Postprint_FoodMicrobiology_2015_V46_P66.docx

advertisement

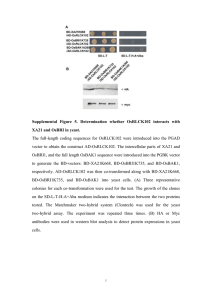

Selection of yeasts with multifunctional features for application as starters in natural black table olive processing S. Bonatsou1, A. Benítez2, F. Rodríguez-Gómez2, E.Z. Panagou1, F.N. Arroyo-López2,* 1 Laboratory of Microbiology and Biotechnology of Foods, Department of Food Science and Human Nutrition, Agricultural University of Athens, Iera Odos 75, Athens, Greece, GR-11855. 2 Food Biotechnology Department. Instituto de la Grasa (CSIC). Avda\ Padre García Tejero nº4, 41012, Seville. Spain. Running title: Olive yeasts as multifunctional starters Corresponding author: F.N. Arroyo-López, Ph.D. Tel: 0034 954692516 ext 115. FAX: 0034954691262. e-mail: fnarroyo@cica.es. 1 1 Abstract: 2 Yeasts are unicellular eukaryotic microorganisms with a great importance in the 3 elaboration on many foods and beverages. In the last years, researches have focused 4 their attention to determine the favourable effects that these microorganisms could 5 provide to table olive processing. In this context, the present study assesses, at 6 laboratory scale, the potential technological (resistance to salt, lipase, esterase and β- 7 glucosidase activities) and probiotic (phytase activity, survival to gastric and pancreatic 8 digestions) features of 12 yeast strains originally isolated from Greek natural black table 9 olive fermentations. The multivariate classification analysis carried out with all 10 information obtained (a total of 336 quantitative input data), revealed that the most 11 promising strains (clearly discriminated from the rest of isolates) were Pichia 12 guilliermondii Y16 (which showed overall the highest resistance to salt and simulated 13 digestions) and Wickerhamomyces anomalus Y18 (with the overall highest 14 technological enzymatic activities), while the rest of strains were grouped together in 15 two clearly differentiated clusters. Thus, this work opens the possibility for the 16 evaluation of these two selected yeasts as multifunctional starters, alone or in 17 combination with lactic acid bacteria, in real table olive fermentations. 18 Keywords: Enzymatic spectrophotometric assays; Growth modelling; Multifunctional 19 starters; Principal component analysis; Table olives; Yeasts. 2 20 1. Introduction 21 Table olives are one of the most important and well known fermented vegetables 22 of the food industry, with an estimated worldwide production that currently exceeds 2.5 23 million tons/year (IOC, 2013). The elaboration of this food is closely related to the 24 culture and diet of many Mediterranean countries, with Spain, Turkey, Egypt, Greece 25 and Italy as the main producers. There is also important production in the USA, Peru, 26 Argentina and Australia. Thus, table olive processing is widespread around the world 27 and represents an important economic source for producing countries. The most usual 28 table olive elaborations are: a) alkali-treated green olives (the so-called Spanish style), 29 b) ripe olives by alkaline oxidation (Californian style), and c) naturally black olives 30 (also known as Greek style) (Garrido-Fernández et al., 1997). 31 Microorganisms, especially lactic acid bacteria and yeasts, play an important 32 role during fermentation of the olive fruit determining the safety, quality and flavour of 33 the final product (Garrido-Fernández et al., 1997). For many years, the search for 34 starters with application in olive fermentation has been practically focused on the 35 activity of lactic acid bacteria. However, in the last years, diverse publications have 36 emphasised the importance of selection of yeasts as starter cultures during table olive 37 processing (Silva et al., 2011; Arroyo-López et al., 2012; Rodriguez-Gómez et al., 38 2012; Bevilacqua et al., 2012, 2013; Tofalo et al., 2013). Although these 39 microorganisms can cause spoilage of the product due to the production of CO2, bad 40 odours and flavours, clouding of brines or softening of fruits, which is especially 41 harmful in olive packaging or storage, they also show some desirable activities with 42 important potential technological and probiotic applications. For this reason, yeasts may 43 be exploited in table olive processing as multifunctional starters. 3 44 In this context, several authors have studied, among others, the lipolytic (lipase 45 and esterase) and β-glucosidase activities (technological characteristics) of different 46 yeast species related to table olives or oleic ecosystems (Psani and Kotzekidou, 2006; 47 Hernández et al., 2007; Bevilacqua et al., 2009, 2012; Aponte et al., 2010; Romo- 48 Sánchez et al., 2010; Bautista-Gallego et al., 2011; Rodriguez-Gómez et al., 2012). It 49 has also been widely proven that many yeast species have excellent aromatic profiles, 50 can improve lactic acid bacteria growth and inhibit undesirable microorganisms (Psani 51 and Kotzekidou, 2006; Querol and Fleet, 2006; Arroyo-López et al., 2012). Recently, 52 the probiotic potential of table olive related yeasts has also begun to be evaluated (Psani 53 and Kotzekidou, 2006; Silva et al., 2011). However, most of the available information 54 until now comes only from qualitative tests carried out on agar-assays, which do not 55 facilitate the comparison and selection of the most appropriate yeast starters. On the 56 contrary, spectrophotometric assays have been developed to quantitatively determine 57 the yeast activity levels for several groups of enzymes (lipases, esterases, β- 58 glucosidades and phytases, among others) (Rosi et al., 1994; Haros et al., 2005; 59 Ciafardini et al., 2006; Rodríguez-Gómez et al., 2012) or to determine the resistance of 60 microorganism to salt by mathematical modelling (Romero-Gil et al., 2013). These 61 methods are easily applicable and inexpensive; they do not need complex instruments 62 and offer objective information on yeast reponse for comparison. 63 Another additional problem is the application of an appropriate methodology for 64 the management of such a large amount of data, necessary when researchers have to 65 analyze several physiological traits (variables) from a considerable number of strains 66 (cases). Multivariate analysis techniques offer an interesting approach to solve this 67 drawback. Principal component analysis (PCA) is a multivariate statistical technique 68 used for data compression, to capture the main features in the multivariate data sets and 4 69 to extract information from them. PCA implies a mathematical procedure that 70 transforms the overall set of original variables into a smaller number of mathematical 71 “constructs”, also called “factors”. Thereby, a new set of axes, called factor axes, is 72 obtained in a lower dimensional space onto which the original space of variables and 73 cases can be projected and classified into categories. Such factors can be viewed as 74 linear combinations of the original variables that are uncorrelated (Jackson, 1991). The 75 new variables thus generated account for the inherent variation of the data to the 76 maximum possible extent. 77 In this work, diverse methodologies (growth modelling, spectrophotometric 78 enzymatic assays and in vitro probiotic tests) have been applied to assess the potential 79 technological (resistance to salt, lipase, esterase and β-glucosidase activities) and 80 probiotic (phytase activity and resistance to gastric, pancreatic and overall digestions) 81 applications of a considerable number of yeast species never before studied in Greek 82 natural black table olive processing. One way ANOVA and multivariate analysis based 83 on PCA were then applied to this quantitative set of data to select the yeast strains with 84 the most promising global characteristics for their use as multifunctional starters. 85 2. Material and methods 86 2.1. Yeast strains 87 A total of 12 yeast strains (Pichia guilliermondii Y16, Pichia kluyveri Y17, 88 Wickerhamomyces anomalus Y18, Candida silvae Y19, Metschnikowia pulcherrima 89 Y20, Saccharomyces cerevisiae Y22, Pichia manshurica Y37, Rhodotorula 90 mucilaginosa Y38, Rhodotorula diobovatum Y39, Aereobasidium pullulans Y40, 91 Debaryomyces hansenii Y57 and Pichia membranifaciens Y67), representative of the 5 92 yeast microbiota usually found in Greek natural black table olives, were used in the 93 present study. All of them were previously isolated by Nisiotou et al. (2010) from 94 distinct phases (early, middle and final stages) of the spontaneous fermentation of 95 naturally black cv. Conservolea olives, and were identified at the species level by PCR- 96 restriction fragment length polymorphism (RFLP) of the 5.8S internal transcribed 97 spacer (ITS) region combined with sequence analysis of the D1/D2 domain of 26S 98 gene. The previous mentioned work was focused only on the identification of the 99 succession of yeasts species during the fermentation of natural black olives, and for this 100 reason, only one strain per species was randomly selected and deposited in the 101 microbiological collection of the Laboratory of Microbiology and Biotechnology of 102 Foods of the Agricultural University of Athens (Greece). Their sequences were also 103 deposited in the NCBI GenBank data library under accession numbers FJ715430, 104 FJ649188 to FJ649197 and GQ140297 to GQ140301. 105 2.2. Modelling the resistance of yeasts to salt 106 Yeast inocula were prepared by inoculating one single colony of each isolate 107 into 5 mL of YM broth medium (DifcoTM, Becton and Dickinson Company, Sparks, 108 USA). After 48 h of incubation at 30ºC, 1 mL from each tube was centrifuged at 9000 x 109 g for 10 min, the pellets were washed with sterile saline solution (9 g/L), centrifuged 110 and re-suspended again in 0.5 mL of a sterile saline solution to obtain a final 111 concentration of about 7.2 log10 CFU/mL, which was confirmed by surface spread on 112 YM agar. These yeast suspensions were used to inoculate the different modelling 113 experiments. 114 Growth was monitored in a Bioscreen C automated spectrophotometer 115 (Labsystem, Helsinki, Finland) with a wideband filter (420-580 nm). Measurements 6 116 were taken every 2 h after a pre-shaking of 5 s. The wells of the microplate were filled 117 with 20 µL of inoculum and 330 µL of medium (according to treatment as described 118 below), always reaching an initial OD of approximately 0.2 (inoculum level above 6 119 log10 CFU/mL). The inocula were always above the detection limit of the apparatus, 120 which was determined by comparison with a previously established calibration curve. 121 Uninoculated wells for each experimental series were also included in the microplate to 122 determine, and consequently subtract, the noise signal. All experiments were carried out 123 in triplicate. 124 Sterilized YM broth was supplemented with NaCl to obtain the following final 125 concentrations of salt in the media: 0, 5, 10, 20, 30, 50, 70, 90, 110, 140, 180, 200 and 126 250 g/L. Thus, a total of 468 growth curves (13 levels NaCl x 12 yeasts x triplicate) 127 were obtained. The use of a well known, standardized synthetic laboratory medium to 128 carry out the experiments was preferred because, in the olive matrix, the presence of 129 diverse components released by fruits such as polyphenols, organic acids, etc., may 130 mask the real inhibitory effect of NaCl. 131 The basis of the technique used for estimating the NIC (non-inhibitory 132 concentration) and MIC (minimum-inhibitory concentration) values of the assayed yeast 133 strains for NaCl was the comparison of the area under the OD/time curve of a positive 134 control (absence of salt, optimal conditions) with the areas of the tests (presence of salt, 135 increasing inhibitory conditions). As the amount of inhibitor in the well increases, the 136 effect on the growth of the organism also increases. This effect on growth is manifested 137 by a reduction in the area under the OD/time curve relative to the positive control at any 138 specified time. The areas under the OD/time curves were calculated by integration using 139 OriginPro 7.5 software (OriginLab Corporation, Northampton, USA). The relative 7 140 amount of growth for each NaCl concentration, denoted as the fractional area (fa), was 141 obtained using the ratios of the test area (areatest) to that of the positive control of the 142 yeast (areacont), according to the following formula: 143 fa = (areatest)/(areacont) 144 The plot of the fa versus the natural logarithm (ln) of the NaCl concentration 145 produced a sigmoid-shape curve that could be well-fitted with a reparameterized 146 modified Gompertz function for decay, which had the following expression: 147 y=exp(-(x/(ln(MIC)/exp(-(ln(ln(NIC)/ln(MIC))/2.71828))))^(-2.71828/(ln(ln(NIC)/ln(MIC))))) 148 where y is the dependent variable (fa), x is the independent variable (ln NaCl g/L), MIC 149 is the minimum NaCl concentration (g/L) above which growth is not observed, and NIC 150 is the NaCl concentration (g/L) above which a inhibitory effect begin to be observed. 151 These parameters were obtained by a non-linear regression procedure, minimizing the 152 sum of squares of the difference between the experimental data and the fitted model, 153 i.e., loss function (observed-predicted)2. This task was accomplished using the non- 154 linear module of the Statistica 7.1 software package (StatSoft Inc, Tulsa, OK, USA) and 155 its Quasi-Newton option. Fit adequacy was checked by the proportion of variance 156 explained by the model (R2) with respect to the experimental data. 157 2.3. In vitro gastric and pancreatic digestions 158 Simulated gastric digestion (GD) was performed using the protocol initially 159 described by Corcoran et al. (2007) with slight modifications. Briefly, synthetic gastric 160 juice was prepared in a buffer solution at pH 2.0 containing NaCl (2.05 g/L), KH2PO4 161 (0.60 g/L), CaCl2 (0.11 g/L) and KCl (0.37 g/L). It was adjusted to pH 2.0 with 1 M 8 162 HCl and autoclaved at 121 ºC for 15 min. Prior to use, pepsin (0.0133 g/L) and 163 lysozyme (0.01 g/L) were added. All the components were obtained from Sigma- 164 Aldrich (St. Louis, USA). The yeast cultures to be tested were grown to early stationary 165 phase, centrifuged (10,000 x g, 10 min) and the pellet was washed with the buffer (pH 166 2.0) mentioned above. Then, the cells were re-suspended in the synthetic gastric juice to 167 a final concentration around 7 log10 CFU/mL and incubated for 2.5 h at 37 ºC in an 168 orbital shaker (~200 rpm) to simulate peristaltic movements. Finally, serial dilutions of 169 the cultures were plated onto YM agar medium and counted after incubation at 30 ºC 170 for 2 days. 171 Simulated pancreatic digestion (PD) was formulated using bile (3.0 g/L, Oxoid 172 LTD, Basingstoke, England) and pancreatin (0.1 g/L, Sigma-Aldrich) in a buffer at pH 173 8.0 (adjusted with 1M HCl) consisting of 50.81 g/L of sodium phosphate dibasic 174 heptahydrate and 8.5 g/L of NaCl. Harvested cells from the previous GD step were 175 washed in saline and re-suspended in the same volume of the simulated pancreatic juice. 176 A colony count on YM agar plates at initial time, to know the initial counts in the 177 freshly prepared simulated pancreatic juice, was performed by serial dilutions of the 178 cultures. After shaking at 200 rpm in an orbital shaker during 3.5 h at 37 ºC, the pellet 179 was washed and then re-suspended in a volume of isotonic solution in order to avoid 180 carryover of the buffers to the agar. Serial dilutions were done, and subsequently plated 181 onto YM agar. A reference probiotic strain (Lactobacillus rhamnosus GG), was used for 182 comparison of the survival rates after simulated GD and PD, but using MRS (de Man, 183 Rogosa and Sharpe) (Oxoid) as culture medium. The use of a bacterium was preferred 184 instead a yeast because they are the most common probiotic microorganisms found in 185 the literature. Overall survival was obtained by comparison of the initial yeast counts 9 186 (CFU/mL) at the beginning of the simulated GD and those cells recovered at the end of 187 the simulated PD. 188 2.4. Assessment of the enzymatic activities 189 Before enzymatic tests, the 12 yeast cultures were previously refreshed on YM 190 agar. After 48 h of incubation at 30ºC, colonies were picked and directly used to 191 inoculate 5 mL of new fresh YM broth. These tubes were then incubated at 30 ºC for 2 192 days and agitated daily for 1 min with a vortex. Then, cells were separated by 193 centrifugation at 9,000 x g for 15 min. The supernatant was sterilized through 194 microfiltration using a sterile syringe-driven filter unit with 0.2 µm of porosity 195 (Millipore Co., Bedford, Massachusetts, USA) and used as the extracellular fraction. At 196 the same time, the cell pellets were washed twice in a sterile 50 mM phosphate buffer 197 (pH 7.0) to remove liquid culture media for lipase and esterase, in a 100 mM citrate- 198 phosphate buffer (pH 5.0) for β-glucosidase, or in a buffer sodium acetate-acetic acid 199 0.1M (pH 5.5) for phytase determinations. Finally, cells were re-suspended in a suitable 200 volume of the corresponding sterile buffer solution to reach a population level between 201 7 and 8 log10 CFU/mL, according to yeast species. Both supernatant and whole cells 202 were used for the enzymatic tests described below. 203 β-glucosidase, esterase and lipase activities were quantitatively determined in 204 duplicate following procedures already mentioned by several authors (Rosi et al., 1994; 205 Ciafardini et al., 2006; Costas et al., 2007; Rodríguez-Gómez et al., 2010, 2012) with 206 slight modifications. Briefly, these activities were evaluated by measuring the amount 207 of p-nitrophenol liberated from the following chromogenic substrates: p-nitrophenyl 208 stearate (Sigma–Aldrich) and 4-nitrophenyl palmitate (Fluka Chemical, Buchs, 10 209 Switzerland) for lipase determination, p-nitrophenyl butyrate (Sigma-Aldrich) for 210 esterase, and p-nitrophenyl-β-D-glucoside (Sigma-Aldrich) for β-glucosidase assays. 211 For lipase and esterase determinations, the corresponding chromogenic 212 substrates were dissolved in undecane to reach a final concentration of 1 mM. The 213 reactions were carried out in a biphasic system formed by 1 mL of the 214 substrate+undecane mix (organic phase) and 1 mL of the extracellular or cellular 215 fractions (aqueous phase). For β-glucosidase evaluation, 0.2 mL of the cellular or 216 supernatant fraction was mixed with another 0.2 mL of a solution formed by the 217 corresponding chromogenic substrate dissolved in 100 mM of a citrate-phosphate buffer 218 to reach a final concentration of 5 mM. After 24 h of incubation at 30ºC for lipase and 219 esterase, or only 1 h at 40°C for β-glucosidase, 0.2 M carbonate buffer (pH 10.2) was 220 added to stop the reaction. The concentration of liberated p-nitrophenol was estimated 221 from the absorbance obtained at 410 (lipase and esterase) or 400 nm (β-glucosidase) in 222 a spectrophotometer model Cary1E UVevis (Varian INC., Palo Alto, CA, USA) using a 223 suitable blank for each case. Results were expressed as the amount of enzyme liberating 224 1 nmol of p-nitrophenol per hour and milliliter (nmol h-1 mL-1) under the assay 225 conditions for both extracellular and cellular fractions. 226 Phytase activity was determined by measuring the amount of liberated inorganic 227 phosphate from sodium phytate using the protocol described by Haros et al. (2005), but 228 with slight modifications. The reaction mixture consisted of 0.5 mL of 0.1 M sodium 229 acetace-acetic acid (pH 5.5), containing 6 mM sodium phytate and 0.5 mL of sample 230 solution. After incubation at 50ºC for 60 min, the reaction was stopped by adding 0.25 231 mL of 20% (w/v) trichloroacetic acid (TCA) solution. The reaction was cooled in ice for 232 15 min and then centrifuged at 9,000 x g for 10 min. Then, 0.9 mL of the aqueous phase 11 233 was mixed with 0.96 mL of phosphorus reagent (Mo-Va:5N H2SO4:acetone in 1:1:2 234 proportion). After 10 min of incubation at room temperature, absorbance was measured 235 at 405 nm. One unit of phytase activity was defined as the amount of enzyme liberating 236 1 nmol of inorganic phosphorous per hour and milliliter (nmol h-1 mL-1) under the assay 237 conditions for both extracellular and cellular fractions. 238 Finally, commercial lipase (from porcine pancreas), esterase (from porcine 239 liver), β-glucosidase (from almonds) and phytase (from wheat) enzymes were purchased 240 from Sigma-Aldrich (references L3126, E3019, G0395 and P1259, respectively), and 241 used in the present study at a final concentration of 5 mg/L as internal control for 242 comparison with the yeast activities. 243 2.5. Statistical data analysis 244 An analysis of variance was performed by means of the one-way ANOVA module 245 of Statistica 7.1 software (Statsoft Inc., Tulsa, USA) to check for significant differences 246 among yeast strains for the different technological and probiotic tests. For this purpose, 247 a post-hoc comparison statistical test was applied by means of the Scheffé test, which is 248 considered to be one of the most conservative post-hoc tests (Winer, 1962). 249 A total of 336 quantitative input data were then subjected to multivariate analysis. 250 PCA was applied to discriminate yeast strains with highly desirable properties, using a 251 varimax rotation. For the selection of the number of Principal Components or Factors, 252 the Kaiser criterion (Jolliffe, 1986) was followed and only factors with eigen-values 253 higher than 1.00 were retained. Cases introduced in the analysis were the 12 assayed 254 yeast strains, while explanatory variables were: NIC and MIC values, survival to 255 gastric, pancreatic and overall digestions (GS, PS and OS, respectively), and cellular 12 256 lipase (L-C), extracellular lipase (L-E), cellular esterase (E-C), extracellular esterase (E- 257 E), cellular β-glucosidase (B-C), extracellular β-glucosidase (B-E), cellular phytase (P- 258 C) and extracellular phytase (P-E) activities. Statistica software version 7.1 was used for 259 data processing and graphic representation. 260 3. Results 261 3.1. Susceptibility and resistance of the assayed yeasts to salt 262 In this survey, a total of 468 OD curves were obtained in synthetic laboratory 263 media to estimate the effect of NaCl concentration on the growth of 12 table olive 264 related yeasts isolated from the fermentation of Greek natural black table olives. Data 265 were fitted using the reparameterized Gompertz equation for decay, with an R2 in many 266 cases above 0.95 (data not shown). As an example, Figure 1 shows the fit for Y40 yeast 267 (A. pullulans), which followed a typical sigmoid decay function. Consequently, yeast 268 response to NaCl was non-linearly dose related. The whole sigmoid-shaped curve for 269 this microorganism could be divided into three sections: i) points corresponding to 270 concentrations from zero up to the NIC (concentrations at which no effect of the 271 inhibitor was observed and fa was around 1), ii) concentrations between NIC and MIC 272 values (within which growth inhibition progressively occurred and the fa decreased), 273 and iii) a third section above MIC (where no growth relative to the control was recorded 274 and fa was around 0). 275 Table 1 shows the NIC and MIC values obtained for all the yeasts assayed by 276 this methodology. For each species, average values were obtained from three 277 independent experiments. The NIC value, related to salt susceptibility, was widespread 278 among yeast strains and ranged from 20.2 (P. membranifaciens Y67) to 109.9 g/L (P. 13 279 guillidermondii Y16), while the MIC value, related to salt resistance, ranged from 123.7 280 (R. mucilaginosa Y39) to 274.4 g/L (S. cerevisiae Y22). Thereby, according to values 281 shown in Table 1, yeasts Y16 and Y22 were the most resistant microorganisms to salt in 282 laboratory medium, with no statistically significant differences between them according 283 to a Scheffé post-hoc comparison test, while yeast Y40 was the less resistant. 284 3.2. Resistance of the assayed yeasts to in vitro digestions 285 Table 2 shows the survival (%) of all assayed yeasts to the simulated in vitro 286 gastric and pancreatic digestions, as well as for the probiotic bacterium (L. rhamnosus 287 GG) used as control. All yeast isolates showed a survival percentage to the gastric 288 digestion higher than the reference probiotic microorganism, which had a survival of 289 only 0.04%. Two strains, P. guillidermondii Y16 and D. hansenii Y57, showed values 290 especially high (492.0% and 90.4%, respectively), indicative that both microorganisms 291 were not affected by the stressed conditions found in the stomach. On the contrary, C. 292 silvae Y19, R. mucilaginosa Y38 and A. pullulans Y40 were the yeasts less resistant to 293 the gastric test, with values close to 30%. 294 After GD, all yeasts were sequentially subjected to the simulated PD. In general, 295 a lower survival frequency in the PD than in the GD was noticed (Table 2). Especially, 296 two strains were considerably affected by this test (A. pullulans Y40 and D. hansenii 297 Y57), which exhibited a high mortality (survival close to 0%). On the contrary, P. 298 guillidermondii Y16, C. silvae Y19 and S. cerevisiae Y22 had values higher than 60%, 299 although only Y22 was statistically different to the probiotic control (14.4% for LGG). 300 The overall yeast survival to the simulated digestive process, comparing the 301 initial CFU/mL with the final population obtained after both gastric and pancreatic 14 302 digestions, is also shown in Table 2. Three yeast strains, P. kluyveri Y17, S. cerevisiae 303 Y22 and R. mucilaginosa Y38, were especially resistant with values around 26% and 304 statistically higher than the probiotic bacterium used as control (0.01%), while the 305 mortality for yeasts Y40 and Y57 was considerable (close to 0% survival). 306 3.3. Enzymatic activities of the assayed yeasts 307 Table 3 shows the average results obtained for the spectrophotometric enzymatic 308 assays. Data were analyzed by means of one-way ANOVA analysis to identify the yeast 309 strains with the highest levels for each enzymatic activity and compared to commercial 310 enzymes. In this way, strain W. anomalus Y18 was the yeast with the highest 311 statistically significant levels (p≤0.05) in four of six enzymatic technological activities 312 (L-C, L-E, E-E and B-C), with also high values for B-E and E-C. However, this 313 microorganism did not show any activity for the phytase tests. It can be observed that 314 the production of lipase enzymes for the majority of yeasts was practically null, except 315 for the above mentioned microorganism that was even above the commercial enzyme. 316 Table 3 also shows that some strains (Y16, Y38 and Y39) did not produce β-glucosidase 317 enzymes under the assayed conditions. However, it is clear that the production of 318 esterases was the most widerspread technological property among the yeasts. 319 Regarding phytase activity, the strain with the highest values for this test was M. 320 pulcherrima Y20 in both cellular and extracellular fractions, while many yeasts (Y18, 321 Y37, Y38, Y39) did not show any levels of activity. The great potential of Y20 to 322 produce phytase enzymes was evidenced when it was compared the commercial enzyme 323 versus the cellular fraction (796 vs 1914 nmol*ml-1*h-1, respectively). Other isolate with 324 high values in both cellular and extracellular fraction was Candida silvae Y19. 15 325 3.4. Multivariate analysis 326 In addition to specific tests, a study which simultaneously considers all of them is of 327 interest for selection of multifunctional starters. For this reason, quantitative data were 328 subjected to PCA in order to condense the information into a reduced number of 329 Factors. PCA led to the identification of four Factors with eigen-values higher than 1 330 (data not shown), indicating that the total number of analyzed variables (13) could be 331 grouped into only four Factors which explained 84.5% of the total variance (37.0% for 332 Factor 1, 22.9% for Factor 2, 16.3% for Factor 3 and 8.8% for Factor 4). 333 The relationship between the two major factors and the original variables can be 334 deduced from Figure 2 (upper panel). In this way, Factor 1 was linearly related (positive 335 correlation in Figure 2) to many of the enzymatic activities (except phytase). Thus, it 336 was re-named as “technological enzymatic activities”. On the contrary, Factor 2 was 337 mainly related (positive correlation) to resistance to digestion (GS, PS and OS) and salt 338 (MIC and NIC) tests, so it was re-named as “resistance to stress”. Figure 2 (upper panel) 339 can also be used to establish relationships among variables. According to this graph, 340 there was no relationship between “stress variables” (GS, PS, OS, NIC and MIC) and 341 “technological enzymatic activities” (L-C, L-E, B-E, E-E, E-C), because they formed an 342 angle close to 90º. 343 The projection of the cases (yeast strains) onto the planes formed by the two major 344 Factors (59.9% of the total variance) led to the segregation of several isolates clearly 345 differentiated from the rest (Figure 2, lower panel). The majority of yeasts were grouped 346 close to the intersection between both factors (one group formed by Y17, Y22, Y38 and 347 Y37, slightly in the positive axis of Factor 2, and other group formed by Y19, Y20, 348 Y39, Y40, Y57 and Y67, slightly in the negative axis of Factor 2), while two cases were 16 349 clearly located outside bouth groups. They were P. guillidermondii Y16 and W. 350 anomalus 18. The former, was characterised by its high resistance to the stress 351 conditions (salt and digestions), while the later was characterized by its considerable 352 high technological enzymatic activities. 353 4. Discussion 354 The presence of yeasts during processing of table olives around the world is very 355 common, particularly species of the genera Candida, Pichia, Rhodotorula, 356 Saccharomyces and Debaryomyces (Garrido-Fernández et al., 1997; Arroyo-López et 357 al., 2012). They can reach population levels above 6 log10 CFU/mL in this fermented 358 vegetable, affecting the organoleptic and nutritional characteristics of the final product 359 (Garrido-Fernández et al., 1997; Rodríguez-Gómez et al., 2010; Arroyo-López et al., 360 2012). These microorganisms play especially an important role during fermentation of 361 natural black olives, where high salt levels (8-10% or even higher) are used, resulting in 362 a process that is basically dominated by yeasts and occasionally by lactic acid bacteria 363 (Heperkan, 2013). This type of table olive elaboration is very common in Greece, 364 especially at farmers’ level. Modelling data obtained in this work corroborate the high 365 resistance of these microorganisms to NaCl, with strains belonging to species P. 366 guilliermondii, P. kluyveri, S. cerevisiae and R. mucilaginosa as the most resistant 367 yeasts with MIC values above 200 g/L. 368 Today, the attention on microbiology of table olive fermentations has been given 369 almost exclusively focused on lactic acid bacteria, which stand among the most 370 important groups of microorganisms found in olive microbiota (Hurtado et al., 2012). 371 However, recent research has revealed the significant contribution that yeasts may have 372 to this fermented vegetable, and how they could improve the process and the added 17 373 value of the final product (Arroyo-López et al., 2008, 2012; Rodríguez-Gómez et al., 374 2010). Selection of yeasts as starter cultures is a complex process including a selection 375 step, validation on laboratory scale and finally demonstration at factory level 376 (Bevilacqua et al., 2012). Potential starters must be assessed on the basis of 377 technological as well as functional traits. In this direction, the screening of an 378 appropriate number of strains is critical in successful starter development. It must be 379 noted that in this work only one strain per yeast species was subjected to technological 380 and functional characterisation. However, the information provided is important for the 381 Greek table olive industry as it refers to the most frequently encountered yeast species 382 in natural black olive fermentation and could become a basis for future research on this 383 issue. 384 Esterase and lipase enzymes (globally recognised as lipolytic activity) are 385 desirable in yeasts because they can improve the flavour of olives through the formation 386 of volatile compounds that can be generated by the catabolism of free fatty acids 387 (Hernández et al., 2007; Rodríguez-Gómez et al., 2010, 2012; Bevilacqua et al., 2012). 388 Microorganisms with β-glucosidase activities are also convenient because they can be 389 used to hydrolyze the glucoside oleuropein, removing the natural bitterness present in 390 directly brined olives, without a lye treatment (Psani and Kotzekidou, 2006; Arroyo- 391 López et al., 2012). Unfortunately, very few quantitative studies are available in the 392 literature about the influence and activity of these microorganisms on real table olive 393 fermentations (Rodríguez-Gómez et al., 2010, 2012; Bautista-Gallego et al., 2011). This 394 work offers, for the first time, quantitative information on the potential technological 395 and probiotic applications of diverse yeast species isolated from natural black Greek 396 table olive fermentation, which were then analysed using PCA for the selection and 397 discrimination of species with the most promising characteristics. Especially two 18 398 strains, W. anomalus Y18 and P. guilliermondii Y16, showed desirable features and 399 were clearly differentiated from the rest of isolates. In the last years, many researchers 400 have also used this methodology for the selection of the most promising yeast starters 401 related with table olive processing (Bevilacqua et al., 2009, 2013; Rodriguez-Gómez et 402 al., 2012). 403 The presence of W. anomalus (previously called Pichia anomala) in directly 404 brined olives, and in table olives in general, is very common (Hernández et al., 2007; 405 Bautista-Gallego et al., 2011; Arroyo-López et al., 2012; Doulgeraki et al., 2012). This 406 species is well adapted to grow under the environmental conditions that drive table olive 407 fermentations such as low pH and high NaCl concentrations. Romero-Gil et al. (2013) 408 reported similar MIC values for NaCl (166.9 g/L) for diverse W. anomalus strains 409 isolated from Spanish table olive processing compared to the isolate assayed in this 410 work (163.2 g/L). In a previous study, Hernández et al. (2007) found diverse strains of 411 this species isolated from table olive fermentations with interesting technological 412 applications. Recently, Bautista-Gallego et al. (2011) and Tofalo et al. (2013) have 413 reported the high β-glucosidase activity of this microorganism. All these features make 414 this species one of the best candidates to obtain isolates with technological applications 415 in table olives, as was also reported recently by Rodriguez-Gómez et al. (2012) and 416 Bevilacqua et al. (2013). Data obtained in this work prove again the high potential 417 technological application that this species, and especially the Y18 isolate, may have 418 during table olive processing because of its high lipase, esterase and β-glucosidase 419 activities. 420 P. guilliermondii is another yeast species usually also found in table olive 421 processing (Nisiotou et al., 2010; Tofalo et al., 2012) and according to results obtained 19 422 in this work with the Y16 isolate, showed interesting potential probiotic properties. 423 According to FAO/WHO (2001), probiotics are "live microorganisms which, when 424 administered in adequate amounts, confer a health benefit to the host". They “should be 425 resistant to gastric juices and be able to grow in the presence of bile”. There is a series 426 of in vitro tests such as acid and bile tolerance, although requiring further refinement, 427 that are usually applied as a first approach for the selection of potential probiotic 428 microorganisms (FAO/WHO, 2001). In the specific case of table olives, only Psani and 429 Kotzekidou (2006) and Silva et al. (2011) have started to assess the probiotic potential 430 of yeasts isolated from this fermented vegetable using these tests. The first authors 431 found diverse T. delbrueckii and D. hansenii strains which tolerated high bile salt 432 concentrations and low pH values, while the later authors found diverse P. fermentans 433 and C. oleophila strains with similar properties. It is remarkable to notify how many of 434 the yeast strains assayed in this work showed survival percentages to simulated 435 digestions higher than the probiotic bacterium used as control, which was especially 436 evident in the case of P. guillidermondii Y16. 437 This is the first time that phytase activity has been studied for table olive related 438 yeasts. Phytic acid or phytate is the primary storage form of phosphorous in mature 439 seeds of plants and it is abundant in legumes, oilseeds and many cereal grains. Phytate 440 has antinutritional effects because of the strong chelating capacity of this compound 441 with divalent minerals (calcium, zinc, etc.). Humans lack the required enzymes in the 442 gastrointestinal tract for the degradation of phytate complexes, but yeasts are able to 443 desphosphorylate these antinutritional compounds by the production of phytase 444 enzymes, which release free inorganic phosphate, inositol phosphate esters and 445 minerals. These enzymes are widespread in yeast species such as I. orientalis, S. 446 cerevisiae, T. delbrueckii and K. lactis (Moslehi-Jenabian et al., 2010; Olstorpe et al., 20 447 2009), many of them usually isolated from diverse table olive processing (Arroyo- 448 López et al., 2012). However, in this work, M. pulcherrima Y20 was the strain with the 449 highest phytase activity levels in both cellular and extracellular fraction in laboratory 450 medium, followed by P. kluyveri Y17 and P. guillidermondii Y16 in the cellular 451 fraction. 452 5. Conclusions 453 The results obtained in this survey have shown that especially two isolates (W. 454 anomalus Y18 and P. guilliermondii Y16) show interesting properties for their use as 455 starters in table olive processing, the former with technological applications and the 456 later as potential probiotic agent. This information provides new perspectives for the 457 industrial sector of natural black olives and enhances the research on the impact of these 458 microorganisms in the characteristics of this fermented vegetable. The selection of the 459 most appropriate strains, in combination with/without lactic acid bacteria, could 460 transform table olives from a traditional food to a novel functional commodity with 461 multiple benefits for the consumers. Thus, the real challenge for the Greek table olive 462 industry is to address this demand of consumers and develop new products with 463 enhanced sensory and functional properties that may have an impact on human health in 464 the long run. However, further studies should be carried out to determine and validate 465 the influence of both microorganisms on industrial scale fermentations. 466 Acknowledgements 467 The research leading to these results has received funding from the Spanish 468 Government (Ramón y Cajal program), and the Junta de Andalucía (through financial 469 support to group AGR-125). S. Bonatsou and F.N. Arroyo-López wish to express 21 470 thanks to the European Erasmus program and Ramón y Cajal postdoctoral research 471 contract (Spanish Government), respectively. 472 References 473 Aponte, M., Ventorino, V, Blaiotta, G., Volpe, G., Farina, V., Avellone, G., Lanza, 474 C.M., Moschetti, G., 2010. Study of green Sicilian table olive fermentations through 475 microbiological, chemical and sensory analyses. Food Microbiology 27, 162-170 476 Arroyo López FN, Bautista Gallego J, Querol A, Garrido-Fernández A. 2008. Role of 477 yeasts in table olive production. International Journal of Food Microbiology 128, 478 189-196. 479 Arroyo-López, F.N., Romero-Gil, V., Bautista-Gallego, J., Rodríguez-Gómez, F., 480 Jiménez-Díaz, R., García-García, P., Querol, A., Garrido-Fernández, A., 2012. 481 Yeasts in table olive processing: Desirable or spoilage microorganisms? 482 International Journal of Food Microbiology 160, 42-49. 483 Bautista-Gallego, J., Rodríguez-Gómez, F., Barrio, E., Querol, A., Garrido-Fernández, 484 A., Arroyo-López, F.N., 2011. Exploring the yeast biodiversity of green table olive 485 industrial fermentations for technological applications. International Journal of Food 486 Microbiology 147, 89-96. 487 Bevilacqua, A., Perricone, M., Cannarsi, M., Corbo, M.R., Sinigaglia, M., 2009. 488 Technological and spoiling characteristics of the yeast microflora isolated from 489 Bella di Cerignola table olives. International Journal of Food Science and 490 Technology 44, 2198-2207. 22 491 Bevilacqua, A., Corbo, M.R., Sinigaglia, M., 2012. Selection of yeasts as starters 492 cultures for table olives: a step-by-step procedure. Frontiers in Microbiology 3. Art. 493 194. 494 495 496 497 Bevilacqua, A., Beneduce, L., Sinigaglia, M., Corbo, M.R., 2013. Selection of yeasts as starters cultures for table olives. Journal of Food Science 78, M742-M751. Ciafardini, G., Zullo, B.A., Iride, A., 2006. Lipase production by yeasts from extra virgin olive oil. Food Microbiology 23, 60-67. 498 Corcoran, B.M., Stanton, C., Fitzgerald, G.F., Ross, R.P., 2007. Growth of probiotic 499 lactobacilli in the presence of oleic acid enhances subsequent survival in gastric 500 juice. Microbiology 153, 291–299. 501 502 Costas, M., Deive, F.J., Longo, M.A. 2007. Lipolytic activity in submerged cultures of Issatchenkia orientalis. Process Biochemistry 39, 2109–2114. 503 Doulgeraki, A.I., Hondrodimou, O., Iliopoulos, V., Panagou, E.Z., 2012. Lactic acid 504 bacteria and yeast heterogeneity during aerobic and modified atmosphere packaging 505 storage of natural black Conservolea olives in polyethylene pouches. Food Control 506 26, 49-57. 507 FAO/WHO (2001). Health and Nutritional Properties of Probiotics in Food including 508 Power Milk with Live Lactic Acid Bacteria. Amerian Códoba Park Hotel, Cordoba, 509 Argentina. Assessed at http://www.who.int/foodsafety/publications/fs_management/en/probiotics.pdf?ua=1 510 Garrido-Fernández, A., Fernández Díaz, M.J., Adams, R.M., 1997. Table Olives: 511 512 513 Production and Processing. London, UK: Chapman & Hall. Haros, M., Bielecka, M., Sanz, Y., 2005. Phytase activity as a novel metabolic feature in Bifidobacterium. FEMS Microbiology Letters 247, 231-239. 23 514 515 Heperkan, D., 2013. Microbiota of table olive fermentations and criteria of selection for their use as starters. Frontiers in Microbiology 4, 143. 516 Hernández, A., Martin, A., Aranda, E., Pérez-Nevado, F., Córdoba, M.G., 2007. 517 Identification and characterization of yeast isolated from the elaboration of seasoned 518 green table olives. Food Microbiology 24, 346-351. 519 520 Hurtado, A., Reguant, C., Bordons, A., Rozès, N., 2012. Lactic acid bacteria from fermented table olives. Food Microbiology 31, 1-8. 521 IOC (International Olive Oil Council), 2013. Statistical of table olive production. 522 http://www.internationaloliveoil.org/estaticos/view/132-world-table-olive-figures. 523 Last access: 24 January 2013. 524 Jackson, J.E., 1991. A user’s guide to principal components. New York, USA: Wiley. 525 Jolliffe, I.T. 1986. Principal component analysis. New York, USA: Springer-Verlag. 526 Moslehi-Jenabian, S., Lindegaard Pedersen, L., Jespersen, L., 2010. Beneficial effects 527 of probiotic and food borne yeasts on human health. Nutrients 2, 449-473. 528 Nisiotou, A.A.., Chorianopoulos, N., Nychas, G.-J.E., Panagou, E.Z., 2010. Yeast 529 heterogeneity during spontaneous fermentation of black Conservolea olives in 530 different brine solutions. Journal of Applied Microbiology 108, 396-405. 531 532 Olstorpe, M., Schnüren, J., Passoth, V., 2009. Screening of yeast strains for phytase activity. FEMS Yeast Research 9, 478-488. 533 Psani, M., Kotzekidou, P., 2006. Technological characteristics of yeast strains and their 534 potential as starter adjuncts in Greek-style black olive fermentation. World Journal 535 of Microbiology and Biotechnology 22, 1329-1336 24 536 537 Querol, A., Fleet, H., 2006. Yeasts in Food and Beverages. Berlin, Germany: SpringerVerlag. 538 Rodríguez-Gómez, F., Arroyo-López, F.N., López-López, A., Bautista-Gallego, J., 539 Garrido-Fernández, A., 2010. Lipolytic activity of the yeast species associated with 540 the fermentation/storage phase of ripe olive processing. Food Microbiology 27, 604- 541 612. 542 Rodríguez-Gómez, F., Romero-Gil, V., Bautista-Gallego, J., Garrido-Fernández, A., 543 Arroyo-López, F.N., 2012. Multivariate analysis to discriminate yeast strains with 544 technological applications in table olive processing. World Journal of Microbiology 545 and Biotechnology 28, 1761-1770. 546 Romero-Gil, V., Bautista-Gallego, J., Rodríguez-Gómez, F., García-García, P., 547 Jiménez-Díaz, R., Garrido-Fernández, A., Arroyo-López, F.N. 2013. Evaluating the 548 individual effects of temperature and salt on table olive related microorganisms. 549 Food Microbiology 33, 178-184. 550 Romo-Sánchez, S., Alves-Baffi, M., Arévalo-Villena, M., Úbeda-Iranzo, J., Briones- 551 Pérez, A., 2010. Yeast biodiversity from oleic ecosystems: Study of their 552 biotechnological properties. Food Microbiology 27, 487-492. 553 554 Rosi, I., Vinella, M., Domizio, P., 1994. Characterization of β-glucosidase activity in yeasts of oenological origin. Journal of Applied Bacteriology 77, 519-527. 555 Silva, T., Reto, M., Sol, M., Peito, A., Peres, C.M., Peres, C., Xavier-Malcata, F., 2011. 556 Characterization of yeasts from Portuguese brined olives, with a focus on their 557 potentially probiotic behavior. LWT Food Science and Technology 44, 1349-1354. 25 558 Tofalo, R., Schirone, M., Perpetuini, G., Suzzi, G., Corsetti, A., 2012. Development and 559 application of a real-time PCR-based assay to enumerate total yeasts and Pichia 560 anomala, Pichia guillermondii and Pichia kluyveri in fermented table olives. Food 561 Control 23, 356-362. 562 Tofalo, R., Perpetuini, G., Schirone, M., Suzzi, G., Corsetti, A., 2013. Yeast biota 563 associated to naturally fermented table olives from different Italian cultivars. 564 International Journal of Food Microbiology 161, 203-208. 565 566 Winer, B.J., 1962. Statistical principles in experimental design. McGraw-Hill. New York. 26 567 Figure Legends 568 Figure 1. Fit of the fractional areas of Aureobasidium pullulans Y40 as a function of ln 569 NaCl (g/L) using the reparameterized Gompertz equation for decay (see materials and 570 methods) for the estimation of NIC (non-inhibitory concentration) and MIC (minimum 571 inhibitory concentration). 572 573 Figure 2. Projection of the two major factors of the PCA as a function of variables 574 (upper panel) and yeast strains (lower panel). GS: gastric digestion, PS: pancreatic 575 digestion, OS: overall digestion, MIC: minimum inhibitory concentration, NIC: non- 576 inhibitory concentration, L-C: cellular lipase, L-E: extracellular lipase, E-C: cellular 577 esterase, E-E: extracellular esterase, B-C: cellular β-glucosidase, B-E: extracellular β- 578 glucosidase, P-C: cellular phytase, P-E: extracellular phytase. 27