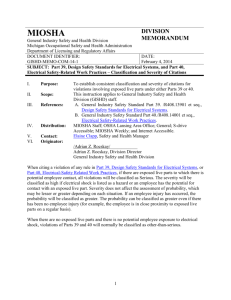

MIOSHA AGENCY INSTRUCTION

advertisement