Final Presentation (PPT, 5 MB + 1.5 MB movie) - 5/13/04

advertisement

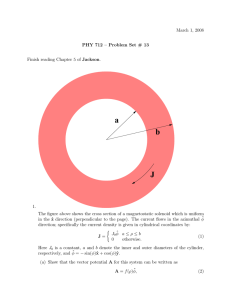

High Temperature Superconducting Solenoid Punch Our Mission Make an actuator using BSSCO 2223 HTS tape from American Superconductor What is an actuator? A device that converts between mechanical energy and other forms Copper solenoids http://www.magnet-schultz.com/msafront2.jpg MEMX High Performance Steerable MicroMirrors http://www.memx.com/products.htm What is a superconductor? A material that conducts without resistance Impenetrable by external magnetic fields (up to a point) Two types: Type I and Type II Examples: YBCO: Yttrium barium copper oxide BSSCO 2212, 2223: (Bi,Pb)2Sr2Ca1Cu2Ox, (Bi,Pb)2Sr2Ca2Cu3Ox Permanent magnet levitating over a superconductor http://helium.ee.tut.fi/supraryhma/images/korkealla.jpg BSSCO 2223 Structure BSSCO 2223 Unit Cell http://www.library.uow.edu.au/adt-NWU/uploads/approved/adtNWU20030305.113225/public/02Whole.pdf Our HTS Tape American Superconductor BSSCO 2223 4 mm (W) x 0.21 mm (T) Up to ~108 A Critical temperature (TC) of 110 K BSSCO 2223 Processing BSSCO 2223: IC vs. H Current vs. Bending Diameter Actuator Choice Persistent actuator? Can’t make superconducting junction Core choice Magnetostrictive Hard magnet Soft magnet Coil Radius Setup Radius Measurements 2.5" Diameter Loop 0.16 0.14 Voltage (mV) 0.12 0.1 0.08 0.06 0.04 0.02 0 0 20 40 60 80 Current (A) 100 120 140 The Apparatus Field Calculations Force Magnetization of Fe: 334225 A/m dF A M B dx 75 50 25 -10 -5 5 -25 -50 -75 Force (N, cm) 10 Apparatus Fabrication Solenoid Assembly Assembled Solenoid Testing: Magnetic Field Testing: Magnetic Gradient Field vs. Position 50 40 30 20 Field (Oersted) 10 0 -10 -20 -30 -40 0 1 2 3 Axial position (in.) Field Measurement Field derivative 1 amp, room temperature 4 5 Self-Field Tests Self-Field Tests Maximum Magnetic Field vs. Current 2 1.8 1.6 1.4 Koersted 1.2 1 0.8 0.6 0.4 0.2 0 0 10 20 30 40 Current (A) 50 60 70 80 Current Tests Critical Current for Solenoid 250 200 Voltage (mV) 150 100 50 0 0 10 20 30 40 Current (A) 50 60 70 80 Load Cell Setup Force Force vs. Displacement 70 60 50 40 Force (N) 30 20 10 0 -10 -20 -1 0 1 2 3 Position (in.) 4 5 6 7 Supercool Conclusions Copper solenoid (1.5” x 2.4”) outperforms our actuator (force), even at room temperature Energy Density Energy density of Supercool solenoid: 17400 J/m3 7.0 cm outer diameter 3.36 J of total energy Energy density of 1.5” x 2.4” Cu solenoid: 16100 J/m3 Further Considerations Commercial tape: > 135 A Colder temperature YBCO 2nd generation tape ~ 7 T at 77K Acknowledgements Professor Chiang Professor Vander Sande Yin-Lin Xie David Bono Ken Stone Ed Moriarty Leslie Bromberg 3.082 staff References YBCO second generation tape: http://www.amsuper.com/html/products/library/2g_white_paper_-_march_2004.pdf Montgomery, D. Bruce. Solenoid Magnet Design: The Magnetic and Mechanical Aspects of Resistive and Superconducting Systems. Wiley-Interscience, New York. 1969. Magnet-Schultz commercial Cu solenoid: http://magnet-schultz.com/newRTP24X19INT.htm