Principles of control

advertisement

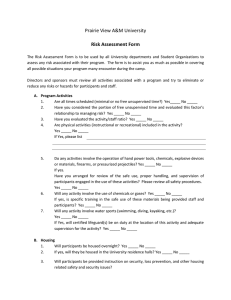

Principles of control Learning outcomes 1. describe the general principles of control and a basic hierarchy of risk reduction measures that encompass technical, behavioural and procedural controls. 2. describe what factors should be considered when developing and implementing a safe system of work. 3. explain the role and function of a permit-to-work system 4 . explain the need for emergency procedures and the arrangements for contacting emergency services 5. describe the requirements for, and effective provision of, first aid in the workplace. General control measures Avoidance of risks by elimination or substitution The best and most effective way of reducing risks is by avoiding a hazard and its associated risks. Substitution describes the use of a less hazardous form of a substance or process. Reduced time exposure This involves reducing the time during the working day that the employee is exposed to the hazard, by giving the employee either other work or rest periods. General control measures Isolation/Segregation Controlling risks by isolating them or segregating people and the hazard is an effective control measure and used in many instances. Engineering controls This describes the control of risks by means of engineering design rather than a reliance on preventative actions by the employee. There are several ways of achieving such controls: 1. Control the risks at the source 2. Control the risk of exposure Proper control of gases and vapours in a laboratory. General control measures Safe systems of work The development of safe operating procedures should address the hazards that have been identified in the risk assessment. Training Training helps people acquire the skills, knowledge and attitudes to make them competent in the health and safety aspects of their work. 1- specific safety training 2- planned training, such as general safety training General control measures Information Organizations need to ensure that they have effective arrangements for identifying and receiving relevant health and safety information from outside the organization. Information to be provided for people in a workplace include: who is at risk and why how to carry out specific tasks safely correct operation of equipment emergency action accident and hazard reporting procedures the safety responsibilities of individual people. General control measures Safety signs All general health and safety signs used in the workplace must include a pictorial symbol categorized by shape, colour and graphic image. Personal protective equipment Personal protective equipment (PPE) should only be used as a last resort. The most important limitations are that PPE: only protects the person wearing the equipment, not others nearby General control measures relies on people wearing the equipment at all times must be used properly must be replaced when it no longer offers the correct level of protection. The benefits of PPE are: it gives immediate protection in an emergency it can be the only practicable way of effecting rescue or shutting down plant in hazardous atmospheres it can be used to carry out work in confined spaces where alternatives are impracticable. But it should never be used to allow people to work in dangerous atmospheres Examples of fire action signs. Examples of first-aid signs Color categories and shapes of signs Fragile roof sign General control measures Examples of warning, mandatory and prohibition signs General control measures Toxic Corrosive Wet floor signs. Examples of chemical warning signs Fire exit Examples of fire safety signs General control measures Smokefree – no-smoking sign. LPG sign. General control measures Welfare Welfare facilities include general workplace ventilation, lighting and heating and the provision of drinking water, sanitation and washing facilities. There is also a requirement to provide eating and rest rooms. Risk control may be enhanced by the provision of eye washing and shower facilities for use after certain accidents. Monitoring and supervision All risk control measures must be monitored for their effectiveness with supervision to ensure that they have been applied correctly. General control measures Competent people who have a sound knowledge of the equipment or process should undertake monitoring. Checklists are useful to ensure that no significant factor is forgotten. Any statutory inspection or insurance company reports should be checked to see whether any areas of concern were highlighted and if any recommendations were implemented. Details of any accidents, illnesses or other incidents will give an indication on the effectiveness of the risk control measures. Any emergency arrangements should be tested during the monitoring phase including first-aid provision. Emergency planning procedures Emergency procedures are about control procedures and equipment to limit the damage to people and property caused by an incident. Local fire and rescue authorities will often be involved and are normally prepared to give advice to employers. Although fire is the most common emergency likely to be faced, there are many other possibilities, which should be considered including: gas explosion electrical burn or electrocution escape of toxic gases or fumes discovery of dangerous dusts like asbestos in the atmosphere Emergency planning procedures terrorist threat aircraft crash if near a flight path spread of highly infectious disease severe weather with high winds and flooding. Emergency services at work Emergency planning procedures Supervisory duties They should ensure that the following precautions are taken: Everyone on site can be alerted to an emergency. Everyone on site knows what signal will be given for an emergency and knows what to do. Someone who has been trained in what to do is on site and ready to co-ordinate activities. Emergency routes are kept clear, signed and adequately Lit. Emergency planning procedures There are arrangements for calling the fire and rescue services and to give them special information about high-hazard work, for example, in tunnels or confined spaces. There is adequate access to the site for the emergency services and this is always kept clear. Suitable arrangements for treating and recovering injured people are set up. Someone is posted to the site entrance to receive and direct the emergency services. Emergency planning procedures Assembly and roll call Assembly points should be established for use in the event of evacuation. It should be at a position, preferably undercover, which is unlikely to be affected at the time of emergency. In the case of small sites, a complete list of the names of all staff should be maintained so that a roll call can be made if evacuation becomes necessary. In those premises where the number of staff would make a single roll call difficult, each area warden should maintain a list of the names of employees and contractors in their area. First aid at work First aid at work (FAW) covers the arrangements employers must make to ensure this happens. It can save lives and prevent minor injuries becoming major ones. The minimum first-aid provision on any work site is: a suitably stocked first-aid box an appointed person to take charge of first-aid arrangements. (Left) First-aid and stretcher sign; (Right) First-aid sign. First aid at work Impact on first-aid provision if risks are significant First-aiders may need to be appointed if risks are significant. This will involve a number of factors which must be considered, including: training for first aiders additional first-aid equipment and the contents of the first-aid box; siting of first-aid equipment to meet the various demands in the premises. informing local medical services of the site and its risks any special arrangements that may be needed with the local emergency services. Contents of the first-aid box First aid at work Appointed persons An appointed person is someone who is appointed by management to: take charge when someone is injured or falls ill. This includes calling an ambulance if required look after the first-aid equipment, for example keeping the first-aid box replenished keeping records of treatment given. Remember that an appointed person should be available at all times when people are at work on site – this may mean appointing more than one. The training should be repeated every 3 years to keep up-to-date. A first aider A first aider is someone who has undergone an HSE approved training course in administering FAW and holds a current FAW certificate. The training should be repeated every 3 years to maintain a valid certificate and keep the first aider up-to-date. It is not possible to give hard and fast rules on when or how many first aiders or appointed persons might be needed. Employees must be informed of the first-aid arrangements . Putting up notices telling staff who and where the first aiders or appointed persons are and where the first-aid box is will usually be enough. Special arrangements will be needed for employees with reading or language difficulties. Suggested numbers of first aiders to be available all the times at work