أخطار وأضرار التكهف في المضخات

advertisement

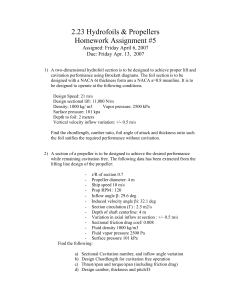

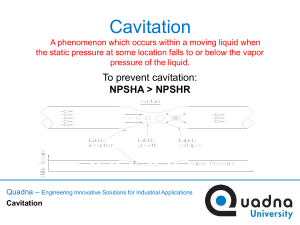

Cavitation Erosion by S. M. Ahmed Wear & Corrosion The progressive deterioration, due to corrosion and wear, of metallic surfaces in use in major industrial plants ultimately leads to loss of plant efficiency and at worst a shutdown Wear: The loss of material surface due to mechanical action Corrosion: The chemical or electrochemical reaction between a material, usually a metal, and its environment that produces a deterioration of the material and its properties. Wear is the loss of material surface resulting from mechanical interaction with another surface, body or fluid, which moves to it. Types of Wear Adhesive Abrasive Cavitation Erosion Fatigue Slurry Corrosive Cavitation Cavitation In Marine Propeller Bubbles in Hydrofoil Models of Nucleation Crevice model( it is inherent for boiling) Particles suspended in the liquid ( it is inherent for cavitation( . Harmful Results From Cavitation in Hydraulic machinery Deterioration of performance Vibration and Shaft Deflection Bearing Failure Packing or Seal Leakage Erosion High Noise Levels Applications of cavitation Applications of cavitation span many industrial sectors, from peening treatment, through ultrasonic lithotripsy, sonochemistry, ultrasonic cleaning and wastewater treatment, to jet cutting. Cavitation Erosion Cavitation is defined by the ASTM standard as the formation and subsequent collapse of cavities or bubbles that contain vapor or mixture of vapor and gas within a liquid. Bubble Collapse Liquid micojet Shock wave The mechanisms o f Cavitation erosion Liquid- Jet impingement A bubble in a liquid irradiated with ultrasound implodes near a solid surface االجهادات الناشئة فى المواد الصلبة Stresses induced solid materiald in due to cavitation Erosion The formation and collapse of vapor bubbles in the vicinity of a solid surface تطبيق عملي دراسة التآكل في مضخات الري في ج.م.ع التكهف يحدث للمضخة نتيجة الحاالت اآلتية: .1عدم وجود الضغط الكافى عند المدخل والسحب .2هواء مسحوب نتيجة حالة اضطراب السائل .3إعادة دوران السائل سواء فى مناطق السحب أو التسليم .4االهتزازات Recirculation at the inlet and outlet of the impeller A complete failure for the vanes of the radial flow impeller Damage of shrouds from vibration Cavitation Cavitation damage of the impeller inlet vane from inadequate net positive suction head عمليات اإلصالح الضارة األجهزة المعملية لدراسة التكهف -1جهااااااااااااااااا التكهاااااااااااااااا الهاااااااااااااااا ا vibratory cavitation device الاااااااااااااااااااااااااااااااا ا -2القاااااااااااااااااااااااااااااااا Rotating disck -3نفااااااااااااااااااااااااااااااااااا التكهااااااااااااااااااااااااااااااااااا Cavitation tunnel Power Amplifier Experimental work Power Supply Transducer Vibratory Horn Stationary Specimen L: Separation Distance Water out Temperature Controller Water in Schematic view of test apparatus Eroded surface pattern. Water 5 wt % O/W 2 wt % O/W 10 wt % O/W Power Supply Power Amplifier Oscilloscope Transducer Horn tip Frequency Counter Vibratory Horn Beaker L: Separation Distance Delay Circuit Mirror Xenon Flash Lamp Micro Pulser Water out Camera Lens Temperature Controller Water in Cooling Bath Fig. 1. Schematic diagram of the experimental set up. Cavitation erosion has long been recognized as one of the major problems in the design and operation of modern highspeed flow systems. Therefore, an early detection tool is needed. Wear particle analysis, based on particle size, shape and surface examination, can play an important role in the diagnosis of machine wear The objective of the present study is to identify the size distribution and shape characteristics of the erosion particles. And clarify their morphology features for the characteristic stages of the vibratory erosion rate-time pattern. Results and discussion Time dependence of cavitation damage 12 3 2 1 4 5 MDPR, mm/min. 10 8 6 MDPR 10 4 (I) (II) Wl A T (IV) (III) 2 0 0 4 8 12 Time, min. 16 20 Mean depth of penetration rate (MDPR) versus time Experimental work steps Area Equivalent diameter (d) Perimeter (P) Elongation ratio (EL) roundness (P2/4πA) Particle morphological features Particle morphological features Incubation period (1) (2) (3) (4) (5) 50 100 150 200 250 300 350 400 50 A B 100 150 200 C A. SEM image of particle, B. the same image of the particle after the application of a noise reduction filter, C. boundary of image 250 RN P / 4 A 2 EL= log2 (major axis/minor axis), or EL= log2 (a/b) a d Morphology study based on the circle with the same area as the particle b Morphology study based on the Legendre ellipse Elongation ratio (EL) 1.2 1 0.8 0.6 0.4 0.2 0 1 2 3 4 5 Elongation ratio (EL) of particles removed at points 1-5 Roundness Factor (P2/4A) 2.7 2.6 2.5 2.4 2.3 2.2 1 2 3 4 5 Roundness (RN) of particles removed at points 1-5 Frequency, % (2) (4) (5) (3) Size, μm. Size distribution of particles removed at points 2-5 ■ CONCLUSIONS: The particles removed during the incubation period have distinctive morphological features that differed from that for the subsequent periods. These features include the lamella shape, folding, curving and one of the particle surfaces was the virgin surface. However, the particles removed during the last three periods of erosion process have similar appearances. They have irregular shape and are thicker than that for the incubation period. The observation of particles characteristics during the incubation period can be used as a successful tool to detect early the cavitation erosion for the ductile materials.