WAREHOUSE MODEL AT THE ATHELETIC SHOE COMPANY

advertisement

WAREHOUSE MODEL AT THE ATHELETIC SHOE COMPANY

Harrell Case Study 3

Submitted By: Anh Pho & Gail Savage

Rensselaer at Hartford

Simulation Modeling and Analysis (DSES-6220)

Professor: Ernesto Gutierrez-Miravete

Due Date: 12/21/00

Table of Contents

Abstract/Executive Summary

Introduction/Background

Objective

Scope

Requirements

Assumptions

Model Development

Verification

Validation

Performance Metrics

Discussion of Results

Conclusion & Recommendations

Appendix A- Model Program Listing

Appendix B- Model Output

Appendix C- Copy of Case 3 from Harrell (pgs 371-373)

Appendix D- Sample of Output Trace

References

Page

2

3

4

4

4

4

5

8

9

9

9

10

11

16

23

26

27

A disk is included at the end of the report with the program, output, trace, final report and

presentation file.

i

Abstract/Executive Summary

This project satisfies two requirements of the Athletic Shoe Company (ASC). The first

requirement is to design the physical layout for the automated storage and retrieval system

(AS/RS) for the warehouse facility. This phase is necessary to determine the warehouse’s ability

to hold its inventory needs. The second requirement of this project is to model the material flow

within the warehouse. A computer simulation using ProModel software was developed to

represent the customer, order material flow and the receiving material order flow.

The model satisfied our performance metrics for a resource utilization rate above 80%, for

maintaining an inventory level of approximately 6,000 pairs of shoes and for meeting a shipping

rate requirement of 7,000 – 8,000 pairs of shoes per day. The following report details the steps

required to develop this model.

2

Introduction/Background

The purpose of our project is to design and model a new warehouse management system

utilizing an automated storage and retrieval system (AS/RS) for the Athletic Shoe Company.

The objective is to meet the needs of the company for timely distribution of its products. The

parameters of the project are described in Case Study #3 in the Harrell, et. al., text book.

The warehouse ships between 100,000 and 150,000 pairs of shoes per day. The shipments are

made to 8,000 – 10,000 destinations. The Athletic Shoe Company wishes to keep an inventory

of 3,000,000 pairs of shoes in order to provide prompt order fulfillment. The inventory consists

of 30,000 stock-keeping units (SKUs). Each SKU will be considered to be a unique combination

of shoe style and size. We assumed that we would equally store 100 pairs of each SKU.

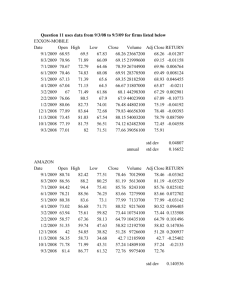

The warehouse has 500,000 square feet available for storage. Based on this, we calculated the

storage dimensions in Figure 1.

681.5 ft

733.5 ft

170.3'

170.3'

Sort,

Wrap

& Pack

Shipping

Store

500,000 sq ft

Unpack

& Scan

Receiving

Figure 1- Basic Warehouse Layout

The warehouse also has a 40 ft height constraint. The project began with the design of the layout

of the rack storage area. Each shoebox measures 18” long X 12” wide X 5” high. The

shoeboxes can be stacked up to 8 high on each other. We designed a bin storage container for

3

our AS/RS system that would hold 112 pairs of shoes. The bin dimensions were computed to 7ft

long X 3 ft wide X 3.5 ft high.

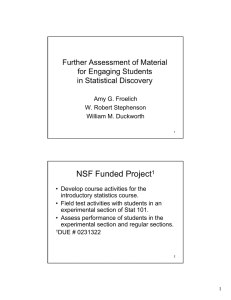

Each single row of storage bins has the configuration in Figure 2.

Single Row Elevation View

Height=35 ft

(10 Bins)

1

2

3

4

5

6

7

8

9

10 11 12 13 14 15

60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75

Storage

Bin

Length= 525 ft

(75 Bins)

Storage/Retrieval

Machine

Storage Layout View (Top View)

P/D

Station

Row 1

P/D

Station

Row 2

Row 3

P/D

Station

Row 20

P/D

Station

Figure 2 – Layout and Elevation of AS/RS Storage System

Each double row has the capacity for 1,500 storage bins (168,000 pairs of shoes). Therefore our

layout requires 20 double rows to accommodate the 3,000,000 pair inventory storage

requirement.

There are two macro view processes occurring in the warehouse. The first process is the

shipping process. This is driven by the customer order, which is broken down to line items for

each SKU ordered. A customer order includes between 10 and 19 pairs of shoes/ order. A single

picker fills the entire order.

4

The second process is the receiving process. It is assumed that between 100,000 and 150,000

pairs of shoes are received each day to maintain the 3,000,000 pairs of shoes inventory. The

shoes are received on pallets and sorted according to the SKU’s. Each SKU is assigned to a

unique storage bin and corresponding aisle location.

Objective

To design a storage layout scheme and build a model of the shipping and receiving systems

to meet the needs of the company for timely distribution of its products, using the student

version of ProMod (4.2).

Scope

This project determines the layout of the warehouse facility and the process flow for

customer/receiving orders used in the warehouse. The rack and storage area was designed to

hold the required inventory. The layout of the automated storage and retrieval systems (AS/RS)

was designed. Due to the complexity of the system, the AS/RS will not be modeled in this

project. The system elements modeled will be the material flows for both the receiving of stock

and shipping of customer orders.

Requirements

The hardware and software requirements to complete this project include: ProModel software

(V.4.20), an IBM compatible PC with Microsoft Windows 95 or higher and at least 16 MB of

memory. At least one simulation analyst proficient in model building with ProModel is also

required. The project will require 2-3 months to complete, with a completion deadline of

December 21, 2000.

Assumptions

The following are our assumptions for the model:

1. All SKUs are equally shipped. The storage requirement for all SKUs are the same

(100 pairs/SKU).

2. One filler picks the entire customer order.

3. One person (“put away guy”) stocks the entire receiving order.

5

4. The warehouse is already fully stocked at the beginning of the simulation.

5. Receiving arrival rate and the shipping arrival rate are the same to maintain a constant

inventory level.

6. The model assumes no down time.

7. All “fillers” and “put away guys” have the same service rate.

8. The warehouse runs 24 hours/day.

Model Development

Because of the size of the problem model, we decided to scale the model down from the original

model. Therefore, our new parameters for the problem become:

Shipping Rate (pairs/day)

7,000 – 8,000

Inventory Requirement (pairs)

6000

Quantity per Shipping Order (pairs/order)

1–4

SKU per Order (Sku/order)

1–4

Receiving Rate (pairs/day)

7,000-8,000

The two sub-processes in the model are filling customer orders and processing receiving orders.

The shipping of products is driven by the receipt of the customer orders. The customer order is

divided into 1 to 4 line items, each representing 1 SKU. There are 0 – 4 pairs of shoes per line

item. The fillers start with the first line item and walk through the pickup tables to select the

items (SKUs) for a customer order. (The AS/RS presents the required SKUs to the pick up table

locations.) When the fillers have selected items for the order, they will drop off the completed

order at the packing queue. The packers will box the order and move it to the shipping queue.

From here the customer order exits the system.

The receiving order route has a similar process flow. The receiving orders are processed at the

receiving station by the inspectors/sorters. The orders then go to the inspection area and are

forwarded to the stocking queue. The “put away guys” will come to the stocking queue, move

the orders to their respective put away locations and then exit the system. (The AS/RS handles

the placing of the SKUs to their shelf locations.)

6

The following table lists the components of the model:

System Components Table

Location

Customer order pickup

Inspection table

Packing queue

Packing table

Pickup tables

Put away tables

Receiving table

Shipping queue

Stocking queue

Description

Place that customer orders enter system

Area where receiving orders are sorted and inspected.

Place that customer orders wait to be packed

Place to pack customer orders

Place where the fillers pick up shoes to fill the line items

for customer orders

Place where the put away guys drop off the received

stocks.

Location where replenishing orders are received

Place where customer orders wait to be shipped

Place where receiving order line items (SKUs) wait to be

put away

Arrival/Process/Wait

Time (min)

N(0.75, 0.25)

N(5,1)

N(0.75,0.25)

N(2.5,0.5)

N(0.75,0.25)

N(5,0.5)

NA

NA

N(2,0.5)

Entities

Customer Orders

Receiving Orders

Resource

Fillers

Packers

Inspectors/Sorters

Put way guys

Forms that transmit customer shoes (SKUs) request

Forms that provide information about the SKUs received.

E(0.75)

E(0.75)

Workers who fill the customer orders

Workers who box the customer orders and move them to

the shipping area

Workers who inspect, sort and move the receiving orders

the stocking queue

Workers who put away the received stocks (SKUs)

NA

NA

7

NA

NA

The diagram below illustrates the flow of the receiving and customer orders:

Verification

Initially, we found several syntax errors, which terminated the running of the program. For

example, we misspelled the variable name. These errors were easy to detect since the program

helped us to identify them. After fixing all the syntax errors, we watched the model animation

and found that the model process flows were as expected. However, detecting semantic errors

was more challenging and required more debugging time. When determining the reasonableness

of the output, we realized that the output did not come out as expected. One of the major logic

errors was found in our customer order and receiving line items program coding. This resulted

in the misuse of the random command as well as calculation errors. In our final step of the

debugging process, we utilized the trace output function in ProModel to step through the

program and verified the proper behavior of the program.

8

Validation

The validation process was begun by again watching the behavior of the animation. The values

of the counters were scrutinized for their proper performance. When we increased or decreased

the customer/receiving orders, the counters (outputs) responded as expected in the correct

direction. For example, when the customer order arrival rate was decreased to 0.75

minutes/order from 4 minutes/order, the number of shoes shipped increased accordingly. To

validate our methodology, demo ProModel programs were used to confirm the modeling

techniques for warehouse flow.

Performance Metrics

The performance of this model is measured by following three metrics:

1. Resource utilization- our goal is to achieve at least 80% utilization for all the resources.

Therefore, we ran iterations of the program until the numbers of fillers, packers, put away

guys, and inspectors/sorters met the utilization goal.

2. Inventory level- the warehouse inventory is required to maintain approximately 6000

pairs of shoes.

3. Number of shipped shoes per day- the warehouse shipping rate requirement is 7000 to

8000 pairs per day.

Discussion of Results

After running several iterations, the model results show that resource utilization of at least 80%

is reached when the resources are at the level listed below:

Resource

Fillers

Packers

Put away guys

Inspectors/Sorters

Number of Unit

5

5

17

9

Average

83.54

82.44

85.70

80.61

Utilization %

Standard Deviation

1.84

1.89

2.29

1.80

After running 10 replications of our model for 24 hours each, the warehouse average inventory

level is 5,738 (39.1 std. dev.) pairs of shoes, which met our above requirement. Our output

satisfied the requirement with a shipping rate of 7,656 (166.4 std. dev.) pairs per 24 hours of

operation.

9

Conclusion and Recommendation

In conclusion, the model was verified, validated and the model output satisfied the performance

metrics. A storage area was designed to accommodate the present inventory demands. The

current model layout and assigned resources are capable of meeting today’s requirements.

Before actually building a real warehouse, we would recommend performing a study to consider

the possibility of increasing throughput capacity in the future. It is also recommended that a

cost analysis on the project be done.

10

Appendix A – Model Program Listing

********************************************************************************

*

*

*

Formatted Listing of Model:

*

*

A:\MANPOW~2.MOD

*

*

*

********************************************************************************

Time Units:

Distance Units:

Minutes

Feet

********************************************************************************

*

Locations

*

********************************************************************************

Name

--------------------Put_Away_Table1

Put_Away_Table2

Put_Away_Table3

Put_Away_Table4

Pick_Up_Table1

Pick_Up_Table2

Pick_Up_Table3

Pick_Up_Table4

Packing_Queue

Stocking_Queue

Inspection_Table

Receiving

Packing_Table

Shipping_Queue

Customer_Order_Pickup

Cap

-------10

10

10

10

10

10

10

10

INFINITE

INFINITE

INF

inf

INF

INFINITE

INF

Units

----1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Stats

----------Time Series

Time Series

Time Series

Time Series

Time Series

Time Series

Time Series

Time Series

Time Series

Time Series

Time Series

Time Series

Time Series

Time Series

Time Series

Rules

Cost

-------------- -----------Oldest, ,

Oldest, ,

Oldest, ,

Oldest, ,

Oldest, ,

Oldest, ,

Oldest, ,

Oldest, ,

Oldest, FIFO,

Oldest, FIFO,

Oldest, ,

Oldest, ,

Oldest, ,

Oldest, FIFO,

Oldest, ,

********************************************************************************

*

Entities

*

********************************************************************************

Name

--------------Customer_Order

Receiving_Order

Speed (fpm)

-----------150

150

Stats

Cost

----------- -----------Time Series

Time Series

11

********************************************************************************

*

Resources

*

********************************************************************************

Res

Name

Units Stats

Search

---------------- ----- -------- -----Fillers

5

By Unit None

Ent

Search Path

Motion

Cost

------ ---------- -------------- -----------Oldest

Empty: 150 fpm

Full: 150 fpm

Packers

5

By Unit

None

Oldest

Empty: 150 fpm

Full: 150 fpm

InspectorSorters 9

By Unit

None

Oldest

Empty: 150 fpm

Full: 150 fpm

Putawayguys

By Unit

None

Oldest

Empty: 150 fpm

Full: 150 fpm

17

********************************************************************************

*

Processing

*

********************************************************************************

Process

Routing

Entity

Location

Operation

Blk Output

Destination

Rule

--------------- --------------------- --------------------- --------------- ---------------- ---------------------Customer_Order Customer_Order_Pickup # Quantity per line item

INC Number_of_C_order

C_Order_Line1=Rand(4)

C_Order_Line1=Round(C_Order_Line1)

AA=4-C_Order_Line1

If AA=0 then

{C_Order_Line2 = 0

C_Order_Line3 = 0

C_Order_Line4 = 0}

Else

{C_Order_Line2 = Rand(AA)

C_Order_Line2 = Round(C_Order_Line2)

BB = 4 - (C_Order_Line1+ C_Order_Line2)}

IF BB = 0 THEN

{C_Order_Line3 =0

C_Order_Line4 =0}

ELSE

{C_Order_Line3 =Rand(BB)

C_Order_Line3 = Round(C_Order_Line3)

12

Move Logic

------------

CC= 4-(C_Order_Line1+ C_Order_Line2 + C_Order_Line3)}

If CC = 0 Then

{C_Order_Line4 = 4}

Else

{C_Order_Line4 = 4 - (C_Order_Line1+C_Order_Line2+C_Order_Line3)}

1

Customer_Order

Pick_Up_Table1

Pick_Up_Table2

Customer_Order

Pick_Up_Table3

Customer_Order

Pick_Up_Table4

Customer_Order

Customer_Order

Packing_Queue

Packing_Table

Customer_Order Shipping_Queue

Receiving_Order Receiving

Pick_Up_Table1

IF C_Order_Line1 >0, 1

MOVE WITH FILLERS FOR 0.5 MIN

Customer_Order

Pick_Up_Table2

IF C_Order_Line2 >0

MOVE WITH FILLERS FOR 0.5 MIN

Customer_Order

Pick_Up_Table3

IF C_Order_Line3 >0

MOVE WITH FILLERS FOR 0.5 MIN

Customer_Order

Pick_Up_Table4

IF C_Order_Line4 >0

MOVE WITH FILLERS FOR 0.5 MIN

WAIT N(.75, 0.25)

AISLE1_INVENTORY = AISLE1_INVENTORY - C_ORDER_LINE1 + R_ORDER_LINE1

1

Customer_Order

Customer_Order

Customer_Order

Customer_Order

Customer_Order

Pick_Up_Table2

Pick_Up_Table3

Pick_Up_Table4

IF C_Order_Line2 >0, 1

IF C_Order_Line3 >0

IF C_Order_Line4 >0

MOVE WITH FILLERS FOR 0.5 MIN

MOVE WITH FILLERS FOR 0.5 MIN

MOVE WITH FILLERS FOR 0.5 MIN

WAIT N(.75, 0.25)

AISLE2_INVENTORY = AISLE2_INVENTORY - C_ORDER_LINE2 + R_ORDER_LINE2

1

Customer_Order Pick_Up_Table3

IF C_Order_Line3 >0, 1 MOVE WITH FILLERS

Customer_Order Pick_Up_Table4

IF C_Order_Line4 >0

MOVE WITH FILLERS

WAIT N(.75, 0.25)

AISLE3_INVENTORY = AISLE3_INVENTORY-C_ORDER_LINE3 +R_ORDER_LINE3

1

Customer_Order Pick_Up_Table4

FIRST 1

MOVE WITH FILLERS

WAIT N(.75, 0.25)

AISLE4_INVENTORY = AISLE4_INVENTORY-C_ORDER_LINE4 +R_ORDER_LINE4

INVENTORY_GRAND_TOTAL = AISLE1_INVENTORY + AISLE2_INVENTORY +AISLE3_INVENTORY + AISLE4_INVENTORY

PAIRS_SHIPPED =PAIRS_SHIPPED+ C_ORDER_LINE1+C_ORDER_LINE2+C_ORDER_LINE3+C_ORDER_LINE4

1

Customer_Order Packing_Queue

FIRST 1

MOVE WITH FILLERS

WAIT N(.75,0.25)

1

Customer_Order Packing_Table

FIRST 1

MOVE WITH PACKERS

WAIT N(2.5,.5)

1

Customer_Order Shipping_Queue

FIRST 1

MOVE WITH PACKERS

1

Customer_Order EXIT

# Quantity per line item

INC Number_of_receiving_order

R_Order_Line1=Rand(4)

R_Order_Line1=Round(R_Order_Line1)

RR1=4-R_Order_Line1

If RR1=0 then

{R_Order_Line2 = 0

R_Order_Line3 = 0

R_Order_Line4 = 0}

Else

{R_Order_Line2 = Rand(RR1)

R_Order_Line2 = Round(R_Order_Line2)

RR2 = 4 - (R_Order_Line1+ R_Order_Line2)}

IF RR2 = 0

THEN

13

FIRST 1

FOR 0.5 MIN

FOR 0.5 MIN

FOR 0.5 MIN

FOR 0.5 MIN THEN FREE

FOR 0.5 MIN

FOR 0.25 MIN THEN FREE

{R_Order_Line3 =0

R_Order_Line4 =0}

ELSE

{R_Order_Line3 =Rand(RR2)

R_Order_Line3 = Round(R_Order_Line3)

RR3= 4-(R_Order_Line1+ R_Order_Line2 + R_Order_Line3)}

If RR3 = 0 Then

{R_Order_Line4 = 4}

Else

{R_Order_Line4 = 4 - (R_Order_Line1+R_Order_Line2+R_Order_Line3)}

1

Receiving_Order Inspection_Table FIRST 1

Receiving_Order Inspection_Table

Receiving_Order Stocking_Queue

WAIT N(5,1)

WAIT N(2,0.5)

1

1

Receiving_Order Put_Away_Table1

WAIT N(5,0.5)

1

Receiving_Order Put_Away_Table2

WAIT N(5,0.5)

1

Receiving_Order Put_Away_Table3

Receiving_Order Put_Away_Table4

WAIT N(5,0.5)

WAIT N(5,0.5)

FREE PUTAWAYGUYS

1

Receiving_Order

Receiving_Order

Receiving_Order

Receiving_Order

Receiving_Order

Receiving_Order

Receiving_Order

Receiving_Order

Receiving_Order

Receiving_Order

Receiving_Order

Stocking_Queue

Put_Away_Table1

Put_Away_Table2

Put_Away_Table3

Put_Away_Table4

Put_Away_Table2

Put_Away_Table3

Put_Away_Table4

Put_Away_Table3

Put_Away_Table4

Put_Away_Table4

1

Receiving_Order EXIT

FIRST 1

IF R_Order_Line1

IF R_Order_Line2

IF R_Order_Line3

IF R_Order_Line4

IF R_Order_Line2

IF R_Order_Line3

IF R_Order_Line4

IF R_Order_Line3

IF R_Order_Line4

FIRST 1

FIRST 1

********************************************************************************

*

Arrivals

*

********************************************************************************

Entity

--------------Customer_Order

Receiving_Order

Location

--------------------Customer_Order_Pickup

Receiving

Qty each

First Time

---------- ---------1

1

Occurrences

----------INF

inf

Frequency Logic

---------- -----------E(0.75)

E(0.75)

********************************************************************************

*

Variables (global)

*

********************************************************************************

ID

------------------------C_Order_Line1

C_Order_Line2

C_Order_Line3

C_Order_Line4

AA

BB

CC

Aisle1_Inventory

Type

-----------Integer

Integer

Integer

Integer

Integer

Integer

Integer

Integer

Initial value

------------0

0

0

0

0

0

0

1500

Stats

----------Time Series

Time Series

Time Series

Time Series

Time Series

Time Series

Time Series

Time Series

14

MOVE WITH INSPECTORSORTERS FOR 0.5 MIN

>0, 1

>0

>0

>0

>0, 1

>0

>0

>0, 1

>0

MOVE

MOVE

MOVE

MOVE

MOVE

MOVE

MOVE

MOVE

MOVE

MOVE

MOVE

WITH

WITH

WITH

WITH

WITH

WITH

WITH

WITH

WITH

WITH

WITH

INSPECTORSORTERS FOR 0.5 MIN THEN FREE

PUTAWAYGUYS FOR 0.5 MIN

PUTAWAYGUYS FOR 0.5 MIN

PUTAWAYGUYS FOR 0.5 MIN

PUTAWAYGUYS FOR 0.5MIN THEN FREE

PUTAWAYGUYS FOR 0.5 MIN

PUTAWAYGUYS FOR 0.5 MIN

PUTAWAYGUYS FOR 0.5 MIN THEN FREE

PUTAWAYGUYS FOR 0.5 MIN

PUTAWAYGUYS FOR 0.5 MIN THEN FREE

PUTAWAYGUYS FOR 0.5 MIN

Aisle2_Inventory

Aisle3_Inventory

Aisle4_Inventory

Inventory_Grand_Total

R_Order_Line1

R_Order_Line2

R_Order_Line3

R_Order_Line4

RR1

RR2

RR3

Number_of_receiving_order

Number_of_C_order

Pairs_shipped

Integer

Integer

Integer

Integer

Integer

Integer

Integer

Integer

Integer

Integer

Integer

Integer

Integer

Integer

1500

1500

1500

6000

0

0

0

0

0

0

0

0

0

0

Time

Time

Time

Time

Time

Time

Time

Time

Time

Time

Time

Time

Time

Time

Series

Series

Series

Series

Series

Series

Series

Series

Series

Series

Series

Series

Series

Series

15

Appendix B – Model Output

-------------------------------------------------------------------------------General Report

Output from A:\MANPOW~2.MOD [WHModel]

Date: Dec/17/2000

Time: 07:05:18 PM

-------------------------------------------------------------------------------Scenario

: Normal Run

Replication

: Average

Period

: Final Report (0 sec to 24 hr Elapsed: 24 hr)

Simulation Time : 24 hr

-------------------------------------------------------------------------------LOCATIONS

Location

Name

--------------------Put Away Table1

Put Away Table1

Put Away Table2

Put Away Table2

Put Away Table3

Put Away Table3

Put Away Table4

Put Away Table4

Pick Up Table1

Pick Up Table1

Pick Up Table2

Pick Up Table2

Pick Up Table3

Pick Up Table3

Pick Up Table4

Pick Up Table4

Packing Queue

Packing Queue

Stocking Queue

Stocking Queue

Inspection Table

Inspection Table

Receiving

Receiving

Packing Table

Packing Table

Shipping Queue

Shipping Queue

Customer Order Pickup

Customer Order Pickup

Scheduled

Hours

--------24

0

24

0

24

0

24

0

24

0

24

0

24

0

24

0

24

0

24

0

24

0

24

0

24

0

24

0

24

0

Capacity

-------10

0

10

0

10

0

10

0

10

0

10

0

10

0

10

0

999999

0

999999

0

999999

0

999999

0

999999

0

999999

0

999999

0

Total

Entries

------1452.3

46.3682

1031.3

40.5217

634.1

27.7547

1891.7

42.298

1442.2

33.6214

1033.2

37.6646

591.9

45.4275

1915.6

41.7751

1913.5

41.9821

1910.6

41.7724

1918.2

40.7616

1919.1

40.7798

1911.7

41.6361

1907.6

41.7112

1922.2

38.424

Average

Minutes

Per Entry

--------5.208821

0.035307

5.275512

0.034613

5.370544

0.036263

4.991695

0.014138

0.751420

0.004809

0.752430

0.004289

0.749977

0.010845

0.747984

0.003994

1.300516

0.139542

4.562805

1.188845

4.992235

0.017024

0.765836

0.169604

2.671312

0.010583

0.149997

0.000009

1.535371

0.319125

Average

Contents

---------5.25344

0.175481

3.77809

0.146958

2.36519

0.111712

6.55754

0.149629

0.752598

0.0195523

0.53991

0.0211273

0.308373

0.0253336

0.995023

0.0222306

1.73025

0.213964

6.05287

1.60443

6.6502

0.14994

1.02346

0.238361

3.54646

0.0836064

0.198704

0.00434603

2.05192

0.43875

Maximum

Contents

-------10

0

10

0

10

0

10

0

4.9

0.316228

4.8

0.421637

4.7

0.483046

5

0

9.1

1.44914

27.9

8.5173

9

0

12.4

2.45855

5

0

2

0

16.9

3.92853

16

Current

Contents

-------5.3

2.35938

3.4

2.67499

3.2

1.68655

5.5

2.54951

0.9

0.994429

0.9

1.1005

0.4

0.699206

1.5

1.2693

1.8

1.22927

6.1

3.87155

7.2

1.61933

0.9

2.5144

3.5

1.17851

0.1

0.316228

3.9

5.83952

% Util

-----52.53

1.75

37.78

1.47

23.65

1.12

65.58

1.50

7.53

0.20

5.40

0.21

3.08

0.25

9.95

0.22

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

1.99

0.04

0.00

0.00

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

LOCATION STATES BY PERCENTAGE (Multiple Capacity)

Location

Name

--------------------Put Away Table1

Put Away Table1

Put Away Table2

Put Away Table2

Put Away Table3

Put Away Table3

Put Away Table4

Put Away Table4

Pick Up Table1

Pick Up Table1

Pick Up Table2

Pick Up Table2

Pick Up Table3

Pick Up Table3

Pick Up Table4

Pick Up Table4

Packing Queue

Packing Queue

Stocking Queue

Stocking Queue

Inspection Table

Inspection Table

Receiving

Receiving

Packing Table

Packing Table

Shipping Queue

Shipping Queue

Customer Order Pickup

Customer Order Pickup

Scheduled

Hours

--------24

0

24

0

24

0

24

0

24

0

24

0

24

0

24

0

24

0

24

0

24

0

24

0

24

0

24

0

24

0

%

Empty

----2.71

0.54

10.63

1.63

30.72

2.65

1.88

0.17

45.92

1.11

60.40

1.46

77.59

1.43

38.40

0.85

23.17

1.90

3.23

0.68

0.12

0.10

68.42

3.88

1.76

0.23

80.14

0.43

50.18

4.37

%

Partially

Occupied

--------89.41

1.13

86.29

1.59

68.08

2.82

83.55

1.28

54.08

1.11

39.60

1.46

22.41

1.43

61.60

0.85

76.83

1.90

96.77

0.68

99.88

0.10

31.58

3.88

98.24

0.23

19.86

0.43

49.82

4.37

%

Full

----7.88

1.26

3.09

1.02

1.21

0.48

14.58

1.35

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

%

Down

---0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

RESOURCES

Resource

Name

-----------------Fillers.1

Fillers.1

Fillers.2

Fillers.2

Units

----1

0

1

0

Scheduled

Hours

--------24

0

24

0

Number

Of Times

Used

-------385.3

11.6909

379.6

7.60409

Average

Minutes

Per

Usage

--------3.123808

0.047500

3.167553

0.043377

% Util

-----83.56

1.86

83.50

1.84

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

17

Fillers.3

Fillers.3

Fillers.4

Fillers.4

Fillers.5

Fillers.5

Fillers

Fillers

Packers.1

Packers.1

Packers.2

Packers.2

Packers.3

Packers.3

Packers.4

Packers.4

Packers.5

Packers.5

Packers

Packers

InspectorSorters.1

InspectorSorters.1

InspectorSorters.2

InspectorSorters.2

InspectorSorters.3

InspectorSorters.3

InspectorSorters.4

InspectorSorters.4

InspectorSorters.5

InspectorSorters.5

InspectorSorters.6

InspectorSorters.6

InspectorSorters.7

InspectorSorters.7

InspectorSorters.8

InspectorSorters.8

InspectorSorters.9

InspectorSorters.9

InspectorSorters

InspectorSorters

Putawayguys.1

Putawayguys.1

Putawayguys.2

Putawayguys.2

Putawayguys.3

Putawayguys.3

Putawayguys.4

Putawayguys.4

Putawayguys.5

Putawayguys.5

Putawayguys.6

1

0

1

0

1

0

5

0

1

0

1

0

1

0

1

0

1

0

5

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

9

0

1

0

1

0

1

0

1

0

1

0

1

24

0

24

0

24

0

120

0

24

0

24

0

24

0

24

0

24

0

120

0

24

0

24

0

24

0

24

0

24

0

24

0

24

0

24

0

24

0

216

0

24

0

24

0

24

0

24

0

24

0

24

386.3

8.01457

385.1

9.19481

382

9.58007

1918.3

41.756

382.6

10.4265

381.1

8.15748

382.6

8.83428

382.6

8.0719

382.8

9.31904

1911.7

41.6361

212.7

5.2079

213.1

6.57352

213.7

4.02906

212.9

4.5326

211.9

6.29727

213

4.59468

213.1

5.70477

214.4

3.53396

213.4

6.13188

1918.2

40.7616

113.2

5.63323

111.6

6.0406

112.2

7.43565

112.8

5.71159

110.5

5.54276

109.5

3.114737

0.046391

3.123451

0.047938

3.151451

0.052731

3.135739

0.033531

3.103154

0.034333

3.115439

0.035560

3.102541

0.021111

3.102618

0.032731

3.101257

0.024796

3.104768

0.011864

5.459187

0.058015

5.446817

0.078550

5.430150

0.063941

5.452346

0.056605

5.479452

0.066076

5.450086

0.081677

5.446875

0.092306

5.418001

0.078343

5.441136

0.060353

5.446268

0.016677

10.914270

0.443578

11.089624

0.664176

11.039457

0.712740

10.956321

0.436786

11.184752

0.507750

11.297640

83.55

1.84

83.52

1.86

83.58

1.81

83.54

1.84

82.44

1.89

82.45

1.89

82.43

1.88

82.43

1.88

82.44

1.89

82.44

1.89

80.63

1.80

80.58

1.79

80.58

1.79

80.61

1.81

80.61

1.78

80.61

1.78

80.59

1.78

80.67

1.85

80.62

1.83

80.61

1.80

85.67

2.32

85.72

2.27

85.71

2.30

85.69

2.24

85.68

2.36

85.78

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

18

Putawayguys.6

Putawayguys.7

Putawayguys.7

Putawayguys.8

Putawayguys.8

Putawayguys.9

Putawayguys.9

Putawayguys.10

Putawayguys.10

Putawayguys.11

Putawayguys.11

Putawayguys.12

Putawayguys.12

Putawayguys.13

Putawayguys.13

Putawayguys.14

Putawayguys.14

Putawayguys.15

Putawayguys.15

Putawayguys.16

Putawayguys.16

Putawayguys.17

Putawayguys.17

Putawayguys

Putawayguys

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

17

0

0

24

0

24

0

24

0

24

0

24

0

24

0

24

0

24

0

24

0

24

0

24

0

408

0

4.19656

115.4

4.14193

113.2

6.89283

111.9

5.56677

109.8

5.90292

113

4.85341

114.9

3.63471

113.8

3.48967

110.1

5.04315

113.3

9.16576

109.6

5.50151

109.7

5.59861

1904.5

41.7619

0.550966

10.696803

0.245012

10.930430

0.504853

11.061118

0.760539

11.265676

0.534138

10.934753

0.469275

10.754893

0.595486

10.841834

0.369481

11.224723

0.385623

10.935217

0.664959

11.286662

0.600462

11.281082

0.694836

11.017171

0.233971

2.20

85.68

2.30

85.73

2.32

85.70

2.33

85.73

2.26

85.69

2.26

85.69

2.28

85.63

2.29

85.72

2.30

85.67

2.25

85.73

2.25

85.73

2.38

85.70

2.29

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

RESOURCE STATES BY PERCENTAGE

Resource

Name

-----------------Fillers.1

Fillers.1

Fillers.2

Fillers.2

Fillers.3

Fillers.3

Fillers.4

Fillers.4

Fillers.5

Fillers.5

Fillers

Fillers

Packers.1

Packers.1

Packers.2

Packers.2

Packers.3

Packers.3

Packers.4

Scheduled

Hours

--------24

0

24

0

24

0

24

0

24

0

120

0

24

0

24

0

24

0

24

%

In Use

-----83.56

1.86

83.50

1.84

83.55

1.84

83.52

1.86

83.58

1.81

83.54

1.84

82.44

1.89

82.45

1.89

82.43

1.88

82.43

%

Idle

----16.44

1.86

16.50

1.84

16.45

1.84

16.48

1.86

16.42

1.81

16.46

1.84

17.56

1.89

17.55

1.89

17.57

1.88

17.57

%

Down

---0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

19

Packers.4

Packers.5

Packers.5

Packers

Packers

InspectorSorters.1

InspectorSorters.1

InspectorSorters.2

InspectorSorters.2

InspectorSorters.3

InspectorSorters.3

InspectorSorters.4

InspectorSorters.4

InspectorSorters.5

InspectorSorters.5

InspectorSorters.6

InspectorSorters.6

InspectorSorters.7

InspectorSorters.7

InspectorSorters.8

InspectorSorters.8

InspectorSorters.9

InspectorSorters.9

InspectorSorters

InspectorSorters

Putawayguys.1

Putawayguys.1

Putawayguys.2

Putawayguys.2

Putawayguys.3

Putawayguys.3

Putawayguys.4

Putawayguys.4

Putawayguys.5

Putawayguys.5

Putawayguys.6

Putawayguys.6

Putawayguys.7

Putawayguys.7

Putawayguys.8

Putawayguys.8

Putawayguys.9

Putawayguys.9

Putawayguys.10

Putawayguys.10

Putawayguys.11

Putawayguys.11

Putawayguys.12

Putawayguys.12

Putawayguys.13

Putawayguys.13

0

24

0

120

0

24

0

24

0

24

0

24

0

24

0

24

0

24

0

24

0

24

0

216

0

24

0

24

0

24

0

24

0

24

0

24

0

24

0

24

0

24

0

24

0

24

0

24

0

24

0

1.88

82.44

1.89

82.44

1.89

80.63

1.80

80.58

1.79

80.58

1.79

80.61

1.81

80.61

1.78

80.61

1.78

80.59

1.78

80.67

1.85

80.62

1.83

80.61

1.80

85.67

2.32

85.72

2.27

85.71

2.30

85.69

2.24

85.68

2.36

85.78

2.20

85.68

2.30

85.73

2.32

85.70

2.33

85.73

2.26

85.69

2.26

85.69

2.28

85.63

2.29

1.88

17.56

1.89

17.56

1.89

19.37

1.80

19.42

1.79

19.42

1.79

19.39

1.81

19.39

1.78

19.39

1.78

19.41

1.78

19.33

1.85

19.38

1.83

19.39

1.80

14.33

2.32

14.28

2.27

14.29

2.30

14.31

2.24

14.32

2.36

14.22

2.20

14.32

2.30

14.27

2.32

14.30

2.33

14.27

2.26

14.31

2.26

14.31

2.28

14.37

2.29

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

20

Putawayguys.14

Putawayguys.14

Putawayguys.15

Putawayguys.15

Putawayguys.16

Putawayguys.16

Putawayguys.17

Putawayguys.17

Putawayguys

Putawayguys

24

0

24

0

24

0

24

0

408

0

85.72

2.30

85.67

2.25

85.73

2.25

85.73

2.38

85.70

2.29

14.28

2.30

14.33

2.25

14.27

2.25

14.27

2.38

14.30

2.29

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

FAILED ARRIVALS

Entity

Name

--------------Customer Order

Customer Order

Receiving Order

Receiving Order

Location

Name

--------------------Customer Order Pickup

Customer Order Pickup

Receiving

Receiving

Total

Failed

-----0

0

0

0

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

ENTITY ACTIVITY

Entity

Name

--------------Customer Order

Customer Order

Receiving Order

Receiving Order

Total

Exits

------1907.5

41.7406

1886.2

43.7259

Current

Quantity

In System

--------14.7

6.54981

32.9

7.47514

Average

Minutes

In

System

--------9.225868

0.410928

25.173054

1.366876

Average

Minutes

In Move

Logic

-------3.369252

0.288661

2.268992

0.213161

Average

Minutes

Wait For

Res, etc.

--------0.295836

0.120367

2.197917

1.169121

Average

Minutes

In

Operation

--------5.349205

0.022865

20.187504

0.147979

ENTITY STATES BY PERCENTAGE

Entity

Name

--------------Customer Order

Customer Order

Receiving Order

Receiving Order

%

In Move

Logic

------36.46

1.61

9.01

0.67

%

Wait For

Res, etc.

--------3.18

1.17

8.54

4.08

%

In Operation

-----------58.08

2.51

80.38

3.90

%

Blocked

------2.27

0.61

2.07

0.20

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

VARIABLES

Average

21

Average

Minutes

Blocked

-------0.211574

0.067214

0.518641

0.037998

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

Variable

Name

------------------------C Order Line1

C Order Line1

C Order Line2

C Order Line2

C Order Line3

C Order Line3

C Order Line4

C Order Line4

AA

AA

BB

BB

CC

CC

Aisle1 Inventory

Aisle1 Inventory

Aisle2 Inventory

Aisle2 Inventory

Aisle3 Inventory

Aisle3 Inventory

Aisle4 Inventory

Aisle4 Inventory

Inventory Grand Total

Inventory Grand Total

R Order Line1

R Order Line1

R Order Line2

R Order Line2

R Order Line3

R Order Line3

R Order Line4

R Order Line4

RR1

RR1

RR2

RR2

RR3

RR3

Number of receiving order

Number of receiving order

Number of C order

Number of C order

Pairs shipped

Pairs shipped

Total

Changes

------3844.4

76.8479

3844.4

76.8479

3844.4

76.8479

1922.2

38.424

1922.2

38.424

1922.2

38.424

1922.2

38.424

1441.3

33.4599

1032.3

38.3233

591.5

45.7025

1914.1

41.5971

1914.1

41.5971

3838.2

81.5595

3838.2

81.5595

3838.2

81.5595

1919.1

40.7798

1919.1

40.7798

1919.1

40.7798

1919.1

40.7798

1919.1

40.7798

1922.2

38.424

1914.1

41.5971

Minutes

Per Change

---------0.374525

0.007306

0.374525

0.007306

0.374525

0.007306

0.749050

0.014612

0.749050

0.014612

0.749050

0.014612

0.749050

0.014612

0.998753

0.022466

1.395714

0.053436

2.439805

0.191716

0.752318

0.016347

0.752318

0.016347

0.375215

0.008065

0.375215

0.008065

0.375215

0.008065

0.750430

0.016130

0.750430

0.016130

0.750430

0.016130

0.750430

0.016130

0.750430

0.016130

0.749050

0.014612

0.752318

0.016347

Minimum

Value

------0

0

0

0

0

0

0

0

0

0

0

0

0

0

1302.6

75.0144

1279.4

67.3155

1361.3

34.9668

1434.1

47.0259

5448.6

59.4983

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

Maximum

Value

------3

0

3

0

3

0

4

0

4

0

4

0

4

0

1524.7

12.0835

1508.1

10.9489

1501.2

1.47573

1548.1

48.606

6007

11.0252

3

0

3

0

3

0

4

0

4

0

4

0

4

0

1919.1

40.7798

1922.2

38.424

7656.4

166.389

Current

Value

-------1.7

1.1595

0.7

0.823273

0.6

0.843274

1

0

2.3

1.1595

1.6

0.843274

1

0

1324.6

78.9292

1285.5

67.6005

1363.4

36.05

1480.6

85.301

5454.6

59.3543

1

1.24722

1.1

1.1005

0.3

0.483046

1.6

0.843274

3

1.24722

1.9

1.1005

1.6

0.843274

1919.1

40.7798

1922.2

38.424

7656.4

166.389

Average

Value

--------1.5029

0.0300971

0.760327

0.0335061

0.369903

0.0343797

1.36504

0.0241146

2.49527

0.0297928

1.73495

0.0395944

1.36504

0.0241146

1420.56

43.5337

1395.14

49.4724

1429.6

22.8533

1492.48

40.9793

5737.96

39.1328

1.49734

0.0240776

0.747844

0.0257622

0.37761

0.0139905

1.37513

0.028033

2.50059

0.0239198

1.75274

0.0263904

1.37513

0.028033

955.13

30.2412

967.282

24.0916

3846.64

95.6109

22

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

(Average)

(Std. Dev.)

Appendix C – Copy of Case 3 from Harrell (pages 371-373)

23

24

25

Appendix D-Sample of Output Trace

Trace Model: A:\Warehouse Project\ManpowerReduction2.MOD

00:00.0 Trace Start

00:00.4 1 Receiving_Order scheduled to arrive at Receiving.

00:00.4 Receiving_Order arrives at Receiving.

00:00.4 For Receiving_Order at Receiving:

00:00.4

Receiving_Order enters Receiving.

00:00.4

Int: Number_of_receiving_order = 1 (old value = 0)

00:00.4

Int: R_Order_Line1 = 1 (old value = 0)

00:00.4

Int: R_Order_Line1 = 1 (old value = 1)

00:00.4

Int: RR1 = 3 (old value = 0)

00:00.4

Int: R_Order_Line2 = 1 (old value = 0)

00:00.4

Int: R_Order_Line2 = 1 (old value = 1)

00:00.4

Int: RR2 = 2 (old value = 0)

00:00.4

Int: R_Order_Line3 = 1 (old value = 0)

00:00.4

Int: R_Order_Line3 = 1 (old value = 1)

00:00.4

Int: RR3 = 1 (old value = 0)

00:00.4

Int: R_Order_Line4 = 1 (old value = 0)

00:00.4

Select route from route block #1; output quantity is 1.

00:00.4 For Receiving_Order at Receiving:

00:00.4

Inspection_Table is selected for routing.

00:00.4

The main entity is routed out as Receiving_Order.

00:00.4

Output is named as Receiving_Order.

00:00.4 Receiving_Order at Receiving picked up by InspectorSorters.1.

00:00.4

Start move to Inspection_Table.

00:00.4 For Receiving_Order at Receiving:

00:00.4

Process completed.

00:00.4

Release the captured capacity.

00:00.4 InspectorSorters.1 arrives at Inspection_Table.

00:00.4 Receiving_Order is dropped off at Inspection_Table by

InspectorSorters.1.

00:00.4 InspectorSorters.1 is kept by Receiving_Order.

00:00.4 Receiving_Order arrives at Inspection_Table.

00:00.4 For Receiving_Order at Inspection_Table:

00:00.4

Receiving_Order enters Inspection_Table.

00:00.4

Wait 4.6 Min.

00:00.7 1 Customer_Order scheduled to arrive at Customer_Order_Pickup.

00:00.7 Customer_Order arrives at Customer_Order_Pickup.

00:00.7 For Customer_Order at Customer_Order_Pickup:

00:00.7

Customer_Order enters Customer_Order_Pickup.

00:00.7

Int: Number_of_C_order = 1 (old value = 0)

00:00.7

Int: C_Order_Line1 = 1 (old value = 0)

00:00.7

Int: C_Order_Line1 = 1 (old value = 1)

00:00.7

Int: AA = 3 (old value = 0)

00:00.7

Int: C_Order_Line2 = 1 (old value = 0)

00:00.7

Int: C_Order_Line2 = 1 (old value = 1)

00:00.7

Int: BB = 2 (old value = 0)

00:00.7

Int: C_Order_Line3 = 1 (old value = 0)

00:00.7

Int: C_Order_Line3 = 1 (old value = 1)

00:00.7

Int: CC = 1 (old value = 0)

00:00.7

Int: C_Order_Line4 = 1 (old value = 0)

00:00.7

Select route from route block #1; output quantity is 1.

00:00.7 For Customer_Order at Customer_Order_Pickup:

00:00.7

Pick_Up_Table1 is selected for routing.

00:00.7

The main entity is routed out as Customer_Order.

00:00.7

Output is named as Customer_Order.

26

References

Banks, Jerry ed. [1998], Handbook of Simulation Principles, Methodology, Advances,

Applications, and Practice, 1st ed., John Wiley & Sons, Inc., New York, NY. Pgs 571-591.

Harrell, C., B.K. Ghosh and R. Bowden [2000], Simulation Using ProModel, 3rd ed., McGraw

Hill. Boston, MA.

Lee Heungsoon F. [1997]. “Performance Analysis for Automated Storage and Retrieval

Systems”. IIE Transactions. 29, 15-28.

Olson, David R. [1990], Establishing Best Order Picking Practices for Your Warehouse

Operation, 1st ed., Warehouse Advisory Council.

Stock, James R. and Douglas M. Lambert [1987], Strategic Logistics Management, 2nd ed.,

Irwin, Homewood, IL. Pgs. 302-343.

Tomkins, James A. and Dale A. Harmelink, eds. [1994], The Distribution Management

Handbook, 1st ed., McGraw Hill, New York, NY. Pgs 18.11-18.27 and 27.10 – 27.25.

Witt, C.E. [1989], “Reebok’s Distribution on Fast Track”. Materials Handling Engineering.

March. 43-46.

27