ALFRED UNIVERSITY Appendix W

advertisement

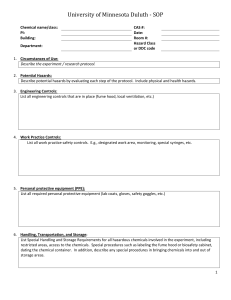

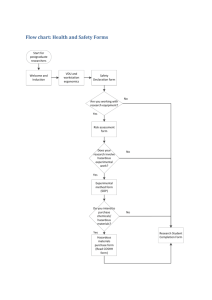

ALFRED UNIVERSITY CHEMICAL HYGIENE PLAN Appendix W Developing Site-Specific SOPs Blank SOP forms for Chemical or Chemical Hazard Class SOP and Process/Experiment/Equipment follow after ‘Instructions for completing site-specific SOP forms’ The purpose of a laboratory (site) specific SOP is to ensure that laboratory workers know how to work safely with the highly hazardous chemicals and equipment that are used in a particular lab. It is the responsibility of the LSF/PI to write site-specific SOPs and ensure they are followed. A copy of the completed SOP must be sent to EH&S along with the site-specific training documentation. The use of electronic SOPs is encouraged to allow for electronic posting and sharing among laboratories. When completing the electronic SOP form, use an ink color that will stand out from the form’s black type. If an SOP is valid for multiple labs, the same SOP can be used as long as it modified to fit the particular laboratory. Three methods that can be used to write an SOP: By Process/Experiment/Equipment such as distillation, synthesis, chromatography If hazardous intermediates are created, consider specific precautions which should be noted. Pre-existing laboratory procedures or instructions do not have to be rewritten, as long as all information required is within the existing plan. Complete first two pages of the SOP form and attach a copy of the existing material to the procedure detail section of the SOP or reference to the pre-written procedure and identify its location. Photos may be inserted into Detail Section to show proper set up of glassware, etc. By Individual Chemical such as acrylamide, formaldehyde, toluene This approach may be most useful if a limited number of hazardous substances are used in the laboratory or if using a particularly hazardous substance. By Class of Chemical such as organic solvents or peroxidizable chemicals Instructions for Completing the Site-Specific SOP Forms Choose proper site-specific SOP form Chemical/Chemical Hazard class or Process/Experiment/Equipment Location/Div means the building and room number(s) where the chemical used or process is performed/ Division or Department name Name means the name of the process or experiment or equipment Chemical means the full name of the chemical(s) used. CAS number means the Chemical Abstract Service Registry number unique to that chemical. Hazard Class means the hazard class of the chemical (carcinogen, reproductive toxins2, flammable, toxic, corrosive…) . Associated Hazards self explanatory NFPA Rating National Fire Protection Association rating found on MSDS and/or label. 1 Chemical Precautions specifies precautions handling, use and storage of chemical(s) Ex: incompatible or reactive with…. usable shelf life, etc. Be as specific as possible. Purchasing purchase or current possession of PHS requires prior approval from EH&S. Storage identifies specific storage area… “flammable cabinet to left of fume hood, room 312”. Security protocol detail procedure to secure chemical… “cabinet locked, etc. Designated area means specific area where the PHS used. Specify security protocol for area. Authorized personnel LSF/PI authorizes lab employee’s use of chemical or performance of process, etc. when the LSF/PI is confident employee demonstrates the level of knowledge required to safely perform the procedure. Complete LSF/PI Site Specific Employee Authorization Form and attach a copy to the SOP. Training requirements See Employee training. The Lab Safety Training (every laboratory employee should have this training) and Site-specific training boxes must always be checked. The check list of written programs and training provided is not inclusive; additional written materials or training may be added at the discretion of the person responsible for training. Retain training documentation records in the lab/department/Division training file; send copies of the completed Site-specific Training Form to EH&S. Engineering/Ventilation Controls describe controls such as laboratory fume hoods, explosion shielding, interlocks or other safety features on equipment required to be used to reduce employees’ exposure to hazardous chemicals and physical hazards. Personal protective equipment requirements may vary greatly depending upon the chemicals in use. Please check all items that apply. If additional safety equipment or conditions are required, please record these items in “other”. Please note the following: There is a requirement to use chemical splash goggles when corrosive liquids or other materials with a potential to splash the eyes or face are in use. Glove selection is particularly critical for carcinogens and acutely toxic materials. Many glove selection charts are available and the MSDSs for many chemicals make recommendations for the type of hand protection required. Refer to inserted links and Appendix C Glove selection. Call EH&S 2190 for assistance in glove selection if necessary. Incidental contact means the type and use of the glove to be worn when no contact with the chemical(s) is anticipated under normal conditions of use. Extended contact means the type and use of the glove to be worn when contact with the chemical(s) is anticipated, such as the immersion of the hands in a chemical when it is used as a cleaning agent, etc. Respirators are rarely needed in a lab setting. Generally speaking, all use of chemicals which pose an inhalation hazard must be conducted in a functional fume hood. All use of respirators at AU must be approved by EH&S. Call 2190 for assistance with respiratory protection if this is required for the chemical(s) in use. Shorts, tank tops, sandals, open toed shoes and other apparel that allow the arms, legs and feet to be exposed are prohibited when corrosives and other chemicals which pose a skin exposure hazard are in use. Long hair, jewelry and other items may present a hazard when hazardous chemicals and energized systems are in use. Remove jewelry and tie back long hair. Emergency Controls means safety equipment or supplies needed in the immediate area. Exposures Check N/A for process not using a hazardous chemical, otherwise list symptoms, first aid and other emergency procedures to be followed in the event that a person is exposed to the chemical(s) in use. The required information may be obtained from the MSDS. Emergency shutdown and evacuation procedures specify procedure for shutting down process or halting work with a hazardous chemical when an emergency occurs that requires evacuation of the lab or building. Spills/Decontamination Check N/A for process not using any chemical, otherwise: Spills describe procedures to be used in the event of a spill or other uncontrolled release of the chemical(s). Decontamination procedures should be developed when necessary/possible: neutralization procedures or a detoxifying method. Please attach a copy of a detailed procedure. Waste disposal be specific in describing proper waste storage and disposal procedures. Phone numbers to be used in the event of an emergency. List 911, 2108 AU Public Safety and EH&S 2190 for all major spills, accidents damaging property (explosions, fires) and substantial personal injuries. 1 NFPA is the National Fire Protection Association which has developed a system of rating the hazards of chemicals on a scale of 0-4 for health, flammability and reactivity. HMIS is a similar but proprietary system used by some chemical companies. The rating scales range from 0 for "no hazard" to 4 for "extremely hazardous" for each of the hazardous characteristics listed above. Many chemical company catalogs contain an explanation of the NFPA/HIMS rating system. 2 The LD50, or Lethal Dose 50, is the mean amount of a chemical that will cause 50% of a population of test animals to die when the chemical is administered via a particular route of exposure for a specified length of time.