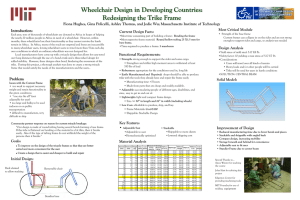

Tricycle Frame Redesign Team Members: Fiona Hughes, Gina Policelli, and

advertisement

Tricycle Frame Redesign Team Members: Fiona Hughes, Gina Policelli, and Jodie Wu Overall Goals Problems Current frame design is too weak to support necessary weight and retain functionality in the given conditions Current frames are “one size fits all” (not adjustable for user) Current tricycles are too large to be used indoors or on public transportation Difficult to make the frame Goals To improve on the design of the tricycle frames so that they are better suited and more convenient for the user Increase…easier and cheaper to build and repair http://web.mit.edu/sp.784/www/projects.html Functional Requirements Strength: The trike frame should be strong enough to support the rider and some cargo. Robustness: The trike should be robust, appropriate for the conditions it will be used in. Easily Built and Repaired: It should be easy to make and repair, and the shops should be able to produce it with the tools they already have. Manufacturable: The trike frame should be made from parts that are cheap and readily available. Adjustable: The trike should be able to accomodate people of different ages, disabilities, and sizes. It should be easy to get in and out of. Lightweight: The trike frame should be light and compact. Low Cost: It should be affordable to produce and to buy. Design Strategy: Symmetric Frame Current Frame: Asymmetric Proposed Strategy: slows down the production process difficult to repair Inaccuracies in bending takes time to adjust, inefficient Create a design in which the right and left sides of the tricycle are identical The new frame will be built with a single jig Develop a design that increases the strength and stability of current tricycle Advantages: Increase production rate New frame easier to repair Eliminates the need to adjust jig for each side Establishes uniformity and improves quality Design Strategy: Use of Bike Frame Current Frame: Built from scratch Proposed Strategy: All bending and welding is done by trike manufacturer Only stock steel is used Investigate the use of bike frame and integrating these parts into the overall design of the tricycle frame Look into the unconventional use of common, readily accessible products (threaded pipe fittings, etc.) Advantages: Less welding Less bending Minimization of cost and manufacture time Easy to build http://www.askadavid.org/photos/photos6 Increases accuracy of manufacturing 9/bicycle_with_tomatoes.jpg Design Strategy: Adjustable Current Frame: “one size fits all” Proposed Strategy: Frame is not adjustable Does not cater to different people’s needs (different sizes, ages, and disabilities) Adjust height of seat Adjust distance from seat to hand crank Create removable storage space/bin Make a design that is scaleable to the user Advantages: More suitable and useful for different types of people More functional and versatile for the user Evaluation of Strategies Parameters Symmetric Bike Frame Adjustable Strength x 2 Robustness x 2 + + + 0 + Repairable Manufacturable + + + 0 - Adjustability x 3 - - + Low Cost 0 + - Total +3 0 +1 Chosen Strategy Symmetric and Adjustable Frame Symmetric: If the symmetric frame cannot be made, we will investigate how to make it easier to build while increasing strength. Adjustable: If we cannot make the frame adjustable, we will at least make it scaleable for different users. In order to accomplish this, we will work closely with the community partners and explore the possibilities.