Addendum #1 Spec Sec 10801

advertisement

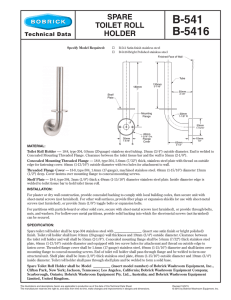

Wesleyan University Construction Services SECTION 10801 - TOILET AND BATH ACCESSORIES PART 1 - GENERAL 1.1 SECTION REQUIREMENTS A. Division 1 - General Requirements is made a part of this section. B. Submittals: Product Data. PART 2 - PRODUCTS 2.1 MATERIALS A. Stainless Steel: ASTM A 666, Type 304, No. 4 finish (polished), 0.0312-inch (0.8-mm) minimum nominal thickness, unless otherwise indicated. B. Sheet Steel: ASTM A 1008/A 1008M, 0.0359-inch (0.9-mm) minimum nominal thickness. C. Mirrors: ASTM C 1503, Mirror Glazing Quality, clear-glass mirrors, nominal 6.0 mm thick. D. Galvanized Steel Mounting Devices: ASTM A 153/A 153M, hot-dip galvanized after fabrication. E. Fasteners: Screws, bolts, and other devices of same material as accessory unit, tamper and theft resistant when exposed, and of galvanized steel when concealed. F. Keys: Provide universal keys for internal access to accessories for servicing and re-supplying. Provide minimum of [six] keys to Owner's representative. 2.2 TOILET AND BATH ACCESSORIES A. Manufacturers: 1. Moen 2. Basco 3. Bradley 4. Parker 5. Bobrick 6. Approved equal B. Paper Towel Dispenser : Provided by Owner, installed by Contractor. C. Toilet Tissue Dispenser : Provided by Owner, installed by Contractor. D. Liquid-Soap Dispenser : Provided by Owner, installed by Contractor. E. ADA Grab Bars (pull down, swing or static); verify with Owner type required for specific location: 1. Manufacturers: Bradley, Parker or equal 2. Material: Stainless steel, 0.05 inch thick. Major Maintenance FY2015/2016 ADDENDUM #1 10801-1 Project No. 2016000000 12/20/14 Revised 3/18/15 Wesleyan University Construction Services 3. 4. 5. F. Mounting: Exposed. Gripping Surfaces: Slip-resistant texture. Outside Diameter: 1-1/4 inches for medium-duty applications. ADA Mirror Unit: 1. Glazing: Tempered glass. 2. Frame: Stainless-steel angle, 0.05 inch thick, stainless-steel channel or stainless steel, fixed tilt based on installation requirements. G. Medicine Cabinet: 1. Medicine Cabinet - Zenith Model #105, Stainless Steel Frame Medicine Cabinet, Frameless; 16.13" X 26.13" 2. Coordinate size and style with Owner for specific installation. 3. Mounting: Surface, recessed or semi-recessed based on location. Height to be determined in the field. 4. Size: Minimum size 16” x 26” or as required based on field conditions (Verify in field). 5. Glass: Premium float glass. 6. Door: Framed mirror door concealing storage cabinet equipped with continuous hinge- reversible for left-hand or right-hand door opening, and spring-buffered, rod-type stop and magnetic door catch. 7. Shelves: 3 minimum, adjustable glass shelves. H. Robe/Towel Hook: 1. Description: Double-prong unit, 2 per bathroom. 2. Material and Finish: Polished chrome-plated zinc alloy (zamac). 3. Mounting Height: To be determined in the field. I. Towel Bar: 1. Moen or approved equal. 2. Towel ring: Moen model #DN2686ch (glenshire) chrome - above toilet. 3. Double post toilet paper holder: Moen model #DN2608ch (glenshire) chrome - on wall adjacent to commode. 4. 24" towel bar: Moen model #DN2624ch (glenshire) chrome - on wall in line with door. 5. Coordinate locations with owner. 6. Mounting: Flanges with concealed fasteners. Height to be determined in the field. 7. Length: 18 inches , 24 inches and/or 30 inches. Coordinate size in the field with Owner prior to installation. 8. Material and Finish: Polished chrome. J. Shower rod 1. 1" dia., 18 gage stainless steel satin model S-106 (length, cut to fit existing span). 2. Rod flanges shall be model S-SH-1, 1" satin stainless steel by "Tubular Specialties Mfg." (ph. 800-472-2227). 3. PART 3 - EXECUTION 3.1 INSTALLATION A. Install accessories using fasteners appropriate to substrate indicated and recommended by unit manufacturer. Install units level, plumb, and firmly anchored in locations and at heights indicated. Major Maintenance FY2015/2016 Project No. 2016000000 ADDENDUM #1 10801-2 12/20/14 Revised 3/18/15 Wesleyan University Construction Services 1. Install grab bars to withstand a downward load of at least 250 lb (1112 N), when tested according to method in ASTM F 446. B. Provide blocking (concealed or surface) as required to meet load requirements. Patch wall. Paint surface applied blocking to match wall color. C. Adjust accessories for unencumbered, smooth operation and verify that mechanisms function properly. Replace damaged or defective items. Remove temporary labels and protective coatings. D. END OF SECTION 10801 Major Maintenance FY2015/2016 Project No. 2016000000 ADDENDUM #1 10801-3 12/20/14 Revised 3/18/15