OPTIMIZATION OF THE ANALYSIS TIME AND COST ANALYSIS Sanjeev saitia

advertisement

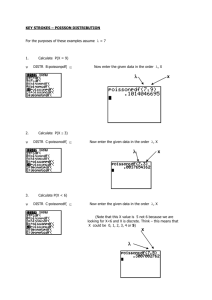

OPTIMIZATION OF THE ANALYSIS TIME AND COST ANALYSIS Sanjeev saitia Pratt & Whitney ABSTRACT: Simulation is widely used in manufacturing for high level planning. Its application is rapidly increasing in other fields such as scheduling, detailed equipment models, and application specific models for use in evaluation, engineering, sales, and marketing. In 1989, the U.S. Department of Defense and Department of Energy specified that simulation and modeling technology is one of the top 22 critical technologies in the Unites States. Another recent focus in task analysis has been placed on simulation of problem solving and other forms of cognitive behavior. In regard to different purposes for which simulation models are used, the following principles are applied: Modeling Principle 6: A model should be evaluated according to its usefulness. From an absolute perspective, a model is neither good or bad, nor is it neutral. Modeling Principle 7: The purpose of simulation modeling is knowledge and understanding, not models. Keeping these principles in mind, this paper provides insight into the model that knowledge the performance of the process and the analyst including time management. The feasibility of doing the time management analytical studies and simulation, and evaluating the performance cost, is demonstrated by successful development of real world problem simulation and verified using statistical empirical results. PROBLEM FORMULATION AND OBECTIVE: In the real world, each project completion takes number of days, hours or months. The analysis time and computation is becoming expensive and time consuming. Since ‘Time is the Money”, every attempt is made to reduce the time of computation. In this project, an application-specific time management problem is analyzed and simulated. In the aircraft engine industry, each engine is composed of different modules. Each module is analyzed from the weight point of view before a best design is achieved. In this paper, the actual time taken (Weight analysis time) by each module of an engine to completion of a project is measured. The objective of this study is to analyze and simulate the actual time taken by each module and to perform cost analysis to achieve the optimum cost of computation and performance. The following figure illustrates the division of an engine into different modules. Aircraft Engine AIRFOIL L FAN AFFA N LPC CORE LPC CORE LPT TEC LPTTEC Nomenclature: Airfoil: LPC : An airfoil is a cross-section of the blade. Low Pressure Compressor ; TEC : Turbine Exhaust Case ; HPC : High Pressure Compressor ; HPT : High Pressure Turbine LPT : Low Pressure Turbine CORE : HPC + D/B + HPT D/B : Diffuser Burner DATA COLLECTION: The Data collection is the crucial and time consuming part of the simulation. The objective of the analysis is half-way achieved based on the quality of data collected. In this case, actual time measured for each weight analysis of different modules, is measured using a watch. The time of start represents when the analysis is started for that particular section. The break time if there is any time taken off for personal or other reasons. The time end is the completion time. The initial means the time of initial run. Since time taken by a project is sometimes more and constitute involvement of other tasks and meetings, the measured data is independent and represents only the analysis time. There is also check phase, which is not considered as the part of this project. It is only the analysis time recorded for this project as represented by initial run . Measured Real Project Data PW8160-OPC3 Dated Component Time of Break Start Time of Time End Taken Minutes 5-Nov 5-Nov 5-Nov 5-Nov 5-Nov 5-Nov 5-Nov 5-Nov 5-Nov 8-Nov 8-Nov 8-Nov 8-Nov 8-Nov 8-Nov 8-Nov 8-Nov 8-Nov DULC HPC D/B HPT CORE CORE LPC LPC LPT LPT LPT HPT HPC LPC LPC-Parametric TEC A/F FAN 11.56 11.58 12.12 12.14 12.2 12.32 1.35 1.45 4.12 9.1 0 0 0 0 0 3.4 3.55 4.4 0 0 0 0 0 0 0 0.3 0 0 0 0 0 0 0 0.05 0 0 Remarks Run # Minutes 11.58 12.11 12.14 12.18 12.31 12.41 1.45 2.55 4.2 9.15 0 0 0 0 0 3.5 4 5 0.02 0.13 0.02 0.04 0.11 0.09 0.1 0.4 0.08 0.05 0.15 0.15 0.25 0.15 150 0.05 0.05 0.2 PROJECT C3 PROJECT C3 PROJECT C3 PROJECT C3 PROJECT C3 PROJECT C3 PROJECT C3 PROJECT C3 PROJECT C3 PROJECT C3 PROJECT C3 PROJECT C3 PROJECT C3 PROJECT C3 PROJECT C3 PROJECT C3 PROJECT C3 PROJECT C3 Initial Initial Initial Initial Check Check Initial Initial Initial Check Check-Add Check-Add Check-Add Check-Add 2,4,6% Parametric Studies Initial Initial Initial Measured Real Project Data (Contd.): STF1156CA Dated Component Time of Break Start Time of Time End Taken Minutes Remarks Run # Minutes 21-Oct A/F 8.35 0 8.45 0.1 ST56CA Initial 21-Oct FAN 9.06 0.1 9.4 0.24 ST56CA Initial 21-Oct FAN 9.5 0 10 0.1 ST56CA Initial 21-Oct FAN-CH 10 0 10.25 0.25 ST56CA Check 22-Oct CORE 2.35 0 3.07 0.32 ST56CA Initial 22-Oct CORE-CH(IP) 3.2 0 3.35 0.15 ST56CA Check -I/p 22-Oct CORE-CH(OP) 3.35 0 4.25 0.5 ST56CA Check-O/P 22-Oct LPC 4.35 0 4.45 0.1 ST56CA Initial 22-Oct LPC-CH 4.45 0 5.55 0.1 ST56CA Check 22-Oct LPT 8.21 0 8.31 0.1 ST56CA Initial 22-Oct LPT 8.32 0 8.35 0.03 ST56CA Check 22-Oct TEC 8.54 0 8.57 0.03 ST56CA Initial 22-Oct TEC 8.57 0 9 0.03 ST56CA Check 22-Oct FAN 9.05 0 9.22 0.17 ST56CA Initial 22-Oct A/F-REV 9.3 0 9.35 0.05 ST56CA Initial 22-Oct FAN-REV 11 0 11.3 0.3 ST56CA Initial 22-Oct FAN-REV 12.5 0 1.15 0.25 ST56CA Initial Break Time of Time Remarks Run # Measured Real Project Data: PW8160 Dated Component Time of Start End Minutes Taken Minutes 6-Oct FAN 12.3 0 1.05 0.35 PW8160 Initial 6-Oct FAN-CH 1.05 0 1.1 0.05 PW8160 Check 6-Oct CORE 2.3 0 4 1.3 PW8160 Initial 6-Oct LPC 1.15 0 1.36 0.21 PW8160 Initial 6-Oct LPC-contd 1.4 0 1.5 0.1 PW8160 Initial 6-Oct LPC-CH 1.5 0 1.55 0.05 PW8160 Check 6-Oct HPC-CH 8.45 0.05 9.27 0.37 PW8160 Check-I/p 6-Oct HPC-CH 9.27 0.05 9.5 0.18 PW8160 Check-O/P 7-Oct LPC-CH 8.35 0.1 8.55 0.1 PW8160 Check 7-Oct LPC-CH 8.55 0.05 9.55 0.05 PW8160 Check 7-Oct LPT 10.27 0 10.5 0.23 PW8160 Initial 7-Oct LPT-CH 10.5 0 11.35 0.45 PW8160 Check 7-Oct LPT-REV 1.1 0 1.32 0.22 PW8160 Initail 7-Oct HPC-CH 1.35 0 2.4 1.05 PW8160 Check 7-Oct HPC-CH 2.4 0 3.15 0.35 PW8160 Check Measured Analysis Time Data: Analysis Time for Each Module (Minutes) TAFF TLP TCR TLTEC Project S. No. AIRFOI L FAN LPC CORE LPT TEC AFFAN LPC CORE LPTTEC 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 5.0 10.0 4.0 4.2 8.7 5.6 6.8 8.9 8.2 7.8 5.3 5.8 9.6 6.1 8.7 9.4 5.5 8.0 7.9 6.9 5.9 9.0 7.8 8.8 4.7 20.0 34.0 35.0 27.2 24.8 28.1 33.4 26.2 31.2 21.7 33.2 25.9 25.3 35.0 31.6 21.0 33.5 30.4 34.3 27.7 24.1 25.7 26.8 29.6 34.2 50.0 10.0 31.0 10.4 31.6 29.9 19.9 43.1 36.9 46.7 16.1 45.9 34.1 38.5 36.1 22.2 46.5 45.1 30.3 44.5 40.5 12.7 44.3 42.9 16.4 41.0 47.0 90.0 87.3 47.1 66.1 67.7 46.7 54.7 56.7 45.9 57.8 61.2 80.8 82.9 86.8 68.6 89.3 65.4 86.9 88.2 83.5 77.0 46.5 78.5 8.0 10.0 23.0 9.4 9.9 13.3 14.0 9.6 15.0 19.3 12.8 20.9 13.8 8.5 12.3 13.7 19.9 21.7 20.3 16.1 19.2 21.7 22.2 8.7 14.0 5.0 3.0 4.0 3.5 4.7 4.4 4.9 3.3 4.0 3.2 3.1 3.8 4.0 4.3 3.3 4.1 3.7 4.7 3.9 4.6 3.8 4.2 4.8 4.5 3.7 25.0 44.0 39.0 31.4 33.5 33.7 40.2 35.1 39.4 29.5 38.5 31.7 34.9 41.1 40.3 30.4 39.0 38.4 42.2 34.6 30.0 34.7 34.6 38.4 38.9 50.0 10.0 31.0 10.4 31.6 29.9 19.9 43.1 36.9 46.7 16.1 45.9 34.1 38.5 36.1 22.2 46.5 45.1 30.3 44.5 40.5 12.7 44.3 42.9 16.4 41.0 47.0 90.0 87.3 47.1 66.1 67.7 46.7 54.7 56.7 45.9 57.8 61.2 80.8 82.9 86.8 68.6 89.3 65.4 86.9 88.2 83.5 77.0 46.5 78.5 13.0 13.0 27.0 12.9 14.6 17.7 18.9 12.9 19.0 22.5 15.9 24.7 17.8 12.8 15.6 17.8 23.6 26.4 24.2 20.7 23.0 25.9 27.0 13.2 17.7 STATISTICAL RESULTS OF THE MEASURED DATA: The statistical analysis of the measured data is tabulated below. The five different distributions are calculated for each modue using four different criteria Ki-suare (2), P-Value, Kolmogorov-Smirnov, and Andereson-Darling. The mode of selection of distribution is prioritized on the basis of Kolmogorov-Simirnov statistical results. TIME STATISTICS OF INDIVIDUAL COMPONENT (Minutes) AFFAN LPC CORE LPT N MIN MAX MEAN MEDIAN STDEV Q1 Q3 25 25 44 35.94 35.1 4.608 32.6 8.75 25 10 50 33.02 36.1 12.7 21.05 44.4 25 41 90 68.14 67.7 16.74 50.9 85.15 25 12.8 27 19.11 17.8 5.03 13.9 23.9 COMPONENT WISE DISTRIBUTION SUMMARY CHART AFFAN STATISTICAL DISTRIBUTION S. NO. DISTRIBUTION 1 Triangular Distr 2 3 PARAMETERS 2 P Kolmogorov-Smirnov Anderson-Darlin Min = 25.0, Max = 44.0 2.4 0.1213 0.1430 0.4757 Beta Distr. = 12.96, = 3.78, Scale = 46.4 6.8 0.009 0.1484 0.3317 Extreme Value Distr. Mode = 38.11, Scale = 3.88 6.8 0.0334 0.1506 0.3795 4 Weibull Distr. Loc = -20.41, Scale = 58.35, Shape = 15.0 6.8 0.009 0.1555 0.3879 5 Logistic Distr. Scale = 2.67, Mean = 36.14 4.4 0.1108 0.1800 0.4787 LPC STATISTICAL DISTRIBUTION S. NO. DISTRIBUTION PARAMETERS 2 P Kolmogorov-Smirnov Anderson-Darlin 1 Triangular Distr Min = 10.0, Max = 50.0 2.8 0.0943 0.1114 0.3914 2 Beta Distr. = 1.64, = 0.84, Scale = 50.02 0.8 0.371 0.1114 0.3602 3 Logistic Distr. Scale = 7.6, Mean = 34.04 2.8 0.2466 0.1224 0.7571 4 Weibull Distr. Loc = -2.07, Scale = 39.29, Shape = 3.02 4.4 0.0359 0.1374 0.8590 5 Normal Distr. Mean = 33.02 , Stand Dev. = 12.70 6.8 0.0334 0.1417 0.8254 CORE STATISTICAL DISTRIBUTION S. NO. DISTRIBUTION PARAMETERS 2 P Kolmogorov-Smirnov Anderson-Darlin 1 Extreme–Value Distr Mode = 76.2, Scale = 13.87 5.2 0.0743 0.1264 0.8934 2 Logistic Distr. Mean = 68.58, Scale = 10.34 1.6 0.4493 0.1331 0.8052 3 Beta Distr. = 3.28, = 1.05, Scale = 90.06 3.2 0.0736 0.1403 0.9222 4 Normal Distr. Mean = 68.14, = 16.74 3.2 0.2019 0.1416 0.8301 5 Weibell Distr. Loc. = 32.41, Scale = 40.34, Shape = 2.26 3.2 0.0736 0.1546 0.8534 LPTTEC STATISTICAL DISTRIBUTION S. NO. DISTRIBUTION PARAMETERS 2 P Kolmogorov-Smirnov Anderson-Darlin 1 Logistic Distr. Mean = 18.93, Scale = 3.07 4.4 0.1108 0.1214 0.7035 2 Normal Distr. Mean = 19.11, = 5.03 4.4 0.2019 0.1416 0.8301 3 LogNormal Distr. Mean = 19.12, = 5.09 4.4 0.1108 0.1405 0.7489 4 Extreme Value Distr. Mode = 16.71, = 4.15 6.4 0.0408 0.1428 0.7728 5 Beta Distr. = 3.93, = 1.84, Scale = 28.08 2.8 0.0943 0.1514 0.8725 MODULAR STATISTICAL DISTRIBUTIONS: Module Section: AFFAN C r y s ta l Ba ll Stu d e n t Ve r s io n A F FA N N o t fo r C o m m e r c ia l U s e Triangular distribution with parameters: Minimum 25.00 Likeliest 34.50 Maximum 44.00 2 5 .0 0 2 9 .7 5 3 4 .5 0 3 9 .2 5 4 4 .0 0 Selected Range is from 25.00 to 44.00 Module Section: LPC Triangular distribution with parameters: Minimum Likeliest Maximum 10.00 45.90 50.00 Selected range is from 10.00 to 50.00 Module Section: CORE C r y s ta l Ba ll Stu d e n t Ve r s io n C OR E N o t fo r C o m m e r c ia l U s e Normal distribution with parameters: Mean Standard Deviation 68.14 16.74 1 7 .9 3 4 3 .0 4 6 8 .1 4 Selected range is from –infinity to +infinity Module Section: LPTTEC Normal distribution with parameters: Mean Standard Dev. 19.11 5.03 Selected range is from –infinity to +infinity MODEL TRANSLATION: The real world problem is portrayed in Discrete Simulation model using Promodel. The components that flow in a discrete system, such as people, equipment, orders, and raw materials, are called entities. 9 3 .2 5 The different engine modules are treated as entities. The goal of a discrete simulation model is to portray the activities in which the entities engage and thereby learn something about the system’s dynamic behavior. Simulation accomplishes this by defining the states of the system and constructing activities that move it from state to state. The beginning and ending of each activity are events. The state of the model remains constant between consecutive event times, and a complete dynamic portrayal of the state of the model is obtained by Advancing simulated time from one event to the next. This timing event is referred to as the next-event approach. The analytical queuing model is created to produce the steady state results regarding the total module output and the average resource utilization. In this way, number of different runs are made at different simulation times to assure that the steady state condition is reached. The empirical model is created using M/G/I and is tabulated to compare with the simulated model. The logic associated with processing the arrival and analysis events depends on the state of the system at the time of the event. In the case of the arrival event, the disposition of the arriving event (file modules) is based on the distribution of each file at the Performance Office Location. At the Analysis event, the status of the module analysis time depends on whether a file is waiting. If the file is waiting in the queue, the analyst status remains busy, and the queue length is reduced by 1. And a analysis file removed from the queue is scheduled, If, however, the queue is empty, the status is idle. At any instant in the simulated time, the model is in a particular state. As events occur, the state of the model may change as prescribed by the logical-mathematical relationships associated with the events. Thus, events define potential changes. The state changes can be viewed from two perspectives: 1) The process that the part encounters as it seeks service or 2) The events that cause the state to change. DISCRETE EVENT MODEL OF THE TIME ANALYSIS SYSTEM: The states of the time analysis system are measured by the number of parts in the system and the status of the analyst. The following figure illustrates the system: Time In System Create Node Queue Node COLCT Node A simple network model illustrates that entities are inserted into the network at the CREATE node. There is a zero time for the part entity to travel to the QUEUE node, so that the parts arrive to it at the same time as they are created. The parts either wait or are processed. The time spent in the system by a part is then collected at the COLCT node VERIFICATION AND VALIDATION OF THE SIMULATION MODELS: The different approaches of verifying and validating the models are: Conceptual Model Validity, Model Verification, Operational Validity, and Data Validity. The model verification and validation, is generally considered to a process and is usually part of the model development process. Model validation is usually defined to mean “Substantiation that a computerized model within its domain of applicability possesses a satisfactory range of accuracy consistent with the intended application of the model”. The model verification is often defined as “ ensuring that the computer program of the computerized model and its implementation are correct” and is the definition adopted in the project. Model accreditation determines if a model satisfies a specified model accreditation criteria according to a specified process. The amount of accuracy required is specified in the beginning of the model development and the data collection process. Since the design variables are random, the properties and functions of the random variables such as means and variances are used to determine the validity of the model and the data. It is often too costly and time consuming to determine that a model is absolutely valid over the complete domain of its indented applicability. The simplified version of the modeling process is drawn below, which includes the data as well as operational validity. Problem Entity Operational Validity Conceptual Model Validity Data Validity Problem Entity Problem Entity Computerized Model Validity The validation of the model is objective (Blaci and Sargent 1984 Bibliography), when it constitutes some type of statistical test or mathematical procedure. The simulation animation is another way of determining the validation. Apart from that the following other validation tests are done: i) Face Vailidity – Validates the logic in the conceptual model by asking Prof. Ernesto (validation from a knowledgeable person about the system). ii) Historical Data Validation. iii) Fixed Values – Comparison with Empirical Results. iv) Internal Validity – Several runs are made and 20 replications are done once it is determined that the steady state is reached at 10,000 runs. v) Operational Graphics – Animation vi) Traces OUTPUT RESULTS: The simulation results and the conceptual results are tabulated for the different models of the engine below: SIMULATION RESULTS – AFFAN SECTION COMPARISON BETWEEN EMPIRICAL AND SIMULATED ANALYSIS TIME TAFF (Min Empirical Results L LQ Q PO 0.023 0.028 4.608 0.817 2.668 1.851 117.4 81.446 0.183 10 Hours 0.928 1.551 0.623 58.15 43.35 0.072 100 Hours 0.777 2.438 1.661 110.8 87.5 0.223 1000 Hours 0.786 2.135 1.349 95.26 72.2 0.214 Simulation Output 10,000 Hours 10,100 Hours 0.795 2.365 1.571 104.2 80.4 0.205 0.795 2.36 1.566 104.0 80.2 0.205 10,500 Hours 0.794 2.34 1.545 103.2 79.38 0.206 100 20 R Lavg LQavg avg Qavg avg SIMULATION RESULTS – LOW PRESSURE COMPRESSOR (LPC) COMPARISON BETWEEN EMPIRICAL AND SIMULATED ANALYSIS TIME TLP (Minu Empirical Results L LQ Q PO 0.022 0.030 12.70 0.718 1.766 1.046 81.23 48.21 0.282 10 Hours 0.779 1.116 0.337 43.8 34.4 0.221 100 Hours 0.679 1.754 1.075 81.29 64.28 0.321 1000 Hours 0.680 1.391 0.711 63.62 46.41 0.320 Simulation Output 10,000 Hours 10,100 Hours 0.675 1.448 0.773 66.36 49.45 0.325 0.675 1.446 0.771 66.27 49.45 0.325 10,500 Hours 0.676 1.445 0.769 66.15 49.24 0.324 100 20 R Lavg LQavg avg Qavg avg OUTPUT RESULTS(Contd.): SIMULATION RESULTS – CORE COMPARISON BETWEEN EMPIRICAL AND SIMULATED ANALYSIS TIME TCR (Minu Empirical Results L LQ Q PO 10 Hours 0.007 0.015 16.70 0.454 0.655 0.200 98.211 30.071 0.546 0.739 0.828 0.089 68.95 63.23 0.261 100 Hours 1000 Hours 0.359 0.443 0.0829 82.94 68.78 0.640 0.463 0.669 0.206 99.25 77.20 0.537 Simulation Output 10,000 Hours 10,100 Hours 0.439 0.618 0.179 96.02 75.77 0.561 0.440 0.620 0.180 96.13 75.82 0.560 10,500 Hours 0.441 0.622 0.181 96.29 75.88 0.559 100 20 R Lavg LQavg avg Qavg avg SIMULATION RESULTS – LOW PRESSURE TURBINE AND EXHAUST CASE COMPARISON BETWEEN EMPIRICAL AND SIMULATED ANALYSIS TIME TLTEC (Min Empirical Results L LQ Q PO 10 Hours 0.029 0.052 5.03 0.546 0.897 0.351 31.397 12.287 0.454 0.546 0.701 0.155 23.38 19.72 0.454 100 Hours 1000 Hours 0.509 0.871 0.302 30.27 22.39 0.491 0.538 0.884 0.346 31.47 23.76 0.462 Simulation Output 10,000 Hours 10,100 Hours 0.539 0.888 0.349 31.45 23.98 0.461 0.539 0.888 0.349 31.46 23.98 0.461 10,500 Hours 0.539 0.888 0.349 31.46 23.99 0.461 Cost estimation is an crucial part of engineering and particularly in the analysis when the most of the time is spent in the computation. The cost is estimated based on the Program Evaluation Review Technique. It involves making a most likely estimate, an optimistic estimate (lowest cost), and a pessimistic estimate (highest cost). The mean and variance for each cost element is calculated as : E(Ci) = Var(Ci) = 0.167(L + 4M +H) (0.167(H-L))**2 100 20 R Lavg LQavg avg Qavg avg E(C1) = Expected Cost of the AFFAN module section E(C2) = Expected Cost of the LPC module section E(C3) = Expected Cost of the Core module section E(C4) = Expected Cost of the LPTTEC module section Var(Ci) = Variance of the Cost of each module section LOWEST COST MODAL COST HIGHEST COST AFFAN E(C1) $33.3 /Hr Var(C1) $47.9 /Hr $ 17.9/Hr $47.4 /Hr LPC $58.7 /Hr LOWEST COST MODAL COST HIGHEST COST CORE $ 54.13 /Hr $79.2 /Hr E(C4) Var(C4) $ 25.9 /Hr $ 9.9 /Hr $ 61.2 /Hr $ 66.7 /Hr Var(C3) $54.7 /Hr $101.5/Hr Var(C2) LPTTEC E(C3) LOWEST COST MODAL COST HIGHEST COST E(C2) $ 13.3 /Hr $96.8 /Hr $ 118.4 /Hr $120.0 /Hr LOWEST COST MODAL COST HIGHEST COST $ 17.1 /Hr $ 25.5 /Hr $ 36.0 /Hr Based on the Central Limit Theorem, the total cost is the added cost of the sub-elements E(CT) = Expected Total Cost in Dollars E(CT) = = = E(C1) + E(C2) + E(C3) + E(C4) 47.4 + 5 4.1 + 96.8 + 25.9 $224.2/ Hr Var(CT) = Variance of Total Cost In Dollars Var(CT) = = = Var(C1) + Var(C2) + Var(C3) + Var(C4) 17.9 + 79.2 + 118.4 + 9.9 $225.4 / Hr CONCLUSIONS AND OBSERVATIONS: 1) There is a good aggrement of simulated and the analytical results. 2) The large values of cost variance indicates that the greater uncertainity and hence more conservatism in the TCR. 3) The estimated cost of analysis is $224/hour. 4) It is recommended to perform sensitivity of some projects based on the existing data. FUTURE IMPLEMENTATION: 1) To analyze the full model with grouping to complete a single project. 2) Implementation of the Optimization of the following function using Neural Network or ADS. Optimization Function Objective : Minimize COST, C(T) = [ 1+ 1.333*T] ** (0.75 / T) subject to : 25 <=TAFF <=44.0 10.0 <= TLP <= 50.0 41.0 <= TCR <= 90.0 12.8 <= TLTEC<= 27.0 REFERENCES: 1) Cerification and Validation of Simulation Models, Robert G. Sargent 2) Discrete-Event Ssytem Simulation, Jerry Banks, John S. Carson, Barry L. Nelson 3) Pormodel User’s Manual and Software 4) Operations Research An Introduction, Hamdy A. Taha 5) Handbook of Industrial Engineering, G. Salvendy 6) Introduction to Simulation and Risk Analysis, James R. Evans, David L. Olson 7) Integrating Targeted Cycle-Time Reduction Into The Capital Planning Process, N.Grewal, Jennifer K.Robinson APPENDICES: ******************************************************************************** * * * Formatted Listing of Model: * * A:\Pjnew.mod * * * ******************************************************************************** Time Units: Distance Units: Minutes Feet ******************************************************************************** * Locations * ******************************************************************************** Name ---------------Table Engineer Performance Analytical_Group Aerodynamist Commun Program_Manager LocInt Cap -------1 1 1 1 1 INFINITE 1 2 Units ----1 1 1 1 1 1 1 1 Stats ----------Basic Time Series Basic Basic Time Series Time Series Time Series Time Series Rules -------------Oldest, , Oldest, , Oldest, , Oldest, , Oldest, , Oldest, FIFO, Oldest, , Oldest, , Cost -----------30.0/hr 50.0/hr ******************************************************************************** * Entities * ******************************************************************************** Name ---------FAN LPC CORE LPT FANLPC Speed (fpm) -----------150 150 150 150 150 Stats Cost ----------- -----------Time Series Time Series Time Series Time Series Time Series ******************************************************************************** * Path Networks * ******************************************************************************** Name Type T/S From -------- ----------- ---------------- -------Net1 Non-Passing Time N1 N2 N3 N4 To -------N2 N3 N4 N5 BI ---Uni Uni Uni Uni Dist/Time ---------98.45 2.57 0.15 0.14 Speed Factor -----------1 1 1 1 ******************************************************************************** * Interfaces * ******************************************************************************** Net Node ---------- ---------Net1 N1 N3 N4 Location -----------Aerodynamist Engineer LocInt ******************************************************************************** * Processing * ******************************************************************************** Process Entity Location Operation Move Logic -------- --------------- ----------------------------FAN Commun WAIT 1 MIN Routing Blk Output Engineer Rule ---- -------- --------------- ------1 MOVE FAN Destination Engineer FIRST 1 WAIT N(28.63,4.50) Var1 = GETCOST() MOVE LPC MOVE LPC MOVE ALL FANLPC MOVE FANLPC Commun Engineer LocInt LocInt 1 FAN LocInt FIRST 1 1 LPC Engineer FIRST 1 1 LPC LocInt FIRST 1 1 FANLPC Program_Manager FIRST 1 1 FANLPC EXIT WAIT 5.0 MIN WAIT N(33.02,12.70) LP=LP+1 WAIT 5.0 Accum 1 Group 1 As FANLPC WAIT 0.1 Program_Manager WAIT 0.1 FIRST 1 ******************************************************************************** * Arrivals * ******************************************************************************** Entity -------FAN LPC Location -------Commun Commun Qty each ---------1 1 First Time ---------0 0 Occurrences ----------INF INF Frequency Logic ---------- -----------E(40)Min E(40) Min ******************************************************************************** * Variables (global) * ******************************************************************************** ID ---------LP Var1 Type -----------Integer Real Initial value ------------0 0 Stats ----------Time Series Time Series