MARINE STEAM POWER PLANT HEAT BALANCE

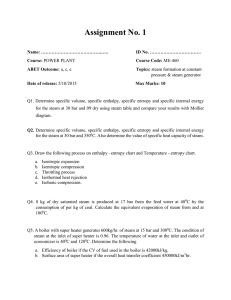

advertisement

MARINE STEAM POWER PLANT HEAT BALANCE

by

Steven A. Gelardi

An Engineering Project Submitted to the Graduate

Faculty of Rensselaer Polytechnic Institute

in Partial Fulfillment of the

Requirements for the Degree of

MASTER OF ENGINEERING IN MECHANICAL ENGINEERING

Approved:

_________________________________________

Ernesto Gutierrez-Miravete, Engineering Project Adviser

Rensselaer Polytechnic Institute

Hartford, Connecticut

August, 2012

(For Graduation August, 2012)

© Copyright 2012

by

Steven A. Gelardi

All Rights Reserved

ii

CONTENTS

MARINE STEAM POWER PLANT HEAT BALANCE....................................................i

CONTENTS ...................................................................................................................... iii

LIST OF SYMBOLS ........................................................................................................ vii

LIST OF FIGURES ............................................................................................................ ii

LIST OF TABLES ............................................................................................................. iii

ACKNOWLEDGMENT ....................................................................................................iv

ABSTRACT ........................................................................................................................ v

1. INTRODUCTION ......................................................................................................... 1

2. METHODOLOGY ........................................................................................................ 4

2.1

Theory .................................................................................................................. 4

2.1.1

2.2

The First Law of Thermodynamics .......................................................... 4

Problem Description............................................................................................. 5

2.2.1

Preliminary Values ................................................................................... 5

2.2.2

Secondary Values ..................................................................................... 6

3. EQUATIONS/MATRICES ........................................................................................... 7

3.1

3.2

3.3

Boilers .................................................................................................................. 7

3.1.1

Component Detail .................................................................................... 7

3.1.2

Boiler Fuel Oil ......................................................................................... 8

3.1.3

Heat Rate ................................................................................................ 10

3.1.4

Steam Drum ........................................................................................... 11

3.1.5

Boiler Efficiency .................................................................................... 11

Superheater ......................................................................................................... 16

3.2.1

Component Detail .................................................................................. 16

3.2.2

Superheater Outlet Flow ........................................................................ 17

Main Propulsion Turbine ................................................................................... 18

3.3.1

Steam Rate (Non-Extraction) ................................................................. 18

iii

3.4

3.5

3.6

3.7

3.3.2

Available Energy.................................................................................... 19

3.3.3

Efficiency of the State Line.................................................................... 21

3.3.4

Temperature Correction Factor .............................................................. 22

3.3.5

State Line Energy ................................................................................... 22

3.3.6

Exhaust Loss .......................................................................................... 24

3.3.7

Mechanical and External Efficiency ...................................................... 25

3.3.8

Gland Leak Off ...................................................................................... 26

Power ................................................................................................................. 27

3.4.1

Power Equation ...................................................................................... 27

3.4.2

Estimated Total Flow Rate from Superheaters ...................................... 27

3.4.3

Power Matrix .......................................................................................... 29

High Pressure Heater (Economizer)................................................................... 30

3.5.1

Component Detail .................................................................................. 30

3.5.2

Terminal Temperature Difference and Temperature Difference ........... 31

3.5.3

Heat Exchange Pressure, Temperatures and Enthalpies ........................ 31

Direct Contact Heater (Deaerating Feed Tank) ................................................. 34

3.6.1

Component Detail .................................................................................. 34

3.6.2

DC Heater and Auxiliary Exhaust Pressure ........................................... 35

3.6.3

DC Heater Flow Rate to Feed Pump ...................................................... 35

3.6.4

Direct Contact Vent Condenser ............................................................. 36

Low Pressure Heater .......................................................................................... 38

3.7.1

3.8

Component Detail .................................................................................. 38

Feed Water Drain Collection Tank .................................................................... 39

3.8.1

Component Detail .................................................................................. 39

3.8.2

Contaminated Drains .............................................................................. 39

3.8.3

Steam Air Heaters .................................................................................. 40

3.8.4

Make-Up Feedwater ............................................................................... 42

iv

3.9

3.8.5

Steam Atomizers .................................................................................... 43

3.8.6

Soot Blowers .......................................................................................... 43

3.8.7

Distilling Plant ....................................................................................... 44

3.8.8

Distiller Air Ejector Flow....................................................................... 46

3.8.9

Feed Water Drain Collection Tank Flow ............................................... 46

Main Condenser ................................................................................................. 48

3.9.1

Component Detail .................................................................................. 48

3.9.2

Main Condenser Flow ............................................................................ 49

3.10 Auxiliary Condenser .......................................................................................... 50

3.10.1 Component Detail .................................................................................. 50

3.10.2 Auxiliary Condenser Flow ..................................................................... 50

3.11 Desuperheater ..................................................................................................... 51

3.11.1 Component Detail .................................................................................. 51

3.11.2 Desuperheater Steam Flow .................................................................... 51

3.11.3 Desuperheated Steam Mass Flow .......................................................... 52

3.11.4 Desuperheated Temperature and Pressure ............................................. 52

3.12 Domestic / Hotel Loads ...................................................................................... 54

3.12.1 Component Detail .................................................................................. 54

3.12.2 Domestic Water Heating ........................................................................ 54

3.12.3 Galley Heating ....................................................................................... 54

3.12.4 Laundry Heating..................................................................................... 54

3.12.5 Total Domestic Hotel Loads .................................................................. 55

4. COMPONENT CALCULATIONS ............................................................................. 56

4.1

Turbo-Generator ................................................................................................. 56

4.1.1

Component Detail .................................................................................. 56

4.1.2

Rated Kilo-Watt Load ............................................................................ 57

4.1.3

Operating Kilo-Watt Load ..................................................................... 57

v

4.2

4.3

4.4

4.1.4

Generator / Turbine Size ........................................................................ 57

4.1.5

TG Temperatures, Pressures and Enthalpies .......................................... 58

4.1.6

TG Turbine Efficiency ........................................................................... 58

4.1.7

TG Steam Rates and Flows .................................................................... 62

Feed Pump .......................................................................................................... 64

4.2.1

Component Detail .................................................................................. 64

4.2.2

Feed Pump Turbine ................................................................................ 65

4.2.3

Feed Pump Pump ................................................................................... 68

4.2.4

Feed Pump Table Overview ................................................................... 71

Air Ejectors ........................................................................................................ 73

4.3.1

Component Detail .................................................................................. 73

4.3.2

Main Air Ejectors ................................................................................... 73

4.3.3

Auxiliary Air Ejectors ............................................................................ 74

4.3.4

Distillate Air Ejectors ............................................................................. 74

4.3.5

Air Ejector Inter-Condensers ................................................................. 74

4.3.6

Air Ejector After-Condensers ................................................................ 75

Plant Cycle Efficiency........................................................................................ 76

4.4.1

Efficiency Theory................................................................................... 76

4.4.2

Cycle Efficiency ..................................................................................... 76

4.4.3

Plant Cycle Efficiency............................................................................ 76

4.4.4

Carnot Efficiency ................................................................................... 77

5. RESULTS/DISCUSSION ........................................................................................... 78

5.1

MASS BALANCE ............................................................................................. 79

5.2

DISCUSSION .................................................................................................... 82

6. CONCLUSION............................................................................................................ 83

7. REFERENCES ............................................................................................................ 84

vi

LIST OF SYMBOLS

A/F, Air to Fuel Ratio

fb, Correction Factor

Aa, Annulus Area, ft^2

fL, Load Correction Factor

AE, Available Energy, BTU/lb

fp, Initial Pressure Correction Factor

B1, High Pressure Heater’s mass flow,

fs, Superheat Correction Factor

lb/hr

ft, Initial Temperature Correction Factor

B2, Steam Air Heaters flow, lb/hr

G(EST), Estimated Total Flow Rate,

B3, Main Turbine Exhaust flow, lb/hr

BHP)OPER,

Operating

lb/hr

Brake

G, Total Flow Rate, lb/hr

Horsepower, hp

GPD, Gallons per Day, GPD

BHP, Brake Horsepower, hp

Cp(Air),

Heat

Capacity

GPM, Gallons per Minute, GPM

of

Air,

h(B), Mean Enthalpy of B1, B2, and B3,

BTU/lbm*°F

BTU/lb

Cp(FO), Heat Capacity of Fuel Oil,

h(B1), Enthalpy of High Pressure

Heater’s mass flow, BTU/lb

BTU/lbm*°F

E(EST), Estimated Total Energy, lb/hr

h(B2), Enthalpy of Steam Air Heaters

E, Total Energy, lb/hr

flow, BTU/lb

EB, Efficiency of the State Line, %

h(B3),

Eb, TG Turbine Efficiency, %/100%

Main

Turbine

Exhaust flow, BTU/lb

Eff(FP), Efficiency of Feed Pump,

h(COMPONENT),

%/100%

enthalpy

of

component, BTU/lb

Eff(TG TURB))OPER, Turbo Generator

h(CONT DRNS), Contaminated Drains

Turbine at Operated Load, %/100%

Eff(TG

Enthalpy of

TURB))RATED,

enthalpy, BTU/lb

Turbo

h(FP TURB EXH), Feed Pump Turbine

Generator Turbine at Rated Load,

Exhaust, BTU/lb

%/100%

h(MAKEUP

EL, Exhaust Loss, lb/hr

FEED),

enthalpy

of

Makeup Feedwater, BTU/lb

Em, Engine efficiency, %/100%

h(MN LEAK OFF), enthalpy of Total

f(D), Distillate Output Heat Steam

Leak Off Steam, BTU/lb

Factor

h(SAH IN), Steam Air Heaters Inlet

f(t), Temperature Correction Factor

enthalpy, BTU/lb

vii

h(SAH OUT), Steam Air Heaters Outlet

hw, enthalpy of the Wheel Used Energy,

enthalpy, BTU/lb

BTU/lb

h(TG EXH), TG Exhaust Enthalpy,

kW(OPER),

BTU/lb

h(VAP

kilo-Watt

Load, kW

FWDCT),

FWDCT

Vapor

kW(RATED), Rated kilo-Watt Load,

enthalpy, BTU/lb

h(VENT

Operational

COND),

kW

Vent

Condenser

kW(TG EST), kilo-Watt Load of Turbo

enthalpy, BTU/lb

Generator (Estimated), kW

h, enthalpy, BTU/lb

kW(TG), Turbo Generator Load, kW

H, Total Head developed per stage, feet

LHP, Windage Loss, hp

Ha, Heat Added to Combustion Air,

N, Number of Persons

BTU/lb

Ns, Rated Specific Speed, RPM

hc1, enthalpy at point Tc1, BTU/lb

P(AUX

hD3, enthalpy of exiting heating steam,

EXH),

Auxiliary

Exhaust

Pressure, psia

BTU/lb

P(AUX EXH), TG Exhaust Pressure,

hF2, High Pressure Inlet Enthalpy,

psia

BTU/lb

P(COMPONENT),

hF3, enthalpy of the Temperature

pressure

of

component, psig

Outlet, BTU/lb

P(DC HTR), Direct Contact Heater

Hg, Stack Loss, BTU/lb

Pressure, psia

HHV, Higher Heating Value, BTU/lb

P(DESUP),

hi, enthalpy of the State Line End Point,

Desuperheater

Pressure,

psig

BTU/lb

P(DISCH), discharge pressure, psig

HL, Heat Loss, BTU/lb

P(HP HTR SHELL), High Pressure

ho, enthalpy of Initial Pressure and

Heater Shell Pressure, psig

Temperature, BTU/lb

P(LP HTR SHELL), Pressure of the

Ho, Heat Input, BTU/lb

Low Pressure Heater Shell, psia

hp, enthalpy of So and pressure of main

P(STM DRUM), Steam Drum Pressure,

condenser, BTU/lb

psig

HR, Heat Rate, BTU/lb/hp

P(SUCT), suction pressure, psig

Hu, Heat Radiation, BTU/lb

P, Power, hp (SHP) or kW

ii

P’o, TG entering Steam pressure, psia

Q(DOM

Po, Initial Pressure, psig

WATER

HEATING),

Domestic Water Heating flow, lb/hr

Pso, Superheater Outlet Pressure, psig

Q(DOM), Domestic Loads flow, lb/hr

Q(AUX A/E), Auxiliary Air Ejector

Q(DUMP), Dump flow, lb/hr

flow, lb/hr

Q(AUX

AC),

Q(FOH), Fuel Oil Heaters flow, lb/hr

Auxiliary

After-

Q(FWDCT),

Condenser flow, lb/hr

Drain

Collection Tank flow, lb/hr

Q(AUX COND), Auxiliary Condenser

Q(LOST EST), Estimated Lost Energy,

flow, lb/hr

lb/hr

Q(AUX IC), Auxiliary Inter-Condenser

Q(LOST), Lost Energy flow, lb/hr

flow, lb/hr

Q(MAKEUP

Q(AUX LEAK OFF), Auxiliary Leak

FEED),

Makeup

Feedwater, lb/hr

Off flow, lb/hr

Q(MN A/E), Main Air Ejector flow,

Q(BLR EST), Estimated Boiler Flow,

lb/hr

lb/hr

Q(MN AC), Main After-Condenser

Q(COMPONENT), flow of component,

flow, lb/hr

lb/hr

Q(MN COND), Main Condenser flow,

Q(CONT DRNS), Contaminated Drains

lb/hr

flow, lb/hr

Q(DESUP

Feedwater

Q(MN IC), Main Inter-Condenser flow,

EST),

Estimated

lb/hr

Desuperheater flow, lb/hr

Q(MN LEAK OFF), Main Leak Off

Q(DESUP), Desuperheater flow, lb/hr

flow, lb/hr

Q(DISTILL A/E), Distillate Air Ejector

Q(MN LEAK OFF), Total Leak Off

flow, lb/hr

Steam, lbs/hr

Q(DISTILL PLT), Distilling Plant Flow,

Q(SAH), Steam Air Heater flow, lb/hr

lb/hr

Q(SOOT BLOWERS), Soot Blowers

Q(DOM GALLEY), Galley Heating

Flow, lb/hr

flow, lb/hr

Q(STM ATOM), Steam Atomizer Flow,

Q(DOM LAUNDRY), Laundry Heating

lb/hr

flow, lb/hr

Q(TG))OPER, Flow of the Turbo

Generator at Operating Load, lb/hr

iii

Q(TG))RATED, Flow of the Turbo

T(COMPONENT),

Generator at Rated Load, lb/hr

temperature

of

component, °F

Q(TG), Turbo Generator flow, lb/hr

T(DESUP), Desuperheater Temperature,

Q(VAP FWDCT), FWDCT Vapor flow,

°F

lb/hr

T(FO), Fuel Oil Temperature, °F

Q(VENT), Vent Condenser flow, lb/hr

T(H), Highest Point Temperature, °F

Q, flow, lb/hr

T(L), Lowest Point Temperature, °F

R, Feed Pump Recirculation Rate, lb/hr

T(MAKEUP

RL, Astern-Turbine Windage, “Hg

SFC,

Specific

Fuel

FEED),

Makeup

Feedwater Temperature, °F

Consumption,

T(SAH), Steam Air Heater temperature,

lb/hr/hp

°F

SHP, Shaft Horseshp, shp

T(SAT), Saturation Temperature, °F

SLEP, energy of the Desuperheated

T(So), TG Exhaust Temperature, °F

T’o, TG entering Steam temperature, °F

Steam, BTU/lb

So, enthalpy of Initial Pressure and

T1,

Temperature, J/K

Steam

Air

Heaters

intake

temperature, °F

SPC(EST), Estimated Specific Power

T2,

Consumption, kWh/kgal

Steam

Air

Heaters

exhaust

temperature, °F

SPC, Specific Power Consumption,

Tc1,

kWh/kgal

Low

Pressure

Heater

Shell

Temperature plus the Heat Exchange

SR(FP), Steam Rate of the Feed Pump,

Terminal

lb/hr/hp or lb/hr/kW

Temperature

Difference, °F

SR(NE), Steam Rate Non-Extraction,

TD, Temperature Difference, °F

lb/hr/hp or lb/hr/kW

TD3, temperature of exiting heating

SR(TG EST), Steam Rate of Turbo

Steam, °F

Generator (Estimated), lb/hr

TF2,

SR(TG)OPER, Operating Steam Rate of

High

Pressure

Heater

Temperature, °F

the Turbo Generator, lb/hp/kW

TF3, Temperature Outlet, °F

SR(TG)RATED, Rated Steam Rate of

Tg, Uptake Temperature, °F

the Turbo Generator, lb/hp/kW

To, Initial Temperature, °F

iv

Inlet

TTD, Terminal Temperature Difference,

X, Condenser Flow, lb/hr

Δh(SAH), Steam Air Heater difference

°F

TTD1,

Terminal

Temperature

in enthalpies, BTU/lb

ΔH(TOTAL), Change in Head Pump,

Difference of Heat Exchanger, °F

UE(SL), State Line Energy, BTU/lb

BTU/hr

UE(W), Wheel Used Energy, BTU/lb

Δh, change in enthalpy, BTU/lb

v(f), volume per pound, ft^3/lb

ΔP(BP), Change in Boiler Pressure, psig

v(L), Direct Contact Heater Outlet

ΔP(CTRL

volume of Liquid, ft^3/lb

DESUP),

Control

Desuperheater Pressure, psig

ΔP(Superheater), Change in Superheater

v, Final Rated Specific Volume of

Steam, ft^3/lb

Pressure, psig

ΔP, Change in pressure, psig

W(FO), Work Done on the Fuel Oil, ft-

ΔT(FO), Change in Temperature of the

lb

W, Work, J or ft-lb

Fuel Oil, °F

ΔT, Change in Temperature, °F

WHP, Wheel Horsepower, hp (WHP) or

kW

v

LIST OF FIGURES

Figure 1 – Basic Marine Steam Power Plant Cycle ........................................................... 1

Figure 2 - Conservation of Energy (1) ............................................................................... 4

Figure 3 - Fuel Oil Fired Steam Boiler (3) ........................................................................ 8

Figure 4 - Steam Drum Internals (4)................................................................................ 11

Figure 5 - Stack Loss, Hg (5 p. 54).................................................................................. 14

Figure 6 - Superheater Tubes (Exposed) (6).................................................................... 16

Figure 7 - Main Propulsion Turbine (Cross Sectional) (7) .............................................. 18

Figure 8 – Propulsion Turbines Replacement Factors (5 p. 42) ...................................... 20

Figure 9 - Main Propulsion Turbine Basic Efficiency (5 p. 34) ...................................... 21

Figure 10 - Throttle Temperature Correction (5 p. 35) ................................................... 22

Figure 11 - State Line (5 p. 38)........................................................................................ 23

Figure 12 - Typical Economizer (9) ................................................................................ 30

Figure 13 - Economizer Flow (aka "Third Stage Heater") (2 p. 11) ............................... 33

Figure 14 - Typical DC Heater (Deaerating Feed Tank) (10) ......................................... 34

Figure 15 - Direct Contact Heater Flow (2 p. 12)............................................................ 37

Figure 16 - Mean Specific Heat (5 p. 48) ........................................................................ 42

Figure 17 - Extraction Steam for Flash Type Evaporators (5 p. 25) ............................... 45

Figure 18 - Feed Water Drain Collection Tank System Diagram (2 p. 15) ..................... 47

Figure 19 – Single-Pass Condenser (11) ......................................................................... 49

Figure 20 - Turbo Generator (Uninstalled without Piping) (12) ..................................... 56

Figure 21 - Basic Efficiency, Eb (5 p. 60) ....................................................................... 59

Figure 22 - Initial Temperature Correction Factor, ft (5 p. 63) ....................................... 59

Figure 23 - Initial Pressure Correction Factor, fp (5 p. 63) ............................................. 60

Figure 24 - Exhaust Pressure Correction Factor, fb (5 p. 60) .......................................... 61

Figure 25 - Load Correction Factor, fL (5 p. 63)............................................................. 61

Figure 26 - Steam Driven Feed Pump (13) ...................................................................... 64

Figure 27 - Windage Loss, LHP (5 p. 66) ....................................................................... 66

Figure 28 - Feed Pump Rated Efficiency (5 p. 76) .......................................................... 69

Figure 29 - Typical Air Ejector (14) ................................................................................ 73

Figure 30 - Main Air Ejector Flow (5 p. 13) ................................................................... 74

ii

LIST OF TABLES

Table 1 - Design Characteristics (2 p. 1) ........................................................................... 5

Table 2 – Standard Capacity of a Distilling Plant (2 p. 23) ............................................. 44

Table 3 - Desuperheater and its Components’ Flows ...................................................... 51

Table 4 - Rated kW and Standard Size Generator (2 p. 23) ............................................ 57

Table 5 - Optimal Feed Pump Table................................................................................ 72

Table 6- Mass Balance..................................................................................................... 79

Table 7 - Matrix of Equations .......................................................................................... 96

Table 8 - Minverse ........................................................................................................... 96

Table 9 – Main Turbine Extraction Stages ...................................................................... 99

Table 10 - Power Matrix ................................................................................................ 100

Table 11 - Superheater Outlet Flow Matrix ................................................................... 100

Table 12 - High Pressure Heater Matrix ........................................................................ 100

Table 13 - Direct Contact Heater Matrix ....................................................................... 101

Table 14 – Feed Water Drain Collection Tank Matrix .................................................. 101

Table 15 - Main Condenser Matrix ............................................................................... 101

Table 16 - Auxiliary Condenser Flow Matrix ............................................................... 102

Table 17 - Desuperheater Steam Flow Matrix ............................................................... 102

iii

ACKNOWLEDGMENT

I’d first like to acknowledge Torii Schopflin, who introduced me to Rensselaer’s

Master’s Program and who also took the liberty to fill out most of the paperwork to

enroll me without asking. I’d like to also thank my wife, Laurel, who has been a constant

supporter of my education and has kept “gently” pushing me to finish my Master’s

Degree.

iv

ABSTRACT

Ever wondered how a Marine Steam Power Plant works, with all its components

working together in unison? This project will lead you through the world of steam ship’s

engine rooms; giving you step-by-step methods and calculations to perform a full heatbalance of a typical marine steam powered plant.

A power plant with a Shaft Horse Power of 32,500 SHP will generate a certain kiloWatt (kW) and will produce a certain flow to the main condenser. To find this, we will

find various component details, such as the Steam-Water Cycle; what it does, what it

includes, and how to solve for temperatures, pressures, flows, and enthalpies of each

basic component. This project will provide equations, tables, and figures to guide you

through solving the basic components of a steam powered engine room.

In each section you will find defining terms and values that are typical for a steam

ship. My final matrix will show step-by-step the values of each component in the total

heat balance and how the total heat balance itself has an equal heat-in and heat-out.

v

1. INTRODUCTION

Steam Plants have been around for well over one-hundred years, and have paved the way

for modern shipping. Steam plants work by heating water past its boiling point, until it’s

superheated, then driving it through multiple turbines to produce electricity and thrust.

The purpose of this project is to set forth data for a specified marine steam power

plant heat balance. This project is not for all power plants however; it is specifically

applicable to oil-fired steam-turbine marine power plants at maximum continuous

power. Some modifications have been made to suit this plant as was saw fit.

A heat balance is a necessary tool for designing a marine power plant. They can also

be used to determine optimum steam conditions and a cycle design or even to analyze

the performance of a power plant already in service. In order to solve the heat balance

calculation, shaft horsepower, steam conditions and the basic steam-water cycle must be

established. Once these have been solved, various steam, feed and condensate, and

exhaust flow can be determined.

The figure below shows a basic rendition of a typical Marine Steam Power Plant

Cycle.

Figure 1 – Basic Marine Steam Power Plant Cycle

1

The Basic Steam-Water Cycle is as follows:

1. Boiler– A boiler contains the heating element of the system; fire generated by

burning fuel, and applies it to boil the medium, water.

2. Throttle Box – This is the means to control the output of the boiler. In this project

I will be using set values to calculate the heat balance.

3. High Pressure (HP) Turbine – The HP Turbine is where the superheated steam

from the boiler is directed to, in order to generate a spinning action of the blades of the

turbine. The more nozzles open, the greater the flow, the greater the power.

4. Low Pressure (LP) Turbine – The LP Turbine is where the now less-superheated

steam travels through after the HP Turbine.

5. Condenser (Main/Auxiliary) – The Condenser is where the steam is dumped after

the HP and LP Turbine. It interacts with a cooling medium (usually Seawater) and heat

transfer occurs, cooling the steam into water. In this project, a Low Pressure Condenser

will be used (at Vacuum Pressure).

6. Condensate Pump – The means of pumping the condensed steam through the

remainder of the system.

7. Air Ejector (Main/Auxiliary) – Air Ejectors remove the non-condensable gases

from the system and helps to draw and maintain vacuum.

8. Low Pressure Heater (First Stage Heater) – Heats the water for hotel loads,

auxiliary loads, and miscellaneous loads.

9. DC Heater (Direct Contact Heater, or Deaerating Feed Tank) – acts as a holding

tank for the incoming water to the feed pump to pump into the boiler, removes noncondensable gas, and heats the water more.

10. Feed Pump – The Feed Pump serves as the driving force of the water into the

boiler. Its discharge pressure must be greater than that of the boilers in order to have

positive flow.

11. High Pressure Heater (Economizer) – Acts as a reheat to the system so a shock

to the system with the entrance of cold water into the boiler will not occur.

12. Boiler – This is considered the last part of the cycle as well as the beginning of

the cycle.

2

A heat balance contains many variable factors. Some of these include fuel, hotel and

domestic loads, ambient conditions (which I am nullifying this project – atmospheric

pressure is equal to 1 atmosphere), and various other ship components. These variables

will vary from ship to ship and will affect its associated calculated results.

For the purpose of this project, I will be providing you typical variables that will be

explained step-by-step throughout the project.

3

2. METHODOLOGY

2.1 Theory

2.1.1

The First Law of Thermodynamics

The First Law of Thermodynamics states that energy is conserved.

“The first law of thermodynamics is a version of the law of conservation of energy,

specialized for thermodynamical systems. It is usually formulated by stating that the

change in the internal energy of a closed system is equal to the amount of heat supplied

to the system, minus the amount of work performed by the system on its surroundings.

The law of conservation of energy can be stated: The energy of an isolated system is

constant”. (1)

Since energy cannot be created nor destroyed, the Figure below (Figure 2 Conservation of Energy) shows that the Energy ‘IN’ (QH) is equal to the Energy ‘OUT’

(Out being summation of QC and W). The Term QH is the heat energy input into the

system, W is the useful work done by the system, and QC is the heat energy output from

the system (into a low temperature sink).

Figure 2 - Conservation of Energy (1)

𝑄(𝐻) = 𝑄(𝐶) + 𝑊

(2.1)

𝑊 = 𝑄(𝐻) − 𝑄(𝐶)

(2.2)

𝑄(𝐻) − 𝑊 − 𝑄(𝐶) = 0

(2.3)

4

2.2 Problem Description

A design requires that the original design characteristics contain a Shaft Horse Power

(SHP) of 32,500 SHP, a complement of 40 persons, 2 boilers, a throttle temperature of

950 degrees Fahrenheit (F) and pressure of 850 pounds-per-square-inch-gauge (psig).

Condenser pressure is 1.5 Inches of Mercury ("Hg) and Auxiliary Condenser is 2 "Hg.

The required Engine efficiency “Em” is given at 0.96. The objective is to complete the

heat balance. Note: The design must contain a total plant flow “E” for 2 boilers.

2.2.1

Preliminary Values

Given the scope of the work, the given values in the problem description are not a lot to

go on. Some preliminary values must be given before we can proceed. The table below

shows what we already know from the problem statement, plus a few components not

yet unidentified.

The Initial Pressure and Temperature, Shaft Horsepower, and Required Engine

Efficiency were calculated from a specific set of factors already given from MARINE

ENGINEERING DESIGN I REPORT (2 p. 1). The Appendices A.1.5 and A.1.2 give us the

values to solve for the Initial Temperature and Pressure. The Complement (Number of

Persons) “N” was chosen as a typical value of people aboard a cargo ship.

Table 1 - Design Characteristics (2 p. 1)

Item

Pressure, Initial (“Po”)

Value

850

864.696

950

Temperature, Initial (“To”)

Main Condenser Pressure

1.5

0.736765

2

0.982353

Auxiliary Condenser Pressure

Shaft Horse Power (“SHP”)

Units

psig

psia

°F

"Hg

psia

"Hg

psia

32,500 SHP

Required Engine Efficiency (“Em”)

Number of Boilers

0.96

2 Boilers

Number of Persons (“N”)

40 Complement

5

2.2.2

Secondary Values

In order to solve the total heat balance for a marine steam-powered plant, some other

conditions have to be solved for. The subsequent sections in this project will show the

areas that are going to be solved. First we will start with the Main Propulsion Turbine

(Section 3.1), then work our way to the Power Equation (Section 0), then the

Superheater and Desuperheater (Sections 3.2 and 3.11), High Pressure Heater (Section

3.5), Direct Contact Heater (Section 3.6), Low Pressure Heater (Section 3.7), Feedwater

Drain Collection Tank (Section 3.8), Main and Auxiliary Condenser (Sections 3.9 and

3.10), and finally the Domestic Loads (Section 3.12) before getting into the Component

Calculations (Section 4).

6

3. EQUATIONS/MATRICES

Boilers

3.1

3.1.1

Component Detail

The boiler’s main purpose is to provide superheated steam to the Propulsion Turbines

and Turbo Generators for propulsion and electrical power. This plant utilizes two boilers

in parallel. Normally, an operating plant would have one boiler carry most of the load;

however for simplicity in equations we will be assuming equal loads throughout the

entirety of the project.

The Boilers are equipped with fuel oil injectors that supply a concentrated yet

distributed spray into the burners. This fuel is consumed (burned) and its energy is

transferred to the steam in the internal piping in the Boilers. The steam is heated to a

superheated, high pressure state where it is sent to the Main Propulsion Turbines and the

Turbo Generators. It’s equipped with a Superheater system, which increases the output

steam to a state with no moisture, a Desuperheater system which controls the output

temperature of the Superheater system, an Economizer which redirects some lost flow

back into the system to conserve energy, and a steam drum that serves as an expansion

tank to the inlet to the Superheater system.

7

Figure 3 - Fuel Oil Fired Steam Boiler (3)

3.1.2

Boiler Fuel Oil

Bunker “C” (Number 6) is the fuel oil consumed in the boiler. It is a low-grade fuel and

is very robust. It will not light if a match is thrown on an open barrel. Its primary

component is Carbon, but it also contains Hydrogen, Sulphur and trace amounts of

Oxygen and Nitrogen. It is a very good oil to use as it has good burning characteristics

and is cheaper than most other grades of fuel oil. Bunker “C” has a standard higher

heating value of 18,500 BTUs per pound.

3.1.2.1 Specific Fuel Consumption

The Specific Fuel Consumption, SFC is the ratio of the fuel mass flow of an engine to its

output power, in specified units. Specific Fuel Consumption is a widely used measure of

8

atmospheric engine performance. Its units are pound-mass-per-hour-per-horsepower

lbm/hr/hp.

𝑆𝐹𝐶

=

(3.1)

(𝐸 − (𝑄(𝐷𝐸𝑆𝑈𝑃) ∗ ℎ(𝑆𝑂)) + ((𝑄 ∗ ℎ)(𝐷𝐸𝑆𝑈𝑃)) − (𝐸 ∗ (ℎ𝐹3)))

𝐴

((𝐸𝑓𝑓(𝐵𝐿𝑅) ∗ 𝑆𝐻𝑃 ∗ 𝐻𝐻𝑉) + (𝐶𝑝(𝐹𝑂) ∗ 𝛥𝑇(𝐹𝑂)) + ((𝐹 ) ∗ 𝐶𝑝(𝐴𝑖𝑟) ∗ 𝛥𝑇(𝐴𝑖𝑟)))

𝑙𝑏

)

ℎ𝑟

𝑆𝐹𝐶 = 0.204

ℎ𝑝

(

3.1.2.2 Fuel Oil Heaters

To solve for “Q(FOH)”, I need the Work Done on the Fuel Oil “W(FO)”. To get this, we

need the product of the Ships Horsepower “SHP” (32,500 SHP) and the Specific Power

Consumption “SPC(EST)” (0.5).

𝑊(𝐹𝑂) = 𝑆𝐻𝑃 ∗ 𝑆𝑃𝐶(𝐸𝑆𝑇) = 16250 𝑓𝑡 ∗ 𝑙𝑏

(3.3)

Now that we have solved the work, we may multiply in a factor of 0.7 pounds

2

lb

squared per foot-hour(hr∗ft) to get the Flow of the Fuel Oil Heaters.

𝑄(𝐹𝑂𝐻) = 0.07 ∗ 𝑊(𝐹𝑂) = 1137.5

𝑙𝑏

ℎ𝑟

(3.4)

3.1.2.3 Fuel Consumption

Fuel consumption is the rate at which the Fuel Oil is consumed in a Boiler. To calculate

the Flow of Fuel Oil “Q(FO)”, I need to find the amount of fuel I consume.

𝑄(𝐹𝑂) = 𝑆𝐹𝐶 ∗ 𝑆𝐻𝑃 =

(0.203790

ℎ𝑝

𝑙𝑏

)

ℎ𝑟 ∗ (32500) ℎ𝑝

(3.5)

𝑙𝑏

𝑔𝑎𝑙

= 6623.175

= 907.167

ℎ𝑟

ℎ𝑟

Bunker C is a bit lighter than water, as a gallon of it weighs 7.3 pounds. Dividing the

Q(FO) by gallons per pounds gets us 907.167 gallons per hour.

To convert this to barrels-per-hour, we need to divide the gallons per hour by the

amount of gallons in a barrel, which are 42. This yields 2.16 barrels per hour and since

9

(3.2)

there are 24 hours in a day, 51.84 barrels per day are consumed. To summate, this steam

power plant uses around 52 Barrels of Bunker “C” Fuel Oil a day.

𝑔𝑎𝑙

907.167

ℎ𝑟 ) ∗ (24 ℎ𝑟 ) = 51.84 𝑏𝑎𝑟𝑟𝑒𝑙𝑠

𝐵𝑎𝑟𝑟𝑒𝑙𝑠 𝑐𝑜𝑛𝑠𝑢𝑚𝑒𝑑 𝑎 𝑑𝑎𝑦 = (

𝑔𝑎𝑙

𝑑𝑎𝑦

𝑑𝑎𝑦

42

𝑏𝑎𝑟𝑟𝑒𝑙

3.1.3

Heat Rate

The rate of heat added into (IN) the system divided by the power output (OUT) is called

the Heat Rate (HR). This is useful in finding the Ships Heat Rate for the Plant and the

Cycle. Its units are in BTUs-per-pound-per-hp.

𝐻𝑅(𝑊𝐻𝑃)(𝑐𝑦𝑐𝑙𝑒) =

((𝐸 − 𝑄(𝐷𝐸𝑆𝑈𝑃) ∗ ℎ(𝑆𝑂)) + ((𝑄 ∗ ℎ)(𝐷𝐸𝑆𝑈𝑃)) − (𝐸 ∗ (ℎ𝐹3))) (3.6)

𝑊𝐻𝑃

𝑊𝐻𝑃 = 33854.17 ℎ𝑝, (solved in Section 3.4.3)

The Wheel Horsepower is calculated by finding the quotient of “SHP” to “Em”.

𝐵𝑇𝑈

)

𝐻𝑅(𝑊𝐻𝑃)(𝑐𝑦𝑐𝑙𝑒) = 3128.115 𝑙𝑏

ℎ𝑝

(

For the final equation, which is the Heat Rate of the Entire Plant “HR(SHP)(plant)”,

we need the value of the Higher Heating Value “HHV”. The “HHV” is a standard higher

heating value by ‘bomb’ calorimeter corrected for specific heat at constant pressure. Its

value is set at 18,500 BTU per pound. With this value now know, we can solve for the

Plant’s Heat Rate. It’s defined by the equation below

𝐵𝑇𝑈

𝑄(𝐹𝑂) ∗ 𝐻𝐻𝑉 ( 𝑙𝑏 )

𝐻𝑅(𝑆𝐻𝑃)(𝑝𝑙𝑎𝑛𝑡) =

,

𝑆𝐻𝑃

ℎ𝑝

(3.7)

After plugging in the values of 6623.175 lb/hr for “Q(FO)”, 18500 for “HHV” and

32500 for “SHP”, we get a Plant’s Heat Rate “HR(SHP)(plant)” of 9250 BTU/lb/hp.

𝑅(𝑆𝐻𝑃)(𝑝𝑙𝑎𝑛𝑡) =

𝐵𝑡𝑢

𝐵𝑇𝑈

∗ 18500

𝑙𝑏

= 9250 𝑙𝑏

32500ℎ𝑝

ℎ𝑝

6623.175

10

3.1.4

Steam Drum

The Steam Drum is where the incoming feedwater is pumped into. From Section 3.11.4,

the Pressure of the Steam Drum is calculated to be 993 psig and its Temperature 543.59

°F.

.

Figure 4 - Steam Drum Internals (4)

3.1.5

Boiler Efficiency

A steam plant boiler is typically 80- to 95-percent efficient. This range is due to the

different types, classes, and styles of boiler design. The Boiler Efficiency Equation is

given below. Notice how it contains various components, including Desuperheater

values, the air to fuel ratio, temperature values, the Higher Heating Value, Specific Fuel

Consumption, enthalpy values, shaft horsepower, and overall energy. All these factors

determine the efficiency of a boiler - how the fuel is burned, the flows going through it,

how much temperature change is used; the list goes on and on.

The following is the initial equation used to solve the Boiler Efficiency.

𝐸𝑓𝑓(𝐵𝐿𝑅)

=

[ℎ(𝑆𝑂) ∗ (𝐸 − 𝑄(𝐷𝐸𝑆𝑈𝑃)) + {𝑄(𝐷𝐸𝑆𝑈𝑃) ∗ ℎ(𝐷𝐸𝑆𝑈𝑃)} − (𝐸 ∗ ℎ𝐹3)]

𝐴

[𝑆𝐹𝐶 ∗ 𝑆𝐻𝑃 ∗ 𝐶𝑝(𝐹𝑂) ∗ {𝛥𝑇(𝐹𝑂) + (𝐹 ) ∗ 𝐶𝑝(𝐴𝑖𝑟) ∗ 𝛥𝑇(𝐴𝑖𝑟) + 𝐻𝐻𝑉}]

11

(3.8)

It contains many variables that have not been discussed. The change in Temperature

of the Fuel Oil “ΔT(FO)” is 100 °F based on a specified range of 100 °F to 200 °F. The

Heat Capacity of Air “Cp(Air)” is equal to 0.2438 BTU-per-pound-degree-Fahrenheit

and the Heat Capacity of the Fuel Oil ”Cp(FO)” is 0.46 BTU-per-pound-degreeFahrenheit. The Higher Heating Value “HHV” is 18500 BTU per pound and the amount

of Excess Air is 0.05, or 5%.

These are a lot of component values to throw at you at once; therefore we will be

looking at the alternate approach in solving the Boiler Efficiency. It involves fewer

values and a simpler equation:

𝐵𝑜𝑖𝑙𝑒𝑟 𝐸𝑓𝑓𝑖𝑐𝑖𝑒𝑛𝑐𝑦, “𝐸𝑓𝑓(𝐵𝐿𝑅)” =

[(𝐻𝑜 + 𝐻𝑎) − 𝐻𝐿]

[𝐻𝑜 − 𝐻𝑎]

(3.9)

This equation will be the equation we will use to solve for the Boiler Efficiency.

Each of these values will be described and solved in the subsequent sections.

3.1.5.1 Heat Input

The Heat Input “Ho” is the higher heating value of the fuel oil burned, corrected for

specific heat at constant pressure, plus the heat in the oil above 100 degrees Fahrenheit.

Its equation is laid out below.

𝐻𝑜 = 𝐻𝐻𝑉 + 𝐶𝑝(𝐹𝑂) ∗ 𝛥𝑇(𝐹𝑂)

(3.10)

With this equation, we only have 3 ‘unknowns’. They are the Higher Heating Value

“HHV”, the Heat Capacity of the Fuel Oil “Cp(FO)”, and the Change in Fuel Oil

Temperature “ΔT(FO)”. Each of these values is known; therefore “Ho” is 18557.5

BTUs-per-pound.

𝐻𝑒𝑎𝑡 𝐼𝑛𝑝𝑢𝑡 “𝐻𝑜”

𝐵𝑇𝑈

𝐵𝑇𝑈

) + (0.46

∗ 100 °𝐹)

𝑙𝑏

°𝐹 ∗ 𝑙𝑏

𝐵𝑇𝑈

= 18557.5

𝑙𝑏

= (18500

3.1.5.2 Heat Added by Air Heater

The Heat Added to the Combustion Air by the Air Heater “Ha” is equal to the product of

the Heat Capacity of the Fuel Oil “Cp(FO)”, the Air to Fuel Ratio “A / F”, and the

12

Difference in the Temperature of Air leaving the Steam Air Heater “T2” and the

Temperature of Air entering the Steam Air Heater “T1”. The equation is listed below for

your convenience.

𝐻𝑎 = 𝐶𝑝(𝐹𝑂) ∗

𝐴

∗ (𝑇2– 𝑇1)

𝐹

(3.11)

The Heat Capacity of the Fuel Oil “Cp(FO)”is equal to 0.46 BTUs-per-pounddegree-Fahrenheit. The Air to Fuel Ratio (A/F) “R” is equal to 15.05 pounds Air to

pounds Fuel. The Temperature of Air leaving the Steam Air Heater “T2” is 200 degrees

Fahrenheit and the Temperature of Air entering the Steam Air Heater “T1” is 75 degrees

Fahrenheit. With all the unknowns solved for “Ha”, we can now solve for the Heat

Added to the Combustion Air by the Air Heater “Ha”. “Ha” is calculated to be 865.375

BTUs-per-pound.

3.1.5.3 Stack Loss

The Stack Loss “Hg” is the amount of energy that is lost to external atmosphere via the

stack. To solve for “Hg”, we need the Temperature of the Uptake (Smoke Stack Gas

Temperature). The Uptake Temperature is designated by the term “Tg”.

To solve for Hg we need to use Figure 5. By finding the point on the 5% Excess

Air Line that meets with the Temperature of the Uptake “Tg”, we can find the

approximate value for the Stack Loss. “Tg”, we will assume is right at the temperature of

boiling, 212 degrees. With that in mind, and lining that up with the excess air curve, we

get a Stack loss of about 7.40 [% * 18546 * BTU / lb]. The units for Stack loss can be

condensed into BTUs per pound. This is done by multiplying the Stack loss initial value

by %-18546/100%. This gets us a Stack Loss of 1372.404 BTUs per pound of Fuel Oil.

13

Figure 5 - Stack Loss, Hg (5 p. 54)

% ∗ 18546 𝐵𝑇𝑈

𝑆𝑡𝑎𝑐𝑘 𝐿𝑜𝑠𝑠 “𝐻𝑔” = 7.40 [(

)∗

]

100%

𝑙𝑏

𝐵𝑇𝑈

= 1372.404

𝑙𝑏(𝐹𝑂)

(3.12)

3.1.5.4 Heat Radiation

The Heat Radiation “Hu” is unaccounted for losses and manufacturer's margin (R-U and

M) therefore it simply is 1.1415 percent of the Heat Input “Ho”. Since “Ho” is 18557.5

BTUs per pound, when we calculate “Hu” we get a value of 262.588625 BTUs per

pound.

𝐻𝑒𝑎𝑡 𝑅𝑎𝑑𝑖𝑎𝑡𝑖𝑜𝑛 “𝐻𝑢” = (1.415% ∗ 𝐻𝑜) = 262.589

14

𝐵𝑇𝑈

𝑙𝑏

(3.13)

3.1.5.5 Heat Loss

The Heat Loss “HL” is equal to the sum of the Heat Radiation “Hu” and the Stack Loss

“Hg”. Since “Hu” is 262.588 BTUs-per-pound and “Hg” is 1372.404 BTUs-per-pound,

we get a Heat Loss “HL” of 1633.323 BTUs-per-pound.

𝐻𝐿 = 𝐻𝑢 + 𝐻𝑔 = 1633.323

𝐵𝑇𝑈

𝑙𝑏

(3.14)

3.1.5.6 Boiler Efficiency Answer

The Boiler Efficiency can now be solved by the formula below.

𝐵𝑜𝑖𝑙𝑒𝑟 𝐸𝑓𝑓𝑖𝑐𝑖𝑒𝑛𝑐𝑦, 𝐸𝑓𝑓(𝐵𝐿𝑅) =

[(𝐻𝑜 + 𝐻𝑎) − 𝐻𝐿]

[𝐻𝑜 − 𝐻𝑎]

(3.15)

Once the values from Sections 3.1.5.1 through 3.1.5.5 have been solved and

plugged into the Boiler Efficiency Equation, we get a Boiler with an Efficiency of 91.59

Percent. This efficiency value is rated at maximum continuous power.

𝐸𝑓𝑓(𝐵𝐿𝑅) = 0.9159 = 91.59%

15

3.2 Superheater

3.2.1

Component Detail

The Superheater is a series of tubes inside the Boiler. It’s meant to increase the

temperature of steam past its saturation state and into the superheated state. This

superheated steam is considered ‘dry steam’ as it has no water moisture in it.

Moisture is extremely detrimental to any steam turbine; it can cause excessive

pounding of the turbine, it can cause extreme erosion of the turbine blades, and in some

cases it can rip the turbine apart. A turbine spinning over 8000 revolutions-per-minute, if

shaken loose from the turbine, can easily shred through the casing. There have been

cases of a spinning turbine blade breaking its shell and whirling out into the engine room

and destroying other engine-room components.

Figure 6 - Superheater Tubes (Exposed) shows a section of Superheater Tubes that

resides in typical marine boiler.

Figure 6 - Superheater Tubes (Exposed) (6)

16

3.2.2

Superheater Outlet Flow

This section will continue from Section 3.4.2, which talks about solving for the Total

Flow “G”. Next I need to solve for Superheater Outlet Flow "G," which is the flow of

the superheated steam leaving the boilers' superheaters. What we know so far are the

values “G” and “Q(LOST EST)”.

𝐺 = 𝑄(𝑇𝐺) + 𝑄(𝐷𝐸𝑆𝑈𝑃) + 𝑄(𝐿𝑂𝑆𝑆)

(3.16)

𝑄(𝐿𝑂𝑆𝑇 𝐸𝑆𝑇) = 0.005 ∗ 𝐸(𝐸𝑆𝑇)

(3.17)

Since I do not have “E”, I have to substitute in “E(EST),” which is the Estimated

value for the Energy of the System. “E(EST)” is important to have solved, as it will

provide a good estimation of the marine steam power plant systems energy. However,

since we don't have “E(EST)”, we need to find it using this given equation.

𝐸(𝐸𝑆𝑇) = (𝑆𝑅(𝑁𝐸) ∗ (

𝑆𝐻𝑃

))

𝐸𝑚

𝑆𝐻𝑃

− (0.25 ∗ (𝑆𝑅(𝑁𝐸) ∗ (

)))

𝐸𝑚

+ [0.25 ∗ (𝑆𝑅(𝑁𝐸) ∗ (

= 139648.4

(3.18)

𝑆𝐻𝑃

ℎ𝐵 − ℎ𝑤

))] ∗ [

]

𝐸𝑚

ℎ𝑜 − ℎ𝑤

𝑙𝑏

ℎ𝑟

We have now just solved for our Estimated Energy of the System, “E(EST).” This

value of 139648.4 is for the whole system. With this value we can solve a variety of

other estimated values. For the estimated desuperheated steam flow, “Q(DESUP EST)”.

𝑄(𝐷𝐸𝑆𝑈𝑃 𝐸𝑆𝑇) = 0.04 ∗ 𝐸(𝐸𝑆𝑇)

(3.19)

This last value can now be plugged into the equation to solve for “G(EST)”.

𝐺(𝐸𝑆𝑇) = 𝑄(𝑇𝐺 𝐸𝑆𝑇) + 𝑄(𝐷𝐸𝑆𝑈𝑃 𝐸𝑆𝑇) + 𝑄(𝐿𝑂𝑆𝑆 𝐸𝑆𝑇)

𝐺(𝐸𝑆𝑇) = (12500) ∗ (0.04 ∗ 𝐸(𝐸𝑆𝑇)) + (0.005 ∗ 𝐸(𝐸𝑆𝑇))

= 18910.5

(3.20)

(3.21)

To solve the Flow per one Boiler, the Estimated E “E(EST)” value must be divided

by two, since this system has installed two boilers that will be running simultaneously.

𝑄(𝐵𝐿𝑅 𝐸𝑆𝑇) =

𝐸(𝐸𝑆𝑇)

𝐵𝑇𝑈

= 9455.25

2 𝐵𝑜𝑖𝑙𝑒𝑟𝑠

𝑙𝑏

17

(3.22)

3.3 Main Propulsion Turbine

The Main Propulsion (or High Pressure, “HP”) Turbine is where the superheated steam

from the boiler is directed to and through to generate a spinning action of the blades of

the turbine. This spinning action in turn generates rotation of reduction gears and

pinions, which in turn spins the main shaft and the propeller to generate movement in

water.

The more nozzles open, the greater the flow, the greater the shaft revolutions-perminute, and generally speaking the greater the speed of the ship.

Figure 7 - Main Propulsion Turbine (Cross Sectional) (7)

3.3.1

Steam Rate (Non-Extraction)

Steam turbines differ according to whether or not a portion of the steam flow is extracted

from the turbine’s intermediate portion. Extraction is where a minor portion of the steam

flow leaves the turbine through a different path to partially reheat the water fed back to

the boiler. Extraction can significantly increase the efficiency of the marine steam power

plant. However, this power plant does not call for an Extraction Turbine; therefore this

turbine will be classified as a ‘Straight-Tube Turbine,’ which means Non-Extraction

Turbine.

18

The equation for Steam Rate Non-Extraction “SR(NE)” is defined as

𝑆𝑅(𝑁𝐸) =

2544.4

(ℎ𝑜 − ℎ𝑤)

(3.23)

where the 2544.4 BTUs-per-hour is equal to 1 horsepower, hp.

The SR(NE) should have a value between five and six. In order to solve for

SR(NE), I need the two unknowns, “hw” and “ho”. The first term “ho” is the Enthalpy at

the Initial Pressure and Temperature Point.

ℎ𝑜 = ℎ(𝑃𝑜, 𝑇𝑜) = 1481.998

𝐵𝑇𝑈

𝑙𝑏

(3.24)

The second term “hw” is the Enthalpy of the ‘Wheel Used Energy.’ It is equal to

“hi” (the State Line End Point, from Section 3.3.3) plus “EL” (Exhaust Loss, from

Section 3.3.6).

ℎ𝑤 = ℎ𝑖 + 𝐸𝐿 = 997.911

𝐵𝑇𝑈

𝑙𝑏

(3.25)

This gives us an enthalpy of “hw” to be equal to 997.911 BTUs-per-pound, and an

enthalpy of “ho” to be equal to 1481.998 BTUs-per-pound.

The Steam Rate can now be solved since I have “ho” and “hw”.

𝑆𝑅(𝑁𝐸) =

2544.4

𝑙𝑏

= 5.256

(ℎ𝑜 − ℎ𝑤)

ℎ𝑟

The Steam Rate (Non-Extraction) falls in-between the range of five to six as was

previously noted. The next Section 3.3.2 will show step-by-step how to solve for the

Available Energy of the Main Propulsion Turbine.

3.3.2

Available Energy

Available Energy, AE, is the theoretical total amount of energy (in BTU/lb) that the

turbines see. The difference in enthalpies of points “ho” and “hp” is theoretically what

the Available Energy is equal to.

𝐴𝐸 = ℎ𝑜 − ℎ𝑝

(3.26)

Since “ho” was previously defined (Initial Pressure and Temperature Enthalpy) and

solved in Section 3.3.1, “hp” is the remaining unknown needed solve for AE.

ℎ𝑜 = ℎ(𝑃𝑜, 𝑇𝑜) = 1482

19

𝐵𝑇𝑈

𝑙𝑏

(3.27)

The Entropy, given by the term “So” in this instance, is solved at the Initial Pressure

and Temperature Point.

As described by Wikipedia about Entropy:

“Entropy is a thermodynamic property that can be used to determine the energy

available for useful work in a thermodynamic process, such as in energy conversion

devices, engines, or machines. Such devices can only be driven by convertible energy,

and have a theoretical maximum efficiency when converting energy to work. During this

work, entropy accumulates in the system, which then dissipates in the form of waste

heat.” (8)

𝑆𝑜 = 𝐸𝑛𝑡𝑟𝑜𝑝𝑦 𝑎𝑡 𝑃𝑜𝑖𝑛𝑡𝑠 (𝑃𝑜, 𝑇𝑜) 𝑢𝑠𝑖𝑛𝑔 Figure 8

= 1.651915

𝐽

𝐾

Figure 8 – Propulsion Turbines Replacement Factors (5 p. 42)

20

(3.28)

The Entropy at Point “Po”, “To” is now known; solving for the Enthalpy (“hp”) is

what remains. The term “hp” is the Enthalpy, in BTU/lb, of points “Po”, “To” and of the

Pressure in the Main Condenser “P(MN COND)”.

ℎ𝑝 = ℎ@(𝑆𝑜, 𝑃(𝑀𝑁 𝐶𝑂𝑁𝐷)) = 907.2985

𝐵𝑇𝑈

𝑙𝑏

(3.29)

Now that we have solved for the Enthalpy of the top point (Boiler Temperature and

Pressure) and of the low point (Main Condenser Temperature and Pressure) we can solve

for the difference of the two. The difference we have already identified to be the

Available Energy.

𝐴𝐸 = ℎ𝑜– ℎ𝑝 = 574.6993

3.3.3

𝐵𝑇𝑈

𝑙𝑏

(3.30)

Efficiency of the State Line

The Efficiency of the State Line, “Eb”, is a way to solve for the Basic Efficiency of the

Main Propulsion Turbine Hear for Non-Extraction Operation. It is solved from either

using Figure 9 - Main Propulsion Turbine Basic Efficiency or by using the following

equation.

𝐸𝑏 =

(ℎ𝑜 − ℎ𝑖)

= 0.86494 = 86.494 %

𝐴𝐸

Figure 9 - Main Propulsion Turbine Basic Efficiency (5 p. 34)

21

(3.31)

3.3.4

Temperature Correction Factor

The Temperature Correction Factor “f(t)” is what is used to correct for the Throttle

Temperature (Temperature of the Steam entering the Main Turbine). It’s solved either

using the Polynomial Equation derived in the Appendices A.2.3 - Temperature

Correction Factor or by using Figure 10 - Throttle Temperature Correction.

Figure 10 - Throttle Temperature Correction (5 p. 35)

I used the derived equation in the Appendices to solve for “f(t)” and then doublechecked the answer against the table to ensure the value is correct. The Temperature

Correction Factor was found to be

𝑓(𝑡) = 1.01202

3.3.5

State Line Energy

The State Line Energy “UE(SL)” will determining the actual Energy for the State Line

for the Main Propulsion system. Since we have already solved for the Available Energy

22

“AE”, Basic Efficiency (Eb), and the Temperature Correction Factor (f(t)), the State

Line Energy can be calculated.

𝑈𝐸(𝑆𝐿) = 𝐴𝐸 ∗ 𝐸𝑏 ∗ 𝑓(𝑡) = 497.0778

𝐵𝑇𝑈

𝑙𝑏

(3.32)

State Line End Point “SLEP” is the energy of the Desuperheated Steam. It is solved

using Figure 11 - State Line.

𝑆𝐿𝐸𝑃 = ℎ𝑖 = ℎ𝑜– 𝑈𝐸(𝑆𝐿) = 984.92

Figure 11 - State Line (5 p. 38)

23

𝐵𝑇𝑈

𝑙𝑏

(3.33)

3.3.6

Exhaust Loss

3.3.6.1 Exhaust Loss Theory

The Exhaust Loss, “EL”, is the amount of steam that is ‘lost’ to the turbine system. This

loss, generally speaking, is the steam that isn’t converted to Work through the turbine; it

bypasses the blades one way or another. The Exhaust Loss in this system dumps straight

to the Condenser, whereas with an Extraction Turbine some Exhaust Loss actually is

rerouted to reheat the incoming boiler water.

To start off, an “EL” value between 4,000 and 6,000 pounds-per-hour is the target

range to get what is called an ‘Annulus Area’ “Aa”. The Annulus Area is the average

cross section area of flow. I am going to assume that our Steam Rate, Non-Extraction

“SR(NE)” is going to be 5.5 (for conditions “Po”, “To”, and “P(MN COND)”). After

solving for the two different values (solved in the Appendices), I got the answers. For a

flow of 4000 lb/hr the Exhaust Loss “EL” is equal to 9.81118 lb/hr, and for a flow of

6000 lb/hr, 17.19019 lb/hr. These values provide the general range of where our Exhaust

Loss lies. It is somewhere between approximately 9.8 lb/hr and 17.2 lb/hr. The next

section will solve for the definitive answer.

3.3.6.2 Annulus Area and Solving of Exhaust Loss

Remembering that the Annulus Area “Aa” is the average cross sectional area of flow for

the Main Turbine, we can now solve for it. The new variable below, “X,” is the actual

Condenser Flow.

𝑆𝐻𝑃

( 𝐸𝑚 )

𝐴𝑎 = 𝑆𝑅(𝑁𝐸) ∗

𝑃(𝑀𝑁 𝐶𝑂𝑁𝐷) ∗ 𝑋

(3.34)

“𝐴𝑎” 𝑎𝑡 4,000 “𝐸𝐿” 𝐹𝑙𝑜𝑤 = 31.031 ft²

“𝐴𝑎” 𝑎𝑡 6,000 “𝐸𝐿” 𝐹𝑙𝑜𝑤 = 20.688 ft²

The closest Annulus Area that we can pick will be a value of 25, as it’s the mean of

the two boundaries solved above. The Actual Condenser Flow “X” will come from the

Annulus Area.

𝑋 = 𝑆𝑅(𝑁𝐸) ∗

𝑆𝐻𝑃

( 𝐸𝑚 )

(𝑃(𝑀𝐴𝐼𝑁 𝐶𝑂𝑁𝐷) ∗ 𝐴𝑎)

24

= 4965.019

𝑙𝑏

ℎ𝑟

(3.35)

With this exact Condenser Flow Value, we can use it to solve for the Exhaust Loss

utilizing the curve fit equation (Appendices A.2.5).

𝐸𝐿 = 12.991

3.3.7

𝐵𝑇𝑈

𝑙𝑏

Mechanical and External Efficiency

The Mechanical and External Efficiency “Em” is the ratio of the Shaft-Horsepower to

the Shaft-Horsepower-plus-Losses.

𝑆𝐻𝑃

(𝑆𝐻𝑃 + 𝐿𝑜𝑠𝑠𝑒𝑠)

(3.36)

(100 − (3.5 + 𝑅𝐿))

100

(3.37)

𝐸𝑚 =

𝐸𝑚 =

In order to solve for “Em” I need all of the Losses of the system. The losses are

given by the following equation below.

𝐿𝑜𝑠𝑠𝑒𝑠 =

(𝑆𝐻𝑃 ∗ (3.5 + 𝑅𝐿))

(100 − (3.5 + 𝑅𝐿))

(3.38)

“RL” is the Astern-Turbine Windage. Windage is essentially friction which occurs

when the turbine blades contact the near-stationary steam when at low or no load

conditions. The Windage losses cause heating of the blades in the last few stages of the

turbine. By utilizing the lowest area available exhaust end of the astern casing, windage

losses can be reduced.

𝑅𝐿 = 0.33 ∗ 𝑃(𝑀𝑁 𝐶𝑂𝑁𝐷) = 0.495 "𝐻𝑔

Now that I have solved for “RL,” the Total Loss equation can be solved.

𝐸𝑚 =

𝑆𝐻𝑃

𝑆𝐻𝑃 ∗ (3.5 + 𝑅𝐿)

(𝑆𝐻𝑃 + (

))

100 − (3.5 + 𝑅𝐿)

= 0.96005

This can be verified utilizing the second equation given above.

𝐸𝑚 =

(100 − (3.5 + 𝑅𝐿))

= 0.96005

100

25

(3.39)

3.3.8

Gland Leak Off

Gland Leak Off is just that, steam and air that leaks off from the glands of the turbine.

For a typical cross-compound marine propulsion turbine with single flow low pressure

elements, such as what this system is using, we may make a few assumptions.

The first is that the Total Leak Off Steam “Q(MN LEAK OFF)” is equal to 200

pounds-per-hour multiplied by 0.3 % of the Shaft Horse Power

𝑄(𝑀𝑁 𝐿𝐸𝐴𝐾 𝑂𝐹𝐹) = 200 + (0.003 ∗ 𝑆𝐻𝑃) = 297.5

𝑙𝑏𝑠

ℎ𝑟

(3.40)

and the second is that the Enthalpy of Leak Off Steam “h(MN LEAK OFF)” is

equal to the equation below.

ℎ(𝑀𝑁 𝐿𝐸𝐴𝐾 𝑂𝐹𝐹) = ℎ𝑜 − 0.4 ∗ 𝑈𝐸𝑊

(3.41)

However, to solve for “h(MN LEAK OFF)”, we need to solve for “UE(W).” The

Wheel Used Energy, “UE(W)” is equal to the Initial Enthalpy minus the State Line End

Point (Remaining Energy). This brings us to solve for “UE(W).”

𝑈𝐸(𝑊) = ℎ𝑜 − ℎ𝑤 = 484.087

𝐵𝑇𝑈

𝑙𝑏

(3.42)

Now that we have the Wheel Used Energy, we can solve for the enthalpy of the

Leak-Off Steam.

ℎ(𝑀𝑁 𝐿𝐸𝐴𝐾 𝑂𝐹𝐹) = 1288.363

26

𝐵𝑇𝑈

𝑙𝑏

3.4 Power

3.4.1

Power Equation

Horsepower was originally defined to compare the output of steam engines with the

power of draft horses in continuous operation. The unit is used to measure the output of

piston engines, turbines, electric motors, and various other pieces of machinery. The

power generated is usually defined in terms of kilo-Watts.

𝑊𝐻𝑃 = 𝑃 = (

3.4.2

𝑆𝐻𝑃

) = 33852.4 ℎ𝑝

𝐸𝑚

(3.43)

Estimated Total Flow Rate from Superheaters

Next I want to solve for the Total Flow Rate leaving the Superheaters in the Boilers that

does not reach the Main Turbine, “G.” The equation for “G” is

𝐺 = 𝑄(𝐷𝐸𝑆𝑈𝑃) + 𝑄(𝑇𝐺) + 𝑄(𝐿𝑂𝑆𝑇)

(3.44)

“G” is the Total Flow Rate, as it contains what is used by the Turbo Generator, what

is lost, and what is desuperheated. Since “G” is equal to these three factors, I will be

solving for “Q(DESUP)”, “Q(TG)”, and “Q(LOST)”. The following three equations

which come from MARINE STEAM POWER PLANT HEAT BALANCE PRACTICES (5))

lay out the needed values.

𝑄(𝑇𝐺) = 𝑆𝑅(𝑇𝐺) ∗ 𝑘𝑊(𝑇𝐺)

𝑄(𝐿𝑂𝑆𝑇) = 0.005 ∗ (𝐸) = 824.5402

(3.45)

𝑙𝑏

ℎ𝑟

𝐵𝐻𝑃

𝑄(𝐷𝐸𝑆𝑈𝑃) = 𝑆𝑅(𝐹𝑃) ∗ (

) ∗ 𝐸(𝐸𝑆𝑇) + 3000

𝐸

(3.46)

(3.47)

Where “kW(TG)” is the Turbo Generators kilo-Watt Load and “E(EST)” is the

Energy Estimate. Instead of using “E”, we are going to be using “E(EST)”, which is the

Energy Estimate, instead to find estimated values of “Q(TG)”, “kW(TG)”, and

“Q(DESUP)” (as we don’t have “E” yet).

𝐸(𝐸𝑆𝑇) − 𝐺(𝐸𝑆𝑇) = 𝑆𝑅(𝑁𝐸) ∗ (

𝑆𝐻𝑃

ℎ(𝐵) − ℎ𝑤

(3.48)

) ∗ [1 − 0.25 ∗ (1 −

)]

(ℎ𝑜 − ℎ𝑤)

𝐸𝑚

To solve for “h(B)”, I need the average of “hB1”, “hB2”, and “hB3”. “hB2” is the

Enthalpy of the Steam Air Heaters. “hB1” is equal to the average of “hB2” and the

27

Initial Enthalpy. Finally, “hB3” is equal to “hB2” and the State Line End Point Enthalpy

average.

ℎ𝑜 + ℎ𝐵2

𝐵𝑇𝑈

= 1377.934

2

𝑙𝑏

𝐵𝑇𝑈

ℎ𝐵2 = ℎ(𝑆𝐴𝐻) = 1273.871

𝑙𝑏

ℎ𝐵2 + ℎ𝑖

𝐵𝑇𝑈

ℎ𝐵3 =

= 1129.396

2

𝑙𝑏

ℎ𝐵1 + ℎ𝐵2 + ℎ𝐵3

𝐵𝑇𝑈

ℎ(𝐵) =

= 1260.4

3

𝑙𝑏

ℎ𝐵1 =

(3.49)

(3.50)

(3.51)

(3.52)

Since “E(EST)” is being solved to find a general area value, I need to find its

components in estimated form. “Q(TG EST)” is equal to “SR(TG EST)” multiplied by

“kW(TG EST)”. I need to find “SR(TG EST)” and “kW(TG EST)”. The values listed

below are rough estimates that I am assuming in order to find the Total Flow Rate “G”,

which will be solved later in this project.

𝑆𝑅(𝑇𝐺 𝐸𝑆𝑇) = 10

𝑙𝑏𝑠

ℎ𝑟 ∗ 𝑘𝑊

𝑘𝑊(𝑇𝐺 𝐸𝑆𝑇) = 1250𝑘𝑊

With these two values we may now solve for the Estimated TG Flow:

𝑄(𝑇𝐺 𝐸𝑆𝑇) = 1250𝑘𝑊 ∗ 10

𝑙𝑏

ℎ𝑟 ∗ 𝑘𝑊

𝑙𝑏

= 12500 (~𝑎𝑝𝑝𝑟𝑜𝑥𝑖𝑚𝑎𝑡𝑒𝑙𝑦 0.4 ∗ 𝐸(𝐸𝑆𝑇))

ℎ𝑟

(3.53)

3.4.2.1 Desuperheated Steam Estimate Flow

The last of the things to find for “G” is the Flow of Desuperheated Steam, or in this case,

the Estimated Flow “Q(DESUP EST).”

𝐵𝐻𝑃

𝑄(𝐷𝐸𝑆𝑈𝑃 𝐸𝑆𝑇) = 𝑆𝑅(𝐹𝑃) ∗ (

) ∗ 𝐸(𝐸𝑆𝑇)

𝐸

(3.54)

The Term “DESUP” is Desuperheated steam, or steam that has moisture in it and is

below its superheated state. “Q(DESUP EST)” will not be solved until after the Steam

Rate of the Feed Pump, “BHP / E” and “E(EST)” are found (Section 3.2.2).

28

3.4.3

Power Matrix

Using Table 10 - Power Matrix, Page 100, we can derive the equation needed to solve

the Power.

𝑃

𝐸−𝐺

𝐸– 𝐺 − 𝐵1

= (

)+(

)

𝑎

𝑏

𝐸 − 𝐺 − 𝐵1 − 𝐵2 − 𝑄(𝑀𝑁 𝐿𝐸𝐴𝐾 𝑂𝐹𝐹)

+(

)

𝑐

(3.55)

𝐸 − 𝐺 − 𝐵1 − 𝐵2 − 𝐵3 − 𝑄(𝑀𝑁 𝐿𝐸𝐴𝐾 𝑂𝐹𝐹)

+(

)

𝑑

Since 𝑊𝐻𝑃 =

𝑆𝐻𝑃

𝐸𝑚

, we can solve for “P”:

𝑃 = 𝑊𝐻𝑃 =

𝑆𝐻𝑃

𝐸𝑚

29

= 33852.4 ℎ𝑝

(3.56)

3.5 High Pressure Heater (Economizer)

3.5.1

Component Detail

The High Pressure Heater is also known as the ‘Third Stage Heater’ or the

‘Economizer’. The High Pressure Heater serves as the last reheat before the water is sent

back into the boiler. Usually, the heat stack (comparable to a chimney in a house) is used

to supply the heat for the Economizer; however an Economizer cannot be too efficient. If

the temperature exchange is too great and the stack’s temperature drops below its

condensation point, then the stack will not be able to perform its purpose of carrying out

soot and ash out of the system. An economizer in this way is designed to be inefficient,

so as to allow the stack to perform properly. Figure 12 below shows a Typical

Economizer and its associated components.

In this section I will solve for the High Pressure “HP” Heater’s mass flow, “B1”,

using the First Law of Thermodynamics (Conservation of Energy), with constant volume

equal to the High Pressure Heater “HP HTR”.

Figure 12 - Typical Economizer (9)

30

3.5.2

Terminal Temperature Difference and Temperature Difference

The Terminal Temperature Difference “TTD” (in heaters) is the difference between the

saturation temperature of the condensed steam (heating steam) and the outlet

temperature of the fluid being heated. If the superheat temperature of the heating steam

is two-hundred degrees Fahrenheit or greater than the saturation temperature, a

desuperheating section can be used. In this section, it will be; therefore our “TTD” will

be equal to zero. If counter flow is assured for the drain cooling section of the heater

(which it will), a temperature difference of 10 degrees Fahrenheit will be used between

the feedwater inlet temperature and the drain outlet temperature.

Just to recap what we just learned:

𝑇𝑒𝑟𝑚𝑖𝑛𝑎𝑙 𝑇𝑒𝑚𝑝𝑒𝑟𝑎𝑡𝑢𝑟𝑒 𝐷𝑖𝑓𝑓𝑒𝑟𝑒𝑛𝑐𝑒 “𝑇𝑇𝐷” = 0 °𝐹

𝑇𝑒𝑚𝑝𝑒𝑟𝑎𝑡𝑢𝑟𝑒 𝐷𝑖𝑓𝑓𝑒𝑟𝑒𝑛𝑐𝑒 “𝑇𝐷”

= 10 °𝐹 (𝐶𝑜𝑢𝑛𝑡𝑒𝑟𝑓𝑙𝑜𝑤 𝐻𝑒𝑎𝑡 𝐸𝑥𝑐ℎ𝑎𝑛𝑔𝑒)

(3.57)

(3.58)

Since a Counter-flow Heat Exchanger is being utilized with this Steam Driven

Power Plant, The Temperature Difference “TD” is equal to ten degrees-Fahrenheit.

3.5.3

Heat Exchange Pressure, Temperatures and Enthalpies

For main steam systems, a seven-percent ‘Pressure Loss’ is from the boiler superheater

outlet to the maneuvering throttle valve inlet flange when the turbine handle valves are

utilized. A seven-percent loss is standard for this type of system, as this system is not

considered a ‘Main Steam System,’ a ‘Desuperheated System,’ or a ‘Bleed (Exhaust)

System Less than 30 psia.’ Those values different from our seven percent; therefore they

will not be used. Exhaust steam will in this section of the project be assumed to have no

loss in enthalpy.

𝑃(𝐻𝑃 𝐻𝑇𝑅 𝑆𝐻𝐸𝐿𝐿) = (1.00 − 0.07) ∗ 𝑃(𝑆1)

= 260.6527 𝑝𝑠𝑖𝑔

(3.59)

The temperatures and enthalpies we are looking for in this section are that of the

High Pressure Heater Shell (Outlet) and the Third Stage Heater (“HP Heater”) Inlet. To

find the Temperature Outlet, we need the Temperature of the Saturated Steam at the HP

Heater Shell. That number needs to have the Terminal Temperature Difference

subtracted from it to find “TF3,” which we will use to designate this value.

31

𝑇𝐹3 = (𝑇(𝑆𝐴𝑇)@𝑃(𝐻𝑃 𝐻𝑇𝑅 𝑆𝐻𝐸𝐿𝐿))– 𝑇𝑇𝐷 = 404.67 °𝐹

(3.60)

With this value, we will then find the Enthalpy “hF3” at this point. We get:

ℎ𝐹3 = ℎ(𝑓)@𝑇𝐹3 = 1202.042

𝐵𝑇𝑈

𝑙𝑏

(3.61)

We have now solved for the Temperature (404.67 °F) and Enthalpy (1202.042

BTU/lb) of the High Pressure Heater Outlet. To find the HP Heater Inlet Temperature

and Enthalpy, we need to solve for “TF2,” the Temperature calculated before we add the

TTD to it, and “hF2”, which is the Enthalpy at the Direct Contact Heater. To solve for

the Inlet Enthalpy, “hF2”, we will use the following equation.

ℎ𝐹2 = ℎ𝐹2@𝑃(𝐷𝐶 𝐻𝑇𝑅) + (

𝑣 ∗ 𝛥𝑃 ∗ 144

)

𝐸𝑓𝑓(𝐹𝑃) ∗ 778

(3.62)

The unknowns in this equation are given below and they both are assumptions.

Per the MARINE ENGINEERING DESIGN I REPORT (2 p. 25):

𝛥𝑃 = 70 𝑝𝑠𝑖𝑔

(3.63)

𝐸𝑓𝑓(𝐹𝑃) = 0.7

(3.64)

This leaves us with an Inlet Enthalpy “hF2” around 1170 BTU/lb and an Inlet

Temperature “TF2”, which is the Temperature at Enthalpy “hF2,” around 272 °F.

ℎ𝐹2 = 1171.367

𝐵𝑇𝑈

𝑙𝑏

𝑇𝐹2 = 271.955 °𝐹

Since the Third Stage Heater is a Heat Exchanger, we need to find a couple of

values associated with it. The flow of the incoming heat exchanging liquid (which is

saturated steam from the Main Propulsion Turbine Exhaust) is given from the equation:

ℎ𝐹3 − ℎ𝐹2

𝑙𝑏

𝐵1 = 𝐸(𝐸𝑆𝑇) ∗ (

) = 164108

ℎ𝐵1 − ℎ𝐷3

ℎ𝑟

(3.65)

This flow is considered constant through the Third Stage Heater, however the

Enthalpy will change. The Enthalpy of Heating Steam is given by the value “hB1,”

which has already been solved to be equal to 1377.934 BTUs-per-pound. To solve the

Enthalpy of the Heating Steam Exiting the Heat Exchange “hD3”, it will be solved using

the following equation. Temperature “TD3” is determined by utilizing the Steam Charts

at that Enthalpy.

ℎ𝐷3 = ℎ(𝑓)@((𝑇(𝑆𝐴𝑇)@ℎ𝐹2) + 𝑇𝐷) = 1176.884

32

𝐵𝑇𝑈

𝑙𝑏

(3.66)

𝑇𝐷3 = 𝑇(𝑆𝐴𝑇)@ℎ𝐷3 = 282.955 °𝐹

(3.67)

Figure 13 - Economizer Flow (aka "Third Stage Heater") shows the flows we have

identified and labels the flow path for both the Main Steam Flow and the Heat

Exchanger Fluid Flow.

Figure 13 - Economizer Flow (aka "Third Stage Heater") (2 p. 11)

33

3.6 Direct Contact Heater (Deaerating Feed Tank)

3.6.1

Component Detail

The Direct Contact (DC) Heater (aka Deaerating Feed Tank) acts as a holding tank for

the incoming water to the feed pump to pump into the boiler. It provides a positive head

pressure for the Feed Pump, as well as removes non-condensable gas, and preheats the

water before it’s pumped into the boiler.

The figure below, (Figure 14), show a cross section of a DC Heater with a water and

steam flow path. Notice how it acts as a retention tank for water, as well as allowing

non-condensable gases to be vented out the top.

Figure 14 - Typical DC Heater (Deaerating Feed Tank) (10)

34

3.6.2

DC Heater and Auxiliary Exhaust Pressure

The Pressure of the Direct Contact Heater is a very small fraction of the Initial Pressure

(usually 1/10th the pressure), as one of its functions is meant to provide a positive head

pressure on the Feed Pump so that no air has the opportunity to be entrapped in the

water.

“𝑃𝑜”, 𝑖𝑛 𝑝𝑠𝑖𝑎

𝑃(𝐷𝐶 𝐻𝑇𝑅) = 0.1 ∗ (

)

2

(3.68)

This value should fall within a range of forty to fifty psia. After substituting in the

Initial Pressure, “Po” (in psia), we get:

864.696

𝑃(𝐷𝐶 𝐻𝑇𝑅) = 0.1 ∗ (

) = 43.235 𝑝𝑠𝑖𝑎

2

This value falls within the range we set; therefore our DC Heater Pressure is an

acceptable value. To solve for the Auxiliary Exhaust Pressure “P(AUX EXH)”, which is

the pressure of the Steam Exhaust of the Feed Pump, it’s found by adding five psia to

that of the DC Heater.

𝑃(𝐴𝑈𝑋 𝐸𝑋𝐻) = 𝑃(𝐷𝐶 𝐻𝑇𝑅) + 5 = 48.235 𝑝𝑠𝑖𝑎

(3.69)

3.6.2.1 Brake Horsepower

The Brake Horsepower “BHP” is equal to the specific volume at the DC “v(DC HTR)”

multiplied by the Change in Pressure Overall (highest to lowest point) “ΔP,” multiplied

by 144, divided by 778, and finally divided by the Efficiency of the Feed Pump

“Eff(FP)”. The specific volume is solved at the Pressure of 43.2348, we get a specific

volume equal to 0.0171872 ft^3/lb. The change in pressure “ΔP” we are going to be

assuming is approximately 1000 psi, so this will be our value. The Efficiency of the Feed

Pump will be assumed to be 70%, or 0.7. This leaves us with the equation for “BHP”

with all factors solved.

𝐵𝐻𝑃 =

3.6.3

𝑣(𝐷𝐶 𝐻𝑇𝑅) ∗ 𝛥𝑃 ∗ 144

= 1706.42 ℎ𝑝

778 ∗ 𝐸𝑓𝑓(𝐹𝑃)

(3.70)

DC Heater Flow Rate to Feed Pump

The mass flow of the Direct Contact Heater to the Feed Pump is solved by multiplying

the Steam Rate Non-Extraction with the Brake Horsepower divided by the Estimated

35

Enthalpy and then multiplied by the Estimated Enthalpy. The value of E(EST) divided

by E(EST) cancels out to equal one. Therefore:

𝐵𝐻𝑃

𝑄(𝐹𝑃) = 𝑆𝑅(𝑁𝐸) ∗ (

) ∗ 𝐸(𝐸𝑆𝑇) = 𝑆𝑅(𝑁𝐸) ∗ 𝐵𝐻𝑃

𝐸(𝐸𝑆𝑇)

𝑙𝑏

= 4354.290

ℎ𝑟

(3.71)

3.6.3.1 Feed Pump Recirculation

The Feed Pump Recirculation Rate “R” will not be used for this system, so it will have a

value of zero.

𝑅 = 0.00

3.6.4

𝑙𝑏

ℎ𝑟

Direct Contact Vent Condenser

The Low Pressure Heater (also known as the First Stage Heater, which will be

explained more in Section 3.7) plays an important role to the Direct Contact Heater. Its

exit flows directly into what is called the Direct Contact Vent Condenser. This action

creates an effect similar to the Air Ejectors, where a change in pressure (from high to

low) causes the non-condensable gases to come out of solution and be vented out the DC

Heater Vent. This action not only provides this feature, but it also helps maintain a

cooling action on the DC Heater, a more consistent pressure, and allows for storage. If

this feed line were to stop allowing flow into the DC Heater, there would be a time-lapse

before the Feed Pump would stop receiving flow. That’s why the DC Heater acts as a

storage tank. It will allow some time to recuperate whatever losses to the DC Heater

before a loss of feed into the boilers occurs.

36

Figure 15 - Direct Contact Heater Flow (2 p. 12)

The flow through the vent condenser on the Direct Connect Heater is also needed to

be found. A typical flow set by the manufacturer is one-hundred pounds (mass) per hour,

therefore:

𝑄(𝑉𝐸𝑁𝑇 𝐶𝑂𝑁𝐷) = 100

𝑙𝑏

ℎ𝑟

The enthalpy at the Vent Condenser “VENT COND” is going to be denoted by the

term “h(VENT COND)”. It’s equal to the enthalpy of saturated steam at the Pressure of

the DC Heater “P(DC HTR)”.

ℎ(𝑉𝐸𝑁𝑇 𝐶𝑂𝑁𝐷) = ℎ(𝑔)@𝑃(𝐷𝐶 𝐻𝑇𝑅) = 1171.367

𝐵𝑇𝑈

𝑙𝑏

(3.72)

Therefore h(VENT COND) is equal to approximately 1170 BTUs-per-pound.

37

3.7 Low Pressure Heater

3.7.1

Component Detail

The Low Pressure Heater is also known as the First-Stage Heater, and generally it

operates at ambient pressure. It’s usually the first stage of heaters (hence the nickname

“First-Stage Heater”) that preheats the water before being pumped back into the steam

drum in the boiler. The Gland Exhaust Condenser supplies the flow to the Low Pressure

Heater, after a Heat Exchange from vapor from the Feed Water Drain Collection Tank

(“FWDCT”). In the next section, we will discuss the FWDCT’s purpose and equations

associated with it.

Since I chose a Counter-Flow Heat Exchanger for my project (as it has the best heat

exchange properties per single pass), I will be using the Counter-Flow values for this

“TTD1” and each Temperature Difference:

𝑇𝑇𝐷1 = 10 °𝐹 (𝐶𝑜𝑢𝑛𝑡𝑒𝑟 − 𝐹𝑙𝑜𝑤)

(3.73)