DESIGN GUIDELINES FOR FLEXURAL STRENGTH OF SINGLY REINFORCED CONCRETE BEAM STRENGTHENED WITH FIBRE REINFORCED POLYMER LAMINATE AT BOTTOM

advertisement

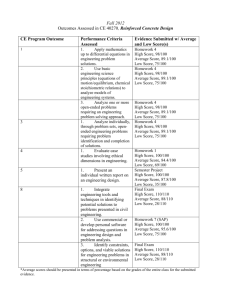

International Journal of Advanced Engineering Technology E-ISSN 0976-3945 Research Article DESIGN GUIDELINES FOR FLEXURAL STRENGTH OF SINGLY REINFORCED CONCRETE BEAM STRENGTHENED WITH FIBRE REINFORCED POLYMER LAMINATE AT BOTTOM K. B. Parikh1 and Dr. C. D. Modhera2 Address for Correspondence Department of Applied Mechanics, Government Engineering College, Surat, Gujarat, India Research scholar, Department of Applied Mechanics, SVNIT, Surat 2 Department of Applied Mechanics, Sardar Vallabhbhai National Institute of Technology, Surat, India E-mail: kbp1977@yahoo.co.in, cdmodhera@yahoo.com ABSTRACT 1 The design guidelines for the determination of limiting moment capacity of reinforced concrete beam strengthened with fiber reinforced polymer laminate at bottom is presented. The results derived from this design oriented model compared with analytical finite element model and others available researchers’ experimental data. This study also presents the design of laminate thickness to attain a specified limiting moment capacity in a given beam. The results show that the design guidelines presented in this study, performed well in the prediction of experimental results. KEYWORDS Fiber reinforced polymer laminate; reinforced concrete beam; design guidelines; thickness of frp. INTRODUCTION Fiber reinforced polymer laminates are strength. Also, since FRP plates used for increasingly external bonding are relatively thin, neither rehabilitation being and applied for the strengthening of the weight of the structure nor its infrastructure in lieu of traditional repair dimensions are significantly increased. In techniques such as steel plates bonding. FRP addition, FRP plates can easily be cut to plates have many advantages over steel length on site. These various factors in plates in this application, and their use can combination make installation much simpler be extended to situations where it would be and quicker than when using steel plates. impossible or impractical to use steel. For There were few analytical studies available example, FRP plates are lighter than steel for the prediction of flexural capacity of plates reinforced concrete beam strengthened with of equivalent strength, which eliminates the need for temporary support external for the plates while the adhesive gains technical report 55, was used the rectangular IJAET/Vol.I/ Issue II/July-Sept.,2010/274-282 laminates. Concrete society International Journal of Advanced Engineering Technology E-ISSN 0976-3945 stress block for concrete. Jones et al. used This paper presents a very simple, easy and the conventional procedure to determine the efficient ultimate moment capacity of RC beams model for the determination of flexural externally strengthened with bonded steel strength plates. They employed rectangular stress strengthened at bottom with fiber reinforced blocks for concrete and the actual stress- polymer laminate. It also provides for the strain steel determination of limit of laminate thickness reinforcement and external steel plates to in order to avoid the tensile failure of beam evaluate the internal forces and moment. due to fiber reinforced polymer and assure Several researchers have come up with the techniques for attempting to predict flexural reinforcement yielding. This design oriented capacities and failure modes for FRP model also allows for the estimation of reinforced structural elements. Results of laminate thickness to attain a specified research performed by Saadatmanesh and limiting moment capacity. The results from Ehsani suggested that reasonably accurate design oriented model compares with the strength predictions of FRP reinforced results of author’s analytical finite element beams could be made using simple force model as well as available researches equilibrium equations. Work by Triantafillou experimental data. and Pleveris indicated that the failure mode DESIGN ORIENTED MODEL of highly IS 456:2000 is Indian standard code of influenced by the reinforcement ratios of the practice for plain and reinforced concrete. FRP and steel. Their research also offers With the help of this code, a systematic equations for strength based on the various procedure/model had been introduced by curves of FRP-reinforced the beams internal was modes of FRP-reinforced beam failure. Perhaps the most accurate method of predicting strength of FRP-reinforced beams, for flexural, is through the use of finite element modeling programs, as suggested by some researchers. A critical factor for flexure capacity design is the adhesion between the concrete and the composite. IJAET/Vol.I/ Issue II/July-Sept.,2010/274-282 computational of tensile reinforced failure due design oriented concrete to steel beam i.e. K.B.Parikh et al. for the determination of flexural strength of singly RC beam strengthened with fiber reinforced polymer at bottom. For the determination of this model following assumptions should be made. The tensile strength of the concrete is ignored. International Journal of Advanced Engineering Technology For design purpose the compressive The fiber reinforced polymer sheet strength of concrete in the structure or laminate has a linear elastic stress- shall be assumed to be 0.67 times the strain relationship to failure. characteristics strength. E-ISSN 0976-3945 There is no relative slip between The maximum strain in concrete at external fiber reinforced polymer the outermost compression fiber is sheet and concrete. taken as 0.0035. From the above assumptions, a stress-strain The maximum strain in the tension diagram has been drawn. reinforcement in the section at failure shall not be less than Partial safety factor for steel is 1.15 and concrete is 1.50. 0.0035 5 b C Xu d D Cross section of beam strengthened with FRP Stress Diagram Strain Diagram Fig. 1 Stress & strain diagram for RC beam with FRP IJAET/Vol.I/ Issue II/July-Sept.,2010/274-282 International Journal of Advanced Engineering Technology E-ISSN 0976-3945 From the above stress and strain diagram of RC beam moment capacity of beam can easily determined from the following equation. The depth of neutral axis is to be determined from the following equation. t thickness of frp laminate/plate/sheet DESIGN THICKNESS OF FRP LAMINA Balanced Condition The thickness of fiber reinforced polymer sheet can be determined for balanced condition. As per above assumption, there is a linear relationship of strain diagram. So, the ratio of found as follows. IJAET/Vol.I/ Issue II/July-Sept.,2010/274-282 can be International Journal of Advanced Engineering Technology E-ISSN 0976-3945 Using equation (2), it is very easy to obtain an equation of thickness of fiber reinforced polymer lamina in balanced condition. For, hence the equation for the thickness of FRP laminate becomes as, For, hence the equation for the thickness of FRP laminate becomes as, Maximum Thickness of FRP Sheet The maximum thickness of fiber reinforced polymer sheet can be evaluated by using the criteria of minimum value of percentage of reinforcement as per IS 456:2000. The basic equation of minimum percentage of reinforcement for beam as per code is as follows. . Using the equation (8), modified the equation (5), (6) and (7) are as follows. Using, various grade of concrete and grade of reinforcement, the equation of thickness of sheet under balanced condition with minimum reinforcement can be generated as, IJAET/Vol.I/ Issue II/July-Sept.,2010/274-282 International Journal of Advanced Engineering Technology E-ISSN 0976-3945 Where the k is the multiplication factor, as shown in table 1. Table 1: multiplication Factor ‘k’ Grade of Concrete/Grade of Reinforcement M15 2.1225 1.8526 M 20 3.0765 2.7166 M 25 4.0305 3.5806 M 30 4.9845 4.4446 General Equation The general equation for the determination, of thickness of fiber reinforced polymer sheet can be expresses as follows. If moment capacity is known, then it is very easy to determine the depth of neutral axis from following equation, Table 2: Physical and Mechanical properties of materials Author(s) H. Saadatmanesh and R. Ehsani Yousef A. AlSalloum A L (mm) 4875 b (mm) 205 D (mm) 455 Ast (mm2) 1472.6 (Mpa) 35 (Mpa) 456 (Mpa) 400 B 4875 205 455 981.8 35 456 400 C 4875 205 455 265.5 35 456 400 D 4875 205 455 981.8 35 456 400 Control 1350 150 200 157 40.1 412 -- G-SBL 1350 150 200 157 40.1 412 540 C-SBL 1350 150 200 157 40.1 412 930 Index IJAET/Vol.I/ Issue II/July-Sept.,2010/274-282 International Journal of Advanced Engineering Technology E-ISSN 0976-3945 VERIFICATION EXAMPLES materials and table 2 shows the comparison In order to evaluate the effectiveness of the of moment capacity of beams found from above equation 1, using author finite element equation, various available experimental research data is used. Also, the model and experimental verification of these equations has been researches. The following table 3 shows the carried by analytical model suggested by maximum thickness and required thickness K.B.Parikh et. al. Following table 1, shows of fiber reinforced polymer sheet under the physical and mechanical properties of balanced condition The following are the comparative charts for the ultimate moments of beam. Fig. 2 Comparative charts of ultimate moment IJAET/Vol.I/ Issue II/July-Sept.,2010/274-282 results of International Journal of Advanced Engineering Technology E-ISSN 0976-3945 Table 3: Comparison of ultimate moment of beams Author(s) Index A Moment capacity or Ultimate Moment Finite element Design oriented Model Results Experimental Results model Results (K.B.Parikh et. al) 326.2 330 337 H. Saadatmanesh B 263.6 268 257.7 and R. Ehsani C 173.3 181 188.3 D 263.6 270 257.7 Control 8.96 12.2 15.27 G-SBL 22.15 23 23.67 C-SBL 35.25 29.8 26.60 Yousef A. AlSalloum Table 4: FRP thickness Author(s) Index Under balanced Condition Sing-Ping Maximum Value Provided A - group 2.38 3.66 1.7 Yousef A. Al- G-SBL 1.48 1.94 1.0 Salloum C-SBL 0.86 1.13 1.19 A - group 0.140 0.233 0.111 Chiew et. al ZHANG Aihui CONCLUSION Here simple and efficient design guidelines experimental results of beam strengthened for the determination of ultimate moment of with fiber reinforced polymer sheet at a beam with fiber reinforced polymer sheet bottom. at bottom provided with the help of IS 456: conclusions can be drawn: 2000. These guidelines provide effective and From the results following The design oriented computational convince procedure for the determination of analysis to determine the ultimate thickness of fiber reinforced polymer sheet moment capacity of singly reinforced under balanced condition. This design model RC beams strengthened with FRP at validated through analytical and researchers IJAET/Vol.I/ Issue II/July-Sept.,2010/274-282 International Journal of Advanced Engineering Technology bottom proved to be efficient and good. The results obtained from this design oriented model were well compared with finite element model results and experimental results. One can easily determine the moment capacity of a beam strengthened with FRP at bottom by using simple approach. It also very easy to determine the thickness of FRP sheet under balanced condition. The design of FRP sheet thickness to attain a desired moment capacity in a given beam can be found out easily. The results showed that all computational models presented here performed well for the determination of experimental results. REFERENCES [1] Sing-Ping Chiew, Qin Sun and Yi Yu, “flexural Strength of RC Beams with GFRP laminates”, Journal of composites for Construction, Vol. 11, No. 5, October 2007, pp. 497-506. [2] K.B. Parikh and C.D. Modhera, “Application of glass fibre reinforced polymer to structural components – A state of art review”, International Conference on Advances in Concrete, Structural and Geotechnical Engineering, BITS, Pilani (India), October 25-27, 2009, pp. 1-10. [3] Zhang Ai-hui, Jin Wei-liang and Li guibing, “Behavior of preloaded RC beams strengthened with CFRP laminates”, Journal of Zhejiang University SCIENCE A, Vol. 7, No. 3, November 2005, pp. 436-444. IJAET/Vol.I/ Issue II/July-Sept.,2010/274-282 E-ISSN 0976-3945 [4] Hamid Saadatmanesh and MR Ehsani, “RC beams strengthened with GFRP plate I: Experimental study”, Journal of Structural engineering, ASCE, Vol. 117, No. 11, November 1991, pp. 3417-3433. [5] Almusallam, R.H. and Y.A.Al-Salloum, “Ultimate strength prediction for RC beams externally strengthened by composite materials”, Journals of composites: Part B Engineering, Vol. 32, February 2001, pp. 609-619. [6] IS 456:2000, “Plain and Reinforced Concrete-Code of Practice, Fourth Revision”, Bureau of Indian Standard, New Delhi. [7] Hutchinson A, Rahimi H., “Flexural Strengthening of Concrete Beams with Externally Bonded FRP reinforcement’, Proceedings of the Second International Conference on Advanced Composite materials in Bridges and Structures, CSCE, Montreal, Canada, 1996. [8] K.B.Parikh and C.D.Modhera, “Analytical model of reinforced concrete beam using glass fiber reinforced polymer”, International journal of Advanced Engineering Technology, Vol. I, No. I, April-June, 2010, pp. 46-58. [9] K.B. Parikh, M.M. Shirgar, K.M. Shiraj and C.D. Modhera, “Experimental Work on Beam by using GFRP Laminates”, A national conference on current trends on research and development in civil and environment engineering – An Indian perspective, SVIT, Vasad (India), January 21-22, 2010, pp. 1-8. [10] C.Arya, J.L. Clarke, E.A. Kay and P.D. O’Regan, “TR 55: Design Guidance for Strengthening Concrete Structures Using Fibre Composite Materials: A Review”, Engineering Structures, Vol. 24, 2002, pp. 889-900. [11] K. Chansawat, T. Potosuk, T. H. Miller, S. C. Yim and D. I. Kachlakev, “FE models of GFRP and CFRP strengthening reinforced concrete beams”, Advances in civil Engineering, Hindawi publishing corporation, 2009, pp. 1-13.