report.doc

advertisement

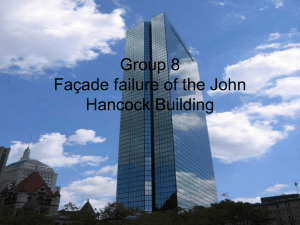

Group 8 Building façade failures : John Hancock Building Introduction The John Hancock Building, consisting of 2 million square feet of space, is a sixty storey structure sheathed in reflective glass. The building was praised for consorting agreeably with landmarks on a historic square and for being “not so much an object as a spectacle of changing light, an intensified comment on the qualities of the sky itself .”— Donlyn Lyndon. The City Observed: Boston. New York: Vintage Books, 1982. p195. This was, of course, due to its’ reflective glass, which up until then had never been used on such a large building. Background In the first half of the 20th century, building facades underwent a transition from massive load-bearing walls to relatively thin, lightweight, non-load-bearing "curtain walls." Before the transition, walls consisted of layers of masonry ("wythes"), which formed part of the load-bearing structure of the building. Floors were supported by the exterior walls and moved with the walls. But by today's standards, these walls were expensive, energy inefficient, and limited in design flexibility. Something else was needed — something that offered improved thermal performance, greater design freedom, and lower cost. Curtain walls proved to be the answer. The transition to curtain walls began in the late 1800s and continued until the middle of the 1900s. In the early part of the transition, walls were still massive, but they no longer supported the structure's floor loads. In the latter part of the transition, lightweight walls were "hung" on the structural frame. The transition from masonry load-bearing walls in many cases meant a transition to glass, now one of the most common cladding materials. The quintessentially brittle material, glass has introduced its own set of challenges. Glass is usually installed in metal framing systems, which means that thermal movement is inevitable: Aluminium frames subjected to a change in temperature can move about 2.5 times more than glass subjected to the same change. Breakage can result if the design does not accommodate this differential movement. This was the case with The John Hancock Building. 1 Façade Failure In 1972 and 1973 the mirror-glass windows of the building began to fracture, and was replaced with more than an acre of plywood. A "gag order" imposed on the parties to the resulting legal dispute prevented the release of the facts regarding the cause of the breakage, giving rise to many theories and myths, some of which exist to this day. Initially, many design professionals thought the reason for the breakage lay in the fact that the tower swayed excessively in the wind. Although it was indeed swaying substantially, this was not the reason for the glass breakage. Another hypothesis was that wind forces at "hot spots," which resulted from the rhomboid shape of the tower, caused overstressing of the glass. Substantial "hot spots" did exist, but only a small percentage of the glass was subject to anything near the load for which it had been designed. Still another myth was that the windows broke because of the stress they endured from the settlement of the tower's foundation. Causes But in fact, extraordinary external forces and the building's structural design were not the cause of the failure. The problem actually lay in the insulating glass itself. 2 The insulating-glass units that made up the facade were fabricated with a thin lead-tape spacer to separate the two panes of glass. The tape was soldered to the glass after the edge of the glass was coated with a film of copper to make it more receptive to the solder. This created a tenacious bond between the spacer and the glass, which constituted the product's greatest strength as well as the source of its demise. Conclusions We now realise that innovation can lead to reduced predictability and increased risk. To meet the challenge that innovation presents, we must use the lessons of this case study, coupled with sound technical fundamentals. References www.greatbuildings.com www.architectureWeek.com www.pubs.asce.org 3