41

vii

Figure 3.3.1-8: Turbulent Kinetic Energy (m2/s2) ........................................................... 42

Figure 3.3.1-9: Production of Turbulent Kinetic Energy ................................................ 42

Figure 3.3.2-1: Turbulent Flow With Heat Transfer Schematic ...................................... 43

Figure 3.3.2-2: Temperature (K) ..................................................................................... 43

Figure 3.3.2-3: Radial Velocity (m/s) .............................................................................. 45

Figure 3.3.2-4: Velocity Magnitude ................................................................................ 45

Figure 3.3.2-5: Wall Shear Stress .................................................................................... 45

Figure 3.4.1-1: Gas Mixing Tank Schematic................................................................... 47

Figure 3.4.1-2: Gas Volume Fraction .............................................................................. 49

Figure 3.4.1-3: Liquid Velocity Vectors (m/s) ................................................................ 49

Figure 3.4.1-4: Gas Velocity Vectors (m/s)..................................................................... 50

Figure 3.4.2-1: Bubble Column Schematic ..................................................................... 51

Figure 3.4.2-2: Gas Volume Fraction .............................................................................. 53

Figure 3.4.2-3: Liquid Velocity Vectors (m/s) ................................................................ 54

Figure 3.4.2-4: Gas Velocity Vectors (m/s)..................................................................... 55

Figure 3.4.2-5: Gas Volume Fraction (0.10 m/s)............................................................. 55

Figure 3.4.3-1: Gas Volume Fraction with PBM ............................................................ 57

Figure 3.4.3-2: Liquid Velocity Vectors with PBM (m/s)............................................... 58

Figure 3.4.3-3: Liquid Velocity Vectors with PBM (m/s)............................................... 59

Figure 3.5.1-1: Pool Boiling Schematic .......................................................................... 61

Figure 3.5.1-2: Instantaneous Gas Volume Fraction ....................................................... 63

Figure 3.5.1-3: Liquid Velocity Vectors (m/s) ................................................................ 64

Figure 3.5.1-4: Gas Velocity Vectors (m/s)..................................................................... 64

Figure 3.5.1-5: Volume Fraction of Vapor on Heated Surface ....................................... 65

Figure 3.5.2-1: Subcooled Flow Boiling Model Schematic ............................................ 69

Figure 3.5.2-2: Case 1 - Temperature (K) ....................................................................... 71

Figure 3.5.2-3: Case 1 - Liquid Volume Fraction ........................................................... 71

Figure 3.5.2-4: Case 1 - Mass Transfer Rate (kg/m3-s) ................................................... 72

Figure 3.5.2-5: Liquid Volume Faction for Cases 1-6..................................................... 73

Figure 3.5.2-6: Liquid Volume Faction for Cases 7-12................................................... 77

viii

ABSTRACT

Various fluid flow and heat transfer regimes were investigated to provide insight

into the phenomena that occur during subcooled flow boiling. The theory of each

regime was discussed in detail and followed by the development a numerical model.

Numerical models to analyze natural convection, laminar flow, turbulent flow with and

without heat transfer, two-phase flow, pool boiling and subcooled flow boiling were

created. The commercial software Fluent was used to produce the models and analyze

the results.

Different modeling techniques and numerical solvers were employed

depending on the scenario to generate acceptable results. The results of each model

were compared to experimental data when available to prove its validity.

Although numerous heat transfer and fluid flow phenomena were analyzed, the

primary focus of this research was subcooled flow boiling. The impact different boiling

model options have on liquid volume fraction was examined. Three bubble departure

diameter models and two nucleation site density models were studied using the same

initial conditions. The bubble departure diameter models did not show any relationship

with liquid volume fraction; however, the Kocamustafaogullari-Ishii nucleation site

density model tended to predict a greater liquid volume fraction, meaning less vapor

production, than the Lemmert-Chawla nucleation site density model.

A second study on how initial conditions impact the liquid volume fraction

during subcooled flow boiling was explored.

The initial conditions of heat flux, inlet

temperature and mass flow rate were increased or decreased relative to a base case value.

The difference in liquid volume fraction between scenarios was compared and

relationships relating the initial conditions with respect to liquid volume fraction were

developed. Overall, the inlet temperature had the greatest impact on liquid volume

fraction, the wall heat flux had the second greatest impact and mass flow rate had the

smallest impact.

ix

1. INTRODUCTION

Since the 19th century, the world’s standard of living has greatly increased

primarily due to the generation and distribution of electricity. Over 80% of the world’s

electricity production is generated by converting thermal energy, from a fuel source into

electrical energy. A common energy conversion process known as the Rankine Cycle

burns fuel to generate steam which is used to turn a turbine and spin an electric

generator.

Electricity production involves numerous engineering processes but is

primarily based around heat transfer and fluid flow.

Coal, oil, natural gas and uranium are some of the different fuel sources

available to electrical power plants. The fuel source in focus here will be uranium or

nuclear fuel. Nuclear power plants harness energy released during fission to heat water.

The energy transfer mechanisms within a nuclear reactor involve all three major forms

of heat transfer; conduction, convection and radiation. The fluid flow through the

reactor core is complex due to the intense energy transfer and phase change.

In

Pressurizer Water Reactors, the water surrounding the reactor core is prevented from

bulk boiling because it is highly pressurized; however, a small amount of localized

boiling does occur. This is known as subcooled flow boiling. This research focuses on

the convective heat transfer and fluid flow phenomena that occur during subcooled flow

boiling.

Specifically, topics on turbulence, two-phase flow and phase change are

discussed.

Subcooled boiling occurs when an under-saturated fluid comes in contact with a

surface that is hotter than its saturation temperature. Small bubbles form on the heated

surface in locations called nucleation sites. The number of bubbles that form is heavily

dependent on fluid inlet temperature, pressure, mass flow, heat flux and microscopic

features of the surface. After the bubbles form on the heated surface, they detach and

enter the bulk fluid. When this occurs, saturated steam is dispersed in a subcooled liquid

which is where the term subcooled boiling originates.

1

1.1

RESEARCH

Subcooled flow boiling is characterized by the combination of convection,

turbulence, boiling and two-phase flow. Determining the amount of voiding that occurs

during subcooled flow boiling has become a topic of great interest in recent years. A

number of mechanistic models for the prediction of wall heat flux and partitioning have

been developed. One of the most commonly used mechanistic models for subcooled

flow boiling was developed by Del Valle and Kenning. This model accounts for bubble

dynamics at the heated wall using concepts developed initially by Graham and

Hendricks for wall heat flux partitioning during nucleate pool boiling. Recently, a new

approach to the partitioning of the wall heat flux has been proposed by Basu et al. The

fundamental idea of this model is that all the energy from the wall is transferred to the

liquid adjacent to the heated wall. Then, a fraction of the energy is transferred to vapor

bubbles by evaporation while the remainder goes into the bulk liquid. [1]

Additionally, focus has been placed on accurately modeling the three most

impactful parameters in subcooled flow boiling.

These parameters are the active

nucleation site density (Na), departing bubble diameter (dbw) and bubble departure

frequency (f). The two most common nucleation site density models were developed by

Lemmert and Chwala and Kocamustafaogullari and Ishii. Both of these models are

available in Fluent. Many correlations have been developed to determine the bubble

departure diameter.

Tolubinsky and Kostanchuk proposed the most simplistic

correlation which evaluates bubble departure diameter as a function of subcooling

temperature.

Kocamustafaogullari and Ishii improved this model by including the

contact angle of the bubble. Finally, Unal produced a comprehensive correlation which

includes the effect of subcooling, the convection velocity and the heater wall properties.

All three of these bubble departure diameter correlations are available in Fluent.

The

most common bubble departure frequency correlation for computational fluid dynamics

was developed by Cole. It is based on a bubble departure diameter model and a balance

between buoyancy and drag forces. The Cole bubble departure frequency model is

available in Fluent.

Recently, the use of population balance equations (PBEs) has been used to improve

the modeling of subcooled flow boiling to better determine how swarms of bubbles

2

interact after detaching from the heated surface. This technique was recommended by

Krepper et. al. [2] and investigated by Yeoh and Tu [1]. Population balance equations

have been introduced in several branches of modern science, mainly areas with

particulate entities such as chemistry and materials. Population balance equations help

define how particle size populations develop in specific properties over time. Population

balance equations are available in Fluent but not in combination with the boiling model.

1.2

CONTENT

This research produced an investigation on subcooled flow boiling using Fluent.

Fluent is a widely accepted commercial computational fluid dynamics code that can

simulate complex heat transfer and fluid flow regimes. This thesis had three major

objectives. The first objective was to gain an understanding of the phenomena that occur

during subcooled flow boiling. The second objective was to determine how the boiling

model options described in Section 1.1 impact the liquid volume fraction at different

axial locations. The third objective was to evaluate how heat flux, inlet temperature and

mass flow rate impact the liquid volume fraction at different axial locations.

Due to its complexity, development of the subcooled flow boiling model was

performed in stages. With the development of each model, a more complicated fluid

flow or heat transfer scenario was analyzed. The first and simplest model created was

for natural convection. The theory of natural convection is described in Section 2.3 and

the analytical modeling results are presented in Section 3.1. Two natural convection

geometries were analyzed. The first was a horizontal cylinder suspended in an infinite

pool and the second was a vertical plate suspended in an infinite pool. The second

model developed was for laminar flow. The theory of laminar flow is described in

Section 2.4 and the analytical modeling results are discussed in Section 3.2. The third

model developed was for turbulent flow. The theory of turbulent flow is described in

Section 2.5 and the analytical modeling results are displayed in Section 3.3. Section 3.3

contains two turbulent flow scenarios; turbulent flow without heat transfer and turbulent

flow with heat transfer. The fourth model developed was for two-phase flow with water

and air. The theory of two-phase flow is described in Section 2.6 and the analytical

3

modeling results for the scenarios analyzed are shown in Section 3.4. The first scenario

is a gas mixing tank and the second scenario is a bubble column. The final and most

complex model created includes a phase transformation (vaporization and condensation).

The theory of boiling heat transfer is described in Section 2.7 and the analytical

modeling results are presented in Section 3.5. Two models were created, the first for

pool boiling and the second for subcooled flow boiling. After each model was created, a

mesh validation was performed and the results were compared to known experimental

data when possible to validate the information generated by Fluent.

4

2. HEAT TRANSFER AND FLUID FLOW: THEORY

This section discusses basic theory behind some common heat transfer and fluid

flow scenarios. It is meant to provide a brief introduction to the phenomena involved in

subcooled flow boiling.

2.1

GOVERNING EQUATIONS

Conservation equations are a local form of conservation laws which state that

mass, energy and momentum as well as other natural quantities must be conserved. A

number of physical phenomena may be described using these equations [3]. In fluid

dynamics, the two key conservation equations are the conservation of mass and the

conservation of momentum.

Conservation of Mass in Vector Form (continuity equation):

𝜕𝜌

⃑ ∙ 𝜌v

+ (∇

⃑)= 0

𝜕𝑡

Conservation of Mass in Cartesian Form:

𝜕𝜌 𝜕

𝜕

𝜕

(𝜌𝑣𝑥 ) +

(𝜌𝑣𝑌 ) + (𝜌𝑣𝑧 ) = 0

+

𝜕𝑡 𝜕𝑥

𝜕𝑦

𝜕𝑧

Conservation of Momentum in Vector Form:

𝜌

𝐷v

⃑

⃑ 𝜌 + 𝜇∇

⃑ 2v

= −∇

⃑ + 𝜌𝑔

𝐷𝑡

Conservation of Momentum in Cartesian Form:

𝜕𝑣𝑥

𝜕𝑣𝑥

𝜕𝑣𝑥

𝜕𝑣𝑥

𝜕𝑝

𝜕 2 𝑣𝑥 𝜕 2 𝑣𝑥 𝜕 2 𝑣𝑥

𝜌(

+ 𝑣𝑥

+ 𝑣𝑦

+ 𝑣𝑧

)=−

+𝜇( 2 +

+

) + 𝜌𝑔𝑥

𝜕𝑡

𝜕𝑥

𝜕𝑦

𝜕𝑧

𝜕𝑥

𝜕𝑥

𝜕𝑦 2

𝜕𝑧 2

𝜌(

𝜕𝑣𝑦

𝜕𝑣𝑦

𝜕𝑣𝑦

𝜕𝑣𝑦

𝜕 2 𝑣𝑦 𝜕 2 𝑣𝑦 𝜕 2 𝑣𝑦

𝜕𝑝

+ 𝑣𝑥

+ 𝑣𝑦

+ 𝑣𝑧

)=−

+𝜇( 2 +

+

) + 𝜌𝑔𝑦

𝜕𝑡

𝜕𝑥

𝜕𝑦

𝜕𝑧

𝜕𝑦

𝜕𝑥

𝜕𝑦 2

𝜕𝑧 2

𝜕𝑣𝑧

𝜕𝑣𝑧

𝜕𝑣𝑧

𝜕𝑣𝑧

𝜕𝑝

𝜕 2 𝑣𝑧 𝜕 2 𝑣𝑧 𝜕 2 𝑣𝑧

𝜌(

+ 𝑣𝑥

+ 𝑣𝑦

+ 𝑣𝑧

)=−

+𝜇( 2 +

+

) + 𝜌𝑔𝑧

𝜕𝑡

𝜕𝑥

𝜕𝑦

𝜕𝑧

𝜕𝑧

𝜕𝑥

𝜕𝑦 2

𝜕𝑧 2

5

In subcooled flow boiling, as in many other instances of fluid dynamics, energy

is added or removed from the system. In this situation, the conservation of energy

equation is important.

Conservation of Energy in Vector Form:

𝜌𝐶̂𝑝

𝐷𝑇

𝜕 ln 𝜌 𝐷𝑝

⃑ ∙ 𝑞) − (

= −(∇

)

𝐷𝑡

𝜕 ln 𝑇 𝑝 𝐷𝑡

Conservation of Energy in Cartesian Form:

𝜕𝑇

𝜕𝑇

𝜕𝑇

𝜕𝑇

𝜕𝑞𝑥 𝜕𝑞𝑦 𝜕𝑞𝑧

𝜕 ln 𝜌 𝐷𝑝

𝜌𝐶̂𝑝 ( + 𝑣𝑥

+ 𝑣𝑦

+ 𝑣𝑧 ) = − (

+

+

)−(

)

𝜕𝑡

𝜕𝑥

𝜕𝑦

𝜕𝑧

𝜕𝑥

𝜕𝑦

𝜕𝑧

𝜕 ln 𝑇 𝑝 𝐷𝑡

2.2

NUMERICAL METHODS

After the conservation laws governing heat transfer, fluid flow and other related

processes are expressed in differential form (Section 2.1), they can solved using

numerical methods to determine pressure, temperature, mass flux, etc. for various

circumstances and boundary conditions.

Each differential equation represents a

conservation principle and employs a physical quantity as its dependent variable that is

balanced by the factors that influence it. Some examples of differential equations that

may be solved through numerical methods are conservation of energy, conservation of

momentum and time averaged equation for turbulent flow. [4]

The goal of computational fluid dynamics is to calculate the temperature,

velocity, pressure, etc. of a fluid at particular locations within a system. Thus, the

independent variable in the differential equations is a physical location (and time in the

case of unsteady flows). Due to computational limitations, the number of locations (also

known as grid points or nodes) must be finite. By only focusing on the solution of the

differential equations at discrete locations, the need to find an exact solution to the

differential equation is not necessary.

The algebraic equations (also known as

discretization equations) involving the unknown values of the independent variable at

chosen locations (grid points) are derived from the differential equations governing the

6

independent variable. In this derivation, assumptions about the value of the independent

variable between grid points must be made. This concept is known as discretization. [4]

A discretization equation is an algebraic relationship that connects the values of

the dependent variable for a group of grid points within a control volume. This type of

equation is derived from the differential equation governing the dependent variable and

thus expresses the same physical information as the differential equation. The piecewise

nature of the profile (or mesh) is created by the finite number of grid points that

participate in a given discretization equation. The value of the dependent variable at a

grid point thereby influences the value of the dependent variable in its immediate area.

As the number of grid points becomes very large, the solution of the discretization

equations is expected to approach the exact solution of the corresponding differential

equation. This is true because as the grid points get closer together, the change in value

between neighboring grid points becomes small and the actual details of the profile

assumption become less important.

This is where the term “mesh independent”

originates. If there are too few grid points (coarse mesh), the profile assumptions can

impact the solution results and the discretization equation solution will not match the

differential equation solution. To ensure that the discretization equation results are not

dependent on the profile assumptions, the solution should be checked for mesh

independence. [4]

One of the more common procedures for deriving discretization equations is

using a truncated Taylor series. Other methods for deriving discretization equations

include variational formulation, method of weighted residuals and control volume

formulation. In the iterative process for solving a discretization equation, it is often

desirable to speed up or to slow down the changes, from iteration to iteration, in the

values of the dependent variable. The process of accelerating the rate of change between

iterations is called over-relaxation while the process of slowing down the rate of change

between iterations is called under-relaxation.

To avoid divergence in the iterative

solution of strongly nonlinear equations, under-relaxation is a very useful tool [4].

Fluent allows for manipulation of the relaxation constants for many independent

variables to improve convergence ability. It also offers numerous spatial discretization

solvers for the various independent variables such as pressure, flow, momentum,

7

turbulence, and energy.

Fluent implements the control volume formulation with

upwinding which was first proposed by Courant, Isaacson, and Rees in 1952. Other

options include QUICK, power law and third-order MUSCL.

2.3

NATURAL CONVECTION

Convection is the transport of mass and energy by bulk fluid motion. If the fluid

motion is induced by some external force, it is generally referred to as forced

convection. Natural convection is a transport mechanism in which the fluid motion is

not generated by any external source (like a pump, fan, suction device, etc.) but driven

by buoyancy-induced motion resulting from internal body forces produced by density

gradients. The density gradients can arise from mass concentration and or temperature

gradients in the fluid [5]. For example, in a system where a heated surface is submersed

in a cooler fluid, the cooler fluid absorbs energy from the heated surface and becomes

less dense. Buoyancy effects due to body forces cause the heated fluid to rise and the

surrounding, cooler fluid moves to take its place. The cooler fluid is then heated and the

process continues forming a convection current that continuously removes energy from

the heated surface.

In nature, natural convection cells occur everywhere from oceanic currents to air

rising above sunlight-warmed land.

Natural convection also takes place in many

engineering applications such as home heating radiators and cooling computer chips.

The amount of heat transfer that occurs due to natural convection in a system is

characterized by the Grashof, Prandtl and Rayleigh numbers.

The Grashof number,

Gr, is a dimensionless parameter that represents the ratio of buoyancy to viscous forces

acting on a fluid; and is defined as:

𝐺𝑟 =

𝑔𝛽(𝑇𝑠 − 𝑇∞ )𝐿3

(𝜇 ⁄𝜌)2

where β is the thermal expansion coefficient:

1 𝜕𝑃

𝛽=− ( )

𝜌 𝜕𝑇 𝑝

8

The Prandtl number, Pr, is a dimensionless parameter that represents the ratio of

momentum diffusivity to thermal diffusivity; and is defined as:

Pr =

Cp μ

k

The Rayleigh number, Ra, is a dimensionless parameter that represents the ratio

of buoyancy and viscosity forces times the ratio of momentum and thermal diffusivities;

and is defined as:

Ra = GrPr

When the Rayleigh number is below a critical value for a particular fluid, heat

transfer is primarily in the form of conduction; when it exceeds the critical value, heat

transfer is primarily in the form of convection.

Like forced convection, natural

convection can either be laminar or turbulent. Rayleigh numbers less than 108 indicate a

buoyancy-induced laminar flow, with transition to turbulence occurring at about 109. [6]

In many situations, convection is mixed meaning that both natural and forced

convection occur simultaneously.

The importance of buoyancy forces in a mixed

convection flow can be measured by the ratio of the Grashof and Reynolds numbers:

Gr

gβΔTL

=

Re2

V2

When this number approaches or exceeds unity, there are strong buoyancy

contributions to the flow. Conversely, if the ratio is very small, buoyancy forces may be

ignored.

2.4

LAMINAR FLOW

Fluid flow can be grouped into two categories, laminar or turbulent flow.

Laminar flow implies that the fluid moves in sheets that slip relative to each other.

Laminar flow occurs at very low velocities where there are only small disturbances and

little to no local velocity variations. In laminar flow, the motion of the fluid particles is

very orderly and can be characterized by high momentum diffusion and low momentum

convection.

9

The Reynolds number is used to characterize the flow regime. The Reynolds

number, Re, is a dimensionless number that represents the ratio of inertial forces to

viscous forces; and is defined as:

Re =

ρVA

μ

The Reynolds number helps to quantify the relative importance of inertial and

viscous forces for given flow conditions. For internal flow, such as within a pipe,

laminar flow occurs at a Reynolds number less than 2300.

The velocity of laminar flow in a pipe is can be calculated by [5]:

𝑢=

𝑟𝑠2

𝑑𝑃

𝑟2

(− ) (1 − 2 )

4𝜇

𝑑𝑥

𝑟𝑠

Or, in terms of the mean velocity, V:

𝑟2

𝑢 = 2𝑉 (1 − 2 )

𝑟𝑠

The above two equations indicate that the velocity for laminar flow is related to the

square of the pipe radius and thus the flow profile is parabolic.

The energy equation for flow through a circular pipe assuming symmetric heat

transfer, fully developed flow and constant fluid properties is [5]:

𝜕𝑇

1𝜕

𝜕𝑇

𝜕 2𝑇

𝑢

= 𝛼[

(𝑟 ) + 2 ]

𝜕𝑥

𝑟 𝜕𝑟 𝜕𝑟

𝜕𝑥

2.5

TURBULENT FLOW

In fluid dynamics, turbulence is a flow regime characterized by chaotic and

stochastic changes. Turbulent flows exist everywhere in nature from the jet stream to

the oceanic currents. Turbulent flows are highly irregular and random which makes a

deterministic approach to turbulence problems impossible. They have high diffusivity,

meaning there is rapid mixing and increased rates of momentum, heat and mass transfer.

Because of these properties, turbulent flows are very important to many engineering

applications.

Turbulent flows involve large Reynolds numbers and contain three10

dimensional vorticity fluctuations. The unsteady vortices appear on many scales and

interact with each other generating high levels of mixing. Also, like laminar flows,

turbulent flows are dissipative. Because turbulence cannot maintain itself, it depends on

its environment to obtain energy. A common source of energy for turbulent velocity

fluctuations is shear in the mean flow; other sources, such as buoyancy, exist too. If

turbulence arrives in an environment where there is no shear or other maintenance

mechanisms, the turbulence will decay and the flow tends to become laminar. [7]

In flows that are originally laminar, turbulence arises from instabilities at large

Reynolds numbers.

For internal flows, such as within a pipe, turbulent flow is

characterized by a Reynolds number greater than 4000. For flows with a Reynolds

number between 2300 and 4000, both laminar and turbulent flows are possible. This is

called transition flow. [7]

A common example of the transition from laminar flow to turbulent flow is

smoke rising from a cigarette [8].

Figure 2.5-1: Transition from Laminar to Turbulent Flow

As the smoke leaves the cigarette, it travels upward in a laminar fashion as

shown by the single stream of smoke. At a certain distance, the Reynolds number

becomes too large and the flow begins to transition to the turbulent regime. When this

11

happens, the flow of the smoke becomes more random and rapidly mixes with the air

causing it to dissipate.

Perfect modeling of turbulent flow requires the exact solution of the Continuity

and Navier-Stokes equations which can be extremely difficult and time consuming due

to the many scales involved. To reduce the complexity, an approximation to the NavierStokes equation was developed by Osborne Reynolds called the Reynolds-averaged

Navier–Stokes equations (or RANS equations).

This method decomposes the

instantaneous fluid flow quantities of the Navier-Stokes equations into mean (timeaveraged) and fluctuating components.

The RANS equations can be used with

approximations based on knowledge of the turbulent flow to give approximate timeaveraged solutions to the Navier–Stokes equations. [9]

For the velocity terms:

𝑢𝑖 = 𝑢̅𝑖 + 𝑢𝑖′

where 𝑢̅𝑖 and 𝑢𝑖′ are the mean and fluctuating velocity components respectively.

Similarly, for scalar quantities:

𝜙 = 𝜙̅ + 𝜙 ′

where 𝜙 denotes a scalar such as energy, pressure, or species concentration.

Substituting expressions of this form for the flow variables into the instantaneous

continuity and momentum equations and taking a time-average yields the time-averaged

continuity and momentum equations [9]. These are written in Cartesian tensor form as:

𝛿𝑝

𝛿

(𝜌𝑢̅𝑖 ) = 0

+

𝛿𝑡 𝛿𝑥𝑖

𝛿

𝛿

𝛿𝑃

𝛿

𝛿𝑢𝑖 𝛿𝑢𝑗 2 𝛿𝑢𝑙

𝛿

′ ′

̅̅̅̅̅̅

(𝜌𝑢̅𝑖 ) +

(𝜌𝑢̅𝑖 𝑢̅𝑗 ) = −

+

[𝜇 (

+

− 𝜁𝑖𝑗

)] +

(−𝜌𝑢

𝑖 𝑢𝑗 )

𝛿𝑡

𝛿𝑥𝑗

𝛿𝑥𝑖 𝛿𝑥𝑗

𝛿𝑥𝑗 𝛿𝑥𝑖 3 𝛿𝑥𝑙

𝛿𝑥𝑗

The two above equations are called the RANS equations. They have the same

general form as the instantaneous Navier-Stokes equations, with the velocities and other

solution variables now representing time-averaged values. The RANS equations can be

used with approximations based on knowledge of the turbulent flow to give approximate

′ ′

̅̅̅̅̅̅

time-averaged solutions to the Navier–Stokes equations. An additional term,(−𝜌𝑢

𝑖 𝑢𝑗 ),

12

known as the Reynolds stress appears in the equation as a results of using the RANS

method. [9]

One way that the Reynolds stress is evaluated in practice is through the k-ϵ

turbulence model. The k-ϵ model was first introduced by Harlow and Nakayama in

1968 [10]. The k-ϵ model has become the most widely used model for industrial

applications because of its overall accuracy and small computational demand. In the k-ϵ

model, k represents the turbulent kinetic energy and ϵ represents its dissipation rate.

Turbulent kinetic energy is the average kinetic energy per unit mass associated with

eddies in the turbulent flow while epsilon (ϵ) is the rate of dissipation of the turbulent

energy per unit mass.

In the derivation of the k-ϵ model, it is assumed that the flow is fully turbulent,

and the effects of molecular viscosity are negligible. As the strengths and weaknesses of

the standard k-ϵ model became known, modifications were introduced to improve its

performance.

These improvements have helped create many, new, more accurate

models, among them, the realizable k-ϵ model which differs from the standard k-ϵ model

in two important ways. First, the realizable model contains an alternative formulation of

the turbulent viscosity. Second, a modified transport equation for the dissipation rate, ϵ,

is derived from an exact equation for the transport of the mean-square vorticity

fluctuation. The term “realizable” means that the model satisfies certain mathematical

constraints on the Reynolds stresses, consistent with the physics of turbulent flows. [9]

2.5.1

CALCULATING TURBULENCE PARAMETERS

All of the computational fluid dynamic models discussed in this thesis use the

k-ϵ turbulence model when applicable. In Fluent, turbulence models require certain

parameters to be established prior to initialization to properly set the initial and boundary

conditions for the flow. For instance, based on the conditions in Table 2.5.1-1, the

equations in Table 2.5.1-2 [9] were used to determine the boundary and initial condition

inputs for the turbulent flow models presented in Section 3.3.

13

Table 2.5.1-1: Turbulent Flow Input

Input Parameter

Mass Flow Rate (𝑚̇)

Pipe Diameter (D)

Viscosity (μ)

Density (ρ)

Turbulence Empirical Constant (Cμ)

Numerical Value

1.0 kg/s

0.03 m

0.001003 kg/m-s

998.2 kg/m3

0.09 [9]

Table 2.5.1-2: Turbulence Parameter Calculation

Variable

Hydraulic Diameter (Dh)

Flow Area (A)

Average Flow Velocity (uavg)

Reynolds Number (ReDh)

Turbulence Length Scale (l)

Equation

Numerical Value

4∗𝐴

𝐷ℎ =

𝑃

𝐷 2

𝜋 ∗ (2 )

=

=𝐷

4∗𝜋∗𝐷

𝐷 2

𝐴 =𝜋∗( )

2

0.03 𝑚 2

=𝜋∗(

)

2

𝑚̇

𝑢𝑎𝑣𝑔 =

𝜌∗𝐴

0.5 𝑘𝑔/𝑠

=

𝑘𝑔

998.2 3 ∗ 0.00070686 𝑚2

𝑚

𝑚̇𝐷ℎ

𝑅𝑒𝐷ℎ =

𝜇𝐴

𝑘𝑔

0.5 𝑠 ∗ 0.03 m

=

𝑘𝑔

0.001003 𝑚 − 𝑠 ∗ 0.00070686 𝑚2

𝑙 = 0.07 ∗ 𝐷ℎ

= 0.07 ∗ 0.03 𝑚

−

Turbulent Intensity (I)

Turbulent Kinetic Energy (k)

Dissipation Rate (ϵ)

0.00070686 m2

1.41726 m/s

42314

0.0021 m

1

𝐼 = 0.16 ∗ 𝑅𝑒𝐷 8

ℎ

=

0.03 m

4.22483 %

1

0.16 ∗ 42314−8

3

2

𝑘 = (𝑢𝑎𝑣𝑔 ∗ 𝐼)

2

2

3

𝑚

= (1.41726 ∗ 0.0422483)

2

𝑠

3/2

3/4 k

ε = C𝜇

𝑙

0.00537853/2

= 0.093/4

0.0021

14

0.0053785 m2/s2

0.030859 m2/s3

2.6

TWO-PHASE FLOW

Fluid flows that contain two or more components are referred to as multiphase

flow. The flow components can be of the same chemical substance but in different

states of matter such as water and steam, be of different chemical substances but the

same state of matter such as water and oil or finally be of different chemical substance

and different states of matter such as water and air. This section focuses on two-phase

flow involving water and air while Section 2.7 focuses on two-phase flows involving

water and steam.

Depending on the volume fraction of each component in the two-phase flow,

different flow patterns can exist. Understanding the flow pattern of the two-phase flow

is important because pressure drops and heat transfer rates are heavily impacted by the

flow type. The characteristic flow patterns for two-phase flow, in order of increasing

gas volume fraction from liquid to gas, are bubbly flow, plug flow, stratification flow,

wavy flow, slug flow, annular flow and spray flow. A schematic representation of each

of these flow patterns is shown in Figure 2.6-1 [11].

Figure 2.6-1: Flow Regimes

The flow patterns shown in Figure 2.6-1 can be classified into three categories,

bubbly flow, slug flow and annular flow. Bubbly flow is when the liquid phase is

continuous and the vapor phase is discontinuous such that the vapor phase is distributed

15

in the liquid phase in the form of bubbles. This flow pattern occurs at low gas volume

fractions. Subcooled boiling is classified as bubbly flow. Slug flow is when there are

relatively large liquid slugs surrounded by vapor. This flow pattern occurs at moderate

gas volume fractions and relatively low flow velocities. Annular flow is when the liquid

phase is continuous along the wall and the vapor phase is continuous in the core. This

flow pattern occurs at high gas volume fractions and high flow velocities. Although not

considered to be a flow regime, film boiling is the opposite of annular flow (the vapor

phase is continuous along the wall and the liquid phase is continuous in the core). Flow

film boiling occurs when the heat flux is relatively large compared to the mass flux.

Film boiling is discussed further in Section 2.7.

As stated previously, knowing the flow pattern is important to determine the

pressure drop and heat transfer rate within a system. The flow pattern changes as a

function of gas volume fraction and flow velocity. The flow pattern of a system can be

determined using the Baker flow criteria shown in Figure 2.6-2 [11].

Figure 2.6-2: Baker Flow Pattern

16

2.6.1

MODELING TWO-PHASE FLOWS

Two-phase flows obey the same basic laws of fluid mechanics that apply to

single phase flows; however, the equations are more complicated and more numerous.

Two-phase flows are more difficult to solve due to the secondary phase and additional

phenomena that must be accounted for such as mass transfer, and phase-interface

interactions (slip and drag). Three common multiphase flow models available in Fluent

are Volume of Fluid (VOF), Mixture and Eulerian, each with varying strengths and

computational demand.

The VOF model is the simplest and least computationally expensive of the three

multiphase models offered in Fluent.

The VOF model can analyze two or more

immiscible fluids by solving a single set of momentum equations and tracking the

volume fraction of each fluid throughout the domain. All control volumes must be filled

with either a single fluid phase or a combination of phases. The VOF model does not

allow for void regions where no fluid of any type is present. The VOF method was

based on the marker-and-cell method and quickly became popular due to its low

computer storage requirements. Typical applications of VOF include stratified or freesurface flows such as the prediction of jet breakup, the motion of large bubbles in a

liquid, the motion of liquid after a dam break, and the steady or transient tracking of a

liquid-gas interface. [9]

The Mixture model is in between the VOF and Eulerian models both in

complexity and computational expense. The Mixture multiphase model can analyze

multiple phases (fluid or particulate) by solving the momentum, continuity, and energy

equations for the mixture, the volume fraction equations for the secondary phases, and

algebraic expressions for the relative velocities. Like the VOF model, it uses a singlefluid approach but has two major differences. First, the Mixture model allows for the

phases to be interpenetrating and therefore the volume fraction of a fluid in a control

volume can be equal to any value between zero and one. Second, the Mixture model

allows for the phases to move at different velocities, using the concept of slip velocities.

The mixture model is a good substitute for the full Eulerian multiphase model in several

cases where a full multiphase model may not be feasible or when the interphase laws are

unknown or their reliability can be questioned.

17

Typical applications include

sedimentation, cyclone separators, particle-laden flows with low loading, and bubbly

flows where the gas volume fraction remains low. [9]

The Eulerian model is the most complex and most computationally expensive

multiphase model offered in Fluent. It solves momentum and continuity equations for

each of the phases, and the equations are coupled through pressure and exchange

coefficients. With the Eulerian multiphase model, the number of secondary phases is

limited only by memory requirements and convergence behavior.

The Eulerian

multiphase model allows for the modeling of multiple separate, yet interacting phases.

The interacting phases can be liquids, gases, or solids in nearly any combination. Due to

its ability to model interacting phases, typical applications of the Eulerian model are

bubble columns, risers, particle suspension, fluidized beds and boiling including

subcooled boiling. [9]

2.6.2

POPULATION BALANCE MODEL

Many industrial fluid flow applications including subcooled boiling involve a

secondary phase with a size distribution. The size distribution of particles may include

solid particles, bubbles, or droplets that evolve in a multiphase system. Thus, in

multiphase flows involving a size distribution, a balance equation is required to describe

the changes in the particle size distribution, in addition to momentum, mass, and energy

balances. This balance is generally referred to as the population balance.

To make use of this modeling concept, a number density function is introduced

to account for the different sizes in the particle population. With the aid of particle

properties (for example, particle size, porosity, composition, etc.), different particles in

the population can be distinguished and their behavior can be described. [9]

The link between the population balance and boiling models has not been fully

developed in Fluent and is therefore not employed in the subcooled boiling model

created in Section 3.5.2.

However, the population balance model is utilized in

Section 3.4.3 to track bubble size distribution within a bubble column.

18

2.7

BOILING HEAT TRANSFER

Boiling is defined as a mode of heat transfer that occurs when saturated liquid

changes to saturated vapor due to heat addition. It is normally characterized by a high

heat transfer capacity and a low wall temperature which is made possible due to the large

amount of energy required to cause a phase change. This is essential for industrial

cooling applications, such as nuclear reactors and fossil boilers. Due to its importance in

industry, a significant amount of research has been carried out to study the capacity and

the mechanism of boiling heat transfer. There are two basic types of boiling, pool

boiling and flow boiling. If heat addition causes a phase change in a stagnant fluid then

it is pool boiling.

If heat addition causes a phase change in a moving fluid then it is

flow boiling. Both types of boiling heat transfer can be separated into four regimes

which are shown in Figure 2.7-1 [12].

Figure 2.7-1: Boiling Heat Transfer Regimes

The first regime of boiling, up to point A, is known as natural convection boiling.

During this regime, no bubbles form; instead, heat is transferred from the surface to the

5/4

bulk fluid by natural convection. The heat transfer rate is proportional to 𝛥𝑇𝑠𝑎𝑡 [11].

The second regime of boiling, from point A to point C, is called nucleate boiling.

During this stage, vapor bubbles are generated at certain preferred locations on the

heated surface called nucleation sites. Nucleation sites are often microscopic cavities or

cracks in the surface. When the liquid near the wall superheats, it evaporates forming

bubbles at the nucleation sites. When the liquid evaporates, a significant amount of

19

energy is removed from the heated surface due to the latent heat of the vaporization.

Vaporization also increases the convective heat transfer by mixing the liquid water near

the heated surface. There are two subregimes of nucleate boiling. The first subregime is

when local boiling occurs in a subcooled liquid (subcooled boiling). In this situation,

bubbles form on the heated surface but tend to condense after detaching from it. The

second subregime is when local boiling occurs in a saturated liquid. In this case, the

bubbles do not condense after detaching from the heated surface since the liquid is the

same temperature as the steam. It is possible for both subregimes to take place between

points A and C. Nucleate boiling is characterized by a very high heat transfer rate and a

small temperature difference between the bulk fluid and the heated surface. For this

reason, it is considered to be the most efficient heat transfer boiling regime. [11]

As the heated surface increases in temperature, more and more nucleation sites

become active. As more bubbles form at the nucleation sites, they begin to merge

together and form columns or slugs of gas, thus decreasing the contact area between the

bulk fluid and the heated surface. The decrease in contact area causes the slope of the

line in Figure 2.7-1 to decrease until a maximum is reached (point C). Point C is

referred to as the critical heat flux. When the critical heat flux is reached, the vapor

begins to form an insulating blanket around the heated surface which dramatically

increases the surface temperature. This is called the boiling crisis or departure from

nucleate boiling. [12]

As the temperature delta increases past the critical heat flux, the rate of bubble

generation exceeds the rate of bubble separation. Bubbles at the different nucleation

sites begin to merge together and boiling becomes unstable. The surface is alternately

covered with a vapor blanket and a liquid layer, resulting in oscillating surface

temperatures. This regime of boiling is known as partial film boiling or transition

boiling and takes place between points C and D. [11]

If the temperature difference between the surface and the fluid continues to

increase, stable film boiling is achieved.

During stable film boiling, there is a

continuous vapor blanket surrounding the heated surface and phase change occurs at the

liquid-vapor interface instead of at the heated surface. During this regime, most heat

transfer is carried out by radiation. [12]

20

3. HEAT TRANSFER AND FLUID FLOW: MODELING

3.1

NATURAL CONVECTION

Two natural convection scenarios were examined in this section. The first was a

heated horizontal cylinder and the second was a heated vertical plate, both were

submerged in an infinite pool of liquid. These examples were chosen because of their

simplicity, because they are commonly found in nature and because they have been

previously studied and results are available for validation of the numerical computations.

3.1.1

HORIZONTAL CYLINDER

A cylinder with an elevated constant surface temperature submerged in an

infinite pool of liquid was analyzed in this section. Energy passed from the slightly

warmer cylinder to the nearby fluid causing its temperature to increase and convection

cells to form. Figure 3.1.1-1 shows a schematic representation of the geometry and

important boundary conditions used to model the horizontal cylinder. The top and

bottom walls of the rectangle represent inlet and outlet pressure boundaries with pressure

conditions set such that the fluid is stagnant until heated by the cylinder. The left and

right walls of the rectangle are slip walls to more accurately model an infinite pool. See

Table 3.1.1-1 for a more detailed list of input parameters used in this section.

Figure 3.1.1-1: Heated Cylinder Schematic

21

Table 3.1.1-1: Horizontal Cylinder Model Input

Input

Geometry

Cylinder Diameter

Pool Height

Pool Width

2D Space

Solver

Time

Time Step Size

Type

Velocity Formulation

Gravity

Models

Energy

Viscous

Density

Initial Conditions

Cylinder Surface Temperature

Initial Fluid Temperature

Material Properties (Water)

Specific Heat

Thermal Conductivity

Viscosity

Density

Solution Methods

Scheme

Gradient

Pressure

Momentum

Energy

Transient Formulation

Value

0.02 m

0.28 m

0.24 m

Planar

Transient

0.05 s

Pressure Based

Relative

-9.8 m/s2 (Y-direction)

Active

Laminar

Boussineq

310 K

300 K

4182 J/kg-K

0.6 W/m-K

0.001003 kg/m-s

See Table 3.1.1-2

PISO

Least Square Cell Based

PRESTO!

Second Order Upwind

Second Order Upwind

Second Order Implicit

Table 3.1.1-2: Horizontal Cylinder Model Water Density

Density (kg/m3)

999.9

994.1

974.9

958.4

Temperature (K)

273

308

348

373

22

Figure 3.1.1-2 shows the liquid temperature field after 20 seconds of heating. As

the temperature increases, the fluid begins to rise due to buoyancy forces.

Figure 3.1.1-2: Temperature (K)

Figure 3.1.1-3 indicates that even the fluid not in direct contact with the heated

cylinder experiences a density change. The density gradient which is caused by energy

transfer via conduction to the bulk fluid is illustrated by the color transition surrounding

the cylinder from least dense (blue) to most dense (red).

Figure 3.1.1-3: Density (kg/m3)

23

As the warm fluid rises, it loses energy to the surrounding bulk fluid which

causes the buoyancy driving head to diminish and the warm fluid climbs more slowly

until it eventually stops. When it reaches its maximum elevation, it is pushed to the left

or right by the fluid travelling upwards below it and fluid recently pushed aside begins to

sink. This motion creates a small convection cell to the left and to the right of the rising

plume about 3 cm above the heated cylinder. This process continues indefinitely as long

as there is a temperature gradient between the cylinder and the bulk fluid. If the bulk

fluid temperature increases, the buoyancy driving head will be smaller and the

convection cells will develop closer to the heated cylinder.

Figure 3.1.1-4 is a velocity vector plot that displays how the liquid moves within

the control volume. The cycle of energy absorption and replacement around the cylinder

and the two convection cells above the cylinder are visible in this figure.

Figure 3.1.1-4: Velocity Vectors (m/s)

To verify that the model produced realistic results, the solution was compared to

experimental data.

Figure 3.1.1-5 shows interference fringes surrounding a heated

horizontal cylinder in natural convection. Each interference fringe can be interpreted as

a band constant temperature.

24

(a)

(b)

Figure 3.1.1-5: Interference Fringes Around a Heated Horizontal Cylinder (K)

(a) From Eckert [13] (b) Isotherms From Fluent

The model of a horizontal cylinder submerged in an infinite pool was in

qualitative agreement to experimental data. Figure 3.1.1-5 shows that the experimental

data and the model solution have isotherms that extend away from the cylinder and grow

in distance away from one another as they get farther from the heated surface.

Quantitative experimental data from Ingham [14] was compared to the Fluent

results to provide model validation. Figure 3.1.1-6, Figure 3.1.1-7 and Figure 3.1.1-8

show a comparison of dimensionless temperature versus dimensionless distance for four

dimensionless times at an angle of 30°, 90° and 180°, respectively, from the positive

x-axis. Dimensionless temperature is T = (T’ – T0) / (Twall – T0) where T’ is the actual

fluid temperature, T0 is the bulk fluid temperature and Twall is the wall temperature.

Dimensionless time is t = t’ * (βgΔT/a)1/2 where t’ is real time, ΔT is (Twall – T0), β is the

coefficient of thermal expansion and a is the diameter of the cylinder.

The heated horizontal cylinder model developed in Fluent showed good

agreement compared to experimental data at the three different radial locations. This

comparison provided confidence that the information obtained from the Fluent model

was accurate.

25

(a)

(b)

Figure 3.1.1-6: Temperature at θ = 30° Vs. Radial Distance

(a) From Ingham [14] and (b) From Fluent

(a)

(b)

Figure 3.1.1-7: Temperature at θ = 90° Vs. Radial Distance

(a) From Ingham [14] and (b) From Fluent

26

(a)

(b)

Figure 3.1.1-8: Temperature at θ = 180° Vs. Radial Distance

(a) From Ingham [14] and (b) From Fluent

To ensure that the mesh had no significant effect on the results, a mesh validation

was performed.

The mesh validation compared the results shown in this section

(“Analysis Value” in Table 3.1.1-3) to a second case with an increased number of finite

volumes (“Mesh Validation” in Table 3.1.1-3). The results from the mesh validation

shown in Table 3.1.1-3 prove that the results are mesh independent.

Table 3.1.1-3: Mesh Validation for Horizontal Cylinder Model

Number of Nodes

Number of Elements

Max Velocity (m/s)

Max Total Temperature (°F)

Min Density (kg/m3)

Analysis Value

19716

38688

0.01627

309.9239

993.1765

27

Mesh Validation

23636

46400

0.01621

309.9531

993.1625

Difference

19.88 %

19.93 %

-0.37 %

0.01 %

0.00 %

3.1.2

VERTICAL PLATE

A vertical plate with an elevated constant surface temperature submerged in an

infinite pool of liquid was analyzed in this section. Energy passed from the slightly

warmer plate to the fluid causing its temperature to increase and the fluid to rise. Figure

3.1.2-1 shows a schematic representation of the geometry and important boundary

conditions used to model the vertical plate. Although the top and bottom walls of the

rectangle represent inlet and outlet pressure boundaries, the fluid is stagnant until heated

by the plate. The left and right walls of the rectangle are slip walls to more accurately

model an infinite pool. See Table 3.1.2-1 for a more detailed list of input parameters

used in this section.

Figure 3.1.2-1: Vertical Plate Schematic

Figure 3.1.2-2 presents the liquid temperature field after 20 seconds. When

energy is exchanged between the plate and the fluid, a thermal boundary layer is created.

Thermodynamic equilibrium demands that the plate, and the fluid in direct contact with

it be at the same temperature. The region in which the fluid temperature changes from

the plate surface temperature to that of the bulk fluid temperature is known as the

thermal boundary layer. The teal color in Figure 3.1.2-2 shows the growth of the

thermal boundary layer. The thermal boundary layer is relatively small at the bottom of

the plate because there has been little heat addition but it grows (teal color expands away

from the plate) as the fluid reaches the top of the plate.

28

Table 3.1.2-1: Vertical Plate Model Input

Input

Geometry

Plate Height

Plate Width

Pool Height

Pool Width

2D Space

Solver

Time

Time Step Size

Type

Velocity Formulation

Gravity

Models

Energy

Viscous

Density

Initial Conditions

Plate Surface Temperature

Initial Fluid Temperature

Material Properties (Water)

Specific Heat

Thermal Conductivity

Viscosity

Density

Solution Methods

Scheme

Gradient

Pressure

Momentum

Energy

Transient Formulation

Value

0.18 m

0.01 m

0.20 m

0.13 m

Planar

Transient

0.05 s

Pressure Based

Relative

-9.8 m/s2 (Y-direction)

Active

Laminar

Boussineq

310 K

300 K

4182 J/kg-K

0.6 W/m-K

0.001003 kg/m-s

See Table 3.1.2-2

PISO

Least Square Cell Based

PRESTO!

Second Order Upwind

Second Order Upwind

Second Order Implicit

Table 3.1.2-2: Vertical Plate Model Water Density

Density (kg/m3)

999.9

994.1

974.9

958.4

Temperature (K)

273

308

348

373

29

Figure 3.1.2-2: Temperature (K)

Figure 3.1.2-3 shows the fluid velocity in vector form.

The growth of the

momentum boundary layer is more visible in this figure (the teal colored arrows expand

away from the plate). The figure shows that the velocity is primarily vertical with a

magnitude that increases with elevation. The increase in fluid velocity is caused by

longer contact time with the heated surface which causes a greater temperature gradient

and therefore a larger buoyancy force.

Figure 3.1.2-3: Velocity Vectors (m/s)

30

Comparing Figure 3.1.2-3 (vertical plate velocity vectors) with Figure 3.1.1-4

(horizontal cylinder velocity vectors) produces interesting results. Because of the larger

heated region, it was expected that the vertical plate would produce a greater maximum

fluid velocity compared to the horizontal cylinder. The vertical plate has a maximum

fluid velocity of 0.0149 m/s while the horizontal cylinder has a maximum fluid velocity

of 0.0177 m/s. Although the difference is small, it is notable. The horizontal cylinder

generates a larger maximum velocity because the buoyancy driving force is not impeded

by the drag force created by the heated surface. Although the vertical plate continues to

heat the fluid as it travels upward, the velocity is limited by friction which causes the

plate scenario to have a smaller maximum velocity.

To ensure that the model was giving realistic results, the solution was compared

to experimental data. Figure 3.1.2-4 shows interference fringes surrounding a heated

vertical plate in natural convection. Each interference fringe can be interpreted as a band

constant temperature.

(a)

(b)

Figure 3.1.2-4: Interference Fringes Around a Heated Vertical Plate (K)

(a) From Eckert [13] and (b) From Fluent

31

The model of a vertical plate submerged in an infinite pool was in qualitative

agreement to experimental data. Figure 3.1.2-4 shows that the experimental data and

model solution have isotherms that extend away from the plate and grow in distance

away from one another as they get farther from the heated surface.

Experimental data from Ostrach [15] was compared to the Fluent results to assess

the quantitative accuracy of the model.

Figure 3.1.2-5 and Figure 3.1.2-6 show a

comparison of dimensionless temperature versus dimensionless distance for five

different Prandtl numbers. Figure 3.1.2-5a shows theoretical values and Figure 3.1.2-5b

compares some of the theoretical values to experimental data.

Dimensionless

temperature is H(η) = (T – T∞) / (T0 – T∞) where T is the actual fluid temperature, T∞ is

the bulk fluid temperature and T0 is the wall temperature. Dimensionless distance is

η = (Y / X) * (Grx / 4)1/4 where Grx is the Grashof number, Y is the vertical height and X

is the distance from the plate.

The information contained in Figure 3.1.2-6 was

calculated by Fluent.

(a)

(b)

Figure 3.1.2-5: Dimensionless Temperature as a Function of Prandtl Number

(a) Theoretical Values and (b) Experimental Values [15]

32

Figure 3.1.2-6: Dimensionless Temperature as a Function of Prandtl Number

The heated vertical plate model developed in Fluent produced similar

temperature results to the experimental data for five different Prandtl numbers. This

comparison provided confidence that the information obtained from the Fluent model

was accurate.

To ensure that the mesh had no significant effect on the results, a mesh validation

was performed.

The mesh validation compared the results shown in this section

(“Analysis Value” in Table 3.1.2-3) to a second case with an increased number of finite

volumes (“Mesh Validation” in Table 3.1.2-3). The results from the mesh validation

shown in Table 3.1.2-3 prove that the results are mesh independent.

Table 3.1.2-3: Mesh Validation for Vertical Plate Model

Number of Nodes

Number of Elements

Max Velocity (m/s)

Max Total Temperature (°F)

Min Density (kg/m3)

Analysis Value

12310

23572

0.01376

309.8089

993.2319

33

Mesh Validation

18081

35168

0.01380

309.7991

993.2365

Difference

46.88 %

49.19 %

0.29 %

0.00 %

0.00 %

3.2

LAMINAR FLOW

A simple axisymmetric laminar flow model was developed in this section.

Figure 3.2-1 shows a schematic representation of the geometry and important boundary

conditions used to model laminar flow within a pipe. The bottom line of the rectangle is

an axis of rotation which is used to simplify the geometry and represents the pipe

centerline. The top line of the rectangle is a no slip wall and after the rotation, becomes

the pipe wall. The left and right lines of the rectangle are the inlet and outlet areas

respectively, which when revolved, are circular. See Table 3.1.1-1 for a more detailed

list of input parameters used in this section.

Figure 3.2-1: Laminar Flow Schematic

Based upon the selected initial conditions, the Reynolds number is 352, which is

well within the laminar regime. A noteworthy characteristics of laminar flow is the

parabolic shape of its velocity profile. Figure 3.2-2 displays the velocity magnitude

versus position (distance from the pipe centerline) at different lengths from the pipe

entrance.

Figure 3.2-2: Velocity Profile

34

For example, “line-10cm” is the velocity profile 10 cm from the pipe entrance. Fluid

velocity within the pipe slowly decreases as distance from the pipe centerline increases.

Also, as the flow develops, the entrance effects dissipate, the velocity profile becomes

more parabolic until it reaches a steady state at about 45 cm from the entrance.

Table 3.2-1: Laminar Flow Model Input

Input

Value

Geometry

Pipe Diameter

Pipe Length

2D Space

Solver

Time

Type

Velocity Formulation

Gravity

Models

Energy

Viscous

Material Properties (Water)

Specific Heat

Thermal Conductivity

Viscosity

Density

Initial Conditions

Pipe Wall Surface Temperature

Fluid Inlet Temperature

Fluid Inlet Velocity

Solution Methods

Scheme

Gradient

Pressure

Momentum

Energy

0.03 m

0.50 m

Axisymmetric

Steady

Pressure Based

Relative

-9.8 m/s2 (X-direction)

Active

Laminar

4182 J/kg-K

0.6 W/m-K

0.001003 kg/m-s

See Table 3.2-2

305 K

300 K

0.05 m/s

Coupled

Least Square Cell Based

Second Order

Second Order Upwind

Second Order Upwind

Table 3.2-2: Laminar Flow Model Water Density

Density (kg/m3)

999.9

994.1

Temperature (K)

273

308

35

Another characteristic of laminar flow is the lack of mixing that occurs within the

fluid as it travels through the pipe. The radial velocity within the pipe is basically zero

and each fluid molecule or atom remains about the same distance from the centerline as

it travels through the pipe. Figure 3.2-3 shows the radial flow velocity. As expected, the

radial velocity for most of the pipe is near zero and is less than 10 -3 times the average

axial velocity. Radial velocity is at a maximum near the entrance of the pipe due to pipe

boundary conditions and entrance effects but these have a negligible impact on system as

a whole.

Figure 3.2-3: Radial Velocity (m/s)

Figure 3.2-4 shows the temperature profile for the laminar flow analyzed.

Because there is little to no radial velocity, diffusion and conduction are the primary

forms of heat transfer which causes the growth of the thermal boundary layer to be very

slow. The growth of the thermal boundary layer is shown in Figure 3.2-4 by the

expansion of the teal colored region.

Figure 3.2-4: Temperature (K)

As in natural convection, laminar flow generates a momentum boundary layer

but its development is not visible pictorially. The momentum boundary layer is created

by drag, or shear, forces created by the wall. Figure 3.2-5 shows the wall shear stress as

a function of distance from the pipe entrance. The wall stress is much larger in the first

10 cm due to entrance effects. Once the entrance effects dissipate, the wall shear stress

slowly decreases as the flow reaches a steady state.

36

Figure 3.2-5: Wall Shear Stress

To ensure that the mesh had no significant effect on the results, a mesh validation

was performed.

The mesh validation compared the results shown in this section

(“Analysis Value” in Table 3.2-3) to a second case with an increased number of finite

volumes (“Mesh Validation” in Table 3.2-3). The results from the mesh validation

shown in Table 3.2-3 prove that the results are mesh independent.

Table 3.2-3: Mesh Validation for Laminar Flow Model

Number of Nodes

Number of Elements

Max Velocity (m/s)

Min Radial Velocity (m/s)

Max Dynamic Pressure (Pa)

Max Temperature (K)

Analysis

Value

26320

25353

0.079561

-0.003293

3.15925

304.6503

37

Mesh

Validation

31000

29970

0.079507

-0.003528

3.155022

304.6855

Difference

17.78 %

18.21 %

-0.07 %

7.12 %

-0.13 %

0.01 %

3.3

TURBULENT FLOW

3.3.1

TURBULENT FLOW WITHOUT HEAT TRANSFER

A simple axisymmetric turbulent flow model was developed in this section.

Figure 3.3.1-1 shows a schematic representation of the geometry and important

boundary conditions used to model turbulent flow within a pipe without heat transfer.

The bottom line of the rectangle is an axis of rotation which is used to simplify the

geometry and represents the pipe centerline. The top line of the rectangle is a no slip