Site-Specific Bloodborne Pathogen Non-Laboratory Exposure Control Plan

advertisement

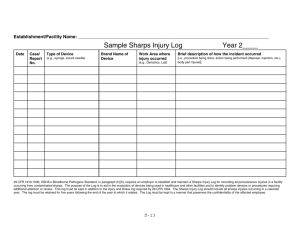

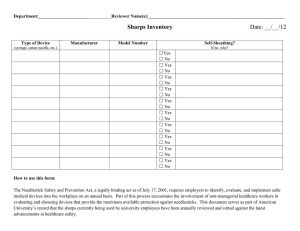

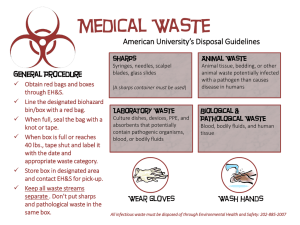

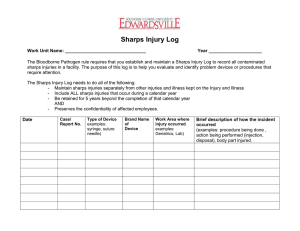

Site-Specific Bloodborne Pathogen Non-Laboratory Exposure Control Plan Program Scope The Northeastern University Exposure Control Plan (ECP) describes how to eliminate or minimize the exposure of personnel to human blood, blood products and other potentially infectious material (OPIM) that may contain bloodborne pathogens (BBP). The ECP is available on the Office of Environmental Health and Safety website for review and downloading. This document provides site-specific information about how the ECP will be carried out in specific areas and supplements the university ECP. Responsibilities: Each supervisor of non-laboratory environments will: 1. Complete this site-specific ECP based on the activities performed in his/her facilities. The plan will remain on file in a central location within the laboratory or workplace along with other safety documents. A copy will be submitted to the Biosafety Program Manager each year to ensure the plan is updated annually. 2. Consider sharps safety devices annually. A review of devices must be completed every year and should involve staff members that work with the sharps. The “Safety Needle/Sharps Annual Review Form” and “Sharps Safety Device Evaluation Form” should be completed each year and retained for record keeping purposes. 3. Assure that faculty, staff and students are referred to complete the Bloodborne Pathogens training provided by EHS at the time of initial assignment and annually thereafter. 4. All eligible faculty, staff and students will be offered the hepatitis B vaccine. Each employee must fill out a “Hepatitis B Vaccination Verification/Declination Form”. This form will be kept on file in the Office of Environmental Health and Safety. 5. Refer employees who would like to get the hepatitis B vaccine to contact the Office of Environmental Health and Safety. Employees may choose to accept the hepatitis B vaccine at any time. Prepared by Date Completed Phone Number Date of annual review and update Building Room Number(s) Principal Investigator Department Person Responsible for ECP Location of ECP 1 Category I This includes workers with job related tasks or procedures that have the potential to involve contact or exposure to mucous membranes with blood or OPIM. This can include the potential for spills or splashes. Activities include research, teaching and clinical work that involves the use of human blood or OPIM. Personnel and/or job title with expected occupational exposure Category II This includes workers with job related tasks or procedures that do not normally involve planned exposure to human blood or OPIM. Potential exposure may result from unplanned tasks and may be a condition of employment. Personnel and/or job title with possible exposure Check all material used in your work area that may result in employee exposure to bloodborne pathogens. Source Material of Potential Bloodborne Exposure Human Blood Cells/Tissues/Organ Cultures – Human Human Blood Components Body fluids with blood (e.g. saliva, vomitus) Human Blood Products All body fluids-can’t differentiate fluids Unfixed Human Tissues Other: Unfixed Human Organs Other: Culture Growth Media Solutions Other: Experimental Animal Blood/Tissues Other: 2 Procedures/tasks with potential exposure Personal Protective Equipment (PPE) required Safety glasses Goggles Face shield Lab coat Disposable gown Coveralls Surgical Mask Gloves: Click here to select type Safety glasses Goggles Face shield Lab coat Disposable gown Coveralls Surgical Mask Gloves: Click here to select type Safety glasses Goggles Face shield Lab coat Disposable gown Coveralls Surgical Mask Gloves: Click here to select type Safety glasses Goggles Face shield Lab coat Disposable gown Coveralls Surgical Mask Gloves: Click here to select type Safety glasses Goggles Face shield Lab coat Disposable gown Coveralls Surgical Mask Gloves: Click here to select type Safety glasses Goggles Face shield Lab coat Disposable gown Coveralls Surgical Mask Gloves: Click here to select type Safety glasses Goggles Face shield Lab coat Disposable gown Coveralls Surgical Mask Gloves: Click here to select type 3 Engineering and Work Practice Controls Please check the appropriate methods of compliance below. Engineering controls – Specify when each is used Incineration box lined with 2 red biohazard bags covered with a plastic lid Sharps container: Tongs or forceps to handle broken glass: Other (describe): Sharps containers are inspected, Whenever necessary to prevent maintained and replaced: overfilling (no more than 2/3 full) By: Every: Sharps container decontamination and disposal procedure: Containers for reusable sharps information and protocol for securing and removing Sharps injury log See Appendix A 4 Work practice controls used to minimize exposure; in conjunction with universal precautions No eating or drinking, applying Reusable sharps are secured cosmetics or contact lenses in areas immediately when not in use (explain how with human materials (blood and/or and where these are stored): OPIM) Wear protective footwear No capping, bending or shearing needles Contaminated sharps are Additional work practice controls immediately placed in sharps container (explain): No mouth pipetting Change gloves whenever soiled, torn or punctured Remove gloves before exiting the lab or clinical environment Follow procedures for proper removal and disposal of PPE Training on use of engineering controls required prior to working in Specimens are transported in secondary, non-breakable, leak proof, sealed and labeled containers when taken outside of the lab Wash hands when gloves are removed or changed, whenever gloves become soiled or contaminated and before leaving the work area How are all personnel and supervisors involved in identifying changes in engineering controls and work practices and evaluating new products or process improvements? Employee feedback (explain): Exposure incident investigation: Other (specify and explain): Name of person responsible for implementing engineering controls and work practice recommendations 5 Personal Protective Equipment (PPE) Please indicate the appropriate methods of compliance below. Location of PPE Person responsible for providing PPE Procedure for removal and handling of used PPE List articles that are laundered Person responsible for laundry & name of company How are articles prepare for laundry and what is the laundry schedule? Decontamination Procedure Potentially contaminated surfaces and equipment shall be decontaminated at the end of each work shift. Use the table below to identify your laboratory/workplace cleaning schedule. Disinfectant (concentration) Contact time (minutes) Spill and decontamination procedures (specify disinfectant and contact time) Handwashing Facilities Hand washing facilities shall be made available and readily accessible however where handwashing facilities are not feasible, antiseptic cleanser with clean paper towels will be available. When antiseptic cleanser is used, employee shall wash his/her hand with soap and running water as soon as feasible. 6 Location of handwashing facilities and/or antiseptic cleaner Person responsible for maintaining supplies and handwashing facility Waste Disposal Bloodborne pathogen waste procedure - explain how waste is handled and disposed of (include PPE): Person responsible for providing lab specific BBP training (required before working with BBP – includes on proper use of engineering controls) Person responsible for reviewing exposure incidents Emergency Procedures 7 Wash area immediately Wounds and needlestick: Thoroughly scrub the area for 15 minutes with warm water and soap. Eye and mucous membrane exposure: Flush immediately at nearest eyewash station for 15 minutes. Seek care immediately While you are treating your exposure area, have a co-worker contact campus police at (617) 373 – 3333 for help. They will triage you and get you to a medical care facility for further treatment if necessary. Be prepared with information for the healthcare providers. Bring information about the agent and/or animal or material involved in your injury or exposure. This information should include agent description, route of exposure, dose and concentration, and any unusual characteristics of the agent Notify your supervisor, PI and the Office of Environmental Health and Safety __________________________________________________________________________________________ Signature of PI or Lab Manager Date reviewed & updated (must be within 12 months of last review/update) 8 Appendix A Sharps Injury Log PI/Supervisor: Dates: Date Entered Date/Time Type/Brand of of Incident Device Department/ Work Area Incident Occurred Description of Incident Retain until _________________________________________ (Five years after end of log year) 9 Safety Needle / Sharps Annual Review Form All sharps that are being used where there is potential for exposure to bloodborne pathogens must be reviewed on an annual basis. During your annual review of devices, you must inquire about new or prospective safer options. Principal Investigator / Supervisor __________________________________________________ Date ____________________ Department __________________________________________ Extension ________________ Address _____________________________________________ Please fill out the table below with the appropriate information for documentation of: 1. Annual consideration of new safer sharps devices; 2. To determine which sharp devices are currently in use; 3. To document the criteria used in the selection of the safer sharp deice in use. Sharps Currently in Use Name of Sharp Manufacturer Size(s) in Use Is it a Safety Sharp? Are there evaluation forms (or exclusion memos) on file? Justification for selection of device (enter N/A if no device is currently available) Principal Investigator / Supervisor Signature _________________________________________ Date _____________________________________________ Sharps Safety Device Evaluation Form 10 Principal Investigator / Supervisor:______________________ Evaluation Date:______________ Evaluator’s Name:__________________________________ Job Title:_____________________ Department:______________________________________ Extension:____________________ Name of Device:________________________________________________________________ Name of Manufacturer:___________________________________________________________ Applications of Device:___________________________________________________________ Number of times used:___________________________________________________________ Please circle the most appropriate answer for each question. Not Applicable (N/A) maybe used if the question does not apply to this product. Please explain all problems with the device in the comments section. 1. The safety feature can be activated using a one-handed technique. Agree….Disagree 1 2 3 4 5 N/A 2. The safety feature does not interfere with the normal use of this product. 1 2 3 4 5 N/A 3. Use of this product requires you to use the safety feature. 1 2 3 4 5 N/A 4. The user’s hands remain behind the needle/sharp until activation of the safety mechanism is complete. 1 2 3 4 5 N/A 5. A clear and unmistakable change (either audible or visible) occurs when the safety feature is activated. 1 2 3 4 5 N/A 6. This product does not require more time to use than a non-safety device. 1 2 3 4 5 N/A 7. The device is easy to handle while wearing gloves. 1 2 3 4 5 N/A 8. The device is easy to handle when wet. 1 2 3 4 5 N/A 9. The safety feature works well with a wide variety of hand sizes. 1 2 3 4 5 N/A 10. The safety feature operates reliably. 1 2 3 4 5 N/A 11. The exposed sharp is permanently blunted or covered after use and prior to disposal. 1 2 3 4 5 N/A 12. This device will work with all required syringe and needle sizes. 1 2 3 4 5 N/A 13. Use of this product does not increase the number of sticks to the patient. 1 2 3 4 5 N/A 14. The user does not need extensive training for correct operation. 1 2 3 4 5 N/A 15. The device can be used without causing more patient discomfort than a conventional device. 1 2 3 4 5 N/A Sharps Safety Device Evaluation Form 11 16. This device offers a good view of any aspirated fluid. Agree….Disagree 1 2 3 4 5 N/A 17. The product stops the flow of blood after the needle is removed from the catheter (or after the butterfly is inserted) and just prior to the line connections or the hep-lock capping. 1 2 3 4 5 N/A 18. It is not easy to skip a crucial step in proper use of the device. 1 2 3 4 5 N/A Additional Questions for I.V. Connectors: 19. Use of this connector eliminates the need to exposed needles in connections. 1 2 3 4 5 N/A 20. The safety feature allows you to collect blood directly into a vacuum tube, eliminating the need for needles. 1 2 3 4 5 N/A 21. The connector can be secured (locked) to Y-sites, hep-locks, and central lines. 1 2 3 4 5 N/A Additional Questions for Vacuum Tube Blood Collection Systems: 22. The safety feature works with a butterfly. 23. The inner vacuum tube needle (rubber sleeved needle) does not present a danger of exposure. Would you recommend using this device? 1 2 3 4 5 N/A 1 2 3 4 5 N/A Yes No Comments (describe problems, list incompatibilities):___________________________________ _____________________________________________________________________________ _____________________________________________________________________________ _____________________________________________________________________________ _____________________________________________________________________________ _____________________________________________________________________________ 12