Unit F560 - Maintaining engineering systems - Scheme of work and lesson plans - Sample (DOC, 588KB)

advertisement

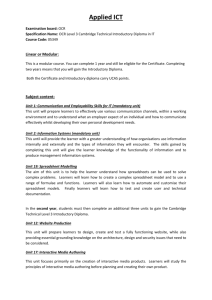

Sample Schemes of Work and Lesson Plans Engineering OCR Level 3 Principal Learning in Engineering H811 Unit F560: Maintaining engineering systems This Support Material booklet is designed to accompany the OCR Engineering Diploma specification for teaching from September 2008. © OCR 2009 Contents Contents 2 Sample Scheme of Work: OCR Level 3 Principal Learning in Engineering H811 Unit F560: Maintaining engineering systems 3 Sample Lesson Plan: OCR Level 3 Principal Learning in Engineering H811 Unit F560 Maintaining engineering systems 10 2 of 11 Engineering Diploma Sample Diploma Scheme of Work OCR Level 3 Principal Learning in Engineering H811 Unit F560: Maintaining engineering systems Unit size 30 GLH Unit level Level 3 Unit overview: This unit will be assessed by the learner producing a series of detailed wall charts and accompanying research folder which could be used to present a specific engineering maintenance system to an employer. The evidence should include: Diagrams, photographs and detailed explanations of an engineering system and its failure modes and the predictive methods that would be used on the system An accompanying research folder outlining the method of data collection and analysis Spreadsheet analysis of the data structures and analysis of the applied formulae Sequential and hierarchical flow charts showing the correlation between the maintenance plan and its effects Costs benefits calculations with appropriate explanations of the procedure and justification Evidence of undertaking a maintenance procedure. This unit will enable the learners to understand about the maintenance of engineered systems. Through this study the learners will develop an understanding of the importance of determining appropriate maintenance strategies on plant and processes, and the effect that this has in terms of efficiency, cost, quality, sustainability of resources, impact on environment and corporate image. = Innovative teaching idea Engineering Diploma = ICT opportunity 3 of 11 Sample Diploma Scheme of Work This unit builds on the knowledge of Level 2 Unit F554 Maintenance. This unit is about strategy and application and could equally well be applied to the study of products or systems. = Innovative teaching idea 4 of 11 = ICT opportunity Engineering Diploma Sample Diploma Scheme of Work OCR Level 3 Principal Learning in Engineering H811 Unit F560: Maintaining engineering systems Suggested teaching time 10 hours Topic Maintenance schedules and activity Topic outline Suggested teaching and homework activities Suggested resources Points to note The learner can: To the group, present the main acronyms used in engineering manufacturing. As a pop quiz in small groups learners write out the terms in full and define. Actual data on reliability could be obtained from an engaged employer. The acronyms should include: MTTF, MTTR, MTBF, SPC, RTF Manufacturers have product data sheets with predicted life details for some products. http://www.gelighting.com/na/ is the link for GE Lighting in North America, details of lighting can be obtained here. Present real data to group containing this data. Debate the choices to be made and justify final selection. A specific WRL employer activity can be centred on maintenance. The key debating points will be on preventative maintenance vs run to failure. Cost, resources and implications of each should be covered. Link back to the Risk Assessment element of unit F556. The acronyms activity and initial work on data handling should take one lesson, with preparation for the strategies debate to be carried out as homework. One lesson should be used for the final preparation and the carrying out of the debate. Research should be completed as homework. Apply statistical mathematical methods to production and maintenance data. Analyse data trends for a complex engineering system. Determine appropriate maintenance strategies to include a risk assessment for a system or product (IE4, CT1) (Maths) Group debate on maintenance strategies. Learners research the maintenance activities of a complex system, preferably the system of an engaged = Innovative teaching idea Engineering Diploma Employer or college based equipment could be used for the maintenance activity. Lawn mowers, mopeds, cars or similar are suitable. Employer maintenance schedules can provide a valuable resource. http://www.spinlife.com/spintips/details/k/ManualWheelchair-Maintenance/a/116/c/2 is a link detailing the maintenance of a wheelchair. = ICT opportunity 5 of 11 Sample Diploma Scheme of Work OCR Level 3 Principal Learning in Engineering H811 Unit F560: Maintaining engineering systems Suggested teaching time 10 hours Topic outline Carry out a maintenance activity (SM3) Topic Suggested teaching and homework activities Suggested resources Points to note employer. http://www.ehow.com/video_4426968_check-beltsriding-lawn-mower.html a site containing videos demonstrating lawn mower maintenance. Individuals use the previous activities to create and justify a maintenance schedule for a piece of equipment. A camera and/or video camera would support the recording of the practical activities. Learners then individually carry out the maintenance activity detailed. Details of the schedule, the activity, reflection on the activity and any changes that would be made to the schedule in light of the activity should be recorded in the learner work book. = Innovative teaching idea 6 of 11 Maintenance schedules and activity The remaining teaching time should be taken up with employer activities and the practical maintenance activities. A range of maintenance strategies could be presented and used as the basis of a balloon debate. The equipment selected for this activity needs to be sufficiently complex to provide stretch and challenge to the learner. = ICT opportunity Engineering Diploma Sample Diploma Scheme of Work OCR Level 3 Principal Learning in Engineering H811 Unit F560: Maintaining engineering systems Suggested teaching time 5 hours Topic System failure Topic outline Suggested teaching and homework activities Suggested resources Points to note The learner can: A group activity to identify causes of failure. Using an established report into a major failure, students identify as many of the causes as possible and create a Root Cause Analysis diagram for the major failure. Identify and explain the various types of system failure and their consequences Explain methods used to predict systems failure (Eng) = Innovative teaching idea Engineering Diploma Explore the concept of Cost Benefit Analysis that will be revisited later. Learners will individually research a range of failures and identify the causes of the failure and the range of consequences arising from the failures. The group will compile a combined report of the causes and Try a reversal technique, ask the learners to design a system that will fail, leading to the identification of the causes listed in the next box. There are reports available on the internet that can be used for this purpose. http://www.railwaysarchive.co.uk/documents/HSE_Hatf_IntRep002.pdf This is the link to the report into the Hatfield rail crash. Library, internet and employer research can all be employed here. Local disasters should be avoided as examples because of the potential for personal involvement. A list of exemplar methods is included in the next box. Methods used by engaged employers, methods suggested in maintenance manuals and promotional literature from companies offering reliability monitoring are all suitable resources to help research. Cost, complexity and business interruption are all factors that need to be considered in these methods. A matrix of methods could be created by the learners to show these attributes. Main causes of failure: Maladjustment Maloperation Run to failure Stress fracture, fatigue, wear, embrittlement Overloading, seizure Anodic and chemical corrosion Lubrication failure, fouling, vibration Poor training Consequences should include: Financial, political, social, personal and technological factors. Methods of predicting failure: Condition monitoring Visual inspection = ICT opportunity 7 of 11 Sample Diploma Scheme of Work OCR Level 3 Principal Learning in Engineering H811 Unit F560: Maintaining engineering systems Suggested teaching time 5 hours Topic outline Topic Suggested teaching and homework activities The learner can: Evaluate the effects of different approaches to maintenance on operational and strategic efficiency (Eng) = Innovative teaching idea 8 of 11 System failure Suggested resources Points to note consequences of failure. Shock pulse metering Learners will use the combined report to determine possible methods of predicting failure. For each method they should identify a real example and evaluate the cost implications of the method. Vibration analysis Oil debris analysis Electrical current monitoring Tool wear Infra-red thermography Ultrasonic testing Taking a given complex system, learners will individually apply the different approaches to maintenance. For each scenario they will evaluate the potential effects of that scenario in terms of operational efficiency and strategic impact. The evaluation will include both the methods of predicting failure and the maintenance activity. This activity will be most effective if the resource is provided by an employer willing to back up the material with interactive workshops. http://www.stemnet.org.uk/home.cfm is a link to the STEMNET website. STEMNET run the STEM Ambassadors scheme and can provide assistance in resourcing this activity. http://www.hse.gov.uk/risk/theory/alarpcba.htm is a link to the HSE site explaining CBA, this is in the context of risk reduction but the principles are the same. An internet search for CBA Template will reveal a number of downloadable forms that can be utilised. When evaluating effects the learners should explore: operator safety scrap and rework poor product quality lost production difficulty in planning production failure to deliver loss of competitiveness = ICT opportunity Engineering Diploma Sample Diploma Scheme of Work OCR Level 3 Principal Learning in Engineering H811 Unit F560: Maintaining engineering systems Suggested teaching time 5 hours Topic outline Carry out a cost benefits analysis of a maintenance programme (Maths) Topic Suggested teaching and homework activities Suggested resources Points to note Learners will recommend and justify an appropriate maintenance plan. loss of business corporate image For the recommended plan, learners will estimate the costs of implementing the plan and the benefits the plan delivers. Leading to a cost benefit analysis of the maintenance plan. reduction of waste energy savings improved product reliability = Innovative teaching idea Engineering Diploma System failure Learners will use the maintenance plan and cost benefit analysis to create a proposal for implementing the maintenance plan. The issues for consideration in the CBA include: financial value of time materials and equipment against financial values of reduced costs and increased business correct stock level of spares = ICT opportunity 9 of 11 Sample Diploma Lesson Plan OCR Level 3 Principal Learning in Engineering H811 Unit F560 Maintaining engineering systems System Failure OCR recognises that the teaching of this qualification above will vary greatly from school to school and from teacher to teacher. With that in mind this lesson plan is offered, as a possible approach but will be subject to modifications by the individual teacher. Lesson length is assumed to be one hour. Learning Objectives for the Lesson Objective 1 Using real data from an accident investigation learners see the “real life context “of systems failure Objective 2 Learners are able to interpret and apply official reports. Objective 3 Learners apply the concepts learned to a specified engineering system Recap of Previous Experience and Prior Knowledge Learners were introduced to Risk Assessment in unit F556 and are revisiting the concept of severity in terms of consequences. Learners should be presented with the case study in advance to study as home work. In this case a simplified version of the full report is used containing Executive Summary, Photographs and investigation data. Content Time Content Pre-work Download an official report into an accident. This example uses the investigation into the Hatfield Rail crash. http://www.railwaysarchive.co.uk/eventsummary.php?eventID=143 is the website where the full report and other media can be downloaded. The Executive Summary and key data from the final report are used to create a case study students study for home work before the lesson. 5 minutes Group review of the case study. 20 minutes Group activity Using the case study the group create a fault tree to highlight the possible causes of the accident. 10 minutes Group activity: compare the Fault Tree outcomes with the list of possible list of 10 of 11 Engineering Diploma Sample Diploma Lesson Plan causes of failure (pre-prepared handout). 10 minutes Group activity: identify all the consequences associated with the failure in the case study Consolidation Time Content 5 minutes Teacher reads out a number of examples of engineering systems that this analysis can be applied to and learners select the system they will study for homework. Class discussion followed by Learning Log entry – What are the similarities and differences between the failure in the case study and an investigation in an engineering system? Learners research the engineering system they chose from the list and for that system they create a Fault Tree, and create a risk assessment matrix based on the fault tree, suggesting contingencies for the failures determined to have the highest risk. 10 minutes Homework Engineering Diploma 11 of 11