MEDUSA Methane Engine Design for Unmanned Small Aircraft Test Readiness Review

advertisement

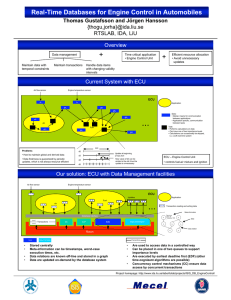

MEDUSA Methane Engine Design for Unmanned Small Aircraft Test Readiness Review University of Colorado at Boulder 03/05/2015 Customer: Dr. Ryan Starkey Daniel Frazier Christopher Jirucha Alexander Truskowski Team Nathan Genrich Crawford Leeds Carlos Torres Advisor: Dr. Jelliffe Jackson Abram Jorgenson Huikang Ma Corey Wilson Outline 2 • Overview Project Overview Corey Wilson and Schedule Mechanical Daniel Frazier • Schedule Software and Electronic Budget • Testing • Budget Project Overview Mechanical Software and Electronic Crawford Leeds Crawford Leeds Engine Integration Budget Project Statement 3 Project Description: Modify a JetCat P90-RXi mini turbo jet engine to run on gaseous methane fuel to address the USAF’s interest in the possible use of the methane gas as fuel. Functional Requirements Engine Control Unit (ECU) Fuel Delivery System (FDS) Project Overview Start, run, and shut down engine Maintain JetCat recommended safe operation conditions Log data Deliver up to 4.2g/s of methane to combustion can Deliver kerosene/oil mix to bearings at stock rates Mechanical Software and Electronic Engine Integration Budget 4 PROJECT OVERVIEW Project CONOPS and Objective RC Signal RC Receiver 5 Current Stock Engine: JetCat P90-RXI JetCat ECU RPM and Temperature from Engine Sensor Board Commands to pump/solenoids Injection point RPM < 130,000 Shaft Lubrication Line Kerosene Fuel/Lubricant Exhaust Temp < 700oC Project CONOPS and Objective Mass Flow Safety Controller Valves Commands to Controller Student ECU Fuel Commands to RPM and Temperature Manifold pump/solenoids from Engine Sensor Board 6 Pressure Regulator Methane Tank RPM < 130,000 Student Engine Board Use stock lubrication hardware Will use stock sensors Six Student injectors Exhaust Temp < 700oC Fuel System Methane Tank RC Controller Kerosene Tank Throttle Command Key Physical Contact Electrical Signal Data 0.9 - 4.2 g/s Mass Flow Controller Fuel Pump Provided Purchased Designed Lubrication System PWM Lubrication Solenoid Logic Algorithms Command Outputs Starter Motor Injectors Combustion Compressor Bearings Can ESB PWM Input Receivers Engine PWM ECU RS-232 Receiver 0-2500 Hz SPI T5 < 700oC Turbine Nozzle Injectors Hall Effect Sensor Cold Junction Compensation & Amplification 7 8 Critical Project Requirements Requirement Subsystem Description CPR.1 FDS The FDS shall deliver 0.9-4.2g/s ± 5% of methane to the combustion chamber CPR.2 FDS The FDS shall deliver lubricant to the bearings at rates equal to or greater than stock rates CPR.3 ESB The ESB shall read data from the existing thermocouple and hall effect sensor CPR.4 ESB The ESB shall transmit sensor data to the ECU CPR.5 ESB The ESB shall drive signals to engine hardware components CPR.6 ECU The ECU shall implement open loop control to control fuel flow rate CPR.7 ECU The ECU shall shutdown the engine should the exhaust temperature exceed 700oC or the RPM exceed 130,000 CPR.8 ECU The ECU shall detect an ignition failure, shutoff fuel flow, and drive compressor Project Overview Mechanical Software and Electronic Engine Integration Budget 9 SCHEDULE Project Overview Mechanical Software and Electronic Engine Integration Budget MEDUSA Current Work Plan Where We Are 10 Week 10 ECU phase II ECU phase I (Completed) Week 12 Week 14 FDS IIIIII: (In progress): ECU Phase III(Completed): (Completed): (In progress): FinalPhase System Test: FDS components ordered, received and ECU& revision ESB:Board Finished bothwith prototypes, ECU &ESB ESB Board manufacturing Integrating ECU and FDS engine manufactured FDS sealfunctional and flow rate manufacturing if necessary passed testsverification test Software: Individual functions ECU & software Integration Mockhardware engine test with hardware Lubrication rate date collection ECU and ESBflow board verified for engine complete test integration Simulator: LabView complete Engine simulator testcode - verify ECU and Methane engine test run – validate the verified. requirements project requirments Spring Break FDS phase I (Completed) Electrical Software MSR Labview ECU Integration Fuel Delivery Lubrication Engine Integration ECU phase III TRR Final system Test FDS phase II SFR Testing Architecture & Presentation Layout April 20 Spring Break Level 3 Engine Functions With Methane Fully integrated engine test Level 2 Drive mechanical components with ECU/ESB Mock engine test with hardware Lubrication Flowrate Data Collection TRR MSR 11 Level 1 Seal & Flow Rate Checks Mechanical Project Overview Mechanical ECU/ESB Integration ECU/ESB Chip Tests ECU Function Development Electrical Software Software and Electronic Engine Integration Engine simulation with Labview Verification Test Budget Testing Architecture & Presentation Progress April 20 Spring Break Level 3 Engine Functions With Methane Fully integrated engine test Level 2 Drive mechanical components with ECU/ESB Mock engine test with hardware Lubrication Flowrate Data Collection TRR MSR 12 Level 1 Seal & Flow Rate Checks Mechanical Project Overview Mechanical ECU/ESB Construction ECU/ESB Chip Tests ECU Function Development Electrical Software Software and Electronic Engine Integration Engine simulation with Labview Verification Test Budget Methane Delivery: Flow Rate Verification 13 Run Engine With Methane CPR.1 Deliver methane from 0.9 - 4.2 g/s (Idle to Full Thrust) Must validate system and predictive models Pressure vs Flow Rate Flow rate vs Temp CPR.1 Meet flow rate command within 5% Project Overview Mechanical Software and Electronic Engine Integration Budget Methane Delivery: Seal Verification 14 • Goal: Verify system has leak rate below 4% of commanded flow rate Performed with air at Boulder Municipal with a blast tunnel 125 PSI (Maximum operational pressure) Air Compressor Safety Valves Mass Flow Controller Fuel Injectors Check Valve Pressure Gauge ∆𝐺𝑎𝑢𝑔𝑒 5% total mass in tubes = 𝐿𝑒𝑎𝑘𝑎𝑔𝑒 < 𝐼𝑑𝑒𝑎𝑙 𝐺𝑎𝑠 𝐿𝑎𝑤 𝑤𝑖𝑡ℎ 𝑎𝑖𝑟: 5𝑝𝑠𝑖/ 𝑠 𝑎𝑡 125𝑃𝑆𝐼 𝑇𝑖𝑚𝑒 Equivalent methane leak within OSHA standards Jan 30 8hr Remain Mar 10 Methane: Pressurized Delivery Verification 15 • Goal: Verify systems delivers methane within 5% of commanded rate (CPR.1) Performed with air at Boulder Municipal with a blast tunnel Manual Control 0.9-4.2g/s Flowrate Delivered Error < 1% of Commanded Rate Relief Valve at operational engine pressure Check Valve Safety Valves Air Compressor Mass Flow Controller Fuel Injectors Pressure Vessel Methane: Pressurized Delivery Verification 15 • Goal: Verify systems delivers methane within 5% of commanded rate (CPR.1) Performed with air at Boulder Municipal with a blast tunnel Command Error Manual Control Flowrate 0.9-4.2g/s Delivered Total Delivery Error < 5% Commanded Leak Error from controller to injectors Check Valve Safety Valves Air Compressor Mass Flow Controller Fuel Injectors Relief Valve at operational Pressure engine pressure Vessel Mar 4 10hr Remain Mar 15 Testing Architecture & Presentation Progress April 20 Spring Break Level 3 Engine Functions With Methane Fully integrated engine test Level 2 Drive mechanical components with ECU/ESB Mock engine test with hardware Lubrication Flowrate Data Collection TRR MSR 16 Level 1 Seal & Flow Rate Checks Mechanical Project Overview Mechanical ECU/ESB Construction ECU/ESB Chip Tests ECU Function Development Electrical Software Software and Electronic Engine Integration Engine simulation with Labview Verification Test Budget Lubrication: Experimental Test 17 Run Engine With Methane CPR.2 Lubricate bearings to prevent seizing Will use stock rates, but these are unknown No documentation, determine experimentally Project Overview Mechanical Software and Electronic Engine Integration Budget Lubrication: Experimental Test 18 • Goal: Find flow through Lubrication Solenoid Performed with kerosene at Boulder Municipal with a blast tunnel Flowmeter Flowmeter 2 1 Pump Fuel Can 1 2 Bearing Lubrication Lubrication Solenoid Bearings Fuel Solenoid Injectors On Hold because of weather Jan 20 5hr Remain Mar 14 Lubrication: Calibration & Error Test Results • Goal: Calibrate flowmeters and calculate test error Performed in Dr. Starkey’s lab with fire extinguisher Fuel Can 250ml Graduated Cylinder 1-3V Power Supply Flowmeters Filter 1 2 Pump Pulses/Quantity=Calibration Factor 1 2 Relative Flowmeter Error Omega 601b Equflow 0045 29000 116000 Manufacturer 36000 110000 Tested 19 Lubrication: Calibration & Error Test Results • Goal: Calibrate flowmeters and calculate test error Performed in Dr. Starkey’s lab with fire extinguisher Fuel Can 250ml Graduated Cylinder 1-3V Power Supply Flowmeters Filter 1 2 Pump Relative Error Calibration Error 𝝈 1 2 𝑵 Error Pulses/Quantity=Calibration Factor Omega 601b Equflow 0045 29000 116000 Manufacturer 36000 110000 Tested 19 Lubrication: Calibration & Error Test Results 19 • Goal: Calibrate flowmeters and calculate test error Performed in Dr. Starkey’s lab with fire extinguisher Fuel Can 1-3V Power Supply Flowmeters Filter 1 Pump Relative Error 0.001±0.046mL/s Calibration Error 0.014±0.011mL/s 2 45 Tests, 6 most refined procedures 250ml Graduated Cylinder 0.07mL/s 2% of Max Achievable Throttle Jan 20 10hr Remain Mar 14 Lubrication: Remaining Work • Complete Engine Testing • Analyze data • Prove ECU can operate lubrication system (CPR.2) • Drive pump with ECU • Check flow rate produced • Test in Dr. Starkey Lab with fire extinguisher ECU Filter 250ml Graduated Cylinder • Predicted 30 hours, has taken 60 so far • 15 hours to go • Not a scheduling problem 20 Pump Lubrication Solenoid 𝐹𝑢𝑒𝑙 𝐷𝑒𝑙𝑖𝑣𝑒𝑟𝑒𝑑 = 𝐹𝑙𝑜𝑤 𝑅𝑎𝑡𝑒 𝑇𝑖𝑚𝑒 Engine Lubrication Tubing Testing Architecture & Presentation Progress April 20 Spring Break Level 3 Engine Functions With Methane Fully integrated engine test Level 2 Drive mechanical components with ECU/ESB Mock engine test with hardware Lubrication Flowrate Data Collection TRR MSR 21 Level 1 Seal & Flow Rate Checks Mechanical Project Overview Mechanical ECU/ESB Construction ECU/ESB Chip Tests ECU Function Development Electrical Software Software and Electronic Engine Integration Engine simulation with Labview Verification Test Budget Software/Electronics: Command Testing 22 Engine Control Unit Run Engine With Methane Engine Control Unit Engine Sensor Board CPRs. 3-8 Control engine state Check safety conditions Test functionality without risking engine damage Project Overview Mechanical Software and Electronic Engine Integration Budget Electrical/Software: Command Flow Raw Sensor Data Processed Sensor Data 23 Key Raw Data Processed Data Command Component Stock Engine Components Student Engine Sensor Board (ESB) Methane Delivery System Component Commands Student Engine Control Unit (ECU) RC Command Electrical/Software: Command Flow 23 Key Raw Data Electronic Data and Commands Signals from/to Stock Hardware RPM Sensor Thermocouple RPM Processed Data TEMP Command Component Starter Motor Student Engine Starter Motor Pump Sensor Board (ESB) Pump Solenoid Solenoid Glow Plug Glow Plug Combustor Flow Control Methane Delivery System Student Engine Control Unit (ECU) RC Command Software Test & Integration Status Item Signal Type PWM Electronic Data and Commands Individual Individual simulated test RPMHardware Test 24 Integration and Test TEMP PWM On/Off On/Off On/Off Complete Complete f Modulation SPI Time Remaining Starter Motor Pump Solenoid Glow Plug RS-232 Complete RC Command Complete Complete Complete Complete 5 Hours Remaining PredictedFlow 92 Hours, Control Spent 60 Jan 1 8hr Remain Mar 7 24 Testing Architecture & Presentation Progress April 20 Spring Break Level 3 Engine Functions With Methane Fully integrated engine test Level 2 Drive mechanical components with ECU/ESB Mock engine test with hardware Lubrication Flowrate Data Collection TRR MSR 25 Level 1 Seal & Flow Rate Checks Mechanical Project Overview Mechanical ECU/ESB Construction ECU/ESB Complete Chip Tests ECU Function Development Electrical Software Software and Electronic Engine Integration Engine LabView simulation Engine Simulator with Labview Test Verification Test Budget Electrical/Software: Command Flow Key Raw Data Processed Data Electronic Data and Commands RPM Signals from/to Stock Hardware RPM Sensor 26 Command Component TEMP Thermocouple Starter Motor Student Engine Starter Motor Pump Sensor Board (ESB) Pump Solenoid Solenoid Glow Plug Glow Plug Injectors Flow Controller Methane Delivery System Student Engine Control Unit (ECU) RC Command LabView Simulation Test 26 • Goal: Verify CPRs 3-8 are met in a simulated environment without danger to the engine Performed in a computer lab Electronic Data Signals from/to and Commands Stock Hardware RPM Sensor RPM Key Raw Data Processed Data Component TEMP Thermocouple Starter Motor Student Engine Starter Motor Pump Sensor Board (ESB) Pump Solenoid Solenoid Glow Plug Glow Plug Flow Controller Command Student Engine Control Unit (ECU) RC Command Full Engine Simulator Test • Goal: Verify CPRs 3-8 are met in a simulated environment without danger to the engine Performed in a computer lab RPM Sensor Thermocouple Starter Motor Pump Solenoid Glow Plug Flow Controller 26 Full Engine Simulator Test 27 • Goal: Verify CPRs 3-8 are met in a simulated environment without danger to the engine Performed in a computer lab Signals from/to stock hardware Expected Signal Acceptable 0-2400Hz (0-144,000 RPM) Simulated Thermocouple 0-41mV (0-1000oC) Simulated Starter Motor 0-8V PWM, 555kHz, 39% Duty Cycle ±0.5V, ±5kHz ±1% Duty Cycle 0.5V ±0.01V Solenoid 10V ±1V Glow Plug 10V ±1V RS-232 ASCII From ECU <3% Baud Rate Error RPM Sensor Pump Flow Controller Engine Run Sequence Wait For User Command Startup Shutdown Engine Running Control Loop Emergency Shutdown Mar 9 25hr Remain Mar 23 Testing Architecture & Presentation Progress April 20 Spring Break Level 3 Engine Functions With Methane Integrated Engine Test Level 2 Drive mechanical components with ECU/ESB Mock Engine Test Lubrication Flowrate Data Collection TRR MSR 28 Level 1 Seal & Flow Rate Checks Mechanical Project Overview Mechanical ECU/ESB Construction ECU/ESB Chip Tests ECU Function Development Electrical Software Software and Electronic Engine Integration LabView Engine Simulator Test Verification Test Budget LabView Simulation Test 29 • Goal: Verify CPRs 3-8 are met in a simulated environment without danger to the engine Performed in a computer lab Electronic Data Signals from/to and Commands Stock Hardware RPM Sensor RPM Key Raw Data Processed Data Component TEMP Thermocouple Starter Motor Student Engine Starter Motor Pump Sensor Board (ESB) Pump Solenoid Solenoid Glow Plug Glow Plug Flow Controller Command Student Engine Control Unit (ECU) RC Command Mock Engine Test 29 • Goal: Verify CPRs 3-8 are met using engine hardware without danger to the engine Performed with air at Boulder Municipal with a blast tunnel Electronic Data Signals from/to and Commands Stock Hardware RPM Sensor RPM Not Connected to each other or the engine Processed Data Command Component TEMP Thermocouple Run as in engine operation Key Raw Data Starter Motor Student Engine Starter Motor Pump Sensor Board (ESB) Pump Solenoid Solenoid Glow Plug Glow Plug Pressure Vessel Flow Controller Methane Delivery System Student Engine Control Unit (ECU) RC Command Mock Engine Test • Goal: Verify CPRs 3-8 are met using engine hardware without danger to the engine Performed with air at Boulder Municipal with a blast tunnel RPM Sensor Thermocouple Starter Motor Pump Solenoid Glow Plug Flow Controller 29 Mock Engine Test 30 • Goal: Verify CPRs 3-8 are met in a simulated environment without danger to the engine Performed with air at Boulder Municipal with a blast tunnel Signals from/to stock hardware RPM Sensor Thermocouple Expected Operation Passing Operation Range 0-2400Hz (0-144,000 RPM) Simulated 0-41mV (0-1000oC) Simulated Starter Motor Pump Solenoid Results TBD Results TBD On/Off On/Off Engine Run Sequence Wait For User Command Startup Shutdown Glow Plug Flow Controller 0.9-4.2 g/s Engine Running Control Loop Emergency Shutdown ±5% commanded rate Mar 20 40hr Remain Apr 4 Testing Architecture & Presentation Progress April 20 Spring Break Level 3 Engine Functions With Methane Fully integrated engine test Level 2 Drive mechanical components with ECU/ESB Mock engine test with hardware Lubrication Flowrate Data Collection TRR MSR 31 Level 1 Seal & Flow Rate Checks Mechanical Project Overview Mechanical ECU/ESB Construction ECU/ESB Chip Tests ECU Function Development Electrical Software Software and Electronic Engine Integration Engine simulation with Labview Verification Test Budget Mock Engine Test 32 • Goal: Verify CPRs 3-8 are met using engine hardware without danger to the engine Performed with air at Boulder Municipal with a blast tunnel Electronic Data Signals from/to and Commands Stock Hardware RPM Sensor RPM Not Connected to each other or the engine Processed Data Command Component TEMP Thermocouple Run as in engine operation Key Raw Data Starter Motor Student Engine Starter Motor Pump Sensor Board (ESB) Pump Solenoid Solenoid Glow Plug Glow Plug Pressure Vessel Flow Controller Methane Delivery System Student Engine Control Unit (ECU) RC Command Integrated Engine Test 32 • Goal: Successful operate engine with methane; Verify all requirements (CPR 1-8) Performed with methane at Boulder Municipal with a blast tunnel Electronic Data Signals from/to and Commands Stock Hardware RPM Sensor RPM Key Raw Data Processed Data Command Component TEMP Thermocouple Starter Motor Student Engine Starter Motor Pump Sensor Board (ESB) Pump Solenoid Solenoid Glow Plug Glow Plug Combustor Flow Controller Methane Delivery System Student Engine Control Unit (ECU) RC Command Integrated Engine Test 33 • Goal: Successful operate engine with methane; Verify all requirements (CPR 1-8) Performed with methane at Boulder Municipal with a blast tunnel Engine Process Data Collected Performance Characterization Engine Run Sequence Startup Objective 1 Startup RPM Maintain engine speed above 35kRPM? Objective 2 Shutdown & Emergency Shutdown Shutdown & Emergency Shutdown Engine shuts down safely Objective 3 Engine Running RPM & Temperature Objective 4 Engine Running Temperature, & Mass Flow Rate Wait For User Command Shutdown Below 130,000 RPM Temperature below 700oC Engine Running Control Loop Emergency Shutdown Flow Rate vs Temperature Apr 25hr Remain Apr 19 34 Critical Project Requirements Requirement Subsystem Description CPR.1 FDS The FDS shall deliver 0.9-4.2g/s ± 5% of methane to the combustion chamber CPR.2 FDS The FDS shall deliver lubricant to the bearings at rates equal to or greater than stock rates CPR.3 ESB The ESB shall read data from the existing thermocouple and hall effect sensor CPR.4 ESB The ESB shall transmit sensor data to the ECU CPR.5 ESB The ESB shall drive signals to engine hardware components CPR.6 ECU The ECU shall implement open loop control to control fuel flow rate CPR.7 ECU The ECU shall shutdown the engine should the exhaust temperature exceed 700oC or the RPM exceed 130,000 CPR.8 ECU The ECU shall detect an ignition failure, shutoff fuel flow, and drive compressor Project Overview Mechanical Software and Electronic Engine Integration Budget 35 BUDGET Project Overview Mechanical Software and Electronic Engine Integration Budget Budget – MSR Recap 37 $3,500 $3,000 Total: $4,273 $350 $2,500 $2,000 $1,500 $2,697 $1,000 $700 $900 $500 $266 $0 ECU $100 $111 $149 FDS Already Spent (MSR) Testing Remaining (MSR) Other Budget – TRR Status 36 $3,500 $200 $3,000 Total: $5,044 $2,500 $2,000 $1,500 $2,945 $1,196 $740 $1,000 $500 $300 $517 $149 $0 ECU FDS Already Spent Testing Expected Future Expenses $192 Other Remaining Available Budget – TRR Remaining 37 $1,400 $1,240 $1,196 $1,200 $1,000 $800 $600 $400 $200 $0 Future Costs ECU, FDS, Other Expected Remaining Available 50 BACKUP SLIDES Methane: Delivery Verification (Detail) • Goal: Verify methane delivery within error bounds (CPR 3) Pressure Relief Valve Manual Control Flowrate Delivered Relief Valve at operational engine pressure Fuel Injectors Methane Cylinder Shutoff Solenoid Mass Flow Controller Check Valve Pressure Vessel Thermocouple Input Software Test • Connect SPI interface to pins C4 throughC7 • Temperature transmitted through SPI bus from ESB • Interrupt based. • Runs continuously • EGT used to regulate engine safety – 700o max Feb 20 2 Hours Remaining Feb 28 Mass Flow Controller Output Software Test • Connect through RX/TX on pins C2, C3 • Mass flow data transmitted via RS-232 communication protocol • Function based • Runs only when called • Mass flow used to control the engine throttle level Feb 20 2 Hours Remaining Feb 28 RC Controller Software Test • Connect RC Receiver to pin D3 • D3 – RC Throttle Input • Interrupt Based • Throttle input used to set the mass flow controller Feb 20 2 Hours Remaining Feb 28 RPM Input Software Test • Connect RPM input to pin A6 • Interrupt based • Must run continuously • RPM used to regulate engine safety – 130,000 max • RPM used to regulate the lubrication flow Feb 20 2 Hours Remaining Feb 28 Starter Motor Output Software Test • Connect starter motor to pin E0 • Starter motor receives PWM signal • Interrupt based • Runs continuously • Starter Motor used to start the engine, as well as safely cool engine in shut down Feb 20 2 Hours Remaining Feb 28 Electrical/Software: Command Flow RPM Sensor RPM Thermocouple TEMP Starter Motor Student Engine Starter Motor Pump Sensor Board (ESB) Pump Solenoid Solenoid Glow Plug Glow Plug Injectors Flow Controller Methane Delivery System RC Command Student Engine Control Unit (ECU) Key Raw Data Processed Data Command Component Jan 1 5hr Remain Feb 22 Electrical/Software: Integrated Testing Part 1 • Goal: Verify Engine Sensor Board reads and transmits engine status (CPR.8) RPM Sensor Student Engine Thermocouple Sensor Board (ESB) Simulated Input: Function Generator DC Power Supply LabView RPM TEMP Recorded Output: Oscilloscope LabView Key Raw Data Processed Data Command Component Jan 1 5hr Remain Feb 22 Electrical/Software: Integrated Testing Part 2 • Goal: Verify Engine Control Unit receives data and sends commands (CPR.X) RPM TEMP Starter Motor Pump Solenoid Glow Plug Flow Controller RC Command Student Engine Control Unit (ECU) Key Raw Data Processed Data Command Component Jan 1 5hr Remain Feb 22 Electrical/Software: Integrated Testing Part 3 • Goal: Verify Engine Control Unit functions with Engine Sensor Board (CPR X) RPM Sensor Student Engine Thermocouple Sensor Board (ESB) RPM TEMP Starter Motor Pump Solenoid Glow Plug Flow Controller RC Command Student Engine Control Unit (ECU) Key Raw Data Processed Data Command Component Jan 1 5hr Remain Feb 22 Electrical/Software: Integrated Testing Part 4 • Goal: Verify Engine Control Unit functions with Engine Sensor Board (CPR X) RPM Sensor RPM Thermocouple TEMP Starter Motor Student Engine Starter Motor Pump Sensor Board (ESB) Pump Solenoid Solenoid Glow Plug Glow Plug Flow Controller RC Command Student Engine Control Unit (ECU) Key Raw Data Processed Data Command Component Jan 1 5hr Remain Feb 22