Laboratory Chemical Hygiene Plan Northeastern University Office of Environmental Health & Safety

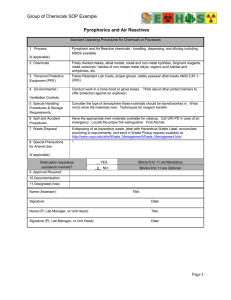

advertisement