1. Introduction

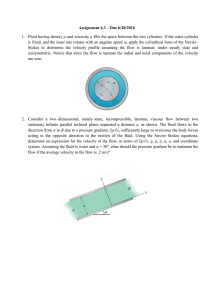

advertisement

1. Introduction Nuclear reactors have been used for commercial electricity production since 1958. They provide roughly 20% of the electricity in the United States and about 13% world-wide. There are two distinct types of nuclear reactors, Pressurizer Water Reactors (PWR) and Boiling Water Reactors (BWR). The more common of the two types is the PWR which heats water that flows past nuclear fuel rods to produce steam. The benefit of having a pressurized system is that the water can be heated to very high temperatures without bulk boiling occurring. This helps to increase efficiency and prevent fuel failure. Energy is removed from the nuclear fuel rods through an efficient heat transfer process known as nucleate boiling. During nucleate boiling, the heated surface temperature is hotter than the saturation temperature of the fluid causing localized boiling in the subcooled bulk fluid. The amount of subcooled boiling and when it occurs in a nuclear reactor is generally unknown. The power in a reactor core is held constant by keeping the reactivity balance at zero. Positive reactivity leads to a power increase while negative reactivity leads to a power decrease. Some of the components that make up the reactivity balance equation are water temperature, water density, fuel temperature and voiding in the core. The accuracy at which each parameter can be measured impacts the ability to calculate core power during a transient. Being able to accurately measure the core power during a transient removes uncertainty in the safety analyses performed. Currently there are methods to accurately calculate the reactivity components listed above except for voiding in the core. If a more accurate method was developed to calculate voiding under varying conditions, there would be less uncertainty in the power calculation and more safety analysis margin could be gained thus allowing plants to increase power and produce more electricity. The purpose of this thesis is to develop a better understanding of subcooled boiling and generate a more accurate method to measure voiding at different axial locations in the core. 1 2. Background Electricity is one of the greatest discoveries of the 19th century and its use has greatly increased the world’s standard of living. It is generated by converting thermal energy, from a fuel source, into electrical energy. This is done generally through the Rankine Cycle where fuel is burned to heat water and form steam. The steam is then used to turn a turbine which spins an electric generator. Electricity production involves numerous engineering processes but primarily based around heat transfer and fluid flow. There are many different fuel sources available to electrical power plants, the one in focus here will be nuclear fuel. Nuclear power plants harness the energy released during the fission process to heat the surrounding water called the Reactor Coolant System (RCS) which is then used to produce steam. The heat transfer mechanisms at work within a nuclear reactor core are extremely complex. All three major forms of heat transfer are at work, conduction, convection and radiation. The fluid flow through the reactor is also complex due to the extreme energy transfer and phase change. The RCS is prevented from bulk boiling due to the highly pressurized system; however, a small amount of localized boiling does occur. This is also known as subcooled boiling. This thesis will focus on the convective heat transfer that occurs in the core, and more specifically, subcooled boiling. Subcooled boiling occurs when a fluid comes into contact with a surface that is hotter than its saturation temperature. Small bubbles form on the heated surface in locations called nucleation sites. Eventually the bubbles detach and enter the bulk fluid. At this point there is saturated steam in a subcooled liquid. The bubbles have three options, they can coalesce with other bubbles, they can grow in size or they can shrink in size. To determine how the bubbles will react within the subcooled fluid, Population Balance Equations (PBE) will be used. Population Balance Equations allow Fluent to calculate probabilities instead of keeping track of each individual steam bubble which would require large amounts of computing power and significant amount of time. 2 The idea of using PBEs for subcooled boiling is a relatively new idea and has shown potential recently to provide great insights into this regime of boiling heat transfer. The amount of voiding that occurs a nuclear reactor core has a direct impact on fission power due to reactivity feedbacks caused by voiding. If a better understanding of the level of voiding due to subcooled boiling was developed, the accuracy at which fission power is calculated during a transient could be improved and the amount of uncertainty reduced. Fluid properties such as temperature, pressure, mass flux and heat flux will be varied and their impact on the amount of subcooled boiling at different axial locations in a nuclear reactor will be determined. 3 3. Methodology A portion of a fuel bundle will be modeled using ANSYS Fluent. The traditional models available (energy equation, turbulence, two-phase, etc.) in Fluent will be implemented along with a Population Balance Equation (PBE) model. Population balance equations have been introduced in several branches of modern science, mainly in branches with particulate entities. Population balance equations define how populations of separate entities develop in specific properties over time. They are nothing more than a balance on the number of particles in a particular state. The PBE model will be used to determine the number of steam bubbles in the core, reveal how they develop over time and decide if the bubbles shrink and collapse or coalesce and grow in size. Ten models will be created, each more advanced than the previous. The final model will be three-dimensional, use multiple heated rods, allow for turbulent, two-phase flow and have the PBE model implemented. For more information about the model progression and development, see the Model Development section. After each model is developed, it will be compared to known experimental data whenever possible in order to validate the information generated by ANSYS Fluent. After the models have been validated and the final model developed, the initial conditions, temperature, pressure, mass flux and heat flux, will be altered so that the voiding at different axial locations can be determined for the various initial conditions. Once the data has been collected, it will be analyzed to produce either a set of equations or a set of tables that will allow the user to quickly determine how much voiding occurs based on the known conditions. 4 4. Equations In fluid dynamics there are three conservation equations that must be solved to fully solve the state of a flow. Those equations are the conservation of continuity, momentum and mass. The conservation equations shown below assume constant density (ρ) and viscosity (μ). Cartesian Form of the Conservation Equations: Conservation of Continuity Equation: 𝛿𝑢𝑗 𝛿𝑢 𝛿𝑣 𝛿𝑤 = + + =0 𝛿𝑥𝑗 𝛿𝑥 𝛿𝑦 𝛿𝑧 Conservation of Momentum Equation: 𝜌𝑢 𝛿𝑢 𝛿𝑢 𝑑𝑃 𝛿 𝛿𝑢 + 𝜌𝑣 =− + (𝜇 ) 𝛿𝑦 𝛿𝑦 𝑑𝑥 𝛿𝑦 𝛿𝑦 Conservation of Mass Equation: 𝜌𝑢 𝛿𝑚𝑗 𝛿𝑚𝑗 𝛿𝑚𝑗 𝛿 + 𝜌𝑣 − (𝛾𝑗 )=0 𝛿𝑥 𝛿𝑦 𝛿𝑦 𝛿𝑦 Radial Form of the Conservation Equations: Conservation of Continuity Equation: 𝛿𝑢 1 𝛿 (𝑟𝜌𝑣𝑟 ) = 0 + 𝛿𝑥 𝑟 𝛿𝑟 Conservation of Momentum Equation: 𝜌𝑢 𝛿𝑢 𝛿𝑢 𝑑𝑃 1 𝛿 𝛿𝑢 + 𝜌𝑣𝑟 =− + (𝑟𝜇 ) 𝛿𝑥 𝛿𝑟 𝑑𝑥 𝑟 𝛿𝑟 𝛿𝑟 Conservation of Mass Equation: 𝜌𝑢 𝛿𝑚𝑗 𝛿𝑚𝑗 1 𝛿 𝛿𝑚𝑗 + 𝜌𝑣𝑟 − (𝑟𝛾𝑗 )=0 𝛿𝑥 𝛿𝑟 𝑟 𝛿𝑟 𝛿𝑟 5 For heat transfer, the Conservation of Energy Equation must be solved. In Cartesian form assuming steady state, it takes on the following form: 𝜌𝑢 𝛿𝑚𝑗 𝛿𝑖 𝛿𝑖 𝛿 𝛿𝑇 𝛿 𝛿𝑢 2 𝑑𝑃 + 𝜌𝑣 − (𝑘 ) − (∑ 𝛾𝑗 𝑖𝑗 ) − 𝜇 ( ) − 𝜇 =0 𝛿𝑥 𝛿𝑦 𝛿𝑦 𝛿𝑦 𝛿𝑦 𝛿𝑦 𝛿𝑦 𝑑𝑥 Assuming that there is no mass diffusion through the heated surface, the thermal conductivity is constant and viscous energy dissipation can be neglected, the Conservation of Energy Equation reduces to: 𝛿𝑇 𝛿𝑇 𝛿 2𝑇 𝑢 +𝑣 −𝛼 2 =0 𝛿𝑥 𝛿𝑦 𝛿𝑦 6 5. Natural Convection 5.1 Introduction Convection can be defined as the transport of mass and energy by potential gradients and by bulk fluid motion. If the fluid motion is induced by some external force, it is generally referred to as forced convection (Convective mass and heat transfer). Natural convection is a mechanism, or type of heat transport, in which the fluid motion is not generated by any external source (like a pump, fan, suction device, etc.) but driven by buoyancy-induced motion resulting from body forces acting on density gradients, which, in turn, arise from mass concentrations and or temperature gradients in the fluid. (Convective mass and heat transfer). In natural convection, fluid surrounding a heated surface absorbs energy, becomes less dense, and rises. Then, the surrounding, cooler fluid moves in to take its place. The cooler fluid is then heated and the process continues, forming a convection current that continuously removes energy from the heated surface. Figure 5.1-1: Natural Convection Currents in a Pot (http://www.google.com/imgres?um=1&hl=en&sa=N&rlz=1C1LENN_enUS447US 447&biw=1366&bih=667&tbm=isch&tbnid=PHpWzJiZ2SEqDM:&imgrefurl=http://w ww.physics.arizona.edu/~thews/reu/the_science_behind_it_all.html&docid=pj2GA6aKq 7 IkvPM&imgurl=http://www.physics.arizona.edu/~thews/reu/Convection.bmp&w=450& h=300&ei=XTwHUOHpEOew2wW4q8UJ&zoom=1&iact=hc&vpx=381&vpy=160&du r=2312&hovh=183&hovw=275&tx=211&ty=120&sig=117866709142432258960&pag e=1&tbnh=144&tbnw=189&start=0&ndsp=18&ved=1t:429,r:1,s:0,i:79) In nature, natural convection cells occur everywhere from oceanic currents to air rising above sunlight-warmed land. Most weather patterns are created by natural convection. Natural convection also takes place in many engineering applications such as home heating radiators that use fins to distribute heat and computer chips. 5.2 Theory Like forced convection, natural convection also builds boundary layers on the surfaces of solid bodies. The equations that govern forced convection are essentially the same as those for external laminar flow free convection. For natural convection problems, it is easiest to assume that the fluid is Newtonian, meaning a fluid whose stress vs. strain rate curve is linear, and the flow field is two dimensional and steady. The continuity equation for two-dimensional natural convection is as follows: 𝛿(𝜌𝑢) 𝛿(𝜌𝑣) + =0 𝛿𝑥 𝛿𝑦 The momentum equation is similar to that shown in Section 4 except it contains the gravitational body force term (-ρg): 𝜌𝑢 𝛿𝑢 𝛿𝑢 𝑑𝑃 𝛿 𝛿𝑢 + 𝜌𝑣 =− − 𝜌𝑔 + (𝜇 ) 𝛿𝑦 𝛿𝑦 𝑑𝑥 𝛿𝑦 𝛿𝑦 The pressure gradient term is due to the hydrostatic pressure field outside the boundary layer and can be written as: 𝑑𝑃 = −𝜌∞ 𝑔 𝑑𝑥 8 Therefore the momentum equation becomes: 𝜌𝑢 𝛿𝑢 𝛿𝑢 𝛿 𝛿𝑢 + 𝜌𝑣 = 𝑔(𝜌∞ − 𝜌) + (𝜇 ) 𝛿𝑦 𝛿𝑦 𝛿𝑦 𝛿𝑦 The energy equation is: 𝜌𝑐𝑢 𝛿𝑇 𝛿𝑇 𝛿 𝛿𝑇 + 𝜌𝑐𝑣 = (𝑘 ) 𝛿𝑥 𝛿𝑦 𝛿𝑦 𝛿𝑦 A more practical way to measure the amount of natural convection occurring is to use the Grashof number. The Grashof number, Gr, is a dimensionless number that approximates the ratio of the buoyancy to viscous forces acting on a fluid. The Grashof number can be calculated by: 𝐺𝑟 = 𝑔𝛽(𝑇𝑠 − 𝑇∞ )𝐿3 𝜐2 where β is the thermal expansion coefficient: 1 𝛿𝑃 𝛽=− ( ) 𝜌 𝛿𝑇 𝑝 The importance of buoyancy forces in a mixed convection flow (i.e., forced and natural convection are occurring simultaneously) can be measured by the ratio of the Grashof and Reynolds numbers: 𝐺𝑟 𝑔𝛽Δ𝑇𝐿 = 2 𝑅𝑒 𝜐2 When this number approaches or exceeds unity, there are strong buoyancy contributions to the flow. Conversely, if the ratio is very small, buoyancy forces may be ignored. In pure natural convection, the strength of the buoyancy-induced flow is measured by the Rayleigh number: 𝑅𝑎 = 𝐺𝑟𝑃𝑟 9 The Prandtl number, Pr, is a dimensionless number that approximates the ratio of momentum diffusivity (kinematic viscosity) to thermal diffusivity. 𝑃𝑟 = 𝑣 𝐶𝑝 𝜇 = 𝛼 𝑘 the thermal diffusivity (α) is: 𝛼= 𝑘 𝜌𝑐𝑝 Rayleigh numbers less than 108 indicate a buoyancy-induced laminar flow, with transition to turbulence occurring over the range of 108 < Ra < 1010. (ANSYS Help Theory Guide) 10 5.3 Examples of Natural Convection Two of the simplest forms of natural convection are a fluid surrounding a horizontal cylinder and fluid surrounding a vertical plate. 5.3.1 Modeling of a Horizontal Cylinder In the first example, a uniformly heated cylinder is submerged in an infinite pool. The cylinder is slightly warmer than the surrounding fluid and therefore energy passes from the cylinder to the surrounding fluid. As the fluid absorbs the energy, its temperature begins to increase. The fluid temperature gradient as calculated by Fluent is shown in Figure 5.3.1-1. Figure 5.3.1-1: Horizontal Cylinder Temperature Plot When the temperature increases, the fluid expands and the density decreases. The hottest fluid is that in direct contact with the cylinder. As the density decreases, buoyancy forces take affect and the warmer, less dense fluid begins to rise. The density 11 changes can be seen in Figure 5.3.1-2. Notice that even some distance away from the cylinder there is a density change. This is caused by small amounts of conduction within the fluid which causes small density changes in the fluid not even in contact with the heated cylinder. Figure 5.3.1-2: Horizontal Cylinder Density Plot As the fluid rises, it separates from the cylinder and new, colder fluid takes its place. When the warm fluid rises, it loses energy to the surrounding, cooler bulk fluid. As this heat transfer process occurs the buoyancy driving head diminishes causing the fluid to climb more slowly until it eventually stops. At this point it is pushed to the side by the fluid travelling upwards below it and begins to sink since it is denser than the fluid that surrounds it. This motion begins to forms a large convection cell which eventually returns the fluid to the bottom where it is reheated by the cylinder. This can be seen in the velocity vector plot shown in Figure 5.3.1-3 12 Figure 5.3.1-3: Horizontal Cylinder Velocity Vector Plot Figure 5.3.1-3 shows the magnitude and direction of the fluid in the pool with a submerged horizontal cylinder. It can be seen that the as the cylinder heats the surrounding fluid, it travels around the cylinder, eventually separating and rising. An interesting point is when the fluid loses heat to its surrounding it begins to fall. Some of that falling liquid is heated by the warmer fluid rising and it begins to rise without being heated by the cylinder. This creates a small convection cell about two diameters above the heated cylinder. This process continues ad infinitum as long as there is a temperature gradient (i.e., buoyancy driving head). To ensure that the ANSYS Fluent generated figures are correct, the results were compared to experimental results. The following figure shows isotherms surrounding a horizontal tube in natural convection flow as revealed by an interference photograph. 13 Figure 5.3.1-4: Horizontal Cylinder Experimental Isotherm Plot Show Figure 93, page 167 from Introduction to the Transfer of Heat and Mass The ANSYS Fluent calculated isotherms for a horizontal cylinder is shown in Figure 5.3.1-5: Figure 5.3.1-5: Horizontal Cylinder Isotherm Plot 14 The modeling of a horizontal cylinder submerged in an infinite pool using ANSYS Fluent 14.0 shows good resemblance to experimental data. Figure 5-5 and 5-6 show comparable results. Both have isotherms that extend away from the plate and grow in distance away from one another as they get farther from the plate. Because the isotherms calculated by ANSYS Fluent are similar to those found experimentally, it can confidently be stated that the results for a uniformly heated horizontal cylinder submerged in a pool are reasonable. 5.3.2 Modeling of a Vertical Plate The second example is similar to the first, except it involves a uniformly heated vertical flat plate submerged in an infinite pool. Like the cylinder, the plate is also slightly warmer than the surrounding fluid and therefore energy passes from the plate to the surrounding fluid. The main difference between the flat plate and the cylinder example is that in the flat plate example, the fluid has more time in contact with the plate as it rises and is therefore able to absorb more energy. As the fluid absorbs the energy, its temperature begins to increase. Because the fluid is heated as it rises along the plate, the fluid temperature is greater in the flat plate example than in the horizontal cylinder example. Figure 5.3.2-1: Vertical Plate Temperature Plot 15 Since heat is exchanged between the plate and the fluid, a thermal boundary layer is created. Thermodynamic equilibrium demands that the fluid in contact with plate is equal to the temperature of the plate. The region in which the temperature changes from the plate surface temperature to that of the bulk fluid is known as the thermal boundary layer. Notice how the thermal boundary layer is small at the bottom of the plate and much larger at the top. The thermal boundary layer expands as the momentum boundary layer expands which helps pull warm fluid away from the hot plate. For more information on thermal and momentum boundary layers, see Convective Heat and Mass Transfer (Reference XX). Figure 5.3.2-2: Vertical Plate Velocity Vector Plot 16 Figure 5.3.2-2 shows how the fluid velocity is highly vertical and increases as it travels up the plate. This is caused by the fluid having lengthy contact time with the heated surface creating a greater temperature gradient and therefore a large buoyancy force. Comparing the vertical flat plate to the horizontal cylinder, it is expected that the vertical plate would have a greater maximum fluid velocity because the fluid is in contact with the heated surface longer. The maximum fluid velocity for the vertical plate is 0.0149 m/s while the maximum fluid velocity for the horizontal cylinder is 0.0177 m/s. This is quite counterintuitive. The reason why the horizontal cylinder actually has a larger maximum velocity is because the buoyancy driving head is allowed to work freely without any drag from the plate. Although the plate is continuing to heat the fluid as it travels up the plate, the velocity is limited due to friction. For this reason, the plate actually has a smaller maximum velocity. To ensure that the ANSYS Fluent generated figures are correct, the results were compared to experimental results. The following figure shows isotherms surrounding a vertical plate in natural convection flow as revealed by an interference photograph. 17 Figure 5.3.2-3: Vertical Plate Experimental Isotherm Plot Show Figure 94, page 168 from Introduction to the Transfer of Heat and Mass The ANSYS Fluent calculated isotherms for a heated vertical plate is shown in the Figure 5.3.2-4. Figure 5.3.2-4: Vertical Plate Isotherm Plot Figure 5.3.2-3 and Figure 5.3.2-4 show comparable results. Both have isotherms that extend away from the plate and grow in distance away from one another as they get farther from the heated surface. Not only do the isotherms match expectations, the momentum boundary layer calculated by ANSYS Fluent also matches experimental expectations. 18 Figure 5.3.2-5: Experimental Momentum Boundary Layer Show Figure 17-2, page 371 from Convective Heat and Mass Transfer Figure 5.3.2-6: Momentum Boundary Layer Plot The trends shown in Figure 5.3.2-5 and 5.3.2-6 are comparable. Having similar isotherms and momentum boundary layers, it can confidently be stated that the results determined by ANSYS Fluent for a uniformly heated vertical plate submerged in a pool are reasonable. 19 6. Laminar Flow with Heat Transfer Single-phase fluid flow can be characterized into two categories, laminar or turbulent flow. Laminar flow implies that the fluid moves in sheets, or “laminae,” that slip relative to each other (Introduction to Thermal and Fluids Engineering). Laminar flow occurs at very low velocities where there are only small disturbances and little to no local velocity variations. At low velocities, the fluid tends to flow without lateral mixing, and adjacent layers slide past one another easily. There are no cross currents perpendicular to the direction of flow, nor eddies or swirling of fluid. In laminar flow, the motion of the fluid particles is very orderly. In fluid dynamics, laminar flow is a flow regime characterized by high momentum diffusion and low momentum convection. (Wikipedia) Turbulent flow, the other category of single-phase flow, is discussed in Section 7. The Reynolds number is used to characterize the flow regime. The Reynolds number, Re, is a dimensionless number that gives a measure of the ratio of inertial forces (fluid resists change in motion) to viscous forces. This helps to quantify the relative importance of these two types of forces for given flow conditions. (Wikipedia) The Reynolds number can be calculated using the following equation: Re = ρVA μ For internal flow, such as within a pipe, laminar flow is characterized by flow with a Reynolds number less than 2300 whereas turbulent flow is characterized by a flow with a Reynolds number greater than 4000. For flow with a Reynolds number between 2300 and 4000, both laminar and turbulent flows are possible. This is called transition flow. The velocity of laminar flow in a pipe is can be calculated by: 𝑢= 𝑟𝑠2 𝑑𝑃 𝑟2 (− ) (1 − 2 ) 4𝜇 𝑑𝑥 𝑟𝑠 However, it is friendlier to express the velocity in terms of the mean velocity, V. 20 𝑟2 𝑢 = 2𝑉 (1 − 2 ) 𝑟𝑠 The energy equation for flow through a circular pipe assuming symmetric heat transfer, fully developed flow and constant fluid properties is: 𝛿𝑇 1𝛿 𝛿𝑇 𝛿 2𝑇 𝑢 = 𝛼[ (𝑟 ) + 2 ] 𝛿𝑥 𝑟 𝛿𝑟 𝛿𝑟 𝛿𝑥 Using ANSYS Fluent, a simple laminar flow problem through a cylindrical pipe with uniform surface termperature was developed. The Reynolds number for the problem was 352 which means the flow in the laminar regime. One of the most notable characteristics of laminar flow is the velocity profile parabolic shape which can be calculated using the equation for velocity above. Figure 6-1 shows the velocity magnitude versus distance from the pipe centerline for various distances from the pipe entrance. The distance from the pipe entrance is given in the legend. For example, “line-10cm” shows the velocity profile 10 cm from the pipe entrance. As the flow developes, i.e., the entrance effects dissipate, the velocity profile becomes more and more parabolic until it reaches a steady state 45 cm from the entrance. This is proven by the fact that the outlet, 50 cm from the entrance, and the velocity profile 45 cm from the entrance are basically the same. 21 Figure 6-1: Laminar Flow Velocity Profile Another characteristic of laminar flow is the lack of mixing that occurs within the fluid as it travels through the pipe. Laminar flow is considered to move in “sheets” and each fluid molecule or atom tends to stay about the same distance from the centerline as it travels through the pipe. This is shown by viewing the temperature profile below. Diffusion and conduction are the primary forms of heat transfer in laminar flow. Notice how the fluid thermal boundary layer grows slowly as it travels down the pipe towards the centerline. Figure 6-2: Laminar Flow Temperature Plot 22 Figure 6-3 shows the radial flow velocity. The greatest radial velocity occurs at the entrance and exit of the pipe. However, as expected, because laminar flow moves in “sheets,” the radial velocity for the middle of the pipe is near zero meaning there is little mixing. Figure 6-4: Laminar Flow Radial Velocity Plot Laminar flow also tends to create large momentum boundary layers which cause frictional force on the wall. The drag force on the wall is shown in Figure 6-5. Figure 6-5: Laminar Flow Wall Shear Stress 23 The wall stress is much larger in the first 5 cm due to entrance effects. Once the entrance effects dissipate, the wall shear stress slowly decreases as the flow becomes more and more parabolic. At the very end, around 49 cm, the wall shear stress begins to increase due to the pipe exit. 24 7. Turbulence In fluid dynamics, turbulence or turbulent flow is a flow regime characterized by chaotic and stochastic property changes. It exists everywhere in nature from the jet stream to the oceanic currents. Giving an exact definition of turbulence is rather difficult. Instead, it is easier to describe a turbulent flow. Turbulent flows are highly irregular or random which makes a deterministic approach to turbulence problems impossible. They have high diffusivity, meaning there is rapid mixing and increased rates of momentum and heat and mass transfer. They all have large Reynolds numbers and contain threedimensional vorticity fluctuations. The unsteady vortices appear on many scales and interact with each other generating high levels of mixing. Finally, turbulent flows are dissipative. Viscous shear stresses perform deformation work which increases the internal energy of the fluid at the expense of kinetic energy. Because turbulence cannot maintain itself, it depends on its environment to obtain energy. A common source of energy for turbulent velocity fluctuations is shear in the mean flow; other sources, such as buoyancy, exist too. If turbulence arrives in an environment where there is no shear or other maintenance mechanisms, the turbulence decays. The Reynolds number decreases and the flow tends to become laminar again (A First Course in Turbulence). In flows that are originally laminar, turbulence arises from instabilities at large Reynolds numbers. As stated previously, laminar flow starts to transition to turbulent at Reynolds numbers around 2100 (A First Course in Turbulence). Although laminar-turbulent transition is not governed by Reynolds number, the same transition occurs if the size of the object is gradually increased, or the viscosity of the fluid is decreased, or if the density of the fluid is increased (Wikidpedia). One of the most common examples of the transition of laminar flow to turbulent flow is smoke rising from a cigarette. 25 http://askphysics.com/wp-content/uploads/2012/01/cigarette.gif As the smoke leaves the cigarette it travels upward in a laminar fashion as shown by the single stream of smoke. At a certain distance, the Reynolds number becomes too large and the flow begins to transition into the turbulent regime. When this happens, the flow becomes more random and mixes with the air causing the smoke to dissipate. Because of its irregular nature, modeling turbulence can be difficult. IT requires the solution to the Navier-Stokes equations which for the x-direction is shown below. 𝛿𝑢 𝛿𝑢 𝛿𝑢 𝛿𝑢 𝑑𝑝 𝛿 2𝑢 𝛿 2𝑢 𝛿 2𝑢 𝜌( +𝑢 +𝑣 +𝑤 )= + 𝜇 ( 2 + 2 + 2 ) + 𝜌𝑔𝑥 𝛿𝑡 𝛿𝑥 𝛿𝑦 𝛿𝑧 𝑑𝑥 𝛿𝑥 𝛿𝑦 𝛿𝑧 Similar equations can be obtained for the y and z directions. The Reynolds-averaged Navier–Stokes equations (or RANS equations) are time- averaged equations of motion for fluid flow. The idea behind the equations is Reynolds decomposition, whereby an instantaneous quantity is decomposed into its time-averaged and fluctuating quantities, an idea first proposed by Osborne Reynolds. The RANS equations are primarily used to describe turbulent flows. These equations can be used 26 with approximations based on knowledge of the properties of flow turbulence to give approximate time-averaged solutions to the Navier–Stokes equations (Wikipedia). In Reynolds averaging, the solution variables in the instantaneous (exact) Navier-Stokes equations are decomposed into the mean (ensemble-averaged or time-averaged) and fluctuating components. For the velocity components: 𝑢𝑖 = 𝑢̅𝑖 + 𝑢𝑖′ where 𝑢̅𝑖 and 𝑢𝑖′ are the mean and fluctuating velocity components (i = 1, 2, 3). Likewise, for pressure and other scalar quantities: 𝜙 = 𝜙̅ + 𝜙 ′ where 𝜙 denotes a scalar such as pressure, energy, or species concentration. Substituting expressions of this form for the flow variables into the instantaneous continuity and momentum equations and taking a time (or ensemble) average (and dropping the overbar on the mean velocity, 𝑢̅) yields the ensemble-averaged momentum equations. They can be written in Cartesian tensor form as: 𝛿𝑝 𝛿 (𝜌𝑢𝑖 ) = 0 + 𝛿𝑡 𝛿𝑥𝑖 𝛿 𝛿 𝛿𝑃 𝛿 𝛿𝑢𝑖 𝛿𝑢𝑗 2 𝛿𝑢𝑙 𝛿 ′ ′ ̅̅̅̅̅̅ (𝜌𝑢𝑖 ) + (𝜌𝑢𝑖 𝑢𝑗 ) = − + [𝜇 ( + − 𝜁𝑖𝑗 )] + (−𝜌𝑢 𝑖 𝑢𝑗 ) 𝛿𝑡 𝛿𝑥𝑗 𝛿𝑥𝑖 𝛿𝑥𝑗 𝛿𝑥𝑗 𝛿𝑥𝑖 3 𝛿𝑥𝑙 𝛿𝑥𝑗 The two equations above are called the Reynolds-averaged Navier-Stokes (RANS) equations. They have the same general form as the instantaneous Navier-Stokes equations, with the velocities and other solution variables now representing ensembleaveraged (or time-averaged) values. Additional terms now appear that represent the ′ ′ ̅̅̅̅̅̅ effects of turbulence. These Reynolds stresses,−𝜌𝑢 𝑖 𝑢𝑗 , must be modeled in order to close the second equation. 27 One way that the Reynolds stress is modeled is using the k-ϵ turbulence model. The k-ϵ model was first introduced by Harlow and Nakayama in 1968. (F. H. Harlow and P. I. Nakayama, Transport of turbulence energy decay rate, Los Alamos Sci. Lab., LA-3854, 1968). The k-ϵ model has become the most widely used model for industrial applications because of its overall accuracy and small computational demand. The k in the k-ϵ model stands for the turbulent kinetic energy and the ϵ stands for its dissipation rate. Turbulent kinetic energy is the mean kinetic energy per unit mass associated with eddies in turbulent flow. Physically, the turbulence kinetic energy is characterized by measured root-mean-square (RMS) velocity fluctuations (Wikipedia). Epsilon (ϵ) is the rate of dissipation of the turbulence energy per unit mass. Two-equation turbulence models allow the determination of both, a turbulent length and time scale by solving two separate transport equations. The standard k- ϵ model in falls within this class of models and has become the workhorse of practical engineering flow calculations in the time since it was proposed by Launder and Spalding. Robustness, economy, and reasonable accuracy for a wide range of turbulent flows explain its popularity in industrial flow and heat transfer simulations. It is a semi-empirical model, and the derivation of the model equations relies on phenomenological considerations and empiricism. The standard k-ϵ model is a model based on model transport equations for the turbulence kinetic energy (k) and its dissipation rate (ϵ). The model transport equation for k is derived from the exact equation, while the model transport equation for ϵ was obtained using physical reasoning and bears little resemblance to its mathematically exact counterpart. In the derivation of the k-ϵ model, the assumption is that the flow is fully turbulent, and the effects of molecular viscosity are negligible. The standard k-ϵ model is therefore valid only for fully turbulent flows. As the strengths and weaknesses of the standard k-ϵ model have become known, modifications have been introduced to improve its performance. 28 Over the years improvements have been made to the Standard k-ϵ model. The improvements helped to create a new model known as the Realizable k-ϵ model. The Realizable k-ϵ model differs from the Standard k-ϵ model in two important ways. First, realizable model contains an alternative formulation for the turbulent viscosity. Second, a modified transport equation for the dissipation rate, ϵ, has been derived from an exact equation for the transport of the mean-square vorticity fluctuation. The term “realizable” means that the model satisfies certain mathematical constraints on the Reynolds stresses, consistent with the physics of turbulent flows. Calculating Turbulence Parameters When using the Realizable k-ϵ in ANSYS Fluent certain parameters need to be established to properly set the initial and boundary conditions of the problem. The following calculations were performed to determine the boundary condition and initial condition inputs for the turbulence model. Mass Flow Rate: 0.5 kg/s (randomly chosen flow rate that will give turbulent flow) Pipe Diameter (D): 0.03 m Viscosity (μ): 0.001003 kg/m-s Density (ρ): 998.2 kg/m3 Turbulence Empirical Constant (Cμ) = 0.09 (recommendation from ANSYS Theory Guide) Hydraulic Diameter (Dh): 29 𝐷ℎ = 𝐷 2 𝜋 ∗ (2) 4∗𝐴 = = 𝐷 = 0.03 𝑚 𝑃 4∗𝜋∗𝐷 Flow Area (A): 𝐷 2 0.03 𝑚 2 𝐴 = 𝜋∗( ) =𝜋∗( ) = 0.00070686 𝑚2 2 2 Average Flow Velocity (uavg): 𝑢𝑎𝑣𝑔 = 𝑚̇ = 𝜌∗𝐴 0.5 𝑘𝑔/𝑠 998.2 𝑘𝑔 ∗ 0.00070686 𝑚2 𝑚3 = 0.708631 𝑚 𝑠 Reynolds Number (ReDh): 𝑅𝑒𝐷ℎ 𝑚̇𝐷ℎ = = 𝜇𝐴 𝑘𝑔 0.5 𝑠 ∗ 0.03 m = 21157 𝑘𝑔 0.001003 𝑚 − 𝑠 ∗ 0.00070686 𝑚2 Turbulence Length Scale (l): 𝑙 = 0.07 ∗ 𝐷ℎ = 0.07 ∗ 0.03 𝑚 = 0.0021 𝑚 Turbulent Intensity (I): − 1 8 1 𝐼 = 0.16 ∗ 𝑅𝑒𝐷ℎ = 0.16 ∗ 21157−8 = 0.0460721 Turbulent Kinetic Energy (k): 𝑘= 2 3 3 𝑚 𝑚2 2 (𝑢𝑎𝑣𝑔 ∗ 𝐼) = (0.708631 ∗ 0.0460721) = 0.00159885 2 2 2 𝑠 𝑠 Dissipation Rate (ϵ): 30 ε= 3/4 k C𝜇 3/2 3/4 𝑙 = 0.09 0.001598853/2 0.0021 Using the above calculated turbulent parameters, the following was determined. Below is a figure of the velocity magnitude versus distance from the centerline for various distances from the pipe entrance. The distance from the pipe entrance is given in the legend. For example, “line-10cm” shows the velocity profile 10 cm from the pipe entrance. The figure shown below is very difference from the similar figure for laminar flow. First the velocity profiles are much flatter. The parabolic shape seen in the laminar flow plot is not as clear. Second, the flow reaches the steady state velocity profile quicker for turbulent flow. The flow is stable at about 40 cm where it takes until about 45 cm to become stable for the laminar flow for the same pipe geometry. 31 Below is the wall shear stress versus distance from the entrance. Notice how the shear stress is very large in the beginning and quickly reduces by about 3 cm. The large shear stress at the beginning is due to entrance effects. Also note that the distance needed to dissipate increased shear stress due to entrance effects is much shorter than for laminar flow. It took the laminar flow about 5 cm to dissipate the impact of the entrance on the shear stress. Once the entrance effects dissipate the wall shear stress slowly decreases as the flow becomes more and more stable. At about 22 cm the shear stress reduces again. This can be explained by boundary layer separation. The structure and location of boundary layer separation often changes, sometimes resulting in a reduction of overall drag (Wikipeida). At the very end of the pipe, around 49 cm, the wall shear stress begins to increase. This is caused by the pipe exit. Another very different feature of turbulent flow compared with laminar flow is the mixing that occurs radially. The figure below shows the radial flow velocity. The 32 greatest radial velocity occurs at the entrance and exit of the pipe. This is also true of laminar flow. However, the radial velocity is non-zero in the middle of the pipe meaning that mixing is occurring. The radial velocity figure for turbulent flow is very different than that for the laminar flow. That is because laminar flow is characterized by moving in “sheets” while turbulent flow is characterized by random motion. The next two figures show the turbulent kinetic energy and the production of turbulent kinetic energy. Notice how all of the turbulent kinetic energy is near the wall. This is because the wall helps generate turbulent kinetic energy. The shape of the production of turbulent kinetic energy versus distance from the entrance has the same trend as that of the wall 33 shear stress. This makes sense because shear stress, caused by the wall, produces turbulent kinetic energy. The entrance effects also help to produce turbulent kinetic energy which is why the most amount of turbulent kinetic energy is produced at the wall near the entrance. 34 8. Turbulence with Heat Transfer The problem of turbulent flow can be further complicated by adding energy transfer. The flow components with heat transfer are basically the same as that for solely turbulent flow however temperature changes and therefore density changes do have a slight impact. The radial energy equation given in Section 4 can be applied for turbulent flow as well as laminar flow. The ANSYS Fluent problem discussed in Section 7 was expanded to include a constant surface heat flux. The figure below shows the fluid temperature change caused by the constant surface heat flux. The turbulent kinetic energy is the same between the two cases which is expected since turbulent kinetic energy is momentum based not thermal based. However, if the heat transfer was large enough that buoyance effects began to influence the flow, then there would be an increase in turbulent kinetic energy in the example with heat transfer. 35 The radial velocity is the same between the two cases, which is expected since the radial velocity is caused by turbulent flow. The velocity profiles for each distance from the entrance except that of the entrance is shifted up a small amount. The heat transfer that occurs causes the density of the fluid to decrease. To keep a constant mass flow through the pipe, the velocity increases slightly. 36 The shear stress is the same which is expected since it is based solely on the flow and momentum boundary layer. 37 9. Two-Phase Flow A large number of flows encountered in nature and technology are a mixture of phases. Physical phases of matter are gas, liquid, and solid, but the concept of phase in a multiphase flow system is applied in a broader sense. In multiphase flow, a phase can be defined as an identifiable class of material that has a particular inertial response to and interaction with the flow and the potential field in which it is immersed. For example, different-sized solid particles of the same material can be treated as different phases because each collection of particles with the same size will have a similar dynamical response to the flow field. Multiphase flow regimes can be grouped into four categories: gas-liquid or liquid-liquid flows; gas-solid flows; liquid-solid flows; and three-phase flows. The area that will be focused on is gas-liquid flow and more specifically gasliquid flow caused by boiling heat transfer. (Theory Guide). Boiling heat transfer is defined as a mode of heat transfer that occurs with a change in phase from liquid to gas. There are two basic types of boiling, pool boiling and flow boiling. Flow boiling is boiling in a flowing stream of fluid, where the heating surface may be the channel wall confining the flow. Since the heat transfer rate in boiling is generally very high, it has been used to cool devices requiring high heat transfer rates such as nuclear reactors. There are four regimes of boiling shown in the figure below. http://www.thermalfluidscentral.org/e-resources/download.php?id=1 38 The first regime of boiling is natural convection boiling, up to point A. During this regime, no bubbles form. Instead, heat is transferred from the surface to the bulk fluid by natural convection (http://www.thermalfluidscentral.org/e5/4 resources/download.php?id=1). The heat transfer rate is proportional to 𝛥𝑇𝑠𝑎𝑡 (Tong). The second regime of boiling, from point A to point C, is called nucleate boiling. During this stage vapor bubbles are generated at certain preferred locations on the heated surface called nucleation sites. Nucleation sites are often microscopic cavities or cracks in the surface (http://www.thermalfluidscentral.org/e-resources/download.php?id=1). When the liquid near the wall superheats it evaporates, forming bubbles at the various nucleation sites. The bubbles transport the latent heat of the vaporization and also increase the convective heat transfer by agitating the liquid water near the heated surface. There are two subregimes of nucleate boiling. The first is local boiling which is boiling in a subcooled liquid, where the bubbles form at the heating surface tend to condense locally. Subcooled boiling is discussed further in Section 11. Bulk boiling is nucleate boiling in a saturate liquid; in this case, the bubbles do not collapse (Tong). Nucleate boiling has very high heat transfer rates for only small temperature difference between the bulk fluid and the heated surface. For this reason it is considered the most efficient boiling regime for heat transfer. As the heated surface increases in temperature, more and more nucleation sites become active. The bubbles begin to merge together and form columns and slugs of gas, thus decreasing the contact area between the bulk fluid and the heated surface. The decrease in contact area causes the slope of the line to decrease until a maximum is reached (point C). Point C is referred to as the critical heat flux. The vapor begins to form an insulating blanket over the heated surface and thereby dramatically increases the surface temperature. This is called the boiling crisis or departure from nucleate boiling. As the temperature delta increases past the critical heat flux, the rate of bubble generation exceeds the rate of bubble separation. Bubbles at the different nucleation sites begin to merge together and boiling becomes unstable. The surface is alternately covered with 39 a vapor blanket and a liquid layer, resulting in oscillating surface temperatures. This regime of boiling is known as partial film boiling or transition boiling (Tong). If the temperature difference between the surface and the fluid continues to increase, stable film boiling is achieved. At this point, there is a continuous vapor blanket that covers the heated surface and phase change occurs at the liquid-vapor interface instead of the heated surface. During this regime, most heat transfer is carried out by radiation (http://www.thermalfluidscentral.org/e-resources/download.php?id=1) (Advanced Heat and Mass Transfer by Amir Faghri, Yuwen Zhang, and John R. Howell). To know the flow pattern of a two-phase flow is as important as to know whether the flow is laminar or turbulent in a single-phase flow. The number of characteristic flow patterns and the name used for them vary somewhat from investigator to investigator. Some of them include, in order of increasing quality from liquid to gas, are bubbly flow, plug flow, stratification, wave flow, slug flow, annular flow, dispersed flow and fog or mist flow. An image of each of these flow types can be seen in the figure below. Add Tong, Figure 3-2, page 50 The flow patterns stated above can be further classified into three categories, bubbly flow, slug flow and annular flow. Bubbly flow is when the liquid phase in continuous and the vapor phase is discontinuous. The vapor is distributed in the liquid in the form of bubbles. The flow pattern occurs at low void fractions. This is the flow pattern of subcooled boiling. Slug flow is when there are relatively large liquid slugs in the flow as a result of the beginning of agglomeration of vapor bubbles. This flow occurs at moderate void fractions and relatively low flow velocities. Annular flow is when the liquid phase is continuous in an annulus along the wall and the vapor phase is continuous in the core. This flow pattern occurs at high void fractions and high flow velocities. (TONG) 40 The following figure depicts the three flow patterns described above as a fluid is heated while travelling in a pipe. Add Tong, Figure 3-6, page 56 The following regimes are gas-liquid: 41 Bubbly flow: This is the flow of discrete gaseous or fluid bubbles in a continuous fluid. Droplet flow: This is the flow of discrete fluid droplets in a continuous gas. Slug flow: This is the flow of large bubbles in a continuous fluid. Stratified/free-surface flow: This is the flow of immiscible fluids separated by a clearly-defined interface. 42 10.Population Boundary Equations 43 11.Subcooled Boiling 44 12.Numerical Methods 45 13.References 46