Swept Volume Representation of Material Deposition Processes for Tissue Scaffold Fabrication

advertisement

Proceedings of DETC’05

ASME 2005 Design Engineering Technical Conferences

September 24-28, 2005, Long Beach, California, USA,

SWEPT VOLUME REPRESENTATION OF MATERIAL DEPOSITION PROCESSES

FOR TISSUE SCAFFOLD FABRICATION

Jie Li, William Regli, Wei Sun

Department of Computer Science

Department of Mechanical Engineering and Mechanics

College of Engineering

Drexel University

Philadelphia, PA 19104

{jie.li, regli, sunwei}@drexel.edu

ABSTRACT

Solid freeform fabrication (SFF) techniques represent a

class of manufacturing processes for creating 3D tissue

scaffolds. A SFF method being developed at Drexel uses

material deposition of polymers from a nozzle that undergoes

piecewise linear motion in the plane. This work develops a

process model for this manufacturing device using a swept

volume representation of the capabilities of the tool.

Specifically, a swept volume describes the tool path information

and defines the scaffold to be fabricated. This swept volume

based model can be used to simulate the scaffold fabrication

process, and to generate a virtual scaffold prototyping.

1. INTRODUCTION

Tissue engineering techniques generally require the use of

scaffold, which provides the necessary support for cells to

attach, proliferate, and maintain their differentiated function [1].

There are various methods for modeling of tissue scaffold with

the requirement of cell growth and material degeneration.

Generation of functional tissue or organ structure requires a

scaffold to guide the overall shape and three-dimensional

organization of multiple cell types. Hence, scaffold

representation and fabrication is a key aspect of computer aided

tissue engineering.

This work examines the use of swept volume models to

model tissue scaffolds and capture the manufacturing process

associated with their creation. Swept volumes have had an

important application in manufacturing design and practice, but

usually in traditional mechanical domains in which material

removal by machining is the common operation. The swept

volumes are almost subject to the motion of object, which plays

a significant role in the design and implementation of a

manufacturing process.

This paper uses a swept volume of cylinder to capture the

process of material deposition to fabricate a tissue scaffold.

We provide a description of the implementation of the

technique and an analysis on how this method might be

improved and extended.

2. BACKGROUND AND LITERATURE REVIEW

Tissue Engineering

3D tissues are required and this is achieved by seeding the

cells onto porous matrices, known as scaffolds, to which the

cells attach and colonise[13]. Scaffold therefore plays an

important role in tissue engineering.

With the development of tissue engineering, especially, it

requires computer aided techniques to make the process of

tissue developing more efficient, such as modeling and

reconstructing 3D tissue, designing tissue scaffold models, and

fabricating physical models for tissues scaffolds. Computeraided tissue engineering (CATE) is such a utilization of

computer-aided technologies in tissue engineering [7]. An

important field in CATE is to design and manufacture tissue

scaffolds. Scaffolds are porous, degradable structures fabricated

from either natural materials or synthetic polymers [6]. The steps

for successful tissue scaffolds based on CATE is usually,

1. generating tissue structural view from computed

tomography (CT) or magnetic resonance imaging (MRI);

2. reconstructing CAD model of external structure;

3. designing internal architecture as well as determining

scaffold materials and internal pattern;

4. selecting appropriate techniques to fabricate scaffold due

to the external and internal properties;

5. evaluating the fabricated scaffolds.

Heterogeneous model of scaffold, in the contrary of

homogeneous model having unique internal architecture, is

developed by various materials or homogeneous internal

structure. Rather than homogeneous scaffold, heterogeneous

tissue scaffold would satisfy both biological requirements and

mechanical requirements. For example, bone is considered

heterogeneous calcified tissue at multi-hierarchical organization

levels. Composite unit cells are then imported for scaffold

modeling [8].

1

Copyright © #### by ASME

There are various scaffold fabrication techniques that can

be selected in the above step 4, such as freeze drying [10], fibre

meshes/fibre bonding [11], photolithography methods [12], and

solid freeform fabrication (SFF). Because of the incapability of

conventional fabrication techniques in precisely controlling

scaffold’s pore size, pore geometry, spatial distribution of pores

and construction of internal channels within the scaffold, SFF

are considered an advanced technique to produce scaffold with

customized external and internal architectures. SFF builds 3D

objects by layered manufacturing strategies. The general

process of SFF involves producing a computer-generated model

using computer-aided design (CAD) software. The computer

representation is a layer-by-layer slicing of the shape into

consecutive two dimensional layers, which can then be fed to

the control equipment to fabricate the part.

SFF entails several different approaches to fabricate:

3D printing: applies a thin layer of powder on a chamber

surface. The ink-jet style spray head deposits a liquid adhesive

onto the powder in a 2-D pattern, bonding the layer to form the

object. It is a kind of high speed and low materials cost

fabrication [14].

Fused Deposition Modeling (FDM): uses a moving nozzle to

extrude a fibre of polymeric material (x- and y-axis control)

from which the physical model is built layer-by-layer[9][15].

3D plotter: involves a moving extruder head (x-, y- and z-axis

control) and uses compressed air to force out a liquid or

pastelike plotting medium[16].

Stereolithography (SLA): is the first process ever developed in

rapid prototyping field with the meaning of 3-dimensional

printing. It uses a light-sensitive liquid polymer and a laser

beam traces out the shape of each layer and hardens the

photosensitive resin [17].

Swept volume representation is important in simulating the

interference between a moving solid and its environment [18].

The application of swept volume computation problem contains

generating finite-element meshes for engineering analysis [],

numerical control (NC) machining verification [], robot

workspace analysis [], collision detection [], geometrical

modeling [], motion planning [], Swept volume is geometric

method for defining a spatial domain [19]. Sweep differential

equation is used to determine the boundary of swept volumes.

In order to determine stationary points, Jacobian matrix is

studied for rank deficiency [20][22].

3. OVERVIEW OF TISSUE SCAFFOLD FABRICATION

3.1 Description of the Manufacturing Process

Freeform fabrication provides an effective process tool to

manufacture many advanced scaffolds with designed properties.

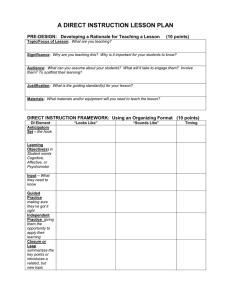

Fig. 1 shows a manufacturing process of PCL scaffold using

Precision Extruding Deposition techniques. The machine

consists of an XYZ position system, a material extruder system,

and a temperature control system [5]. Here, materials are

deposited according to the process tool path, which is generated

by data processing software, to form a layered 3D scaffold.

Fig. 1. Scaffold fabrication using Precision Extruding

Deposition (PED) process

Fig. 2 shows the nozzle motion during the fabrication.

.

other representations (implicit surfaces, i.e. work at Uwash

by Gantner et al).

Process model description?

Fig 2 nozzle motion

3.2 Fabricating Tissue Scaffolds

Traditionally, one technique on fabricating scaffolds of tissue

engineering is solid freeform fabrication[4]. In the process of

SFF, CAD scaffold models are sliced first and then fabricated

using the sliced information. Tool paths are kept in the sliced

models to control the fabrication. The following is the three

2

Copyright © #### by ASME

steps in the scaffold fabrication process:

a. Input scaffold model;

b. Slice the model;

c. Manufacture the model slice by slice.

After including swept volumes into fabricated scaffold, we

can fabricate the swept volumes directly (Fig. 2).

Solid Model

Swept Volumes

Sweeping

Extract

Fabricate

Tool Path

Fig. 2. Fabricating scaffold by swept volume based model

4. SWEPT VOLUME REPRESENTATION

4.1 Overview of the Sweep Equation

Swept volume is the volume generated by the motion of an

arbitrary object along an arbitrary path (or even a surface)

possibly with arbitrary rotations [2]. It is widely used in the field

of numerically controlled machining verification, robot analysis

and solid modeling.

The basic equation of swept volumes is as follows[3]:

( w) (t ) R(t )

Where characterizes the set of all points inside and on the

boundary of the swept volume. (t ) is a (3 1) vector

representing 3D specified path, which is actually replacement

function. R(t) is a rotation function of the swept volumes and

[ x1 ,..., xM ]T , which is parameterized surface used as the

base of sweeping.

Here t is a variable in the range of [0..1],

x

u

y

J (u , v, t )

u

z

u

x

v

y

v

z

v

x

t

y

t

z

t

Since it is a square matrix, its determinant is an analytic

function. Set the function to be zero, we can get the singular

points of the sweep equation. Singular surfaces will be got by

substituting these singular points into sweep equation. In our

case, the boundary of swept volumes comes from sweeping the

boundary of surface and singular surfaces.

4.2 Mathematical Model of Swept Volumes for Process

Modeling

To approximate the model in manufacturing scaffold process,

we consider two key issues: sweep primitive and sweep path.

Especially, sphere and cylinder are regarded as two appropriate

primitives of swept volumes in our paper in order to make the

sweep efficient.

4.2.1 Two basic primitives of swept volumes for scaffold

process modeling

According to the different materials extruded from the nozzle

and different temporary they are heated, we considered the

following primitives as the base of swept volumes.

(a) Sweep-sphere volume

If the material is soft or of high temporary, it is mostly

approximately to sphere soon after extruded. The diameter of

the sphere is near to the diameter of nozzle of fabrication

machine.

As an example, we sweep a sphere along a parabola.

and w [ x1 ,..., xM , t ] .

To form the boundary of swept volumes, singular surfaces are

found by Jacobian rank deficiency method[22]. Jacobian row

rank deficiency condition is used to determine all entities that

appear internal or external to swept volume. The matrix

T

( w)

J ( w) i

w j

Sweep along the curve

is called the Jacobian of the sweep. Consider a 3D surface

parameterized in terms of two variables as a (3×1) vector

given by

Jacobian is

[ x(u, v), y(u, v), z (u, v)]T , the sweep

(b) Sweep-cylinder volume

If the material is a little bit hard or of low temporary, we use

a cylinder to approximate this process model. The diameter of

the cylinder is near to the diameter of nozzle of fabrication

machine, and the height of the cylinder is equal to its diameter.

If we sweep the cylinder along the same parabola curve, the

swept volume is as below:

3

Copyright © #### by ASME

4.2.2 Two kinds of paths to sweep

(a) Spline sweep

Spline curve can be created by some sampling points from

the boundary of layered surface. To make the swept volume fill

in the surface symmetrically, we select equidistant points of the

boundary, which are symmetrical of the y-axis. The following

figure is an example of spline sweep filling in a circular surface,

Where 5 points from the circle boundary are used to create a 3degree spline curve. The number of sampling points depends on

the size of the surface and the size of primitive.

Fig 4

5. IMPLEMENTATION

As an example, we considered how to represent the process

of generating a bone scaffold as a swept volume. We used

Quickslice to slice the CAD model and create swept volumes by

Maple 9.

First, the STL file of the bone is sliced layer by layer, where

each layer is full with connected lines. To simplify the

representation of sliced file, we represented lines as point pairs.

Second, we read the sliced file and put the points into an array

and then get lines from the array as the paths of swept volume.

Finally, we create swept volumes based on the above paths with

a primitive sphere, which approximate the motion of the nozzle

performing material deposition. Fig. 5 is a swept volume of the

bone.

(b) Piecewise line sweep

Even though spline curve is smooth, which is easy for

fabrication, it makes the mathematical model complex. In

real manufacturing process, it is also difficult to control

spline curves. Thus line, as most easily controlled curve, is

more widely used in real word. We consider piecewise line to

fill the surface. In the circle boundary of above example, we

create a piecewise line from 12 points picked up from the

boundary, and then sweep along the piecewise line using a

sphere.

Fig. 5. Swept volume implementation of bone

4.3 Mesh model of Swept Volumes for Process Modeling

The cost of computing mathematical model of swept volume

is very expensive. Fig 4 shows mesh model of swept volumes

by Pro/E.

6. DISCUSSION AND FUTURE WORK

To simulate the real manufacturing process and make the

swept volume model approximate to real objects fabricated by

the machine, the paths are very dense, that means it should cost

large of memory and a long time to calculate the whole model.

There are several ways to simplify the density.

(a) Reduce the number of paths. For example, pick up every

two paths, so the density is reduced to 50% of the origin. Also,

the density can be adjusted according to the feature distribution

of the object. In some layers, if there are no extra detail features

inside such as hole, the paths can be sparse.

(b) Since the size of basic circle to be swept can be changed,

in some sparse areas, we can choose a bigger circle to sweep to

4

Copyright © #### by ASME

make sure the total volume is the same. That is to say, some

paths of small circle can be combined into one path of large

circle. This is similar to unite the swept volumes.

7. ACKNOWLEDGMENTS

The authors would like to acknowledge funding support from

NSF/DARPA-0310619 grant for this research.

8. REFERENCES

[15] Scott CS, “Apparatus and method for creating three-dimensional objects”,

US Patent 5121329, 1991.

[16] Landers R, Mulhaupt R, “Desktop manufacturing of complex objects,

prototypes and biomedical scaffolds by means of computer-assisted

design combined with computer-guided 3D plotting of polymers and

reactive oligomers”, Journal of Macromolecular Materials and

Engineering Vol 282, 2000: 17-21

[17] Hull C (1990) Method for production of three-dimensional objects by

stereolithography. US Patent 4929402

[1]

Hutmacher DW., “Scaffold design and fabrication technologies for

engineering tissues--state of the art and future perspectives.” J Biomater

Sci Polym Ed. 2001;12(1):107-24.

[2]

K. Abdel-Malek, D. Blackmore, K. Joy, “Swept volumes: Foundations,

Perspectives, and Applications”, International Journal of Shape

Modeling, 2004

[3]

D. Blackmore, M.C. Leu, F. Shih, “Analysis and modelling of deformed

swept volumes”, Computer Aided Design, V26 n 4 pp. 315-326

[20] Leu M. C., Park S. H., Wang K. K, “Geometric presentation of

translational swept volumes and its applications”, ASME Journal of

Engineering for Industry, Vol 108, 1986 :113-119

[4]

Starly, B. Lau, A., Sun, W. Lau, W. and Bradbury T., “Direct Slicing of

STEP Based NURBS Models for Layered Manufacturing,” ComputerAided Design, Vol 37, Issue 4, April 2005, pp 387-397

[21] Abdel-Malek K, Yeh H. J, “Determining intersection curves between

surfaces of two solids”, Computer-Aided Design, Vol 28, 1996:539-549

[5]

Wang, F., Shor, L., Darling, A., Khalil, S., Sun, W., Güçeri, S. and Lau,

A., “Precision Extruding Deposition and Characterization of Cellualr

Poly-e-Caprolactone Tissue Scaffolds”, Rapid Prototyping Journal, Vol.

10, Issue 1, 2004. pp. 42-49.

[6]

Linda G. Griffith, Gail Naughton, “Tissue Engineering-Current

Challenges and Expanding Opportunities”, Science, Vol 295, Feb

8,2002

[7]

Wei Sun, Lallavi Lal, “Recent Development on Computer Aided Tissue

Engineering –a Review”, Journal of Computer Methods and Programs in

Biomedicine. Vol 67, 2002, 85-103

[8]

W. Sun, F. Lin, X. Hu, “Computer-aided Design and Modeling of

Composite Unit Cells”, Journal of Composites Sciences and Technology,

Vol 61, 2001, 289-299.

[9]

E. Sachlos, J.T. Czernuszka, “Making Tissue Engineering Scaffolds

Work. Review on the Application of Solid Freeform Fabrication.”

Journal of European Cells and Materials, Vol 5, 2003: 29-40

[18] W.P Wang, K.K. Wang, “Geometric modeling for swept volume of moving

solids”, IEEE Computer Graphics and Application, Vol 6, 1986:8-17

[19] Andrew S. Winter and Min Chen, “Image-Swept Volumes”, Eurographics,

V21, 2002

[22]

Abdel-Malek K, Yeh H. J, “Geometric representation of the swept

volume using Jocobian rank-deficiency conditions”, Computer-Aided

Design, Vol 29, 1997: 457-468

[10] Hsu YY, Gresser JD, Trantolo DJ, Lyons CM, Gangadharam PRJ, Wise

DL ,”Effect of polymer foam morphology and density on kinetics of in

vitro controlled release of isoniazid from compressed foam matrices”,

Journal of Biomedical Materials Science, Vol. 35: 107-116.

[11] Cima LG, Vacanti JP, Vacanti C, Inger D, Mooney D, Langer R. ”Tissue

engineering by cell transplantation using degradable polymer substrates”.

Journal of Biomechanical Engineering , Vol 113, 1991: 143-151.

[12]

Chihchen Chen, Danny Hirdes, Albert Folch, “Gray-scale

photolithography using microfluidic photomasks”, Proceedings of

National Academy of Sciences of the United States of America, Vol 100,

2003: 1499-1504

[13] Langer R, Vacanti JP, “Tissue engineering”. Science Vol 260, 1993: 920926.

[14] Bredt JF, Sach E, Brancazio D, Cima M, Curodeau A, Fan T ,”Three

dimensional printing system”, US Patent 5807437,1998.

5

Copyright © #### by ASME