Greenland june 2015

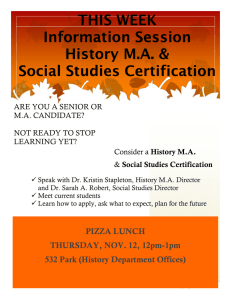

advertisement

The certification scheme for training institutions Presentert av Ellington Wilkins Lead auditor ASAS Sertifisering AS ASAS SERTIFISERING AS Training institutions: 102 Certified technical control: 54 Both: 38 Total: 194 Certification body Third-party conformity assessment body operating certification schemes. Impartiality No commercial, financial or other pressures to compromise impartiality Certification body Confidentiality at all times Commitment to the management of all information recieved or created during certification Training requirements All persons working with dangerous equipment in Norway Certified safety training is required for the following types of work equipment: Gantry cranes and overhead travelling cranes (if use involves danger to life or health). Tower cranes Mobile cranes Portal cranes Training requirements Certified safety training is required for the following types of work equipment: Cranes with a capacity greater than 2 tm when mounted on a truck or truck trailer Lifting and stacking vehicles for goods with a permanent operator’s cabin on the vehicle • Earth moving machines with an effect greater than 15 kW (20.4 hp). CERTIFICATION SCHEME Based on specific requirements Training institutions/Technical control entities Regulation governing organisation and management, Workplace, work activity, forskrift om administration criteria’s, Trainee guidelines & additional criteria’s Regulations Regulation 1355 Organisation, management and participation Regulation 1357 Work operations Regulation 1356 For the workplace Regulation 1360 For Administrative requirements Example of the evaluation process Upon completion of this module, the trainee will be able to do the following: 1. Describe basic prestart activities for heavy equipment machinery. Describe basic safety measures associated with operating heavy equipment. Explain how to properly start, operate, and shut down the following types of heavy equipment: Dozers, loaders, backhoes, excavators, compaction equipment, motor graders, scrapers, on road dump trucks, off-road dump trucks. 2. 3. Certification process – – – – – – – – Application for certification Accept of application / review Document evaluation Certification audit Accept and correction of non - conformities Verification Certification documentation / certificate Surveillence Document evaluation Procedures for training in the use of earth moving equipment Routines for access to necessary equipment that are in good technical operation Routines for access to qualified competent instructors Routines for maintenance of competence Documentation of the technical control of equipment by impartial third party Document evaluation Documentation of access to necessary and accepted literature Documentation of acceptable course plan with allotted time Routines/procedures for the examination of candidates (theoretical and practical) Procedures for candidates with writing and or reading disabilities Certification audit Consists of confirmation/ verification of the before mentioned documentation Verification of qualified instructors Verification of the maintenance of competence of instructors Verification of the participation of candidates Verification of the use of theoretical literature/course materiel Certification audit Verification of the use of the required time Verification of the theoretical examination of all candidates Verification of access to and use of correct equipment for practical training Verification of the practical examination of all candidates Correction and accept of non-conformities Based on the type of non-conformity (severe or non-severe) A time frame for correcting the non-conformity will be agreed upon. Review and accept of non-conformity. Certification documentation Four years Requires annual surveillance by the certification body Must adhere to the certification scheme and any directions from the certification body. Surveillance Annual audit/surveillance of the certified entity Re-certification after four years Sertifiseringsrevisjonen Re-sertifisering SERTIFIKAT – CERTIFICATE Organisasjons nr.: Org. nr. Sertifiseringsnummer ATSHar dokumentert og demonstrert kunnskap i kravene for produktsertifisering og kravene i Forskrift om bruk av arbeidsutstyr, best. nr. 555, §50 GYLDIGHETSOMRÅDE: Sertifisert for sikkerhetsopplæring av førere/operatører av arbeidsutstyr som er nevnt i §49, best. nr. 555, herunder ; - Løfte og stablevogner for gods Sertifiseringen forutsetter regelmessig oppfølging frem til sertifikatets utløpsdato. Virksomheten er selv ansvarlig for utført opplæring 1. gang sertifisert: Utstedelsesdato: _________________________________ ___________________________________ Gyldig til: Appreciate your attention Thank you